Study on preparation of aerated concrete block from vanadium-titanium magnetite tailing

-

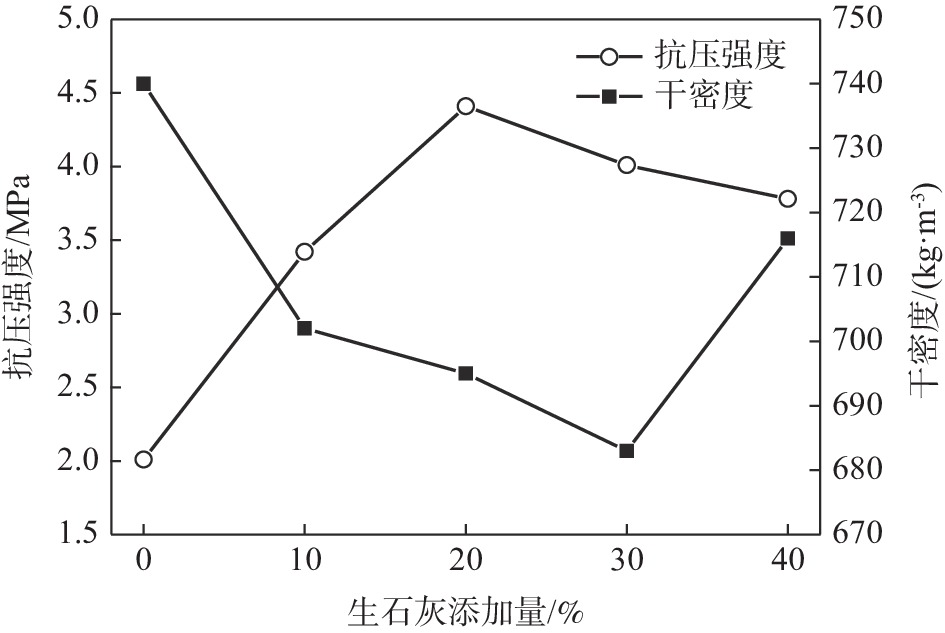

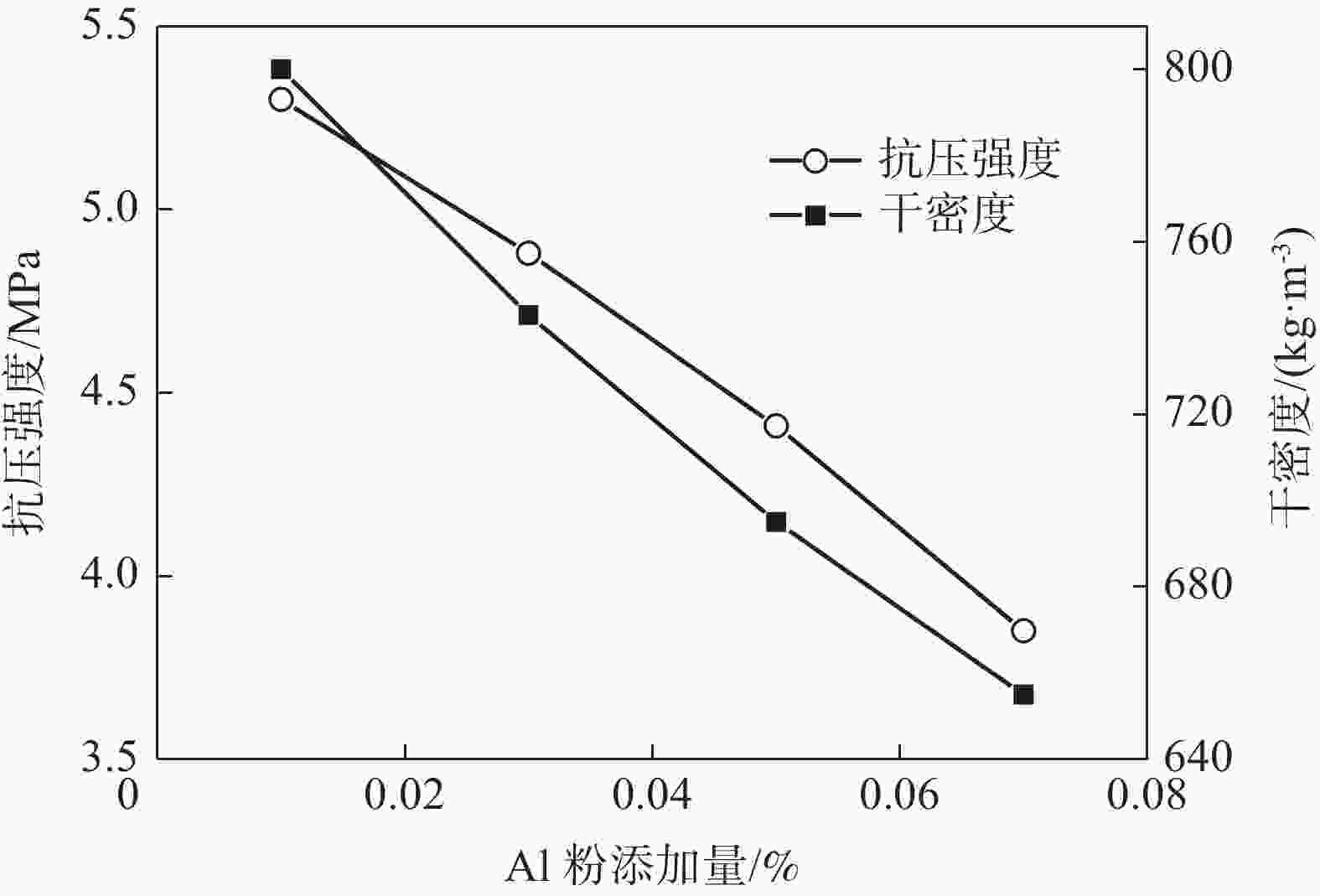

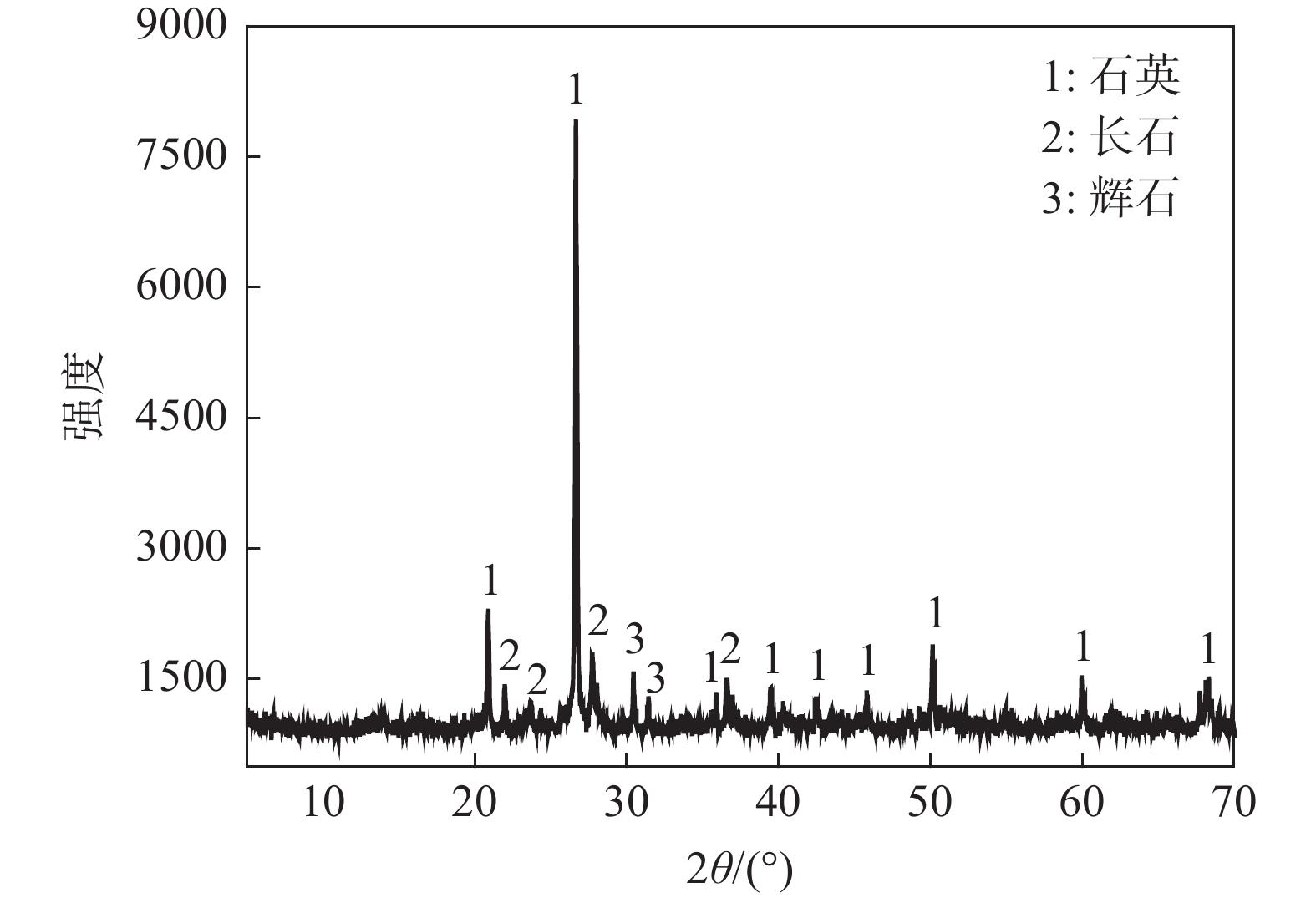

摘要: 以承德某钒钛磁铁矿尾矿为主要原料,采用免蒸压的方法,制备了一种性能优良的加气混凝土砌块,研究了配方组成对样品干密度与抗压强度的影响。结果表明:添加水泥与石灰使样品的抗压强度先增大后减小,干密度先减小后增大,添加矿渣可提高样品的抗压强度与干密度,添加Al粉造成样品的抗压强度与干密度下降。采用最佳配方(钒钛磁铁矿尾矿∶矿渣∶生石灰∶水泥∶石膏=6∶ 6∶4∶3∶1,铝粉添加量为0.05%)可制备出抗压强度为4.41 MPa,干密度为695 kg/m3的加气混凝土砌块。样品经28 d养护后,生成了托勃莫来石与水化硅酸钙等水化产物。样品孔隙结构发达,大量结晶良好的叶片状及纤维状的托勃莫来石与CSH相互交织,形成典型的“桥连”结构,从而赋予样品较低的导热系数、优良的耐热性及环境安全性。为高效利用承德地区的钒钛磁铁矿尾矿提供了依据。Abstract: The aerated concrete block was prepared with the tailings as the main raw material by autoclave-free method. The influence of formula composition on dry density and compressive strength was studied. The results showed that the compressive strength increased first and then decreased, while the dry density had the opposite trend with the addition of cement and lime. The slag improved the compressive strength and dry density, which was lowered by the introduction of Al powder. Aerated concrete blocks with compressive strength of 4.41 MPa and dry density of 695 kg/m3 could be achieved, when the optimum formula (vanadium titanomagnetite tailings∶slag∶quicklime∶cement∶gypsum = 6∶6∶4∶3∶1, 0.05% aluminum powder) was adopted. After 28 days of curing, tobermorite and calcium silicate hydrate were produced. A large number of well-crystallized and fibrous tobermorite interweaved with CSH, forming a typical bridging structure. Therefore, the samples were endowed with low thermal conductivity, excellent water resistance, environmental safety, heat and fire resistance. This paper provides reference for efficient utilization of vanadium titanomagnetite tailings in Chengde.

-

Key words:

- vanadium titanomagnetite /

- tailings /

- aerated concrete block /

- compressive strength /

- dry density /

- microstructure

-

表 1 钒钛磁铁矿尾矿的化学成分

Table 1. Chemical compositions of the vanadium-titanium magnetite tailings

% SiO2 Al2O3 CaO MgO Fe2O3 FeO Na2O V2O5 TiO2 SO3 烧损 72.05 11.03 3.21 1.26 2.77 2.50 0.49 0.20 2.30 0.49 3.70 表 2 钒钛磁铁矿尾矿粒度分析

Table 2. Particle size analysis of the vanadium-titanium magnetite tailings

粒度范围/mm 含量/% −0.25~+0.18 3.10 −0.18~+0.12 5.30 −0.12~+0.106 5.30 −0.106~+0.074 6.20 −0.074 80.10 表 3 矿渣化学成分

Table 3. Chemical composition of the slag powder

% SiO2 Al2O3 CaO MgO FeO Na2O 32.23 24.41 32.95 9.68 0.69 0.04 表 4 相关试验仪器

Table 4. Related experimental instruments

仪器名称 型号 生产厂家 瓷衬球磨机 XMCQ 武汉探矿机械厂 增力电动搅拌器 JJ-1 金坛市易晟仪器制造有限公司 水泥胶砂搅拌机 JJ-5 无锡市建工仪器有限公司 快速沸煮箱 ZSA-5A 北京三思行测控技术有限公司 恒温干燥箱 101-4 上海新正机械仪器制造有限公司 智能测力仪 RFP-03 济南天辰试验机制造有限公司 表 5 砌块相关性能

Table 5. Related performance of block

性能 干密度/(kg·m−3) 抗压强度/MPa 干缩值/

%导热性能/(W·m−1·K−1) 抗冻性 质量损失/% 冻后强度/MPa 砌块 695 4.41 0.69 0.11 2.9 4.09 标准值 ≤725 ≥4.0 ≤0.80 ≤0.18 ≤5.0 ≥4.0 表 6 样品耐热性测试结果

Table 6. Heat resistance test results of samples

温度/℃ 冷却强度/MPa 外观 200 4.55 正常 300 4.38 正常 400 4.40 灰黑色 500 2.63 灰白色 600 1.44 有裂纹 700 1.21 有裂纹 表 7 样品重金属浸出浓度与相关标准要求

Table 7. Leaching concentration of heavy metals from sample and the corresponding standard requirements

mg/L Cu Pb Cd Cr Zn 含量 0.013 0.001 0.001 0.040 0.100 标准限值 <3.00 <5.00 <1.00 <15.00 <100.00 -

[1] Zhang Jun. New light wall materials can be produced by low-temperature autoclaving process from low-lean vanadium ilmenite resources[J]. Building Materials Development Orientation, 2013,(5):107−108. (张均. 低贫钒钛铁矿资源可以采用低温蒸压工艺生产的新型轻质墙体材料[J]. 建材发展导向, 2013,(5):107−108. [2] 于明珠. 承德市尾矿库安全监管问题与对策研究[D]. 保定: 河北大学, 2014.Yu Minzhu. Study on safety supervision and management of tailings pond in Chengde [D]. Baoding: Hebei University, 2014. [3] Zhang Shaomin. Recovery of iron and titanium from a vanadium-titanium magnetite concentrate tailings in Chengde area[J]. Modern Mining, 2013,29(10):108−109. (张韶敏. 承德地区某钒钛磁铁矿选铁尾矿回收铁、钛试验[J]. 现代矿业, 2013,29(10):108−109. [4] Song Xiaomin, Wang Yonggang. Comprehensive recovery of titanium and iron from a tailings in Twin Towers mountain in Chengde[J]. Modern Mining, 2015,(1):86−87. (宋晓敏, 王永刚. 承德双塔山某尾矿综合回收钛、铁试验[J]. 现代矿业, 2015,(1):86−87. [5] Liu Changmiao, Wu Dongyin, Lv Zhihu, et al. Study on beneficiation of ilmenite in tailings of a vanadium titanium magnetite ore[J]. China Mining, 2015,(5):115−117. (刘长淼, 吴东印, 吕子虎, 等. 某钒钛磁铁矿尾矿中钛铁矿的选矿研究[J]. 中国矿业, 2015,(5):115−117. [6] Zou Xiaotong, Wu Qisheng, Guang Jianmiao, et al. Effect of calcium-silicon ratio on properties of hydrothermal nickel slag aerated concrete[J]. Materials Report, 2016,30(10):126−129. (邹小童, 吴其胜, 光鉴淼, 等. 钙硅比对水热合成镍矿渣加气混凝土性能的影响[J]. 材料导报, 2016,30(10):126−129. [7] Wang Changlong, Ni Wen, Li Dezhong. Experimental study on preparation of aerated concrete from low silicon iron tailings in Lingqiu, Shanxi[J]. Journal of Coal Mine, 2012,37(7):1129−1133. (王长龙, 倪文, 李德忠, 等. 山西灵丘低硅铁尾矿制备加气混凝土的试验研究[J]. 煤炭学报, 2012,37(7):1129−1133. [8] Yang Liyuan, Wan Huiwen, Li Jie. Exploration and study on technological parameters of preparation of aerated concrete from phosphorus tailings[J]. Journal of Wuhan University of Technology, 2011,(9):20−22. (杨力远, 万惠文, 李杰. 利用磷尾矿制备加气混凝土工艺参数的探索研究[J]. 武汉理工大学学报, 2011,(9):20−22. [9] Du Hui, Liu Xingwei, Li Qiuyi, et al. Effect of ultrafine mineral powder on the strength of high performance concrete[J]. Journal of Qingdao Technological University, 2009,30(4):162−165. (杜辉, 刘星伟, 李秋义, 等. 超细矿粉对高性能混凝土强度的影响[J]. 青岛理工大学学报, 2009,30(4):162−165. [10] Guang Jianmiao, Wu Qisheng, Liu Xiaoyan, et al. Hydrothermal synthesis of nickel slag aerated concrete and its hydration products[J]. Journal of Materials Science and Engineering, 2016,34(3):421−426. (光鉴淼, 吴其胜, 刘小艳, 等. 水热合成镍矿渣加气混凝土及其水化产物[J]. 材料科学与工程学报, 2016,34(3):421−426. [11] 王斌. 铁尾矿加气混凝土的制备及其性能研究[D]. 沈阳: 沈阳建筑大学, 2015.Wang Bin. Study on preparation and performance of iron tailings aerated concrete [D]. Shenyang: Shenyang Construction University, 2015. [12] Wang Changlong, Ni Wen, Qiao Chunyu, et al. Preparation and properties of iron tailings aerated concrete[J]. Journal of Materials Research, 2013,(2):157−162. (王长龙, 倪文, 乔春雨, 等. 铁尾矿加气混凝土的制备和性能[J]. 材料研究学报, 2013,(2):157−162. [13] Wu Xiaomei, Fan Yueming. Types and microstructure of hydration products of aerated concrete from fly ash[J]. Journal of South China University of Science and Technology (Natural Science Edition), 2003,31(8):57−61. (吴笑梅, 樊粤明. 粉煤灰加气混凝土水化产物的种类和微观结构[J]. 华南理工大学学报(自然科学版), 2003,31(8):57−61. [14] Sun Guokuang, Tang Di, Zhao Yuping. Study on carbonization of aerated concrete and its hydration products[J]. Journal of the Chinese Ceramic Society, 1985,(4):24−33. (孙国匡, 唐弟, 赵宇平. 加气混凝土及其水化产物碳化的研究[J]. 硅酸盐学报, 1985,(4):24−33. [15] Mu Shanbin, Sun Zhenya. Study on hydration products and structure of aerated concrete with fly ash[J]. Comprehensive Utilization of Fly Ash, 2002,(1):16−18. (牟善彬, 孙振亚. 粉煤灰加气砼的水化产物及其结构的研究[J]. 粉煤灰综合利用, 2002,(1):16−18. doi: 10.3969/j.issn.1005-8249.2002.01.008 [16] Sun Baozhen, Su Erda. Crystallinity and carbonization rate of hydrated calcium silicate[J]. Journal of the Chinese Ceramic Society, 1984,(3):25−30,132. (孙抱真, 苏而达. 水化硅酸钙的结晶度与碳化速度[J]. 硅酸盐学报, 1984,(3):25−30,132. -

下载:

下载: