Investigating kinetics in preparation of precipitated silica from iron ore tailings

-

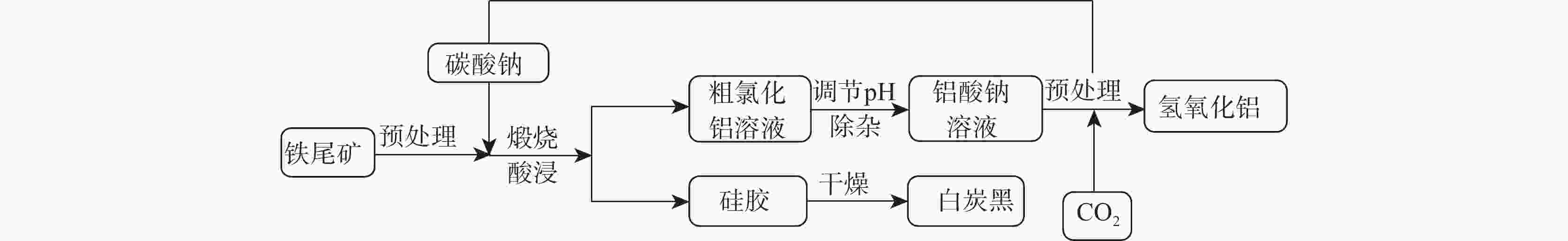

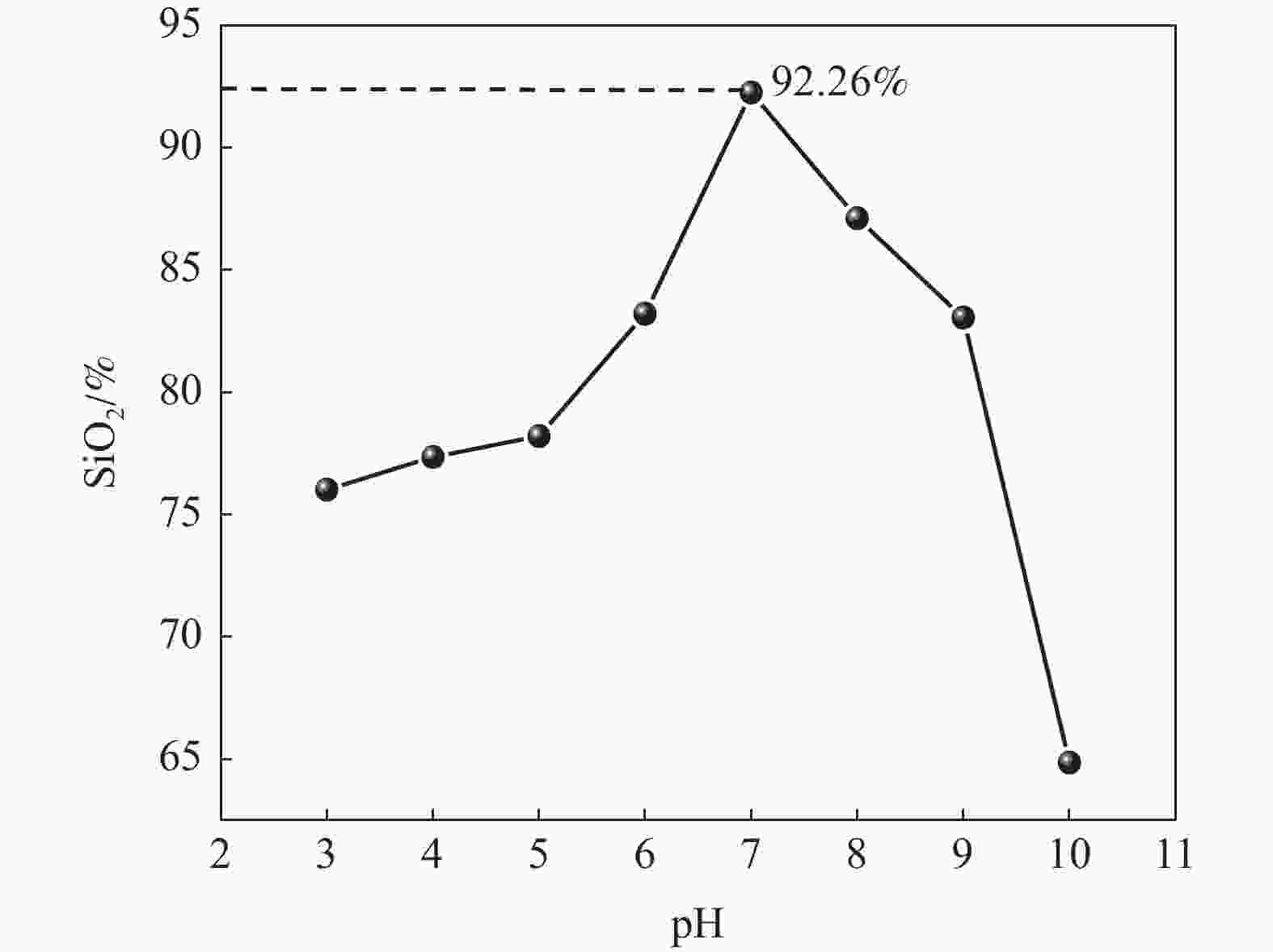

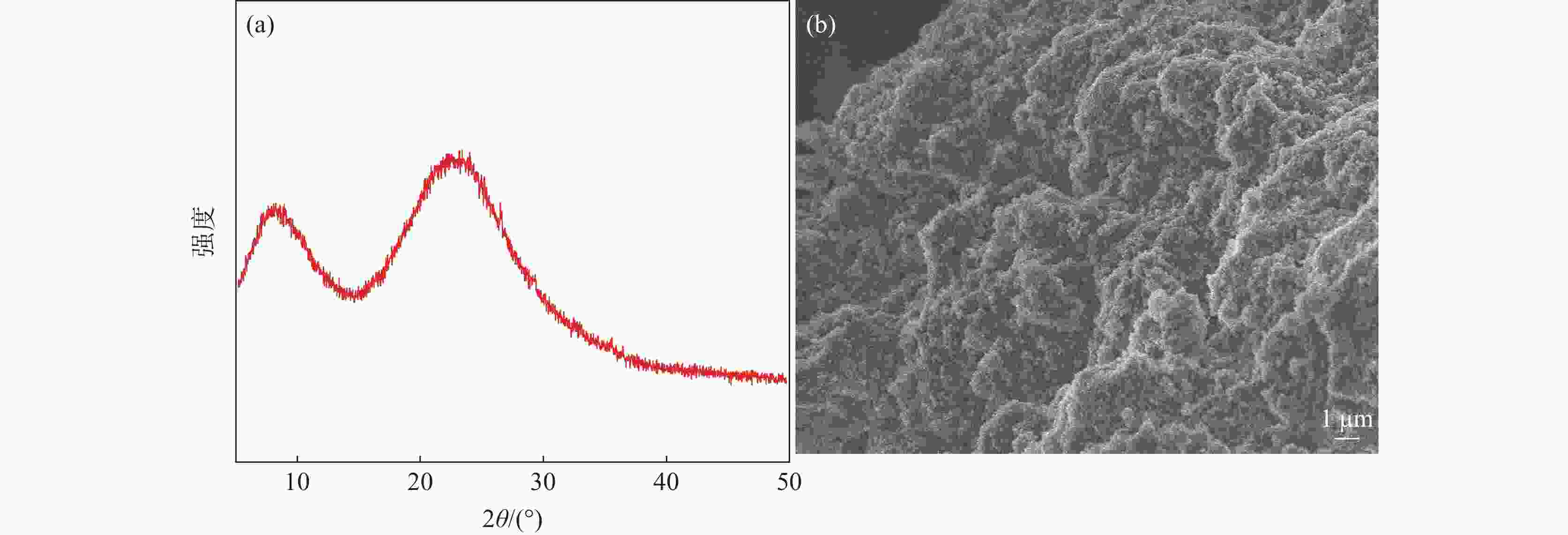

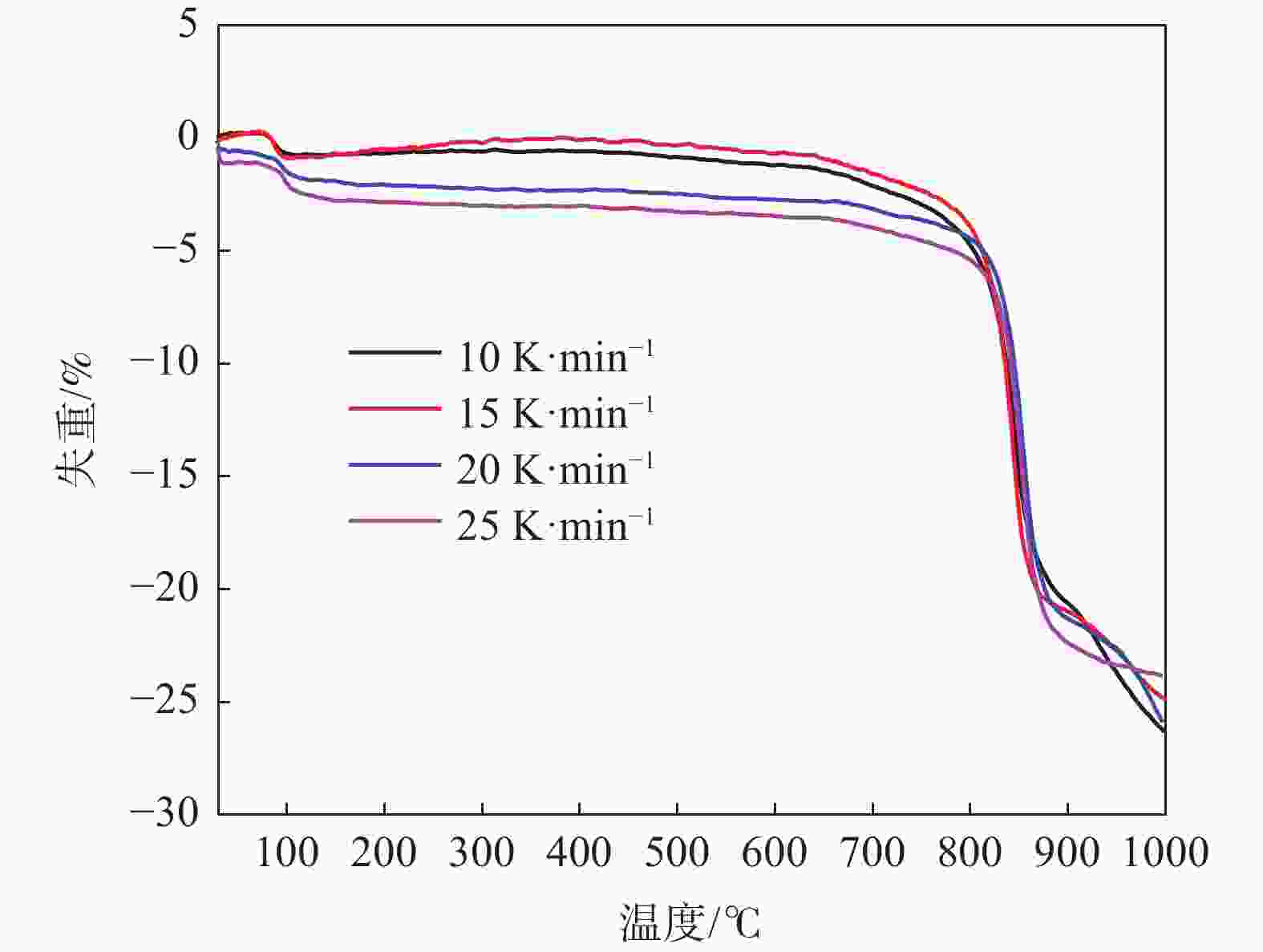

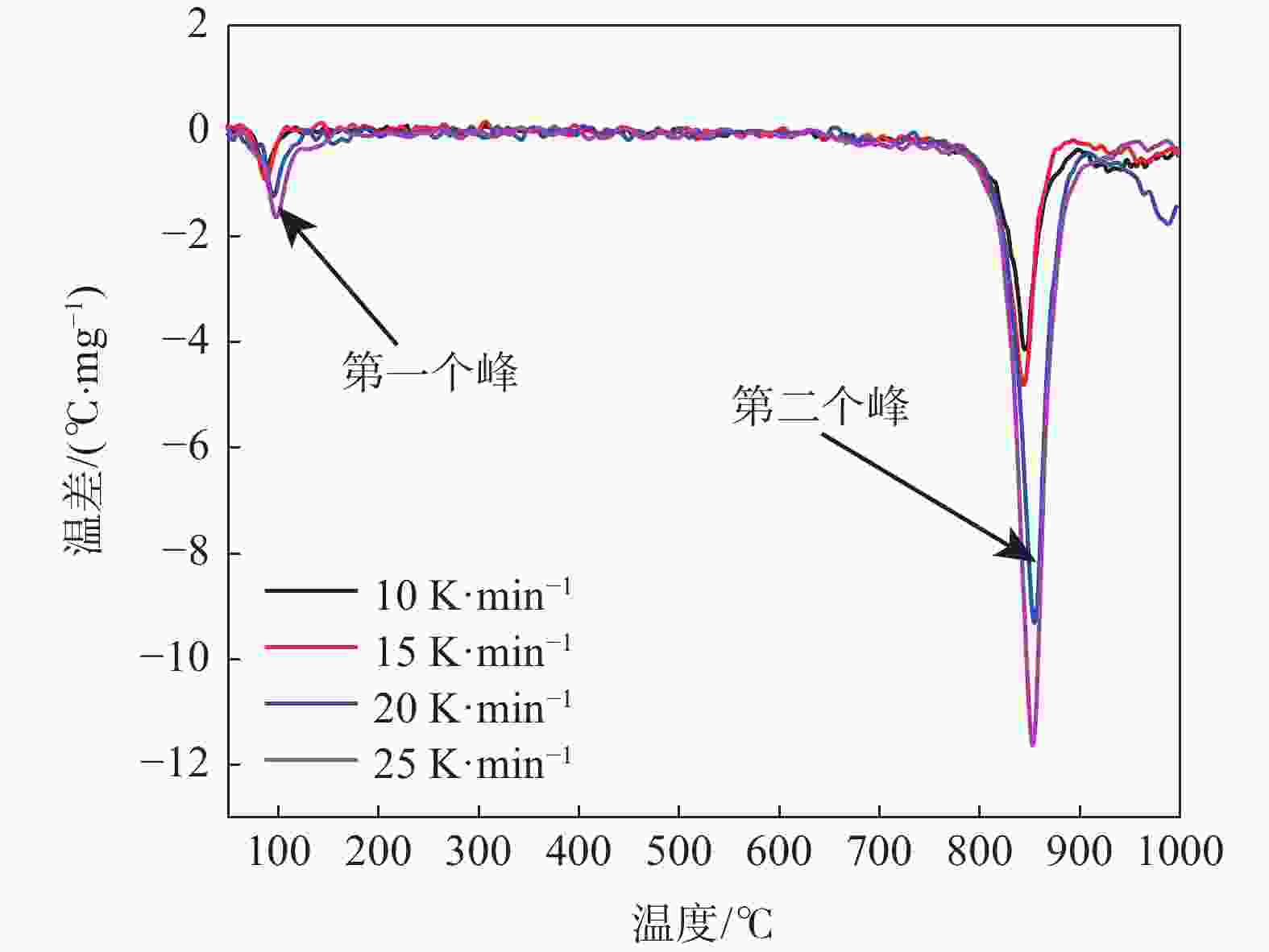

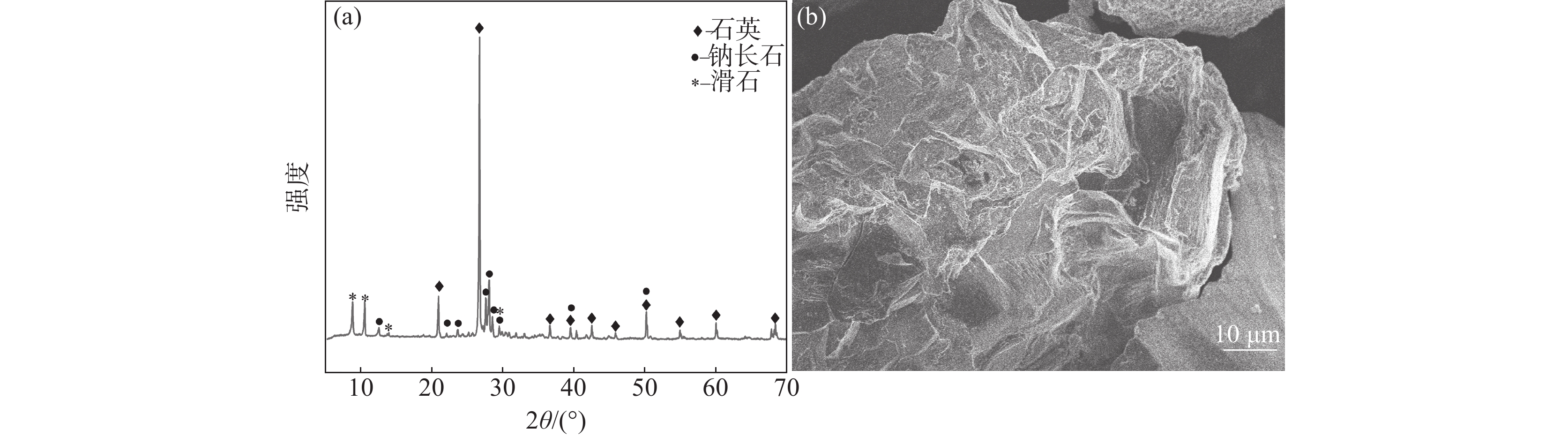

摘要: 铁尾矿是钢铁工业生产过程的废弃物,目前堆存量已超过百亿吨,考虑其千亿元以上的潜在价值,将其作为二次资源回收利用将成为必然趋势。铁尾矿成分主要以SiO2为主,因此从铁尾矿中提取SiO2再利用是实现其资源化利用的重要发展方向。通过对河北某钢厂铁尾矿成分解析发现,其SiO2的含量达到68.64%,其中硅的氧化物主要以石英、钠长石、滑石等晶体形式稳定存在于尾矿中。因此提出采用煅烧酸浸法制备白炭黑。具体工艺为:首先对铁尾矿进行高温碱熔活化预处理,再通过酸浸法制备白炭黑。最终确定了最佳碱熔煅烧-酸浸工艺参数:活化温度为850 ℃、活化时间为2 h、Na2CO3/SiO2=1:1.5;酸浸过程溶液pH值为7,搅拌温度60 ℃。在此条件下,铁尾矿硅元素的提取率可达到86.43%,酸浸得到的白炭黑SiO2含量达到92.26%。此外,对铁尾矿不同升温速率条件下的碱熔煅烧过程进行了动力学研究,推导出碱熔煅烧过程的数学模型,为铁尾矿活化焙烧工艺提供理论依据。Abstract: Iron ore tailings (IOT), which are by-product of the ore-smelting process. It will be an inevitable trend to recycle them as a secondary resource due to the potential value of more than 100 billion yuan. Through the composition analysis of IOT from a steel plant in Hebei Province, the SiO2 in IOT reaches 68.64%, existing mainly in the form of quartz, albite, talc and other crystals. Therefore, the calcination–acid leaching method was proposed to produce silica. The optimum calcination parameters were determined as follows: calcination temperature = 850 ℃, calcination time = 2 h, Na2CO3/SiO2 = 1:1.5. For the acid leaching process, the pH value of the solution is 7 and the stirring temperature is 60 ℃. The results show that the extraction rate of Si from IOT reached 86.43 %, and the content of SiO2 was 92.26%. In addition, the kinetics of the calcination process was studied, and the activation reaction mechanism and kinetic parameters of IOT were deduced, which provided a theoretical basis for the activation calcination process of IOT.

-

Key words:

- iron ore tailings /

- resource utilization /

- precipitated silica /

- calcining and acid leaching /

- kinetics

-

表 1 铁尾矿主要化学成分

Table 1. Main chemical compositions of IOT

% SiO2 Fe2O3 CaO MgO Al2O3 K2O Na2O SO3 P2O5 Cr2O3 68.64 9.47 3.41 2.26 13.14 3.64 0.74 0.36 0.16 0.14 注:含量低于0.1%的组分未列出。 表 2 正交分析因素与水平

Table 2. Factors and levels of orthogonal test

水平 因素 煅烧时间/h 煅烧温度/℃ n(Na2CO3)/n(SiO2) 1 1 750 1∶1.0 2 2 800 1∶1.25 3 3 850 1∶1.5 表 3 正交试验结果

Table 3. Results of orthogonal test

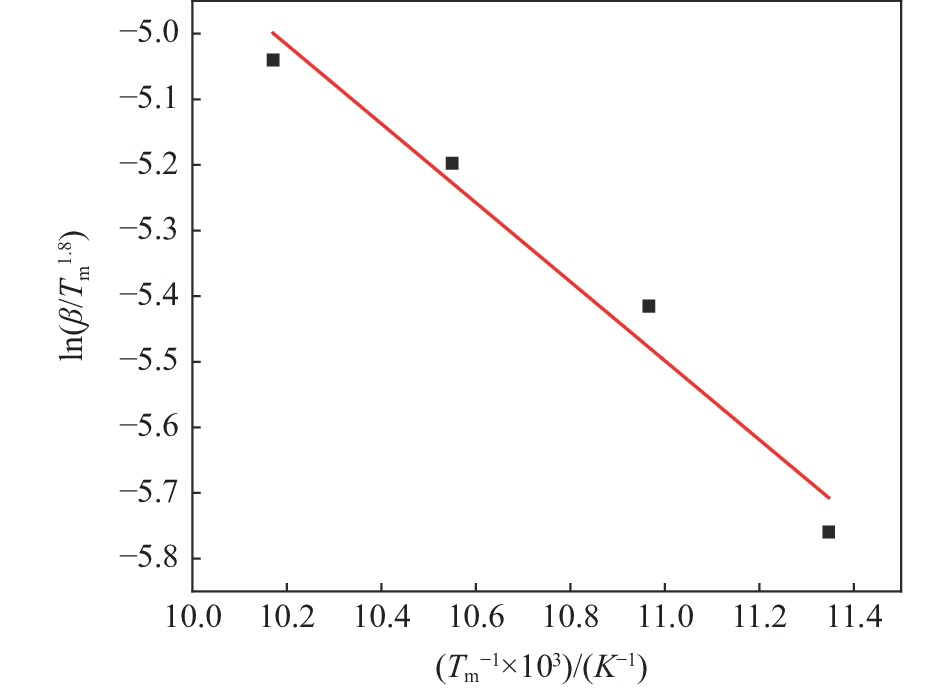

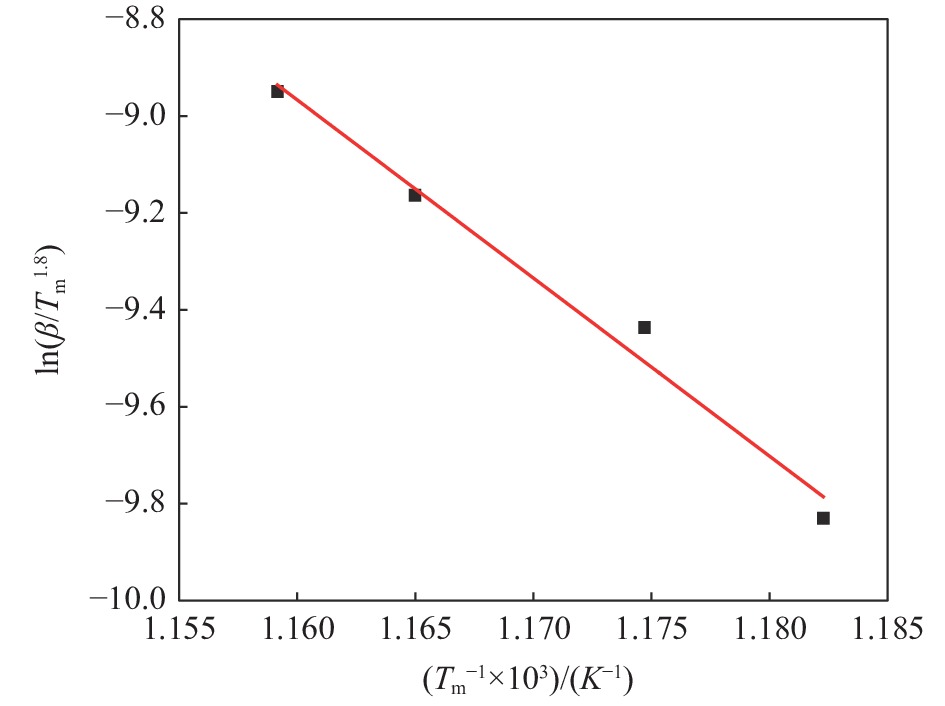

试验号 活化温度/℃ 活化时间/h n(Na2CO3)/n(SiO2) 硅元素提取率/% 1 750 1 1:1.0 24.79 2 750 2 1:1.25 37.26 3 750 3 1:1.5 63.14 4 800 1 1:1.25 43.16 5 800 2 1:1.5 70.72 6 800 3 1:1.0 49.58 7 850 1 1:1.5 84.19 8 850 2 1:1.0 49.48 9 850 3 1:1.25 69.88 K1 41.73 50.71 41.28 K2 54.49 52.49 50.10 K3 67.85 60.87 72.68 极差R 26.12 10.16 31.40 表 4 两个吸热峰不同升温速率动力学参数

Table 4. Kinetics coefficients of the two endothermic peaks at different heating

β/(K∙min−1) 第一吸收峰 第二吸收峰 Tm/K I n A×10−3 E/(kJ∙mol−1) γ Tm/K I n A×10−3 E/(kJ∙mol−1) γ 10 88.13 1.17 1.36 2.91 4.99 0.9841 845.83 0.87 1.17 3.07 280.93 0.9829 15 91.19 1.09 1.31 2.96 851.28 1.02 1.27 3.16 20 94.79 1.35 1.46 2.93 858.38 1.07 1.34 3.21 25 98.32 1.30 1.44 2.97 862.69 0.98 1.25 3.39 平均 1.39 2.94 1.26 3.21 -

[1] 中国工业固废网. 2018~2019年度中国大宗工业固体废物综合利用产业发展报告[R]. 2019.Industrial Solid Waste Network. China industrial solid waste network 2018-2019 China bulk industrial solid waste comprehensive utilization industry development report[R]. 2019. [2] Sun Qiurong, Liu Lei. Experimental study on carbonization resistance of concrete containing iron tailings[J]. Iron Steel Vanadium Titanium, 2020,41(2):82−87. (孙秋荣, 刘磊. 含铁尾矿砂混凝土抗碳化性能试验研究[J]. 钢铁钒钛, 2020,41(2):82−87. doi: 10.7513/j.issn.1004-7638.2020.02.016 [3] Yan Qiping. Study on the development and utilization of iron ore tailings in China[J]. Scrap Iron and Steel in China, 2014,(3):33−38. (闫启平. 我国铁矿尾矿渣粉开发利用之研究[J]. 中国废钢铁, 2014,(3):33−38. [4] Tan Xin, Wang Fuliang, Wang Rongsheng. Study on preparation of white carbon black from deoiled residue of oil shale[J]. Mining & Metallurgy, 2004,13(1):59−63. (谭欣, 王福良, 王荣生. 油页岩脱油残渣制备白炭黑的试验研究[J]. 矿冶, 2004,13(1):59−63. doi: 10.3969/j.issn.1005-7854.2004.01.015 [5] Jin Hui. Production process and application of silica[J]. Fine Chemical Raw Materials and Intermediates, 2004,(6):25−27. (金辉. 白炭黑生产工艺及应用[J]. 精细化工原料及中间体, 2004,(6):25−27. [6] Lian Shuixia, Gao Xinmei, Wen Zhenyu. Research progresses in preparation of white carbon black from SiO2-rich industrial solid wastes[J]. Environmental Protection of Chemical Industry, 2021,(1):1−9. (连水瑕, 高新梅, 温振宇. 富含SiO2工业固体废弃物制备白炭黑研究进展[J]. 化工环保, 2021,(1):1−9. doi: 10.3969/j.issn.1006-1878.2021.01.001 [7] Xiang Pengcheng, Xie Yingliang. Economical potentiality analysis of tailings utilization[J]. Conservation and Utilization of Mineral Resources, 2002,(1):50−54. (向鹏成, 谢英亮. 尾矿利用的经济性潜力分析[J]. 矿产保护与利用, 2002,(1):50−54. doi: 10.3969/j.issn.1001-0076.2002.01.012 [8] 胡荣祖,史启祯. 热分析动力学[M]. 北京: 科学出版社, 2001: 47−52.Hu Rongzu, Shi Qizhen. Thermal analysis kinetics[M]. Beijing: Science Press, 2001: 47−52. -

下载:

下载: