Titanium flotation dynamics study for a beneficiation plant in Panxi

-

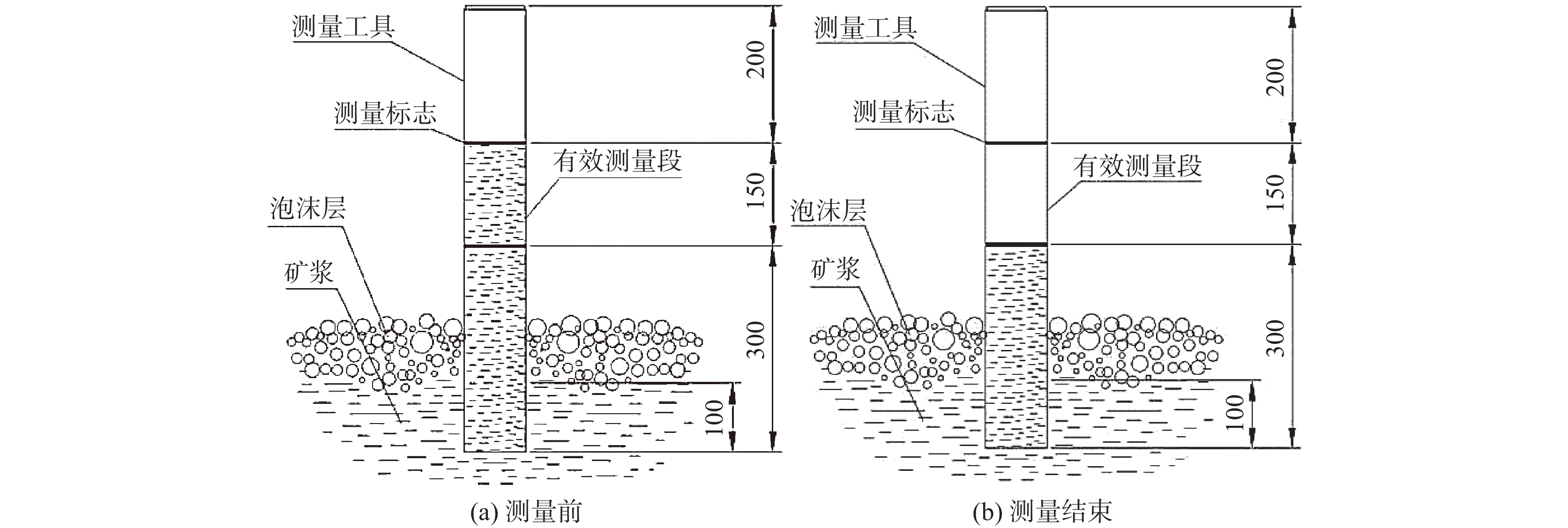

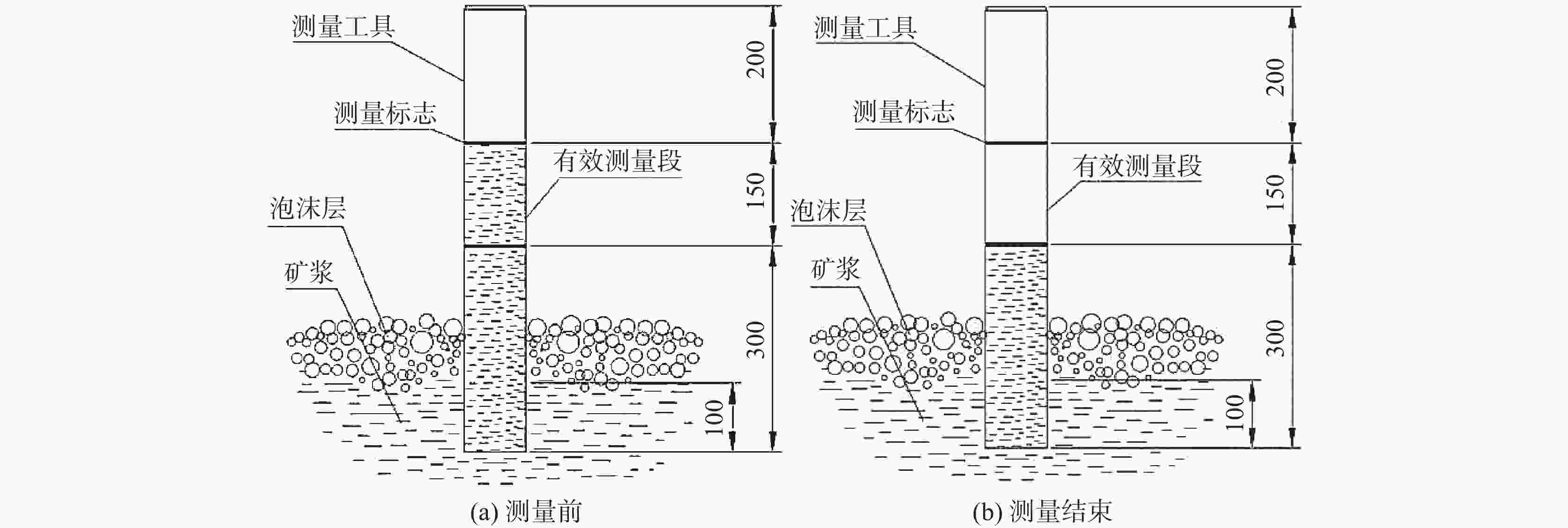

摘要: 针对攀西某选厂粗粒浮选流程,研究了选钛浮选机的动力学特性。利用排水取气法对不同作业的浮选机的充气量和空气分散度进行了测试。结果表明:钛粗扫选充气量0.16~0.51 m3/(m2·min)。直流槽浮选机空气分散度明显优于吸浆槽浮选机。浮选机内矿化气泡从距溢流堰深度1000 mm运动到200 mm的过程中,携带的矿物品位几乎不变,气泡负载基本相当,说明粗选矿化气泡运动至距溢流堰深度1 000 mm后比较稳定,矿物颗粒粘附在气泡上较难脱落。浮选机内存在较为明显的分层现象,即距溢流堰1 500 mm以下矿浆浓度相差不大,随着距溢流堰深度减小,浓度明显下降。Abstract: The paper studies the dynamics characteristics of flotation cells for a beneficiation plant in Panxi. Based on the method of collecting air via draining water, the air flowrate is 0.16~0.51 m3/(m2·min) for rougher and scavenger. The air dispersion of direct flow cell is better than that of the pumping cell. During mineralized bubbles transporting from 1 000 mm towards 200 mm distance from the lip, the grade of mineral and bubble loading is almost same. It demonstrates that mineralized bubbles are stable after the mineralized bubbles transporting to 1 000 mm and minerals are difficult to detach from the bubbles. The solid concentration exists layering in flotation cell. Deeper than 1 500 mm from the lip, the solid concentration remains similar. With the distance decreasing, the solid concentration decreases sharply.

-

Key words:

- titanium /

- flotation /

- air dispersion /

- bubble loading /

- concentration distribution

-

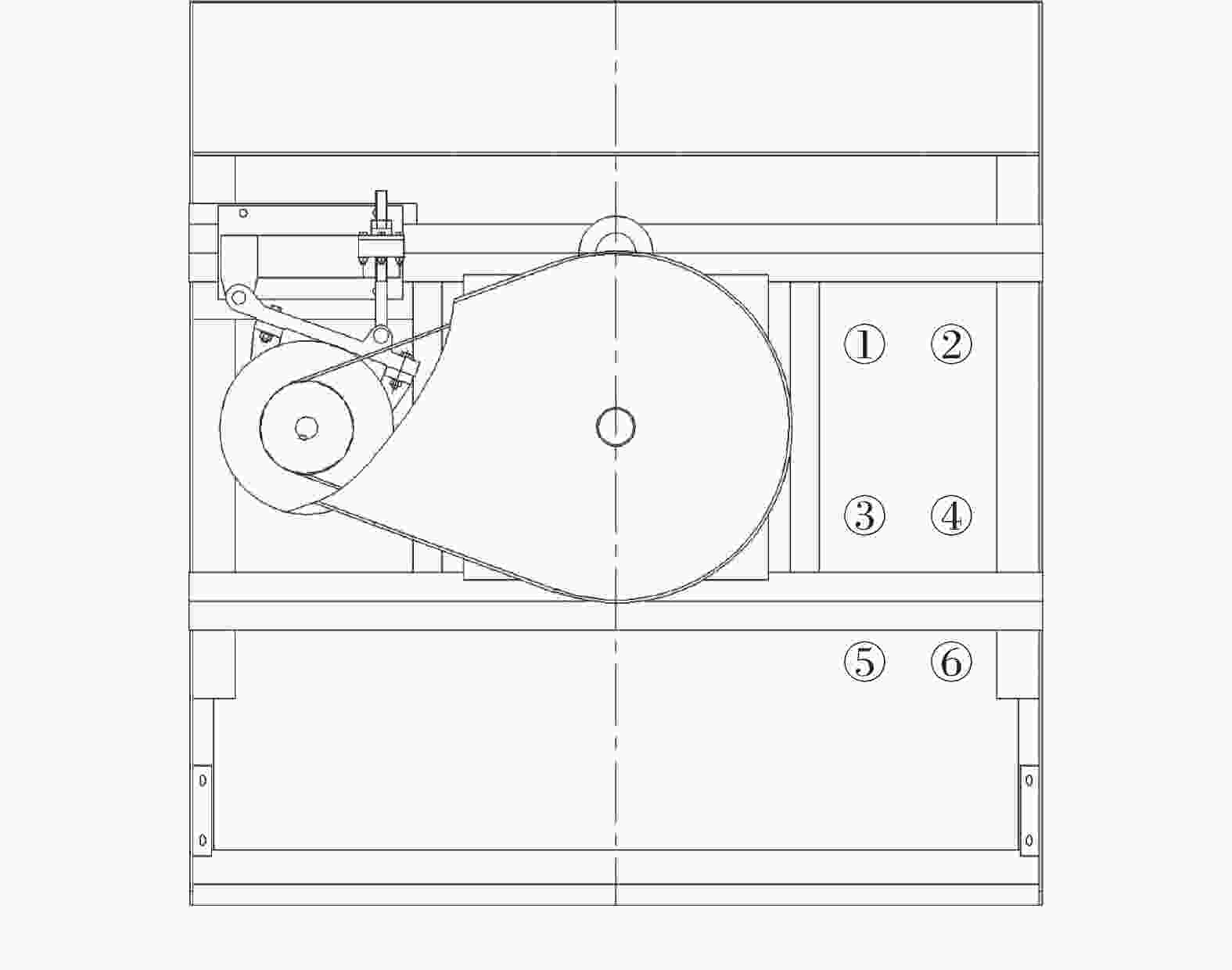

表 1 充气量和空气分散度测试结果

Table 1. Test data for air flowrate and air dispersion

作业位置 充气量Jg /[ m3·(m2·min)−1] 空气分散度 1 2 3 4 5 6 扫一第3槽 0.35 0.33 0.35 0.31 0.33 0.28 4.64 扫二第1槽 0.43 0.42 0.33 0.31 0.24 0.30 1.79 表 2 气泡负载分布

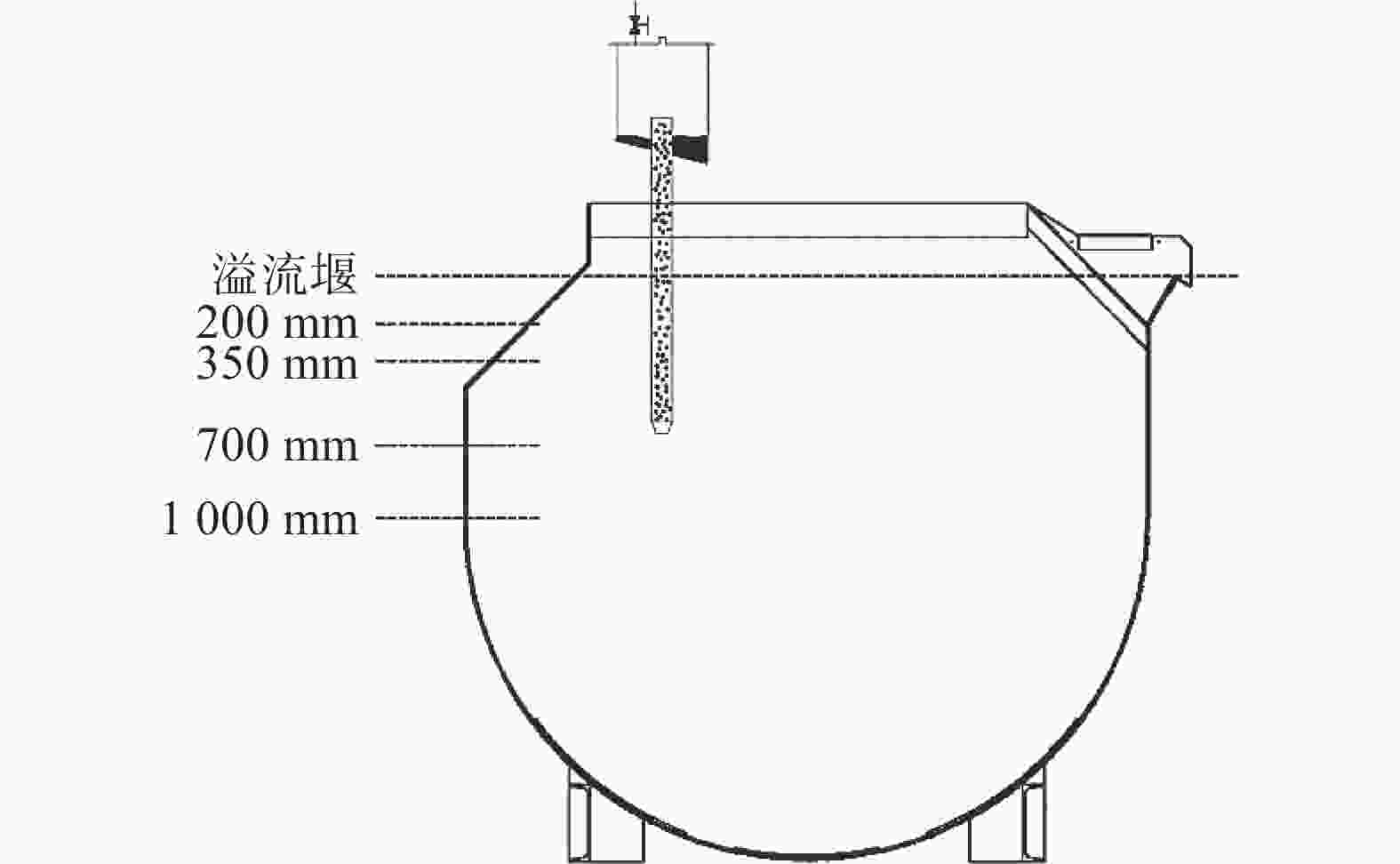

Table 2. Data for bubble loading distribution

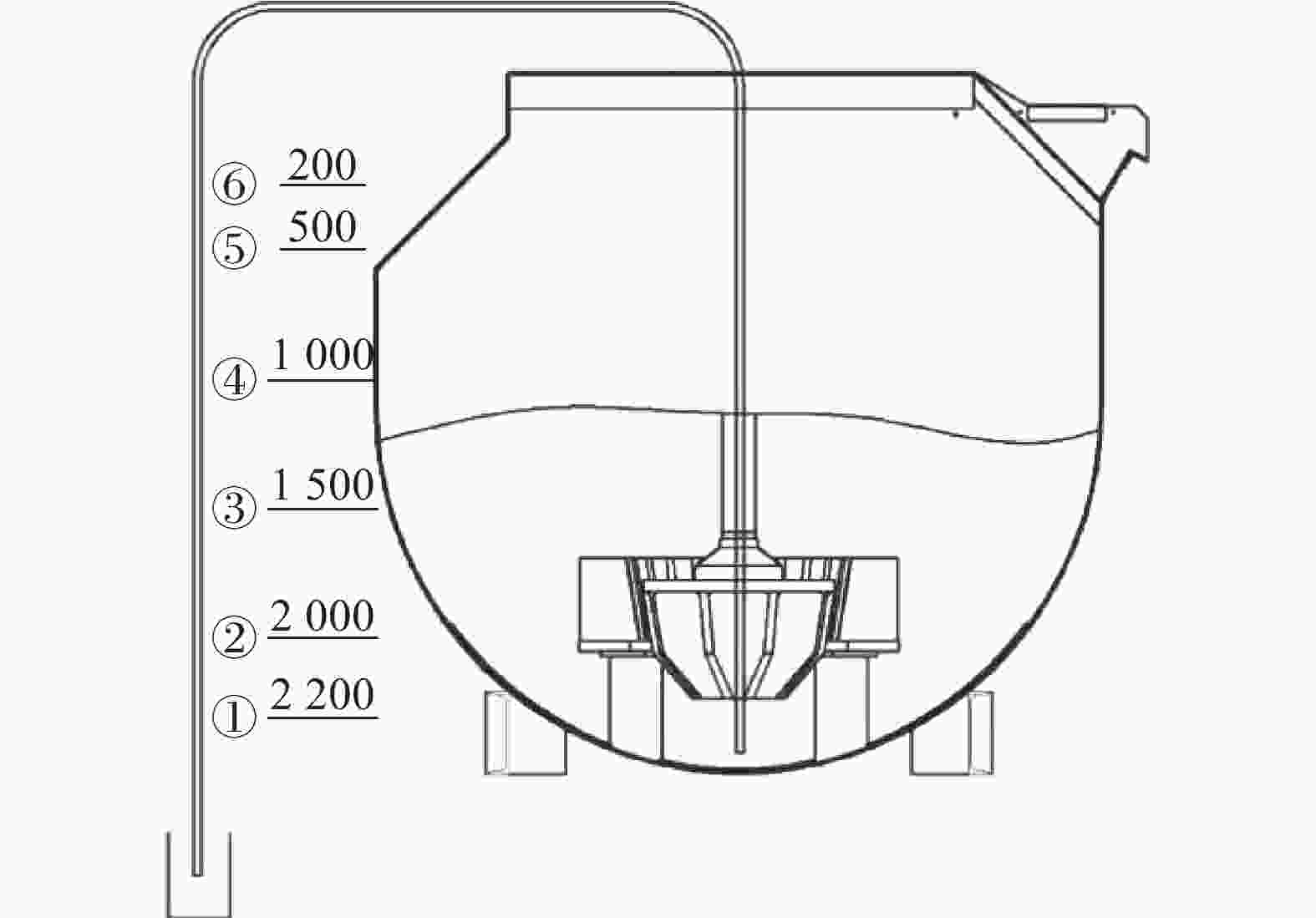

距溢流堰深度/mm TiO2品位/% 气泡负载/(g·L−1) 1000 49.18 62 700 49.35 102 350 49.84 60 200 49.98 55 表 3 浮选机内浓度分布

Table 3. Data of concentration distribution in flotation cell

离溢流堰

深度/mm粗一第1槽(XCF-16) 粗一第4槽(KYF-16) 浓度/% TiO2品位/% 浓度/% TiO2品位/% 200 27.00 33.42 12.15 9.42 500 21.13 33.00 12.39 8.00 1000 53.01 15.06 22.94 4.45 1500 57.09 15.38 39.79 3.30 2 000 55.69 14.65 42.06 5.46 2200 54.79 14.57 42.88 3.47 -

[1] Tan Qiyou, Chen Bo, Zhang Yushu, et al. Characteristics and current situation of comprehensive utilization of vanadium titano-magnetite resources in Panxi region[J]. Multipurpose Utilization of Mineral Resources, 2011,(6):6−10. (谭其尤, 陈波, 张裕书, 等. 攀西地区钒钛磁铁矿资源特点与综合回收利用现状[J]. 矿产综合利用, 2011,(6):6−10. doi: 10.3969/j.issn.1000-6532.2011.06.002 [2] Xiao Liangchu. Improvement research on titanium concentration technology for Panxi vanadium-titanium magnetite[J]. Multipurpose Utilization of Mineral Resources, 2012,(2):57−60. (肖良初. 攀西钒钛磁铁矿选钛工艺改进研究[J]. 矿产综合利用, 2012,(2):57−60. doi: 10.3969/j.issn.1000-6532.2012.02.016 [3] Yang Renxin. Investigation on beneficiation process of Hongge vanadium and titanium magnetite with application of high pressure roller mill[J]. Metal Mine, 2011,416(2):47−50. (杨任新. 应用高压辊磨机的红格钒钛磁铁矿选矿工艺研究[J]. 金属矿山, 2011,416(2):47−50. [4] Xiao Liujun. Characteristics of Panzhihua vanadium titanium magnetite ore resource and its mineral magnetism[J]. Metal Mine, 2001,295(1):28−30. (肖六均. 攀枝花钒钛磁铁矿资源及矿物磁性特征[J]. 金属矿山, 2001,295(1):28−30. doi: 10.3321/j.issn:1001-1250.2001.01.011 [5] Shen Zhengchang, Lu Shijie. Industrial trial research of large-scale flotation machine KYF-160[J]. Nonferrous Metals(Mineral Processing Section), 2006,(3):37−41. (沈政昌, 卢世杰. KYF-160型浮选机工业试验研究[J]. 有色金属(选矿部分), 2006,(3):37−41. [6] Han Dengfeng, Shi Shuaixing, Wu Feng, et al. Comparison and analysis of bubble load characteristics in the process of flotation[J]. Nonferrous Metals(Mineral Processing Section), 2017,(B11):114−117. (韩登峰, 史帅星, 吴峰, 等. 浮选过程差异性的气泡负载特性对比分析[J]. 有色金属(选矿部分), 2017,(B11):114−117. [7] Shen Zhengchang. Research and design of 200 m3 air forced flotation machine[J]. Nonferrous Metals Engineering, 2009,61(2):100−103. (沈政昌. 200 m3超大型充气机械搅拌式浮选机设计与研究[J]. 有色金属工程, 2009,61(2):100−103. doi: 10.3969/j.issn.2095-1744.2009.02.025 -

下载:

下载: