Study on the correlation between particle size and blue phase indicators of rutile titanium dioxide

-

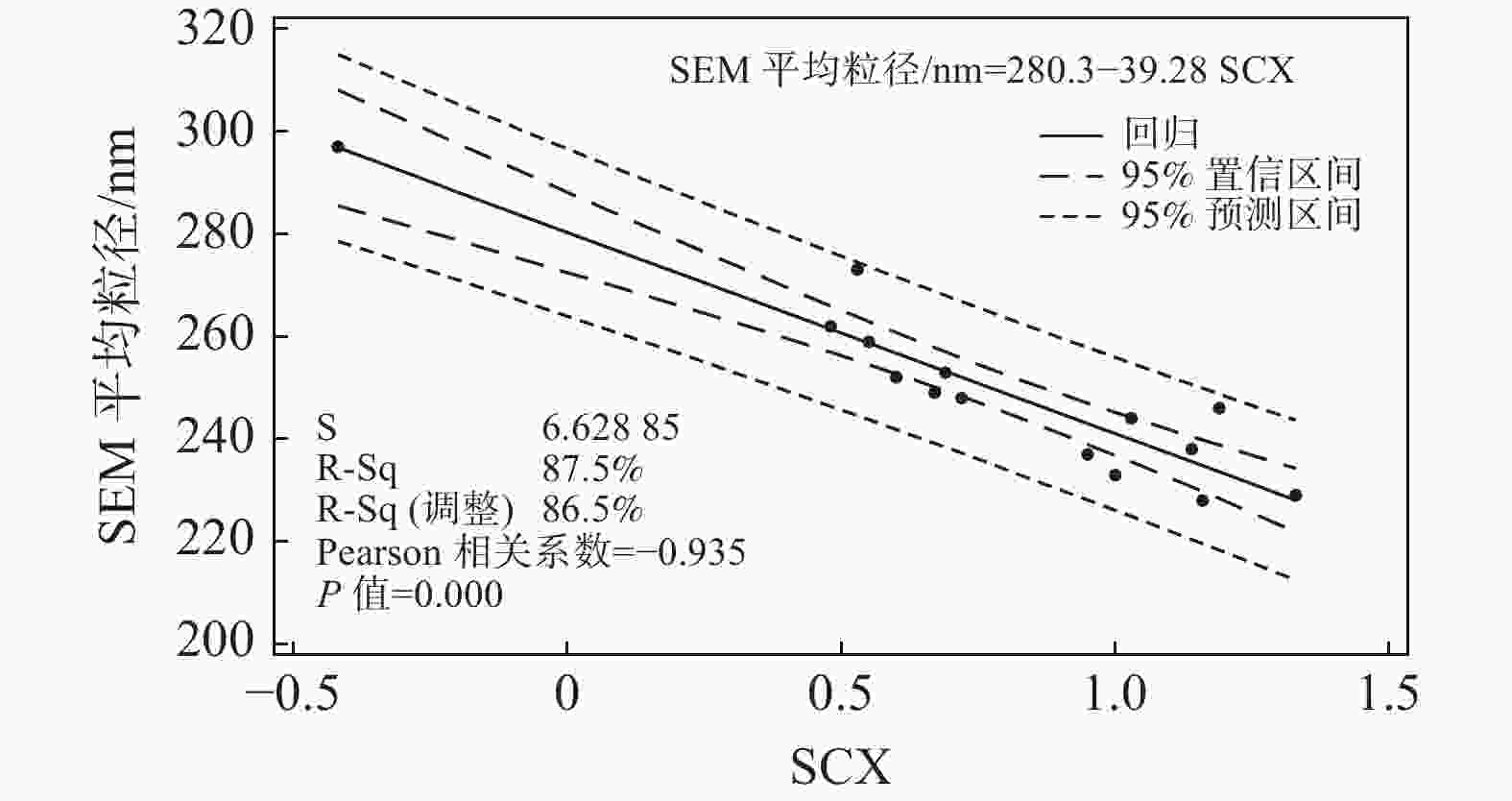

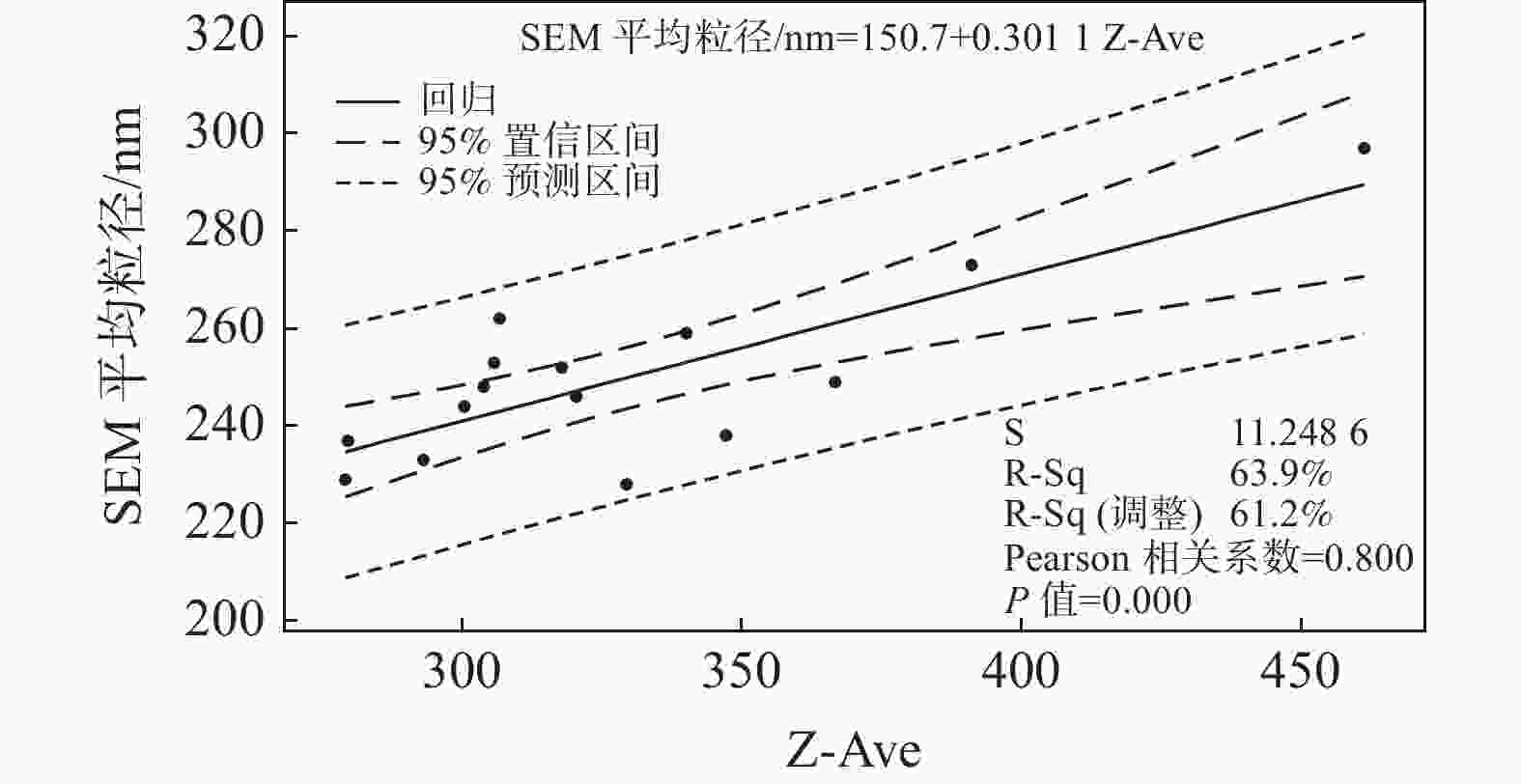

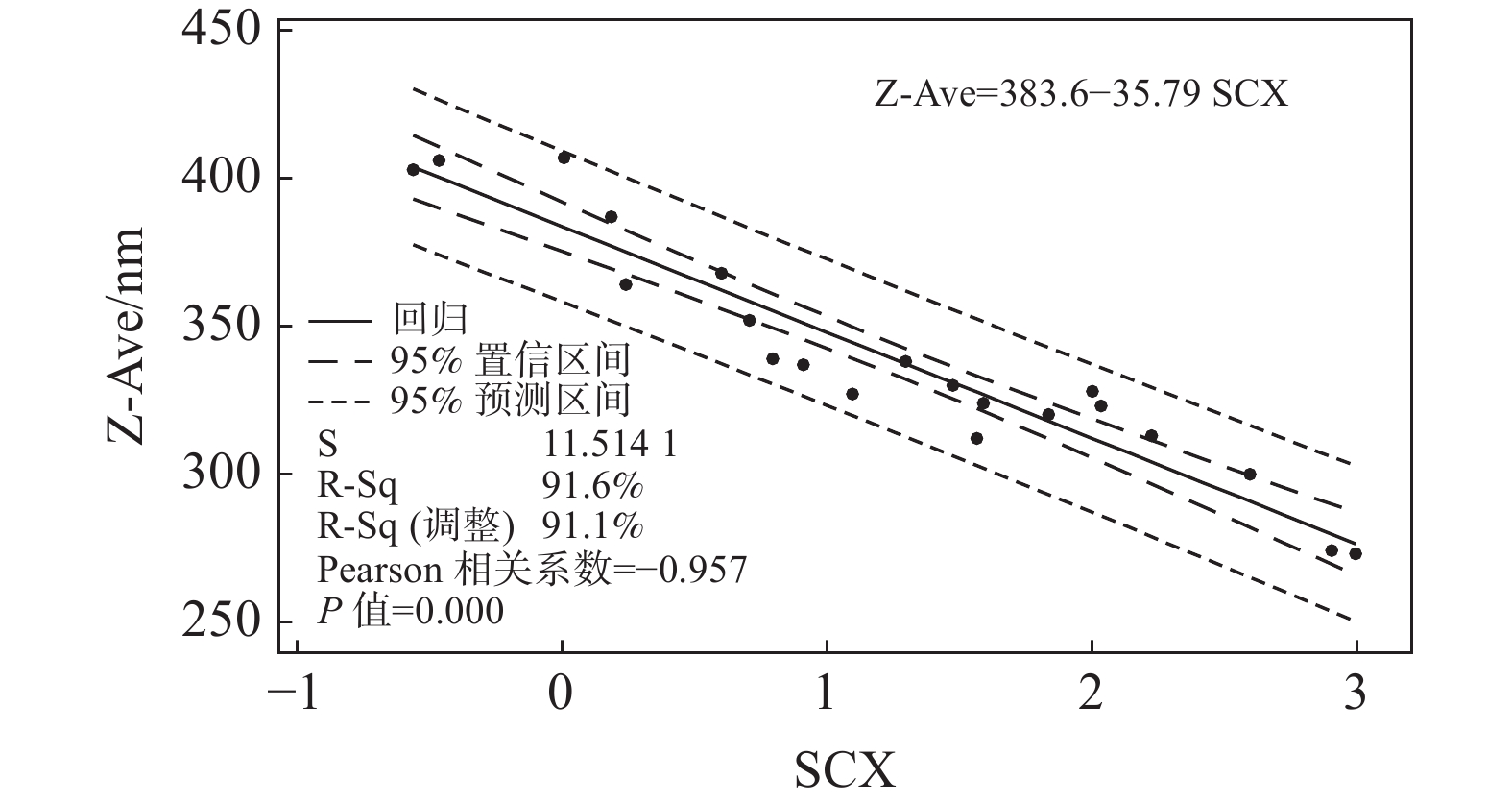

摘要: 采用不同的K2O、P2O5、ZnO盐处理配方处理偏钛酸,煅烧后得到金红石含量合格的硫酸法钛白初品,检测蓝相指标SCX、ZS90平均粒径Z-Ave和SEM平均粒径,并通过线性拟合和回归等手段分析三者之间的线性相关性。结果表明,钛白初品的ZS90平均粒径Z-Ave和SEM平均粒径与SCX的线性相关性指标Pearson相关系数分别达到了−0.957和−0.935,说明该两项粒径指标大小均与SCX值成负线性相关性。SCX与Z-Ave线性回归方程的R-Sq达到了91.6%,SCX与SEM平均粒径线性回归方程的R-Sq达到了87.5%,线性回归结果表明,采用SCX值对Z-Ave的预测有效性要稍高于对SEM平均粒径的预测有效性。钛白粉厂家可将常规监测指标SCX值带入相应的拟合方程式来对产品粒径进行统计分析和跟踪,并据此对工艺技术进行调整。Abstract: In this paper, different K2O-P2O5-ZnO salt treatment formulas were used to treat meta-titanic acid, and eligible rutile titanium dioxide was obtained after calcination. SCX value as the blue phase indicators, Z-Ave value as the ZS90 mean particle size and SEM mean particle size were detected. The linear correlation among them was analyzed by means of linear fitting and regression. The results show that as the correlation indicators, the Pearson correlation coefficients of Z-Ave value and SCX value, SEM mean particle size and SCX value are respectively −0.957 and −0.935. There is a negative linear correlation between the two particle size indicators and SCX value. The R-Sq value of the linear regression equation between SCX value and Z-Ave is 91.6%, while this value between SCX value and SEM mean particle size is 87.5%. The linear regression results show that the prediction effectiveness of the SCX value for Z-Ave value is slightly better than that for SEM mean particle size. Manufacturers can put the conventional monitoring index SCX value into the corresponding fitting equation to carry out statistical analysis and tracking of product particle size, and adjust the process technology accordingly.

-

Key words:

- rutile TiO2 /

- ZS90 /

- SEM /

- SCX /

- correlation

-

表 1 仪器设备

Table 1. Instruments and equipment

名称 型号 厂家 平磨仪 PM240-2 广西梧州市润讯宝石机械厂 台式色彩检测仪 800 V Datacolor 纳米激光粒度仪 Nano-ZS90 Malvern 扫描电镜 JSM-7001F Thermal Field Emission 表 2 钛白初品Z-Ave与蓝相指标SCX线性回归分析结果

Table 2. Linear regression analysis of Z-Ave value and SCX value

方差分析 来源 自由度 AdjSS AdjMS F值 P值 回归 1 19.535 19.5349 206.13 0.000 SCX 1 19.535 19.5349 206.13 0.000 误差 19 1.801 0.0948 合计 20 21.336 模型汇总 S R-sq/% R-sq(调整)/% R-sq(预测)/% 0.307847 91.56 91.12 89.85 系数 项 系数 系数标准误 T值 P值 方差膨胀因子 常量 9.919 0.608 16.31 0.000 SCX −0.02558 0.00178 −14.36 0.000 1 表 3 钛白初品SEM平均粒径与SCX线性回归分析结果

Table 3. Linear regression analysis of SEM mean particle size and SCX value

方差分析 来源 自由度 AdjSS AdjMS F值 P值 回归 1 3988.5 3988.49 90.77 0.000 SCX 1 3988.5 3988.49 90.77 0.000 误差 13 571.2 43.94 合计 14 4559.7 模型汇总 S R-sq/% R-sq(调整)/% R-sq(预测)/% 6.62885 87.47 86.51 84.43 系数 项 系数 系数标准误 T值 P值 方差膨胀因子 常量 280.29 3.62 77.36 0.000 SCX −39.28 4.12 −9.53 0.000 1 表 4 钛白初品SEM平均粒径与Z-Ave线性回归分析结果

Table 4. Linear regression analysis of SEM mean particle size and Z-Ave value

方差分析 来源 自由度 AdjSS AdjMS F值 P值 回归 1 2915 2914.8 23.04 0.000 Z-Ave 1 2915 2914.8 23.04 0.000 误差 13 1645 126.5 合计 14 4560 模型汇总 S R-sq/% R-sq(调整)/% R-sq(预测)/%

11.2486 63.93 61.15 50.67

系数 项 系数 系数标准误 T值 P值 方差膨胀因子 常量 150.7 20.9 7.22 0.000 Z-Ave 0.3011 0.0627 4.8 0.000 1 -

[1] 陈朝华, 刘长河. 钛白粉生产及应用技术[M]. 北京: 化学工业出版社, 2005: 35−48.Chen Zhaohua, Liu Changhe. Production and application technology of titanium dioxide pigment[M]. Beijing: Chemical Industry Press, 2005: 35−48. [2] 邓捷, 吴立峰. 钛白粉应用手册[M]. 北京: 化学工业出版社, 2005: 1−35.Deng Jie, Wu Lifeng. Application handbook of titanium dioxide pigment[M]. Beijing: Chemical Industry Press, 2005: 1−35. [3] Vargas W E, Greenwood P, Otterstedt J E, et al. Light scattering in pigmented coatings: experiments and theory[J]. Solar Energy, 2000,68(6):553−561. doi: 10.1016/S0038-092X(00)00024-4 [4] Saila Karvinen. The effects of trace elements on the crystal properties of TiO2[J]. Solid State Sciences, 2003,5:811−819. doi: 10.1016/S1293-2558(03)00082-7 [5] Grzmil B, Kic B, Rabe M. Inhibition of the anatase-Rutile phase transformation with addition of K2O, P2O5, and Li2O[J]. Chemical Papers- Slovak Academy of Sciences, 2004,58(6):410−414. [6] Tian Yingzi, Chen Kefu, Zhang Heng. Study of the particles of nanometric SiO2, CaCO3 and Al2O3 with Malvern Mastersizer[J]. China Pulp and Paper, 2003,17(3):33−35. (田英姿, 陈克复, 张恒. Malvern粒度仪的使用和测试分析[J]. 中国造纸, 2003,17(3):33−35. [7] Gesenhues U. Doping of TiO2 pigments by Al3+[J]. Solid State Ionics, 1997,101-103(11):1171−1180. [8] Gesenhues U. Calcination of metatitanic acid to titanium dioxide white pigments[J]. Chemical Engineering & Technology, 2001,24(7):685−694. [9] Xu C, Lai X, Zajac G W, et al. Scanning tunneling microscopy studies of the TiO2(110) surface: Structure and the nucleation growth of Pd[J]. Physical Review B, 1997,56(20):13464−13482. doi: 10.1103/PhysRevB.56.13464 [10] Francisco M S P, Mastelaro V R. Inhibition of the anatase-rutile phase transformation with addition of CeO2 to CuO-TiO2 system: Raman spectroscopy, X-ray diffraction, and textural studies[J]. Chem. Mater., 2002,16(4):2514−2518. [11] Lydia D N . Photostable rutile titanium dioxide: WO, WO2003006559 A1[P]. 2003. [12] Ratajska H. The effect of certain promoters on TiO2 crystal structure transformation[J]. Journal of Thermal Analysis, 1992,38(9):2109−2114. doi: 10.1007/BF01979623 [13] José Criado, Concha Real. Mechanism of the inhibiting effect of phosphate on the anatase→rutile transformation induced by thermal and mechanical treatment of TiO2[J]. Journal of the Chemical Society, 1983,79(1):2765−2771. -

下载:

下载: