Anisotropy of tensile and low cycle fatigue properties of commercial pure titanium TA2

-

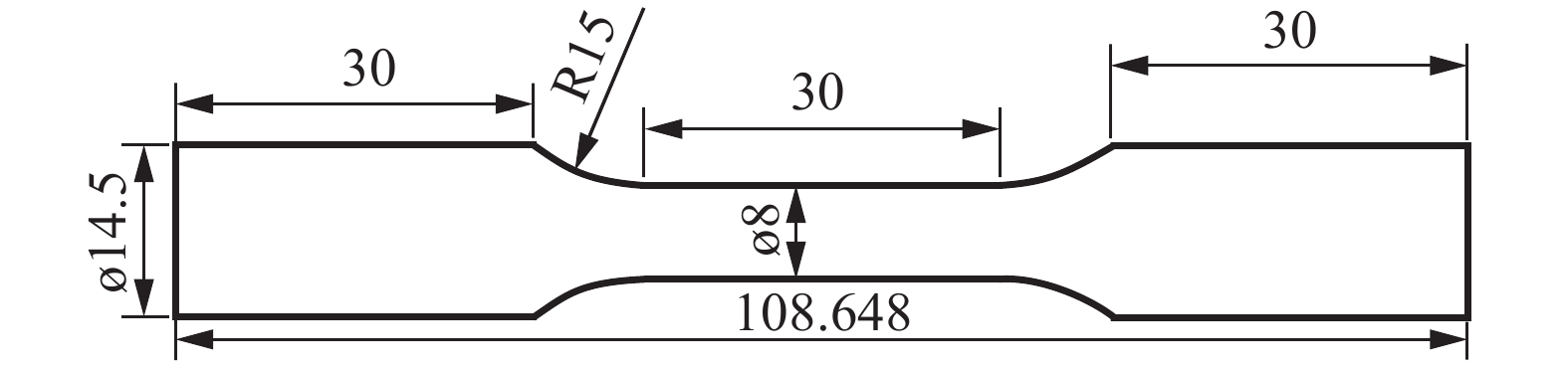

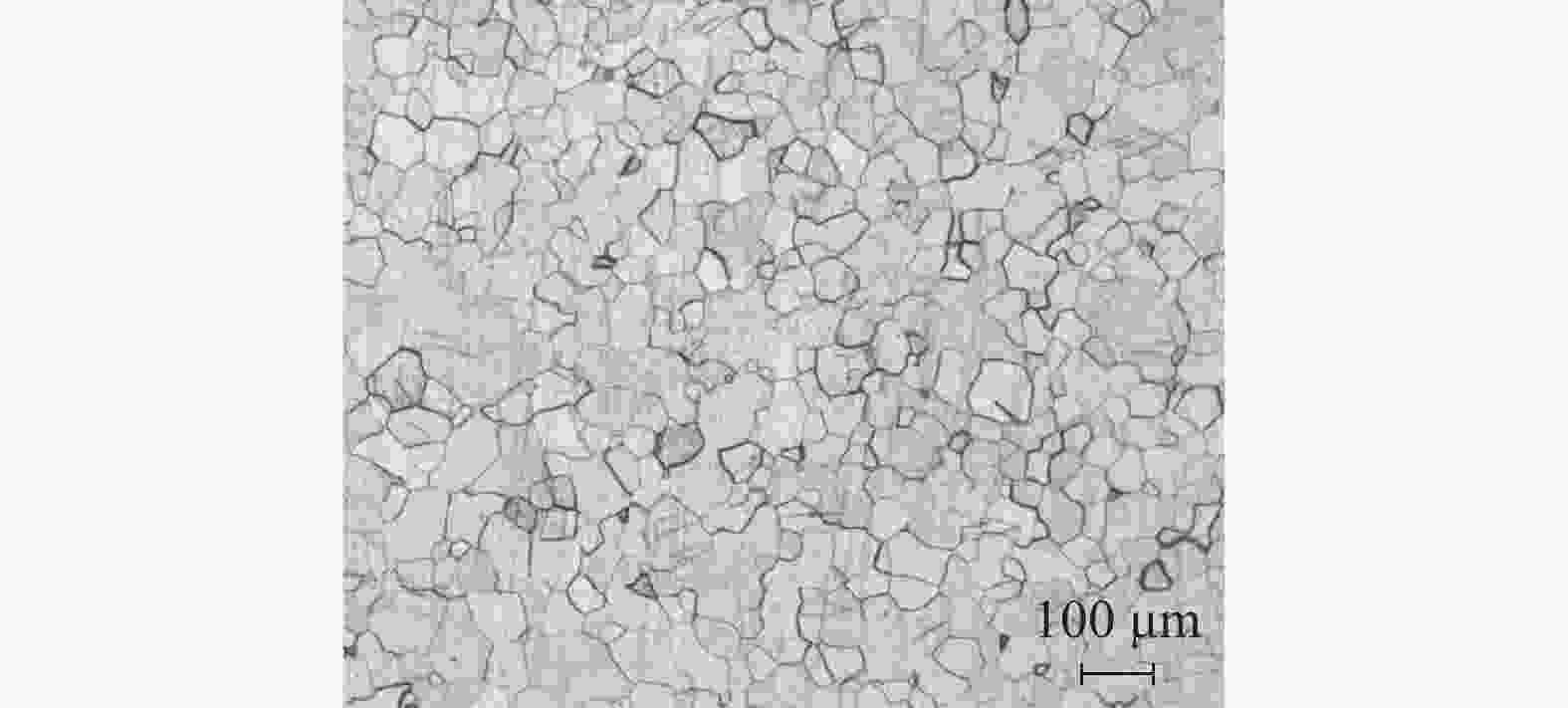

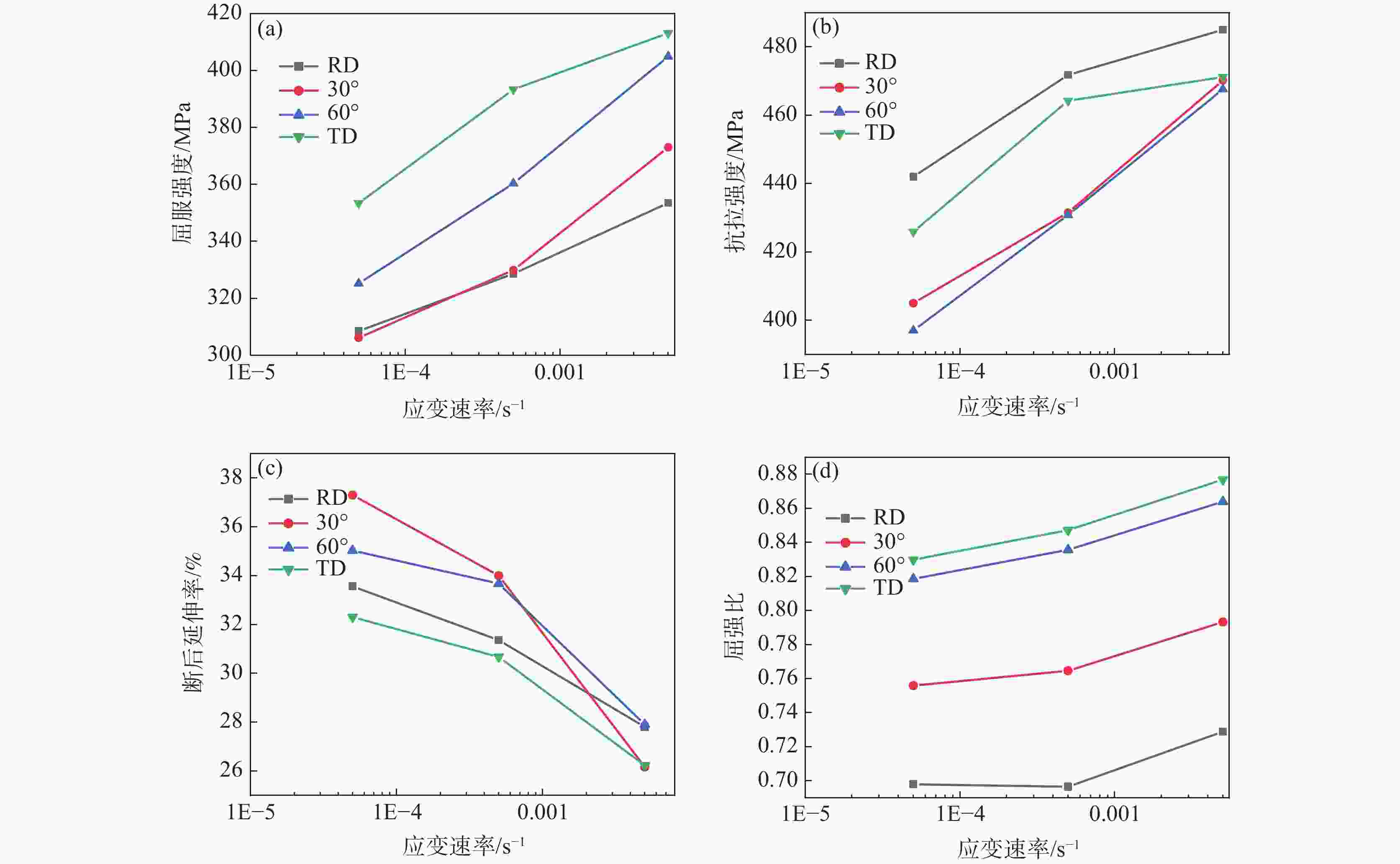

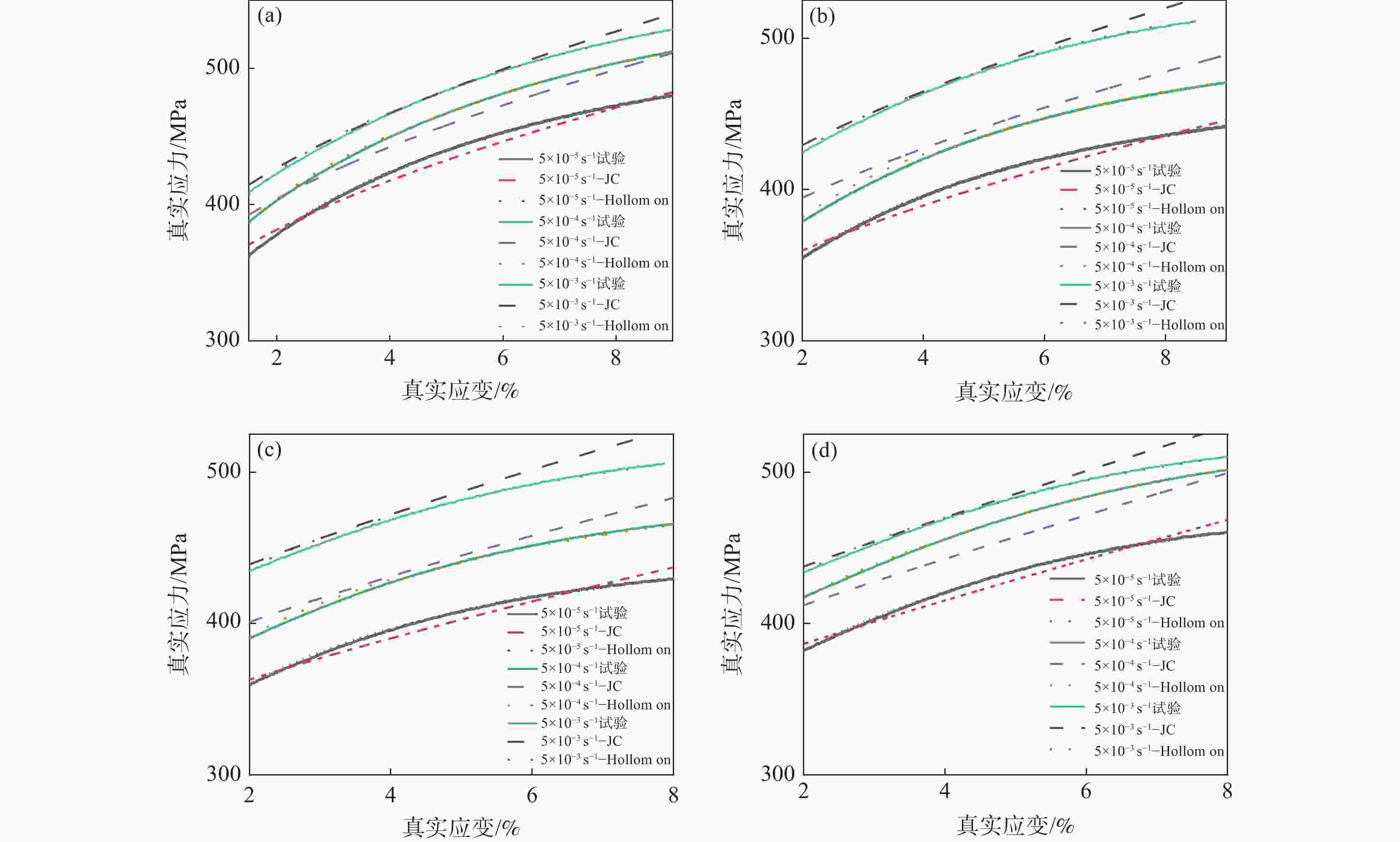

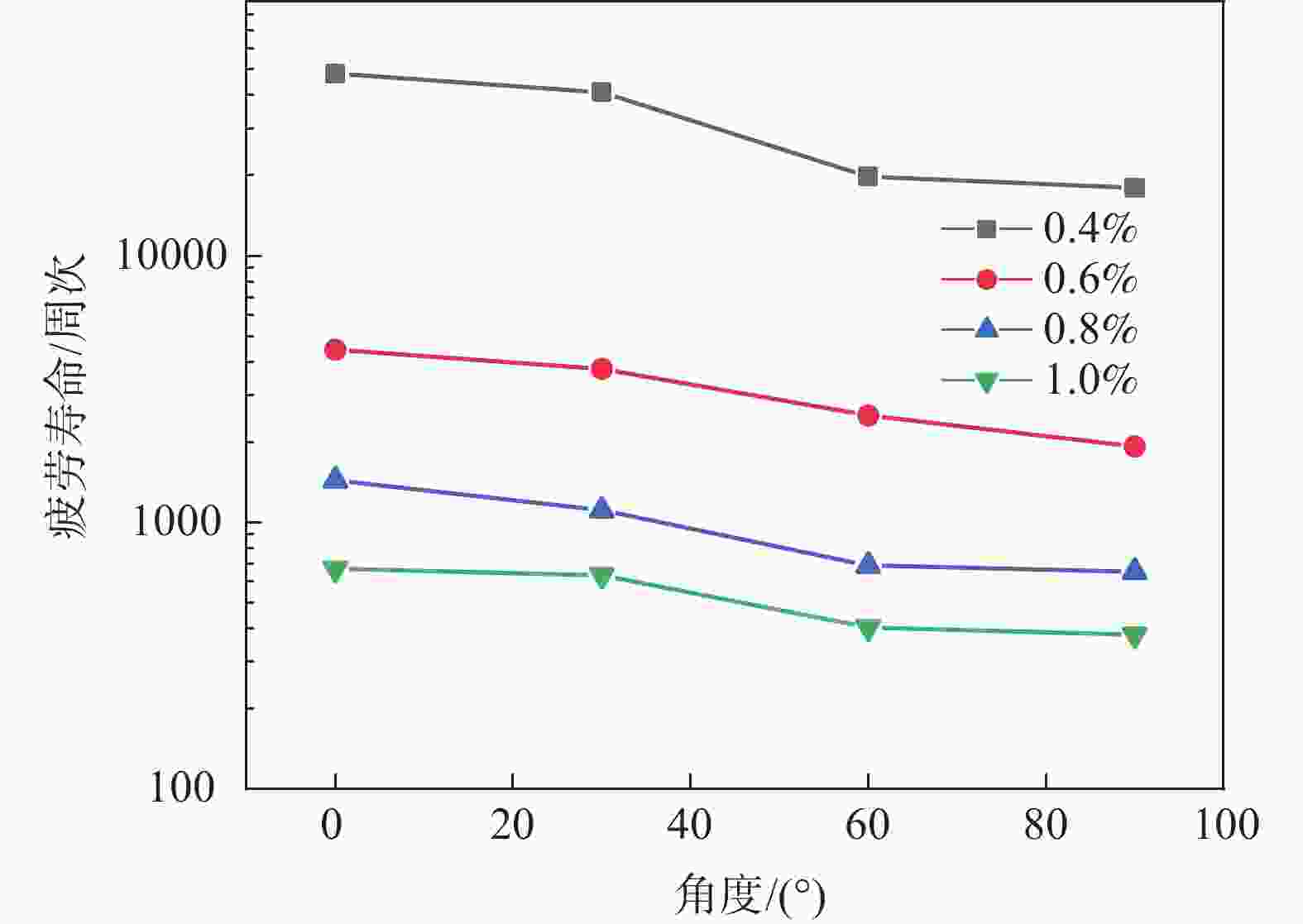

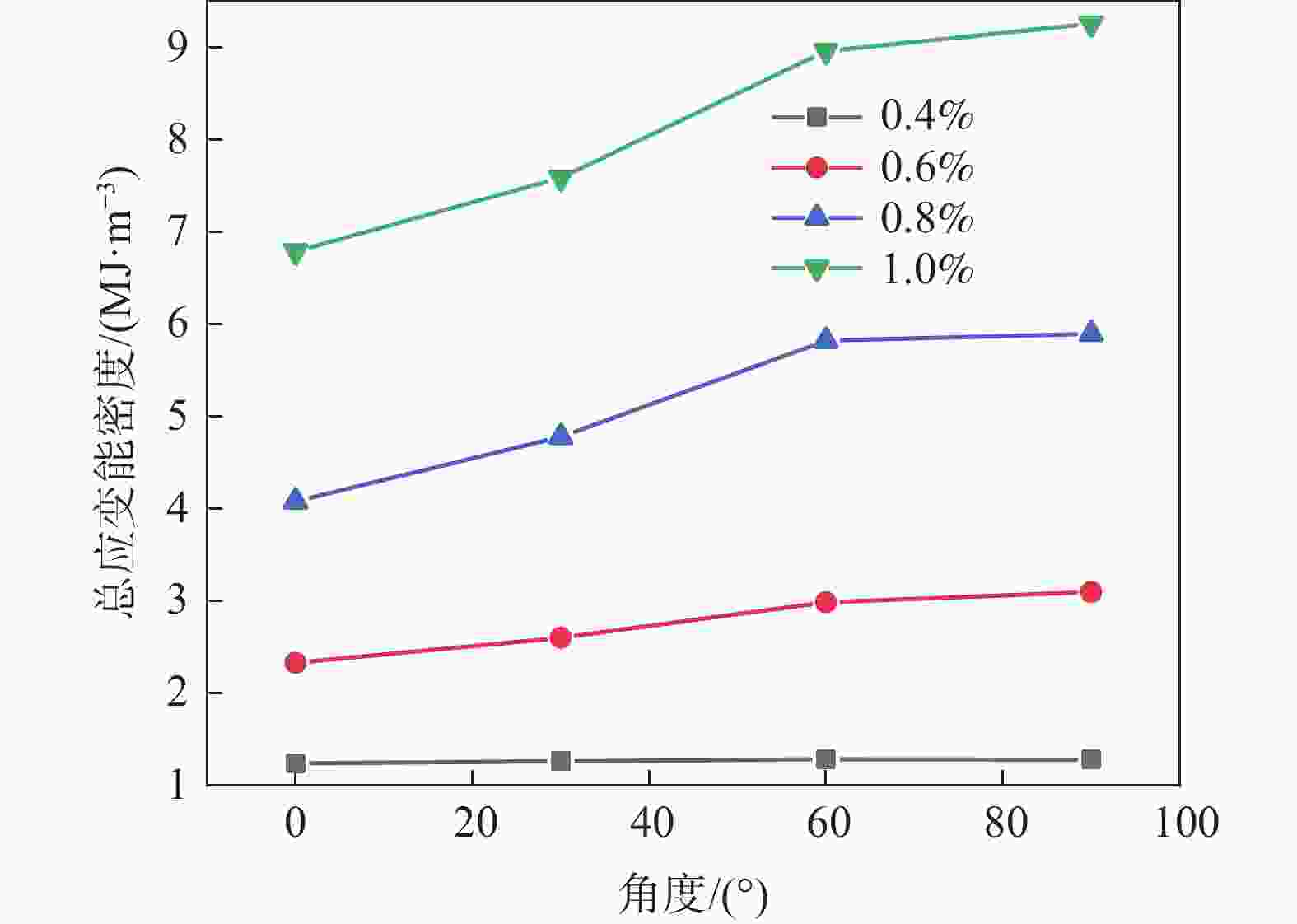

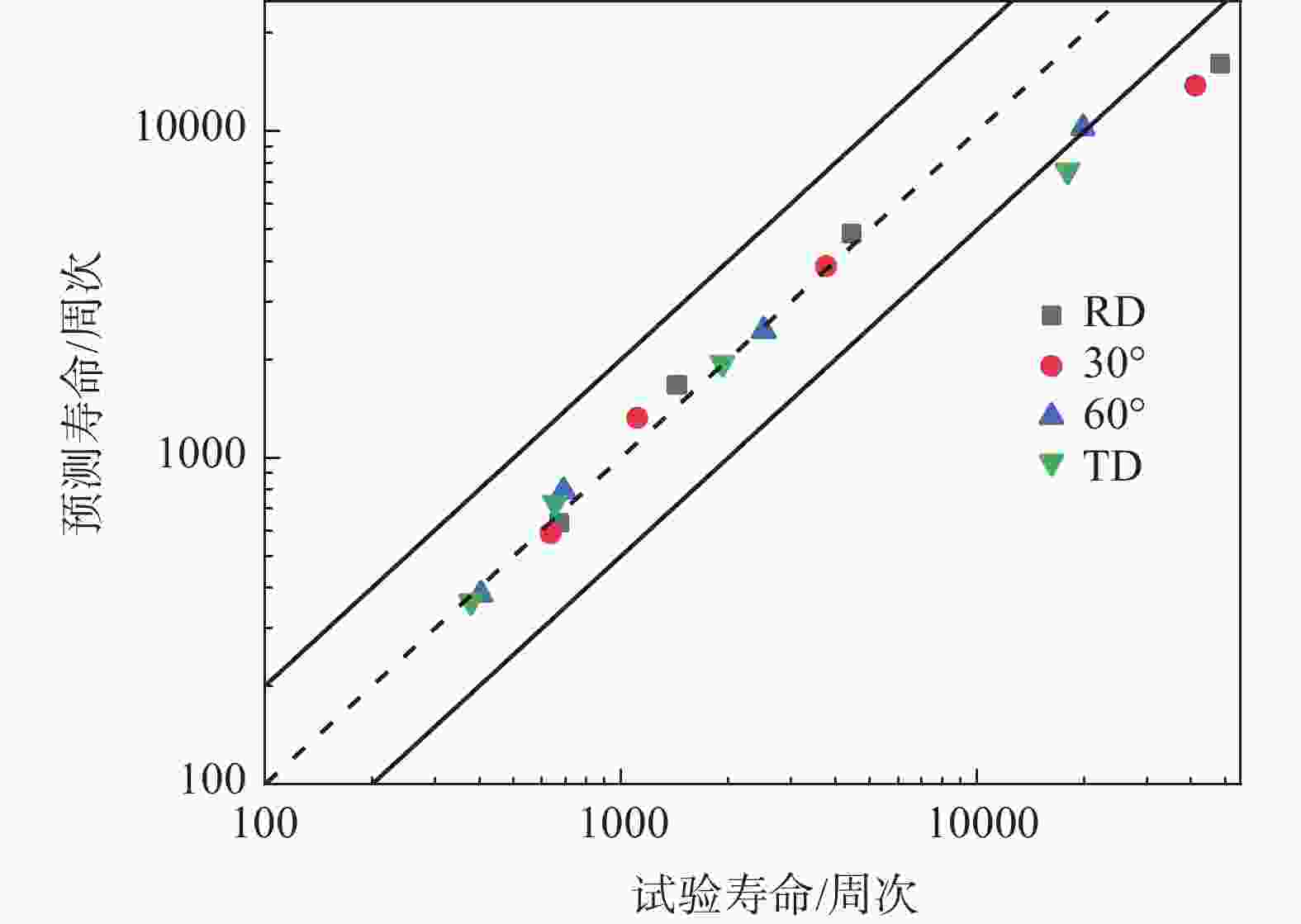

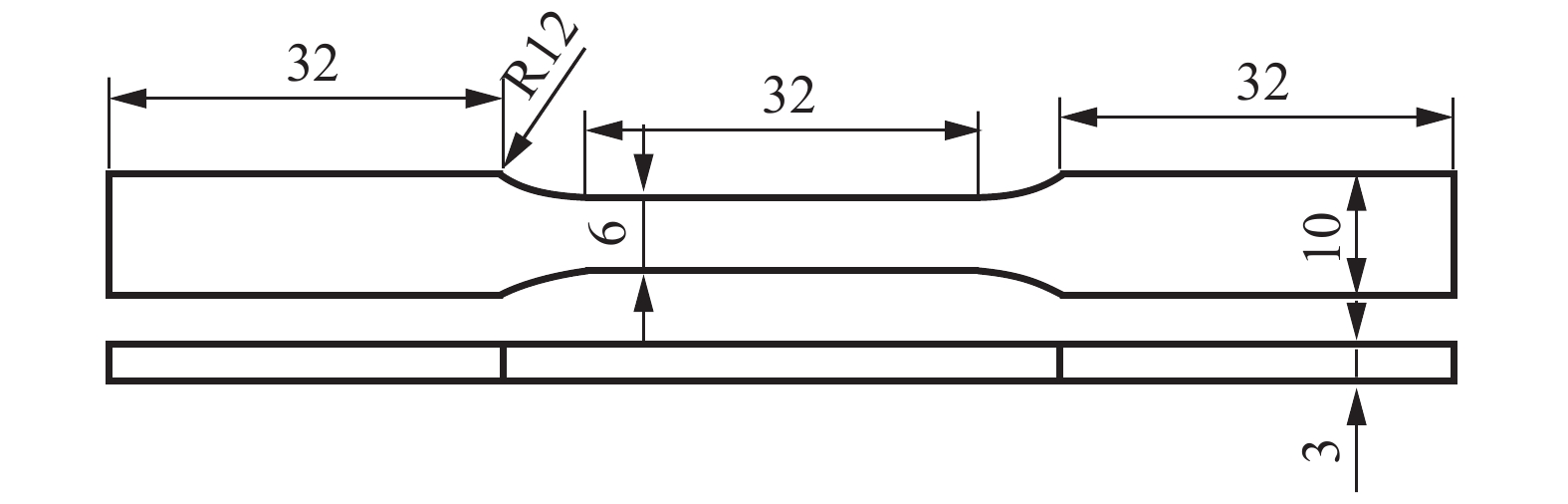

摘要: 为系统研究工业纯钛TA2拉伸性能及低周疲劳性能的各向异性,沿轧制方向(RD)、与RD呈30°方向(RD-30°)、与RD呈60°方向(RD-60°)及垂直轧制方向(TD)开展了室温拉伸及低周疲劳试验。结果表明:随着取样角度增加,屈服强度增加,屈强比上升,材料的塑性下降。基于Hollomon模型及Johnson-Cook模型对工业纯钛真实应力应变曲线进行预测,发现Hollomon模型预测精度更高。低周疲劳试验结果表明:不同取样方向的试样均呈现循环软化特征,随着取样角度增加,恒定应变幅下循环应力幅值增加,总的应变能密度增加,导致疲劳寿命呈下降趋势。不同取向试样的低周疲劳寿命满足Manson-coffin经验关系式。Abstract: To systematically study the anisotropy of tensile and low cycle fatigue properties of commercial pure titanium, tensile and low cycle fatigue tests at room temperature were carried out along the rolling direction (RD), 30° to RD (RD-30°), 60° to RD (RD-60°) and transverse direction (TD). With the increase of sample angle, the yield strength and yield ratio increase, and the plasticity of the material decreases. The Hollomon model and Johnson-Cook model were used to predict the true stress-strain curve of commercial pure titanium, and it was found that the Hollomon model has higher prediction accuracy. Low cycle fatigue test results find that all samples show cyclic softening feature. The cyclic stress amplitude increases with the increase of sample angle, and the total strain energy density increases, resulting in a decreasing trend of fatigue life. The low cycle fatigue life of specimens with different orientations satisfies Manson- Coffin empirical relation.

-

Key words:

- commercial pure titanium /

- tensile properties /

- low cycle fatigue properties /

- anisotropy

-

表 1 TA2的化学成分

Table 1. Chemical compositions of TA2

% Ti Fe C N H O 其它元素 单个 总和 > 99 0.02 0.01 0.01 0.002 0.14 < 0.1 < 0.4 表 2 不同疲劳模型参数拟合值

Table 2. Fitting values of different fatigue model parameters

加载方向 Manson-coffin模型 基于总能量密度模型 $\sigma _{{f}}^{'}$ $\varepsilon _f^{'}$ b c k c RD 852.23 5.57 −0.1072 −0.3104 1.99 −0.524 30o 804.06 6.35 −0.0966 −0.3378 2.84 −0.568 60o 862.81 7.46 −0.1008 −0.3908 2.99 −0.590 TD 925.24 8.21 −0.1028 −0.4191 4.3 −0.651 -

[1] Chang Hui, Zhou Lian, Wang Xiangdong. Development and future of Chinese titanium industry and technology[J]. Journal of Aeronautical Materials, 2014,34(4):39. (常辉, 周廉, 王向东. 我国钛工业技术进展及展望[J]. 航空材料学报, 2014,34(4):39. [2] Jia Hong, Lu Fusheng, Hao Bin. Report on China titanium industry in 2020[J]. Iron Steel Vanadium Titanium, 2021,42(3):1−9. (贾翃, 逯福生, 郝斌. 2020年中国钛工业发展报告[J]. 钢铁钒钛, 2021,42(3):1−9. doi: 10.7513/j.issn.1004-7638.2021.03.001 [3] Peng L, Hao Y, Zhang B, et al. Tension-compression asymmetry in yielding and strain hardening behavior of CP-Ti at room temperature[J]. Materials Science and Engineering:A, 2017,707:172−180. doi: 10.1016/j.msea.2017.09.042 [4] Roth A, Lebyodkin M A, Lebedkina T A, et al. Mechanisms of anisotropy of mechanical properties of α-titanium in tension conditions[J]. Materials Science & Engineering A, 2014,596:236−243. [5] Takao K, Kusukawa K. Low-cycle fatigue behavior of commercially pure titanium[J]. Materials Science & Engineering A, 1996,213(1-2):81−85. [6] Ishihara S, Taneguchi S, Shibata H, et al. Anisotropy of the fatigue behavior of extruded and rolled magnesium alloys[J]. International Journal of Fatigue, 2013,50:94−100. doi: 10.1016/j.ijfatigue.2012.02.011 [7] Mao P, Liu Z, Wang C. Texture effect on high strain rates tension and compression deformation behavior of extruded AM30 alloy[J]. Materials Science & Engineering A, 2012,539:13−21. [8] 刘定凯. 工业纯钛板材的成形性能及各向异性研究[D]. 重庆: 重庆大学, 2016.Liu Dingkai. The study of formability and anisotropy in commercially pure titanium sheet[D]. Chongqing: Chongqing University, 2016. [9] Tian Chenchao, Jiao Lei, Zhang Juan, et al. Anisotropy of plastic deformation of pure titanium sheet during tensile test at room temperature[J]. Welded Pipe and Tupe, 2018,41(10):18−21. (田晨超, 焦磊, 张娟, 等. 纯钛板材室温拉伸塑性变形的各向异性[J]. 焊管, 2018,41(10):18−21. [10] Chang L, Ma T H, Zhou B B, et al. Comprehensive investigation of fatigue behavior and a new strain-life model for CP-Ti under different loading conditions[J]. International Journal of Fatigue, 2019,129:105220. doi: 10.1016/j.ijfatigue.2019.105220 [11] Chang L, Zhou B B, Ma T H, et al. The difference in low cycle fatigue behavior of CP-Ti under fully reversed strain and stress-controlled modes along rolling direction[J]. Materials Science & Engineering A, 2019,742:211−223. [12] Neeraj T, Hou D H, Daehn G S, et al. Phenomenological and microstructural analysis of room temperature creep in titanium alloys[J]. Acta Materialia, 2000,48(6):1225−1238. doi: 10.1016/S1359-6454(99)00426-7 [13] Johnson G R, Cook W H. Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures[J]. Engineering Fracture Mechanics, 1985,21(1):31−48. doi: 10.1016/0013-7944(85)90052-9 [14] Becker H, Pantleon W. Work-hardening stages and deformation mechanism maps during tensile deformation of commercially pure titanium[J]. Computational Materials Science, 2013,76:52−59. doi: 10.1016/j.commatsci.2013.03.028 [15] Lv F, Yang F, Duan Q Q, et al. Tensile and low-cycle fatigue properties of Mg–2.8% Al–1.1% Zn–0.4% Mn alloy along the transverse and rolling directions[J]. Scripta Materialia, 2009,61(9):887−890. doi: 10.1016/j.scriptamat.2009.07.023 [16] Lin Y C, Chen X M, Liu Z H, et al. Investigation of uniaxial low-cycle fatigue failure behavior of hot-rolled AZ91 magnesium alloy[J]. International Journal of Fatigue, 2012,48:122−132. -

下载:

下载: