| [1] |

Wen Jing, Jiang Tao, Zhou Wanying, et al. A cleaner and efficient process for extraction of vanadium from high chromium vanadium slag: Leaching in (NH4)2SO4-H2SO4 synergistic system and NH4+ recycle[J]. Separation and Purification Technology, 2019,(216):126−130.

|

| [2] |

Hu Pengcheng, Zhang Yiming, Liu Tao, et al. Source separation of vanadium over iron from roasted vanadium-bearing shale during acid leaching via ferric fluoride surface coating[J]. J. Clean. Prod., 2018,(181):399−407.

|

| [3] |

Liu Zhixun, Dai Hongzhang, Liu Jia, et al. Current situation and suggestions on the exploration, development and utilization of stone coal resources in China[J]. China Mining, 2016,25(S1):18−21. (刘志逊, 代鸿章, 刘佳, 等. 我国石煤资源勘查开发利用现状及建议[J]. 中国矿业, 2016,25(S1):18−21.

|

| [4] |

Hu Yibo, Ye Guohua, Wang Heng, et al. Vanadium market analysis and progress of vanadium extraction process from stone coal[J]. Iron Steel Vanadium Titanium, 2019,40(2):31−40. (胡艺博, 叶国华, 王恒, 等. 钒市场分析与石煤提钒工艺进展[J]. 钢铁钒钛, 2019,40(2):31−40. doi: 10.7513/j.issn.1004-7638.2019.02.006

|

| [5] |

Hu Yangjia, Zhang Yimin, Bao Shenxu, et al. Effects of the mineral phase and valence of vanadium on vanadium extraction from stone coal[J]. International Journal of Minerals Metallurgy and Materials, 2012,19(10):893−898. doi: 10.1007/s12613-012-0644-9

|

| [6] |

Xue Nannan, Zhang Yimin, Liu Tao, et al. Mechanism of vanadium extraction from stone coal via hydrating and hardening of anhydrous calcium sulfate[J]. Hydrometallurgy, 2016,166:48−56. doi: 10.1016/j.hydromet.2016.08.013

|

| [7] |

张一敏, 包申旭, 刘涛, 等. 石煤提钒[M]. 北京: 科学出版社, 2014.Zhang Yimin, Bao Shenxu, Liu Tao, et al. Vanadium extractionfrom stone coal[M]. Beijing: Science Press, 2014.

|

| [8] |

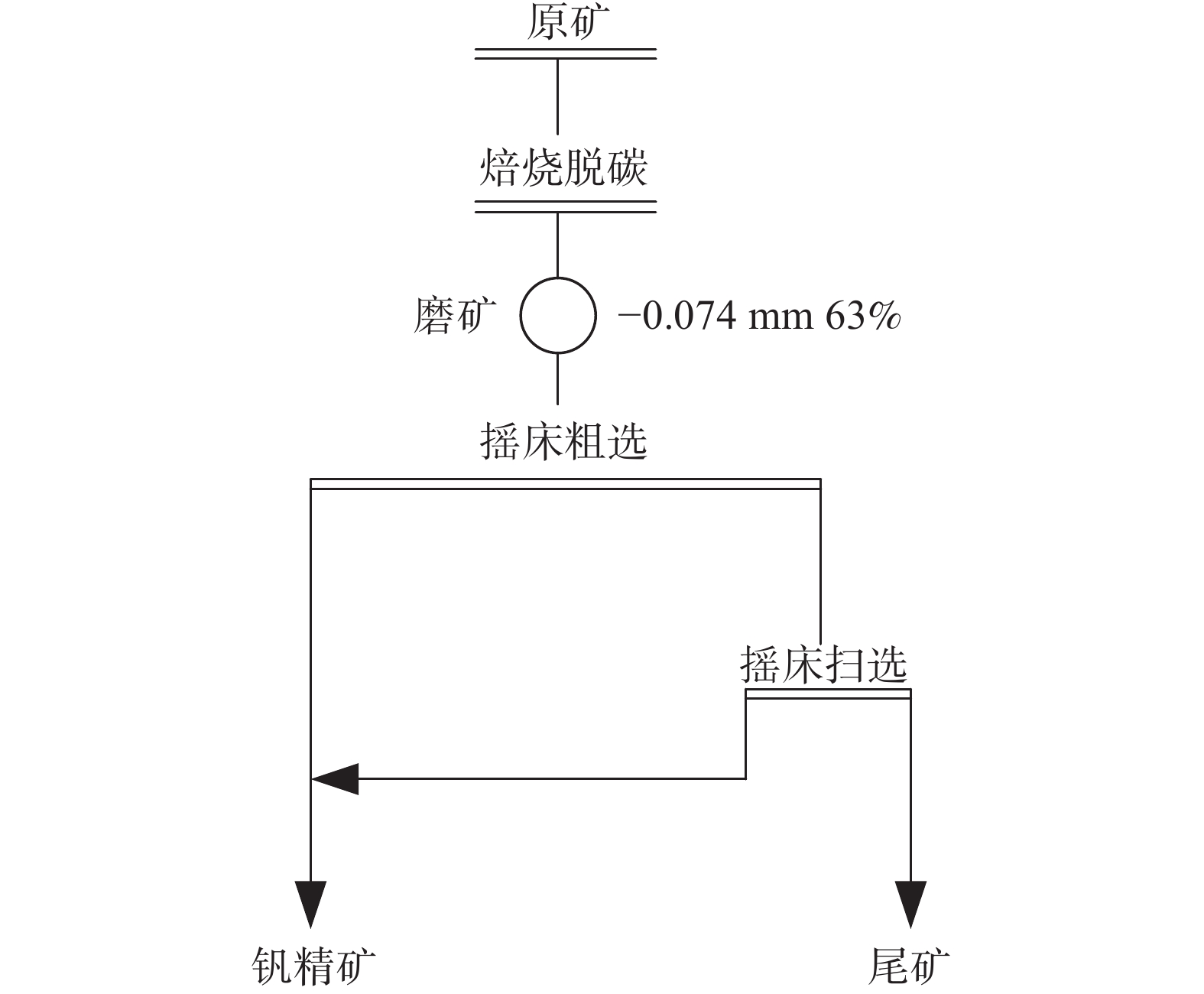

He Dongsheng, Li Qiaoshuang, Yang Cong, et al. Experimental study on pre separation of vanadium bearing stone coal[J]. Nonferrous Metals Mining and Metallurgy, 2013,29(6):23−25. (何东升, 李巧双, 杨聪, 等. 含钒石煤预分选试验研究[J]. 有色矿冶, 2013,29(6):23−25. doi: 10.3969/j.issn.1007-967X.2013.06.008

|

| [9] |

Zhao Yunliang, Zhang Yimin, Liu Tao, et al. Pre-concentration of vanadium from stone coal by gravity separation[J]. International Journal of Mineral Processing, 2013,121:1−5. doi: 10.1016/j.minpro.2013.02.014

|

| [10] |

Bian Ying, Zhang Yimin, Zhao Yunliang, et al. Shaking table pre tailing test of a decarburized stone coal in Hubei[J]. Metal Mine, 2013,(1):94−96,150. (边颖, 张一敏, 赵云良, 等. 湖北某脱碳石煤摇床预抛尾试验[J]. 金属矿山, 2013,(1):94−96,150. doi: 10.3969/j.issn.1001-1250.2013.01.027

|

| [11] |

Wang Li, Sun Wei, Liu Runqing, et al. Flotation recovery of vanadium from low-grade stone coal[J]. Transactions of Nonferrous Metals Society of China, 2014,24(4):1145−1151. doi: 10.1016/S1003-6326(14)63173-3

|

| [12] |

Lu Keke, Shi Zhuoxiong. Experimental study on flotation preconcentration of a low-grade stone coal vanadium ore[J]. Modern Mining, 2019,35(6):20−22. (卢可可, 施卓雄. 某低品位石煤钒矿浮选预富集试验研究[J]. 现代矿业, 2019,35(6):20−22. doi: 10.3969/j.issn.1674-6082.2019.06.006

|

| [13] |

Yan Mingtao, Li Guang, Liu Zhichao. Experimental study on beneficiation process of a vanadium ore in Shaanxi[J]. Hydrometallurgy, 2013,32(5):293−296. (闫明涛, 李广, 刘志超. 陕西某钒矿石选矿工艺试验研究[J]. 湿法冶金, 2013,32(5):293−296.

|

| [14] |

Hu Yang, He Dongsheng, Xie Zhihao, et al. Research status of preconcentration technology of stone coal vanadium ore[J]. Metal Mine, 2018,(12):73−79. (胡洋, 何东升, 谢志豪, 等. 石煤型钒矿预富集技术研究现状[J]. 金属矿山, 2018,(12):73−79.

|

| [15] |

Wei Min, Wu Dongyin, Zhang Yanjiao. Experimental study on scrubbing beneficiation of Xichuan vanadium ore[J]. Mineral Protection and Utilization, 2007,(2):34−36. (卫敏, 吴东印, 张艳娇. 淅川钒矿擦洗选矿试验研究[J]. 矿产保护与利用, 2007,(2):34−36. doi: 10.3969/j.issn.1001-0076.2007.02.010

|

| [16] |

Chen Xiaoqing, Yang Jinzhong, Mao Yilin, et al. Study on new technology of comprehensive utilization of low-grade clay vanadium ore resources[J]. Nonferrous Metals (Beneficiation), 2010,(5):9−12. (陈晓青, 杨进忠, 毛益林, 等. 低品位黏土型钒矿资源综合利用新技术研究[J]. 有色金属(选矿部分), 2010,(5):9−12.

|

| [17] |

Chen Chun, Zhang Yimin, Bao Shenxu, et al. Separation and enrichment of vanadium from acid leaching solution of stone coal by tertiary amine N235[J]. Rare Metals, 2017,41(4):422−428. (谌纯, 张一敏, 包申旭, 等. 叔胺N235从石煤酸浸液中分离富集钒[J]. 稀有金属, 2017,41(4):422−428.

|

| [18] |

Lin Hai, Li Jie, Dong Yingbo. Effect of particle size on Static Leaching of heavy metals from stone coal vanadium ore waste[J]. Rare Metals, 2017,41(6):693−700. (林海, 李洁, 董颖博. 粒度对石煤钒矿废石重金属静态淋溶的影响规律[J]. 稀有金属, 2017,41(6):693−700.

|

| [19] |

Huang Jun, Zhang Yimin, Huang Jing, et al. Study on vanadium extraction and impurity reduction by cyclic pressurized acid leaching of stone coal calcined samples[J]. Rare Metals, 2017,41(6):701−708. (黄俊, 张一敏, 黄晶, 等. 石煤焙烧样循环加压酸浸提钒降杂研究[J]. 稀有金属, 2017,41(6):701−708.

|

| [20] |

Li Jie, Ma Jing. Study on mechanical beneficiation and tailing technology of black rock vanadium ore[J]. Nonferrous Metals (Beneficiation), 2010,(4):25−28. (李洁, 马晶. 黑色岩系钒矿的机械选矿抛尾工艺研究[J]. 有色金属(选矿部分), 2010,(4):25−28.

|

| [21] |

Liu Yuanchao, Wang Li, Sun Wei, et al. Experimental study on beneficiation of low-grade siliceous stone coal vanadium ore[J]. Nonferrous Metals (Beneficiation), 2016,(2):47−51,84. (刘源超, 王丽, 孙伟, 等. 低品位硅质石煤钒矿的选矿试验研究[J]. 有色金属(选矿部分), 2016,(2):47−51,84.

|

| [22] |

Liu Xin, Zhang Yimin, Liu Tao, et al. Combined weight flotation pre tailing test of a mica vanadium bearing stone coal in Hubei[J]. Metal Mine, 2017,(5):93−98. (刘鑫, 张一敏, 刘涛, 等. 湖北某云母型含钒石煤重—浮联合预抛尾试验[J]. 金属矿山, 2017,(5):93−98. doi: 10.3969/j.issn.1001-1250.2017.05.019

|

| [23] |

Fu Lipan, Zhang Yimin, Liu Tao, et al. Effect of acid-base additives on roasting effect of siliceous vanadium bearing shale[J]. Metal Mine, 2012,(1):111−114. (付利攀, 张一敏, 刘涛, 等. 酸碱性添加剂对硅质含钒页岩焙烧效果的影响[J]. 金属矿山, 2012,(1):111−114. doi: 10.3969/j.issn.1001-1250.2012.01.029

|

| [24] |

Peng Hao. A literature review on leaching and recovery of vanadium[J]. Journal of Environmental Chemical Engineering, 2019,7(5):103313−103313. doi: 10.1016/j.jece.2019.103313

|

| [25] |

Zou Jianjun, Liu Xiaoxing. Research status of vanadium extraction from stone coal[J]. Scientific and Technological Innovation and Application, 2015,(28):22−23. (邹建军, 刘小星. 石煤提钒工艺研究现状[J]. 科技创新与应用, 2015,(28):22−23.

|

| [26] |

Deng Qingyun, Liu Songying. Experimental study on a new process of extracting vanadium from stone coal by sodium roasting, acid leaching and ion exchange[J]. Rare Metals and Cemented Carbides, 1993,(4):27−33. (邓庆云, 刘松英. 石煤钠化焙烧、酸浸、离子交换提钒新工艺的试验研究[J]. 稀有金属与硬质合金, 1993,(4):27−33.

|

| [27] |

Shi Ling, Wang Juan, Xie Jianhong. Study on technological conditions of vanadium extraction by sodium process[J]. Mining and Metallurgy Engineering, 2008,(1):58−61. (史玲, 王娟, 谢建宏. 钠化法提钒工艺条件的研究[J]. 矿冶工程, 2008,(1):58−61. doi: 10.3969/j.issn.0253-6099.2008.01.016

|

| [28] |

Zhang Yimin, Hu Yangjia, Bao Shenxu, et al. Vanadium emission during roasting of vanadium-bearing stone coal in chlorine[J]. Minerals Engineering, 2012,30:95−98. doi: 10.1016/j.mineng.2012.02.003

|

| [29] |

Zhang Ying, Zhang Ting, an, David Dreisinger, et al. Recovery of vanadium from calcification roasted-acid leaching tailing by enhanced acid leaching[J]. Journal of Hazardous Materials, 2019,369:632−641. doi: 10.1016/j.jhazmat.2019.02.081

|

| [30] |

Wen Jing, Jiang Tao, Zhou Mi. Roasting and leaching behaviors of vanadium and chromium in calcification roasting–acid leaching of high-chromium vanadium slag[J]. International Journal of Minerals Metallurgy and Materials, 2018,25(5):515−526. doi: 10.1007/s12613-018-1598-3

|

| [31] |

Peng Hao, Guo Jing, Zheng Xiaogang, et al. Leaching kinetics of vanadium from calcification roasting converter vanadium slag in acidic medium[J]. Journal of Environmental Chemical Engineering, 2018,6(4):5119−5124. doi: 10.1016/j.jece.2018.08.003

|

| [32] |

汪博. 钙质焙烧添加剂对页岩提钒过程的影响及机理研究[D]. 武汉: 武汉科技大学, 2017.Wang Bo. Effect and mechanism of calcium roasting additives on vanadium extraction from shale[D] . Wuhan: Wuhan University of Science and Technology, 2017.

|

| [33] |

Zhang Xiaogang, Gao Yongbo, Xu Qiang, et al. Experimental study on alkali leaching of vanadium from stone coal vanadium ore by calcification roasting[J]. Applied Chemical Industry, 2013,42(6):1026−1028,1032. (张晓刚, 高永波, 徐强, 等. 石煤钒矿钙化焙烧碱浸提钒工艺的实验研究[J]. 应用化工, 2013,42(6):1026−1028,1032.

|

| [34] |

Zhang Yimin, Bao Shenxu, Liu Tao, et al. Thetechnology of extracting vanadium from stone coal in China: history, current status and future prospects[J]. Hydrometallurgy, 2011,109(1):116−124.

|

| [35] |

王学文, 王明玉, 李青刚, 等. 一种石煤提钒矿石分解方法: 中国, CN101260464[P]. 2008-09-10.Wang Xuewen, Wang Mingyu, Li Qinggang, et al. A decomposition method for extracting vanadium from stone coal: China, CN101260464 [P]. 2008-09-10.

|

| [36] |

Liang Huanlong, Xie Yingbang, He Hangjun, et al. A new process for extracting vanadium pentoxide from stone coal by sulfation and microwave roasting[J]. Nonferrous Metals (Smelting part), 2015,(8):39−42. (梁焕龙, 谢营邦, 何航军, 等. 石煤硫酸化微波焙烧提取五氧化二钒新工艺[J]. 有色金属(冶炼部分), 2015,(8):39−42.

|

| [37] |

Ye Guohua, Xie Yu, Hu Yibo, et al. Study on low temperature sulfation roasting water leaching of vanadium from low-grade stone coal vanadium ore[J]. Rare Metals, 2020,44(7):753−761. (叶国华, 谢禹, 胡艺博, 等. 低品位石煤钒矿低温硫酸化焙烧-水浸提钒研究[J]. 稀有金属, 2020,44(7):753−761.

|

| [38] |

何东升, 张泽强, 张汉泉, 等. 一种从含钒石煤中提取五氧化二钒的复合焙烧添加剂及其应用: 中国, CN102296192A[P]. 2011-12-28.He Dongsheng, Zhang Zeqiang, Zhang Hanquan, et al. A composite roasting additive for extracting vanadium pentoxide from vanadium bearing stone coal and its application: China, CN102296192A[P]. 2011-12-28.

|

| [39] |

Gao Feng, Hua Jun, Yan Wenbin, et al. Vanadium extraction process by clean roasting of stone coal[J]. Nonferrous Metal Engineering, 2020,10(5):44−48. (高峰, 华骏, 颜文斌, 等. 石煤清洁焙烧提钒工艺[J]. 有色金属工程, 2020,10(5):44−48. doi: 10.3969/j.issn.2095-1744.2020.05.009

|

| [40] |

Zhang Chengqiang, Sun Chuanyao, Yin Wanzhong, et al. Study on vanadium extraction process by roasting combined leaching of a illite vanadium bearing coal mine stone composite additive[J]. Metal Mine, 2018,(10):92−97. (张成强, 孙传尧, 印万忠, 等. 某伊利石型含钒石煤矿石复合添加剂焙烧—联合浸出提钒工艺研究[J]. 金属矿山, 2018,(10):92−97.

|

| [41] |

蒋谋锋. 云母型含钒石煤空白焙烧酸浸提钒机理研究[D]. 武汉: 武汉理工大学, 2015.Jiang Moufeng. Study on mechanism of vanadium extraction from mica vanadium bearing stone coal by blank roasting acid [D] . Wuhan: Wuhan University of Technology, 2015.

|

| [42] |

Pan Zhankai, Li Qingchun, Ye Shufeng, et al. Study on blank roasting leaching process of Fangshankou stone coal vanadium ore[J]. Computer and Applied Chemistry, 2014,31(12):1557−1560. (潘占开, 李青春, 叶树峰, 等. 方山口石煤钒矿空白焙烧—助浸剂浸出工艺研究[J]. 计算机与应用化学, 2014,31(12):1557−1560.

|

| [43] |

Zhang Bo, Gao Zhaoguo, Liu Hongzhao, et al. Directacid leaching of vanadium from stone coal[J]. High Temperature Materials and Processes, 2017,36(9):877−883. doi: 10.1515/htmp-2016-0055

|

| [44] |

何伟. 粘土钒矿不磨不焙烧常压活化酸浸提钒的研究[D]. 昆明: 昆明理工大学, 2014.He Wei. Study on extraction of vanadium from clay vanadium ore by atmospheric pressure activated acid without grinding or roasting [D]. Kunming: Kunming University of Technology, 2014.

|

| [45] |

He Dongsheng, Li Qiaoshuang, Zhang Jiangang, et al. Study on leaching process of vanadium bearing stone coal flotation concentrate[J]. Rare Metals and Cemented Carbides, 2016,44(6):7−9. (何东升, 李巧双, 张建刚, 等. 含钒石煤浮选精矿浸出工艺研究[J]. 稀有金属与硬质合金, 2016,44(6):7−9.

|

| [46] |

Li Xin, Wang Yi, Zhu Jun. Study on direct acid leaching of vanadium from low-grade vanadium ore[J]. Iron Steel Vanadium Titanium, 2010,31(3):10−14. (李欣, 王毅, 朱军. 低品位钒矿直接酸浸提钒工艺研究[J]. 钢铁钒钛, 2010,31(3):10−14. doi: 10.7513/j.issn.1004-7638.2010.03.003

|

| [47] |

Zhang Xiaoyun, Yang Kang, Tian Xueda, et al. Vanadium leaching from carbonaceous shale using fluosilicic acid[J]. International Journal of Mineral Processing, 2011,100(3):184−187.

|

| [48] |

Zhang Chengqiang, Sun Chuanyao, Yin Wanzhong, et al. Acid leaching process of vanadium from a certain illite vanadium bearing stone coal with calcium fluoride as leaching aid[J]. Comprehensive Utilization of Minerals, 2019,(5):42−47. (张成强, 孙传尧, 印万忠, 等. 以氟化钙为助浸剂的某伊利石型含钒石煤酸浸提钒工艺[J]. 矿产综合利用, 2019,(5):42−47. doi: 10.3969/j.issn.1000-6532.2019.05.009

|

| [49] |

Tian Lei, Xu Zhifeng, Chen Lijie, et al. Effect of microwave heating on the pressure leaching of vanadium from converter slag[J]. Hydrometallurgy, 2018,184:45−54.

|

| [50] |

Huang Jun, Zhang Yimin, Huang Jing, et al. Study on roasting-pressure acid leaching of vanadium from stone coal[J]. Metal Mine, 2015,(10):85−89. (黄俊, 张一敏, 黄晶, 等. 石煤焙烧—加压酸浸提钒研究[J]. 金属加工, 2015,(10):85−89.

|

| [51] |

Deng Zhigan, Wei Chang, Fan Gang, et al. Extracting vanadium from stone-coal by oxygen pressure acid leaching and solvent extraction[J]. Transactions of Nonferrous Metals Society of China, 2010,20:118−122. doi: 10.1016/S1003-6326(10)60024-6

|

| [52] |

杨德芹. 石煤硫酸化焙烧—超声浸出提钒工艺的研究[D]. 绵阳: 西南科技大学, 2015.Yang Deqin. Study on extraction of vanadium from stone coal by sulfation roasting ultrasonic leaching[D] . Mianyang: Southwest University of Science and Technology, 2015.

|

| [53] |

Chen Bo, Bao Shenxu, Zhang Yimin, et al. A high-efficiency and sustainable leaching process of vanadium from shale in sulfuric acid systems enhanced by ultrasound[J]. Separation and Purification Technology, 2020,240(C):1−9.

|

| [54] |

Ouyang Guoqiang, Zhang Xiaoyun, Tian Xueda, et al. Effect of microwave roasting on vanadium extraction from stone coal[J]. Chinese Journal of Nonferrous Metals, 2008,(4):750−754. (欧阳国强, 张小云, 田学达, 等. 微波焙烧对石煤提钒的影响[J]. 中国有色金属学报, 2008,(4):750−754. doi: 10.3321/j.issn:1004-0609.2008.04.031

|

| [55] |

Li Yinli, Song Yonghui, Wang Kepeng, et al. Study on vanadium extraction from stone coal by microwave leaching[J]. Nonferrous Metals (Smelting part), 2016,(3):36−39. (李银丽, 宋永辉, 王科鹏, 等. 石煤微波浸出提钒工艺研究[J]. 有色金属(冶炼部分), 2016,(3):36−39.

|

| [56] |

Lin Hai, Wang Xin, Dong Yingbo, et al. Effect of heterotrophic bacteria on microbial leaching of vanadium bearing stone coal[J]. Rare Metals, 2017,41(9):1050−1055. (林海, 王鑫, 董颖博, 等. 异养细菌对含钒石煤微生物浸出效果的研究[J]. 稀有金属, 2017,41(9):1050−1055.

|

| [57] |

杨盟. 生物浸出法从含钒矿物中提取钒及选择性吸附富集研究[D]. 北京: 中国地质大学(北京), 2018.Yang Meng. Study on extraction of vanadium from vanadium bearing minerals by bioleaching and selective adsorption enrichment [D]. Beijing: China University of Geosciences (Beijing), 2018.

|

下载:

下载: