A study on fatigue damage behavior of single-wire MIG welding joint for TC4 titanium alloy

-

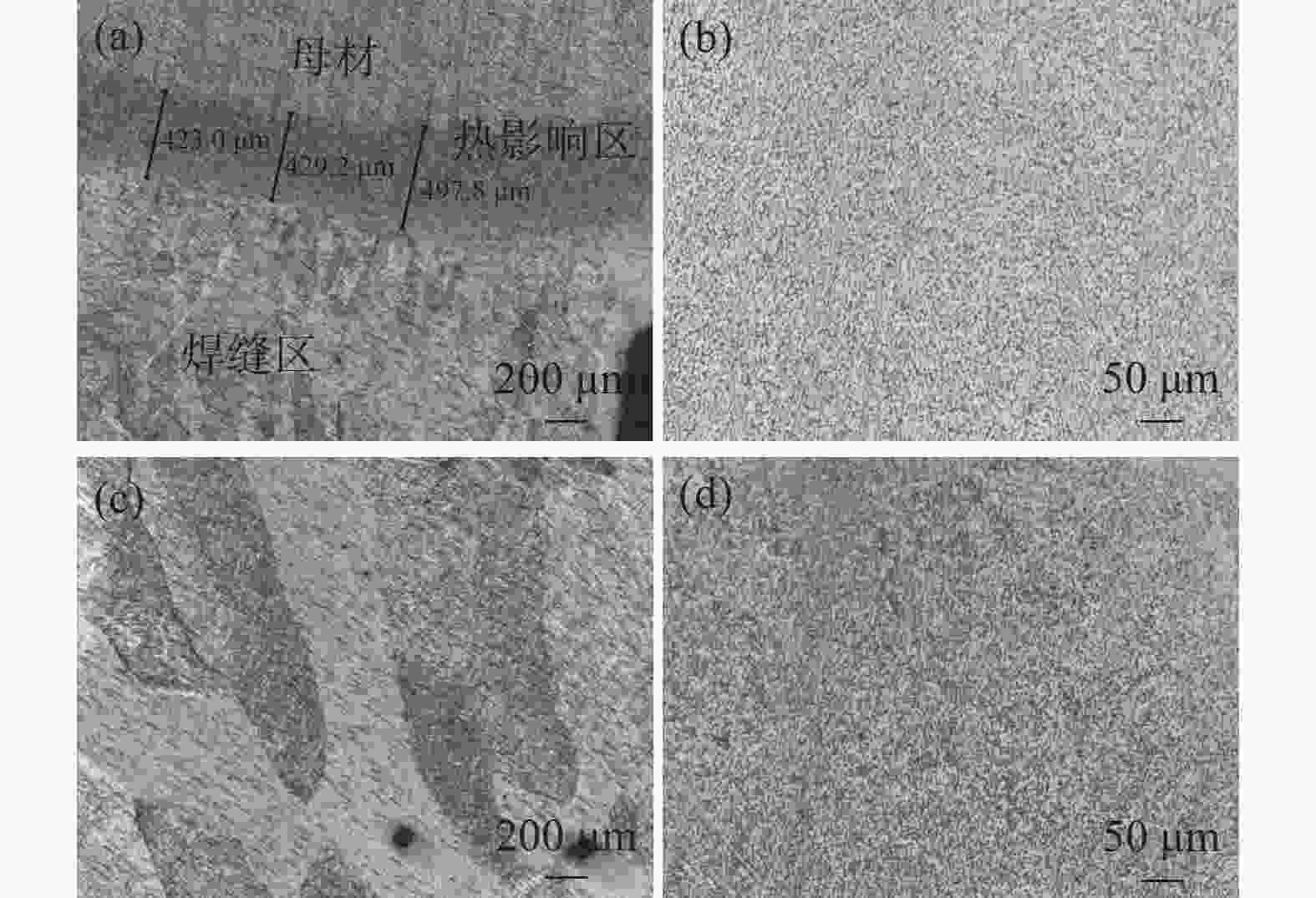

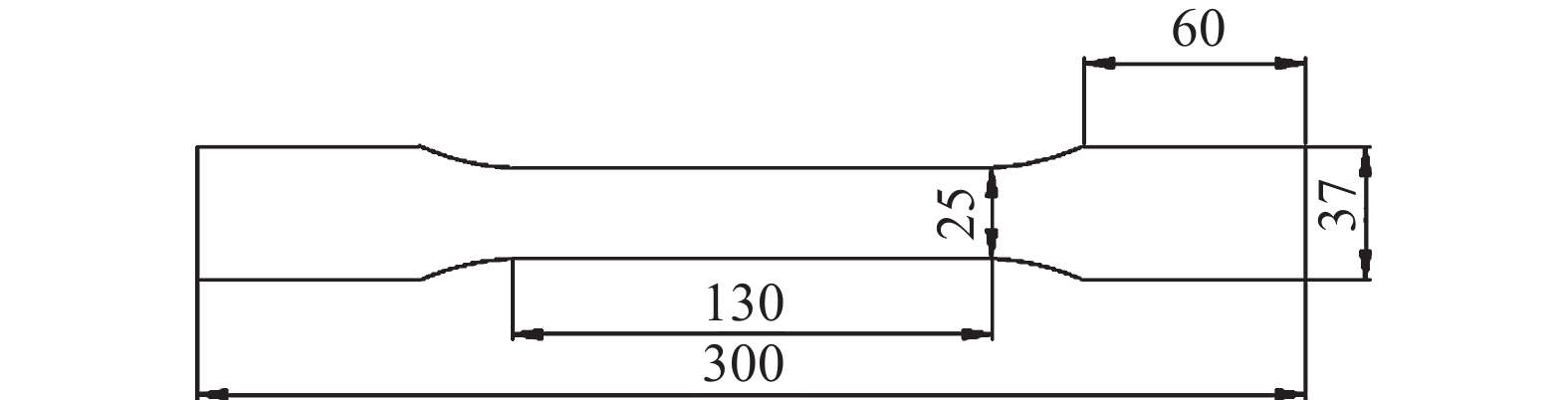

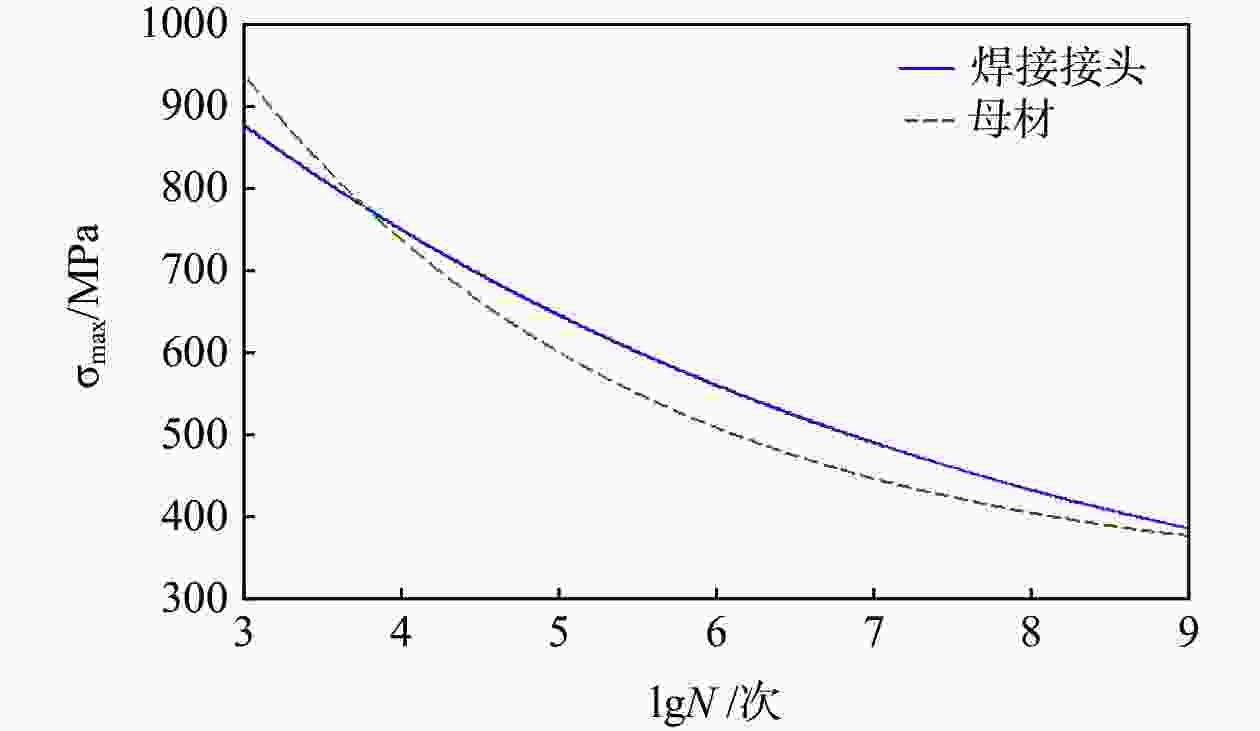

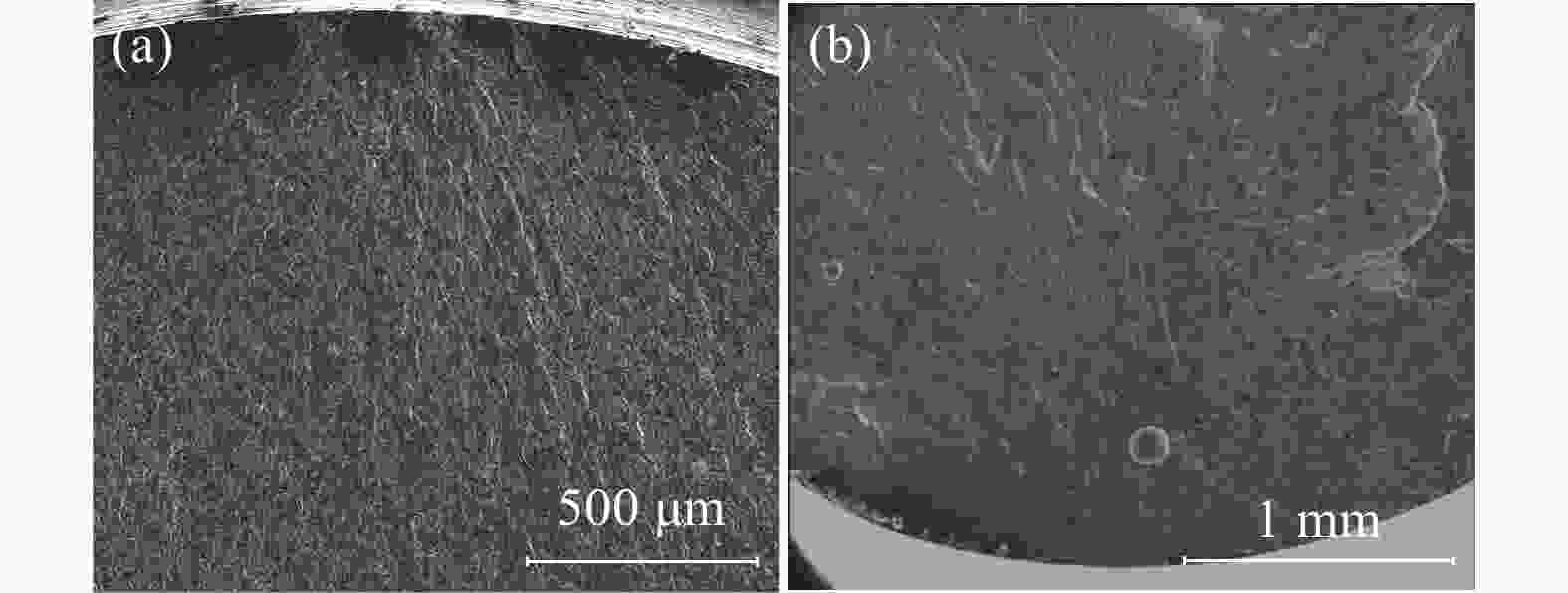

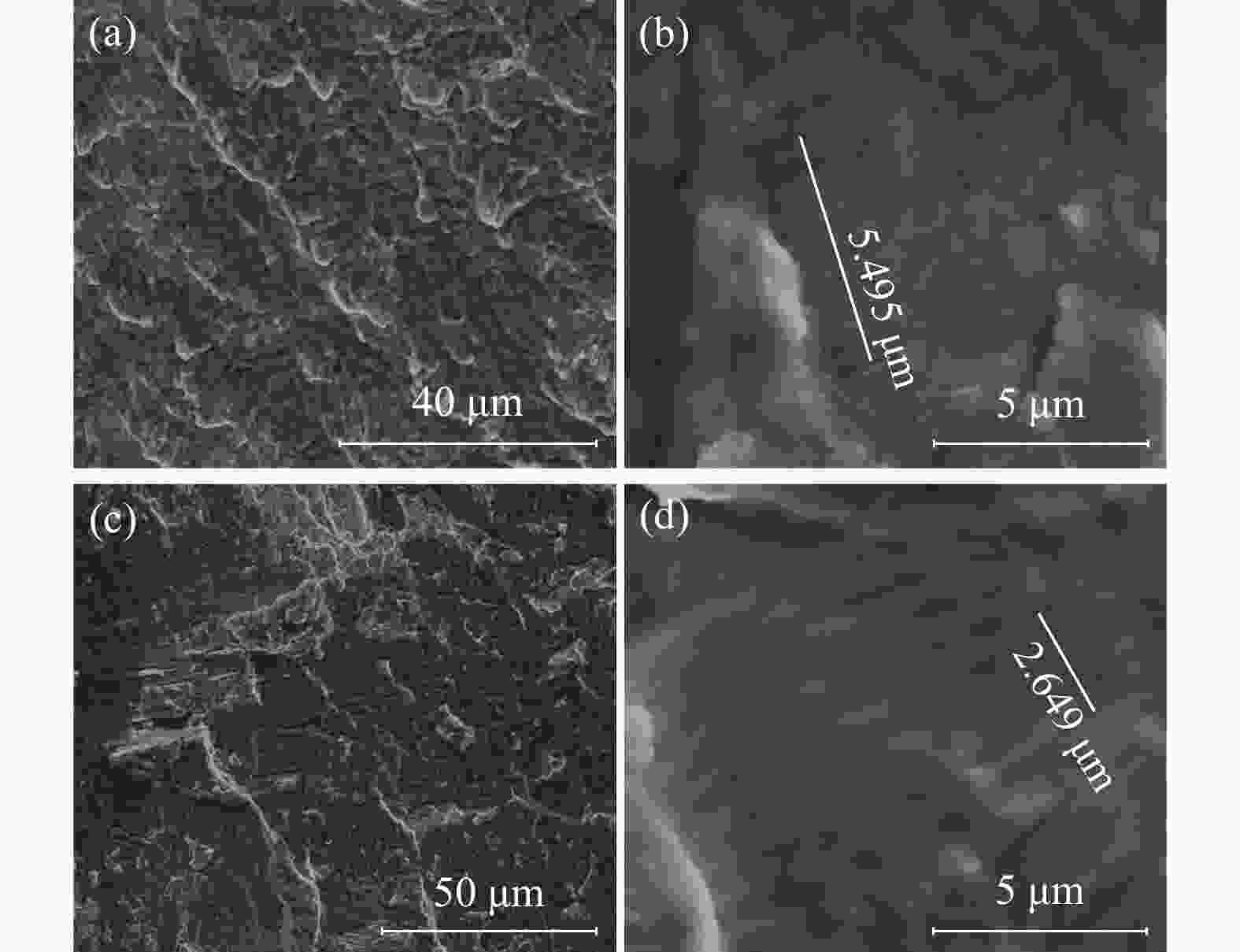

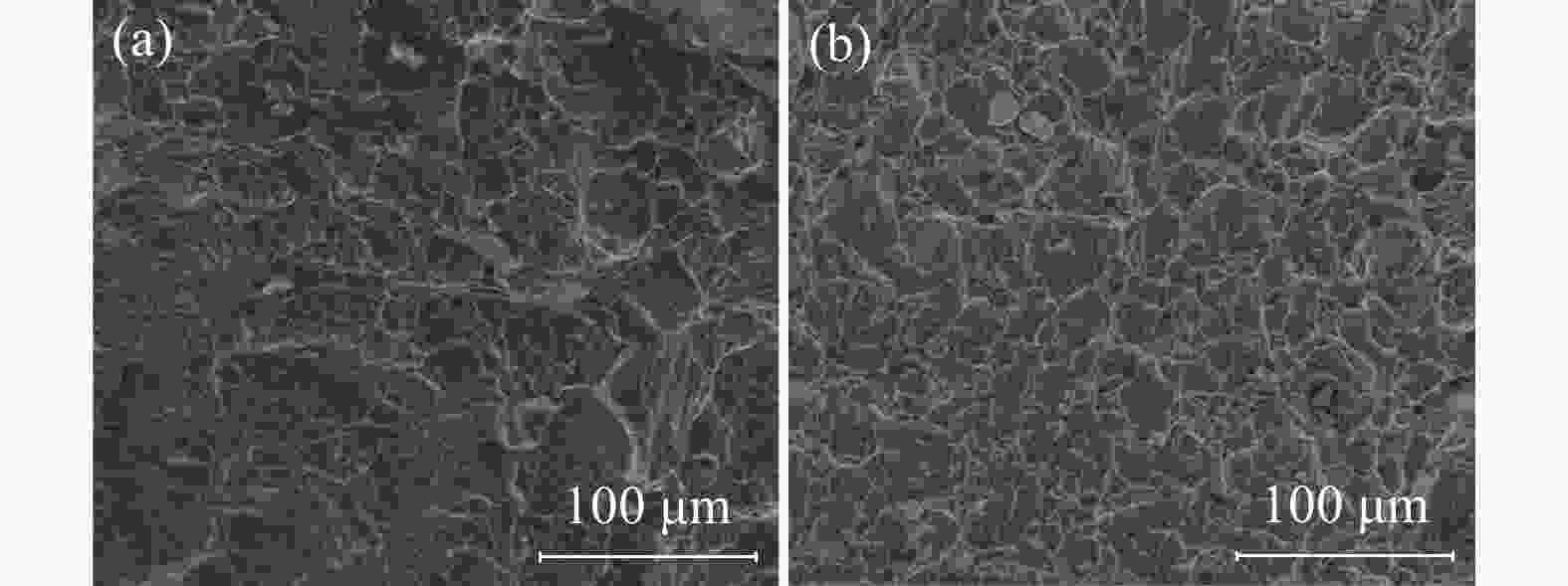

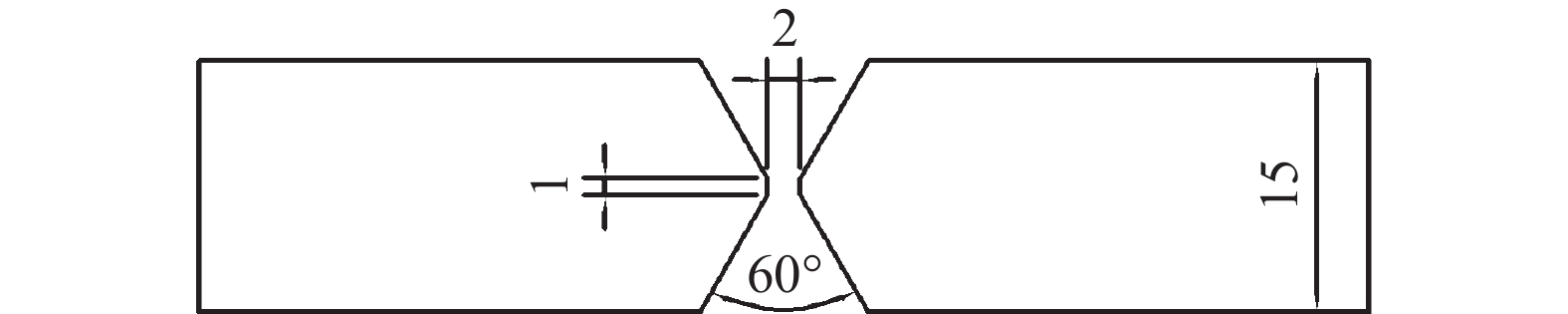

摘要: 采用单丝MIG焊工艺焊接15 mm厚TC4钛合金,对母材和焊接接头的组织、拉伸性能、疲劳性能进行分析测试。结果表明:焊接接头分为母材、热影响区和焊缝区3个部分,其中母材为α+β等轴组织,热影响区为α+β和α′马氏体组成的混合组织,焊缝区在强烈热冲击作用下,晶粒粗化,晶粒内为α′马氏体组织。接头拉伸试样断裂在母材处,断后延伸率为10.5%。母材和焊接接头疲劳寿命随着应力水平的增加而减小,在高应力水平下,母材疲劳寿命高于母材,低应力水平下则相反;母材疲劳源位于试样表面的划痕处,接头疲劳起源于内部气孔处,接头疲劳扩展区有许多二次裂纹,接头扩展区疲劳条带间距小于母材,接头和母材瞬断区都有大量韧窝。Abstract: A single-wire MIG welding process was carried out to weld TC4 titanium alloy with a thickness of 15 mm. The base metal and welded joint microstructure, tensile, and fatigue properties were analyzed and tested. The results showed that the welded joints were divided into the base metal, heat-affected zone, and weld zone. The base metal had an α+β equiaxed structure, and the heat-affected zone was a mixture of α+β and α′-martensite. The grains in the weld zone presented a coarse state under the intense thermal shock; meanwhile, the α′-martensite structure formed the interior of the grain. The tensile specimen fractured at the base metal, and the elongation after fracture was 10.5%. The fatigue life of base metal and welded joints decreased with increased stress levels. The fatigue life of base metal was higher than that of base metal at high-stress levels but opposite at low-stress levels. The fatigue source of the base metal was located at the surface scratches of the sample, and the joint fatigue originated from the internal pores. Many secondary cracks formed in the fatigue propagation zone of the joint, the spacing of the fatigue bands in the fatigue propagation zone was more minor than that of the base metal, and there were many dimples in the transient fracture zone of the joint and the base metal.

-

Key words:

- TC4 titanium alloy /

- single-wire MIG welding /

- microstructure /

- α′-martensite /

- fatigue performance

-

表 1 母材和焊丝化学成分

Table 1. Chemical composition of base metal and welding wire

% Ti Al V Fe C N H O 母材 余量 6.28 4.04 0.136 0.017 0.01 0.001 0.13 焊丝 余量 5.58 4.13 0.22 0.05 0.03 0.015 0.4 表 2 焊接工艺参数

Table 2. Welding process parameters

焊接电流/A 焊接速度/(m·min−1) 干伸长/mm 保护气流量/(L·min−1) 弧长修正/% 140~180 0.3~0.6 12~15 20~25 +30 表 3 拉伸试验结果

Table 3. Tensile test results

样品名称 样品编号 抗拉强度/MPa 延伸率/% 母材 1-1 846 12.5 母材 1-2 840 14.0 母材 1-3 843 11.0 焊缝 1-1 848 11.5 焊缝 1-2 850 11.0 焊缝 1-3 852 12.0 表 4 疲劳试验测试结果

Table 4. Fatigue test results

样品 应力水平/MPa 疲劳寿命N/次 母材 422 34354900 506 1435500 548 317700 590 118300 焊缝 425 100000000 510 4351100 552 1114700 595 320400 -

[1] Han Xu, Li Qiang, Jiang Xunyong, et al. Research on corrosion of TC4 titanium alloy in concentrated high-salt wastewater environment[J]. Iron Steel Vanadium Titanium, 2021,42(6):133−137. (韩旭, 李强, 姜训勇, 等. 高盐废水浓缩环境中的TC4钛合金腐蚀研究[J]. 钢铁钒钛, 2021,42(6):133−137. doi: 10.7513/j.issn.1004-7638.2021.06.018 [2] Zhao Qinyang, Chen Yongnan, Xu Yiku, et al. Progress and prospects of cost-effective manufacturing technologies for titanium alloys[J]. The Chinese Journal of Nonferrous Metals, 2021,31(11):3127−3140. (赵秦阳, 陈永楠, 徐义库, 等. 钛合金材料低成本化制备技术进展与展望[J]. 中国有色金属学报, 2021,31(11):3127−3140. [3] Zhao Yongqing, Ge Peng, Xin Shewei. Progresses of R&D on Ti-alloy materials in recent 5 years[J]. Materials China, 2020,39(7):527−534. (赵永庆, 葛鹏, 辛社伟. 近五年钛合金材料研发进展[J]. 中国材料进展, 2020,39(7):527−534. [4] Feng Jing, Fan Limin, Geng Naitao, et al. Research on TIG welding process of high strength titanium alloy[J]. Iron Steel Vanadium Titanium, 2021,42(6):158−163. (冯靖, 樊立民, 耿乃涛, 等. 高强钛合金TIG焊接工艺研究[J]. 钢铁钒钛, 2021,42(6):158−163. doi: 10.7513/j.issn.1004-7638.2021.06.023 [5] Liu Jia, Xu Jialei, Ma Zhaowei, et al. Research on hybrid welding technique based on plasma and MIG of titanium alloy[J]. Materials Reports, 2021,35(S02):358−360. (刘甲, 徐家磊, 马照伟, 等. 钛合金等离子和MIG复合焊接技术研究[J]. 材料导报, 2021,35(S02):358−360. [6] Liu Shouyi, Wang Youjun, Geng Tao. Study on microstructure and mechanical properties of MIG welded joint of TA5 titanium alloy[J]. Journal of Dalian Jiaotong University, 2018,39(3):86−88. (刘守义, 王有君, 耿涛. 钛合金MIG焊接头组织性能[J]. 大连交通大学学报, 2018,39(3):86−88. [7] Mou Gang, Hua Xueming, Xu Xiaobo, et al. Comparative study on welding procedure and performance of 8 mm thick TC4 titanium alloy with TIG and MIG[J]. Electric Welding Machine, 2020,50(4):70−74. (牟刚, 华学明, 徐小波, 等. 8 mm厚TC4钛合金TIG、MIG焊接工艺及性能对比研究[J]. 电焊机, 2020,50(4):70−74. [8] Li Ruiwu, Qiu Shengwen, Xu Jialei, et al. Double-sided double-arc MIG welding process of titanium alloy T-joint[J]. Welding & Joining, 2020,(8):39−44,63. (李瑞武, 邱胜闻, 徐家磊, 等. 钛合金T形接头双面双弧MIG焊工艺[J]. 焊接, 2020,(8):39−44,63. [9] He Yifan, Chen Donggao, Zhang Long, et al. Research on microstructure and properties of TC4 titanium alloy MIG welded joints after heat treatment[J]. Iron Steel Vanadium Titanium, 2021,42(6):164−170. (何逸凡, 陈东高, 张龙, 等. TC4钛合金MIG焊接头热处理后组织性能研究[J]. 钢铁钒钛, 2021,42(6):164−170. doi: 10.7513/j.issn.1004-7638.2021.06.024 [10] Xu Liang, Su Juji, Zhou Song, et al. Fatigue performance and fracture mechanism of dual-beam laser welded T-joints of TC4 titanium alloy[J]. The Chinese Journal of Nonferrous Metals, 2019,29(7):1408−1416. (许良, 苏居季, 周松, 等. TC4钛合金激光双光束焊T形接头疲劳性能及断裂机理[J]. 中国有色金属学报, 2019,29(7):1408−1416. [11] Yang Wulin, Yang Xiaohua, Li Xiaoyan, et al. Analysis on fatigue property and fracture mechanism of TC4 titanium alloy joint during laser welding[J]. Transactions of the China Welding Institution, 2012,33(3):105−108,118. (杨武林, 杨晓华, 李晓延, 等. TC4钛合金薄板激光焊接接头的疲劳寿命及断口分析[J]. 焊接学报, 2012,33(3):105−108,118. [12] Xiao Lei, Feng Ganjiang. Low-cycle fatigue behavior of new single crystal superalloy WZ4 at high temperature[J]. Hot Working Technology, 2019,(2):50−54. (肖磊, 冯赣江. 新型单晶高温合金WZ4的高温低周疲劳行为[J]. 热加工工艺, 2019,(2):50−54. -

下载:

下载: