Development and application instances of vacuum stirring evaporation technology of titanium tetrachloride slurry

-

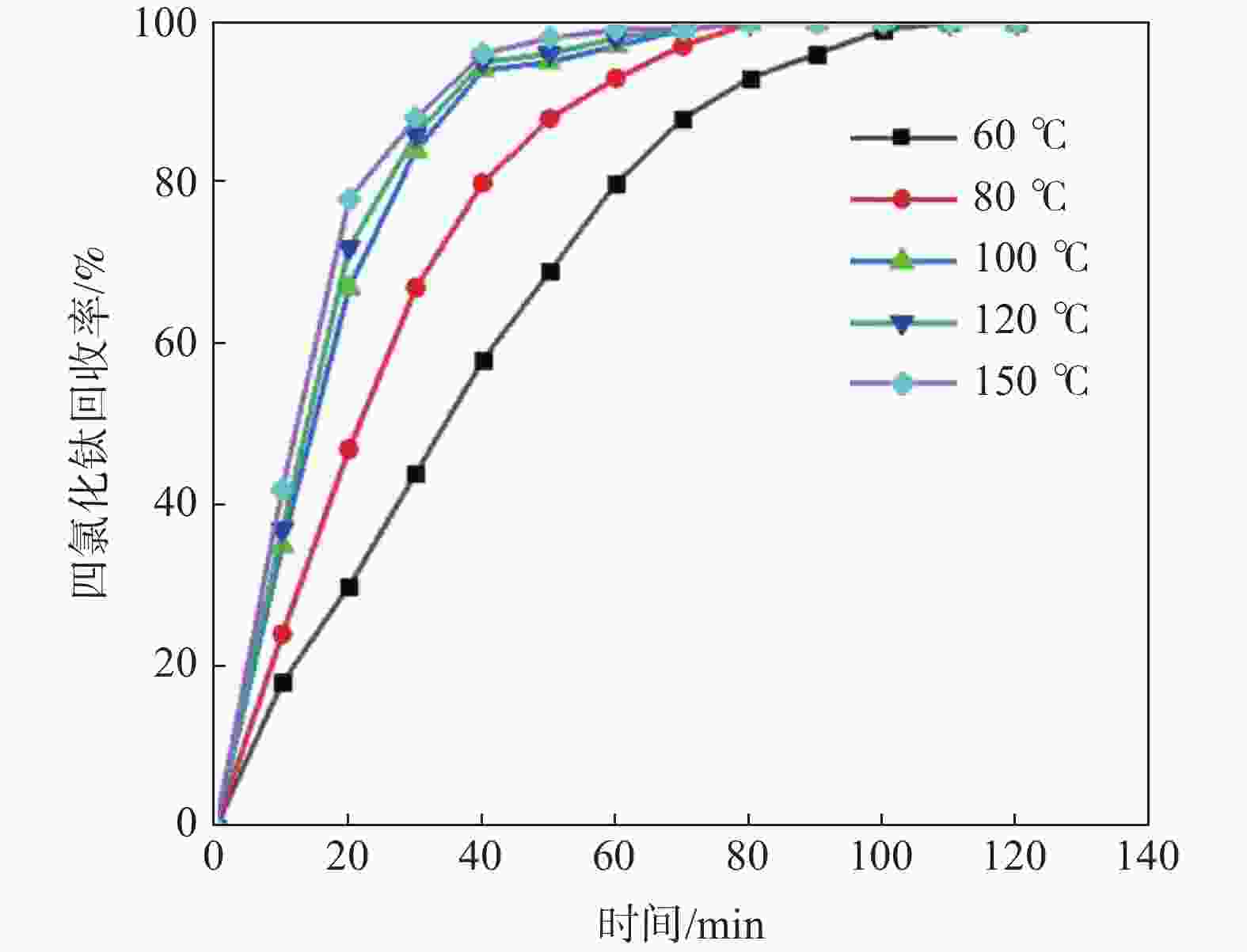

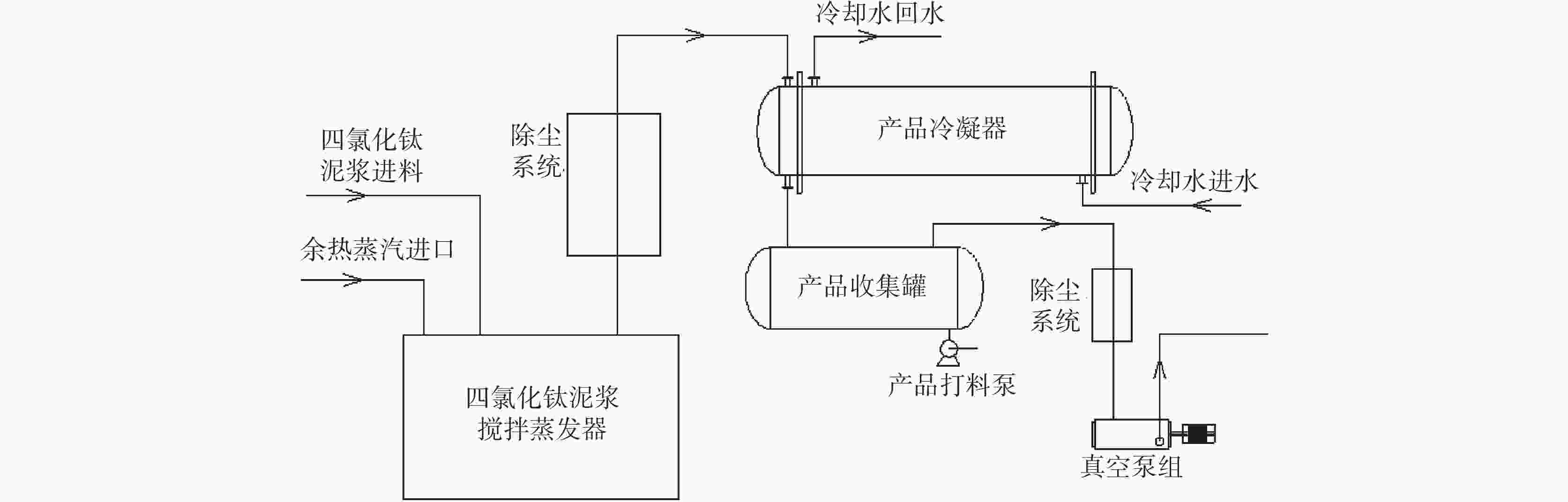

摘要: 为实现泥浆中四氯化钛及有价金属的高效回收利用,进行了四氯化钛泥浆真空旋转蒸发试验,并设计了真空搅拌蒸发系统。利用余热蒸汽加热四氯化钛,螺杆真空泵组提供较高真空度,搅拌桨叶对泥浆进行搅拌,所得四氯化钛干粉含湿率低于1%,四氯化钛回收率达99%,有效解决了四氯化钛泥浆难处理及泥浆中有价金属难回收的问题。且该系统运行对环境友好,设备运行效率高,自动化程度高,适用于大规模的四氯化钛生产。Abstract: In order to realize the efficient recovery and utilization of titanium tetrachloride and valuable metals in the slurry, a vacuum rotary evaporation experiment and vacuum stirring evaporation system for titanium tetrachloride slurry were designed. This paper, used the waste heat steam to heat the titanium tetrachloride, the screw vacuum pump set provided a higher vacuum degree, and the stirring blade stirred the slurry. The moisture content of the obtained dry titanium tetrachloride powder was less than 1%, and the recovery rate of titanium tetrachloride was 99%, effectively solving the complex treatment problems of titanium tetrachloride slurry and difficult recovery of valuable metals in the slurry. The system was environmentally friendly, with high operation efficiency and automation, and was suitable for large-scale titanium tetrachloride production.

-

Key words:

- titanium tetrachloride /

- slurry /

- vacuum evaporation /

- airtight stirring /

- waste heat steam

-

表 1 真空蒸发时间对四氯化钛回收率和固体含湿率的影响

Table 1. The effect of vacuum evaporation time on the recovery rate of titanium tetrachloride and solid moisture content

蒸发时间/

minTiCl4

回收率/%固体含

湿率/%蒸发时间/

minTiCl4

回收率/%固体

含湿率/%0 0 73 50 99 2.9 10 65 48 60 99.2 2 20 90 21 90 99.3 1.1 30 96 11.1 120 99.5 1 40 98 6.2 表 2 四氯化钛泥浆蒸发后固体颗粒物含量

Table 2. Solid particles content after evaporation of titanium tetrachloride slurry

% 试样 TiO2 Al2O3 TFe SiO2 V2O5 ZrO2 Nb2O5 冷凝泥浆 3.1 15.1 10 8.84 0.7 36.94 8.9 精制泥浆 5.4 17.1 16.6 12 5.3 21.8 1.6 -

[1] 莫畏, 邓国珠, 罗方承. 钛冶金[M]. 北京: 冶金工业出版社, 2007.Mo Wei, Deng Guozhu, Luo Fangcheng. Titanium metallurgy[M]. Beijing: Metallurgical Industry Press, 2007. [2] Wang Juan. Research and application of the method of recovering titanium tetrachloride from mud in the process of sponge titanium smelting[J]. Energy Saving of Nonferrous Metallurgy, 2015,(5):35−38. (王鹃. 海绵钛冶炼过程中从泥浆回收四氯化钛的方法研究与应用[J]. 有色冶金节能, 2015,(5):35−38. [3] Wang Xuewen, Wang Mingyu, Xiang Xiaoyan, et al. Spray drying to recover TiCl4 in sedimentation slurry[J]. Titanium Industry Progress, 2012,29(5):36−38. (王学文, 王明玉, 向小艳, 等. 喷雾干燥回收沉淀泥浆中的TiCl4[J]. 钛工业进展, 2012,29(5):36−38. [4] Liu Yunlong, Gui Jinsong. New technology for extracting vanadium from chloride slurry in titanium tetrachloride refining work shop[J]. Titanium Industry Progress, 2013,30(3):36−39. (柳云龙, 桂劲松. 四氯化钛精制车间氯化物泥浆提钒新工艺[J]. 钛工业进展, 2013,30(3):36−39. [5] Xiang Xiaoyan, Wang Xuewen, Wang Mingyu, et al. Recovery of TiCl4 from crude titanium tetrachloride precipitation slurry by molten salt distillation[J]. Rare Metals, 2016,40(1):57−63. (向小艳, 王学文, 王明玉, 等. 熔盐蒸馏法回收粗四氯化钛沉淀泥浆中的TiCl4[J]. 稀有金属, 2016,40(1):57−63. [6] Chen Zuchun, Zhao Jianxing, Tang Xiaolan. Optimization of a titanium tetrachloride slurry evaporation recovery treatment process[J]. Chemical Management, 2017,(2):35−36. (陈祖春, 赵建兴, 唐小兰. 对一种四氯化钛泥浆蒸发回收处理工艺的优化[J]. 化工管理, 2017,(2):35−36. doi: 10.3969/j.issn.1008-4800.2017.02.030 -

下载:

下载: