Experimental study on the prediction model of carbonization depth in high Ti-bearing blast furnace slag concrete

-

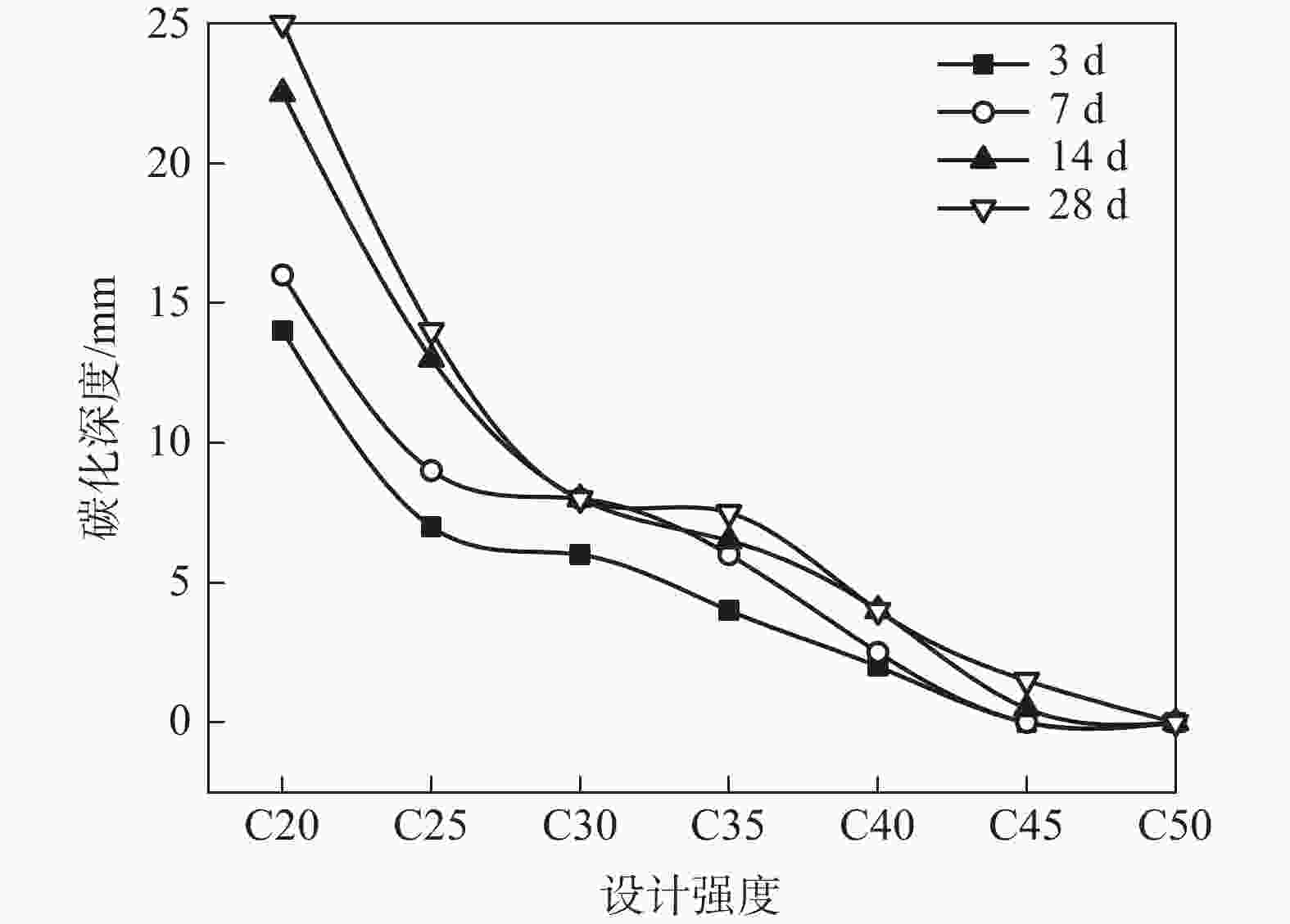

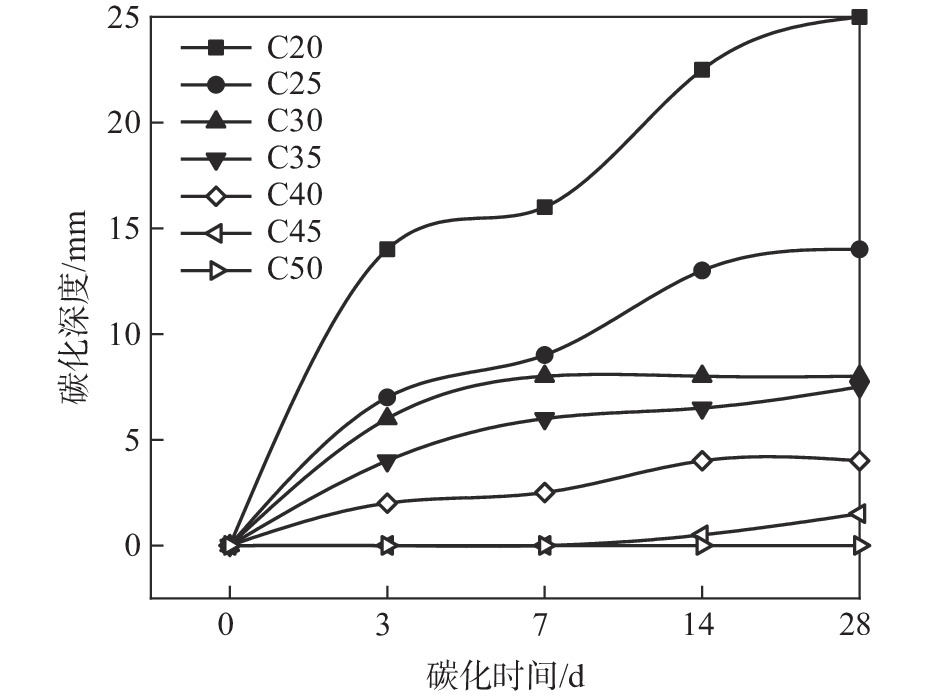

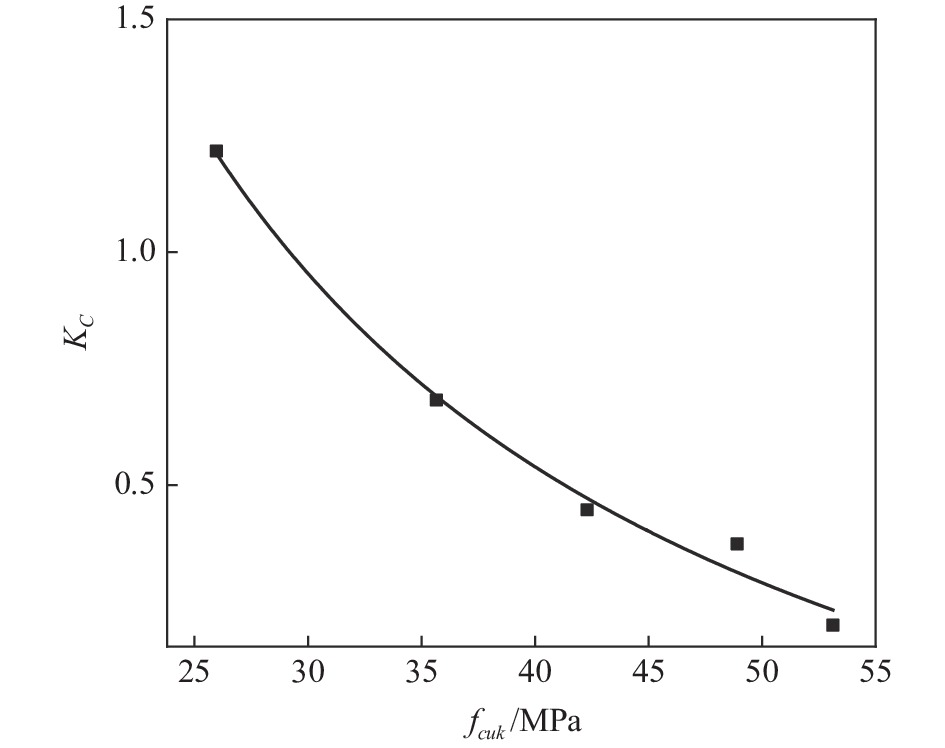

摘要: 混凝土碳化造成钢筋锈蚀是混凝土结构耐久性失效的主要原因。为研究攀枝花高钛型高炉渣混凝土抗碳化性能,对不同强度高钛型高炉渣混凝土进行不同碳化时间的室内加速碳化试验,结果表明:高钛型高炉渣混凝土强度越低,越容易被二氧化碳侵蚀;碳化时间越长,碳化现象越明显。基于Fick第一定律,根据高钛型高炉渣混凝土强度、碳化时间,建立了高钛型高炉渣混凝土碳化深度预测模型。经与试验结果对比,吻合度高,验证了预测模型准确度。Abstract: Reinforcement corrosion caused by concrete carbonation is the main reason of durability failure of concrete structures. In order to study the carbonation resistance of Panzhihua high-titanium blast furnace slag concrete, we herein carried out the indoor accelerated carbonation test of high-titanium blast furnace slag concrete with different strength at different carbonation time. The results show that the lower the strength of high-titanium blast furnace slag concrete, the easier it is to be corroded by carbon dioxide. The longer the carbonation time, the more obvious the carbonation phenomenon. Based on Fick’s first law, a model for predicting the carbonation depth of high-titanium blast furnace slag concrete is established according to the strength and carbonation time of high-titanium blast furnace slag concrete. By comparing with the experimental results, the accuracy of the prediction model is verified.

-

Key words:

- high-titanium blast furnace slag /

- concrete /

- carbonation depth /

- prediction model

-

表 1 全高钛型高炉渣集料混凝土(泵送)配合比

Table 1. Blend ratio of full high-titanium furnace slag aggregate concrete (pumping)

kg/m3 强度等级 42.5

水泥粉煤

灰高钛型高

炉渣砂高钛型高

炉渣碎石用水

量胶结

料C20泵送 239

(32.5 R)117 1139 760 255 356 C25泵送 264 108 1098 795 250 372 C30泵送 285 105 1030 890 220 390 C35泵送 341 92 1000 852 240 433 C40泵送 373 88 920 930 230 461 C45泵送 416 77 898 899 230 493 C50泵送 453 72 830 950 230 525 表 2 混凝土碳化深度及强度值

Table 2. Carbonation depth and strength of concrete

强度

等级碳化深度(标准碳化)X/mm fcuk

/MPa3 d 7 d 14 d 28 d C20 14 16 22.5 25 25.96 C25 7 9 13 14 35.66 C30 6 8 8 8 42.29 C35 4 6 6.5 7.5 48.90 C40 2 2.5 4 4 53.12 C45 0 0 0.5 1.5 62.01 C50 0 0 0 0 64.85 -

[1] Li Bei, Li Xinyan, Jin Nanguo, et al. Discussion on evaluation of concrete carbonation depth by nondestructive testing technology[J]. Concrete, 2021,(4):140−145. (李蓓, 李鑫焱, 金南国, 等. 无损检测技术评估混凝土碳化深度的探讨[J]. 混凝土, 2021,(4):140−145. [2] Huang Shuanghua, Chen Wei, Sun Jinkun, et al. The application of high titanium slag in concrete materials[J]. New Building Materials, 2006,(11):71−73. (黄双华, 陈伟, 孙金坤, 等. 高钛高炉渣在混凝土材料中的应用[J]. 新型建筑材料, 2006,(11):71−73. [3] Wang Jie, Zhao Bijian, Zhang Guiyu. Development and application of high-titanium slag series building materials[J]. New Building Materials, 2002,(2):35−36. (王杰, 赵碧建, 张桂玉. 高钛渣系列建材产品的开发及应用[J]. 新型建筑材料, 2002,(2):35−36. doi: 10.3969/j.issn.1001-702X.2002.02.016 [4] Wang Jie, Xu Xiaoqian, Huang Shuanghua. Experiment research on normal section flexural performance of flexural member by high titanium blast furnace slag[J]. Construction Technology, 2015,(s1):513−515. (汪杰, 徐晓倩, 黄双华. 高钛型高炉渣受弯构件正截面抗弯性能研究[J]. 施工技术, 2015,(s1):513−515. [5] Wang Jie. Experimental analysis on recycled concrete with high titanium heavy slag and bond properties of steel bars[J]. Revista de la Facultad de Ingeniería, 2017,32(10):204−210. [6] Zhou Wenbo, Ke Changming, Zhang Qin, et al. Application of Pangang blast-furnace slag in construction industry[J]. Multipurpose Utilization of Mineral Resources, 2007,(3):35−37. (周文波, 柯昌明, 张芹, 等. 攀钢高炉渣在建筑行业中的应用[J]. 矿产综合利用, 2007,(3):35−37. doi: 10.3969/j.issn.1000-6532.2007.03.010 [7] Li Xinghua, Pu Jiangtao. The latest developments of integrated utilization on Panzhihua high titanium-bearing BF slag[J]. Iron Steel Vanadium Titanium, 2011,32(2):10−14. (李兴华, 蒲江涛. 攀枝花高钛型高炉渣综合利用研究最新进展[J]. 钢铁钒钛, 2011,32(2):10−14. [8] Du Yingji, Liang Zhengping. Study on prediction of concrete carbonation depth of Weishui inverted siphon project[J]. Advances in Science and Technology of Water Resources, 2005,25(3):48−50. (杜应吉, 梁正平. 韦水倒虹工程混凝土碳化深度预测研究[J]. 水利水电科技进展, 2005,25(3):48−50. doi: 10.3880/j.issn.1006-7647.2005.03.015 [9] 阿列克谢耶夫. 钢筋混凝土结构中钢筋腐蚀与保护[M]. 黄可信译. 北京: 中国建筑工业出版社, 1983.Nikolai Alexeyev . Corrosion and protection of reinforcement in reinforced concrete structure[M]. Huang Kexin. Beijing: China Construction Industry Press, 1983. [10] Wu Junxi, Wang Yan. Research status of concrete carbonation[J]. Sichuan Building Science Research, 2011,37(6):202−204. (武俊曦, 王艳. 混凝土碳化研究现状[J]. 四川建筑科学研究, 2011,37(6):202−204. doi: 10.3969/j.issn.1008-1933.2011.06.051 [11] Li Jiucun, Tong Peizhou. Experimental study on carbonation resistance of steel fiber reinforced concrete[J]. New Building Materials, 2021,(3):63−66. (李久存, 仝培周. 钢纤维混凝土抗碳化性能试验研究[J]. 新型建筑材料, 2021,(3):63−66. doi: 10.3969/j.issn.1001-702X.2021.03.015 [12] Zhang Yang, Niu Ditao, Li Shengbin. Research on carbonation of fly ash concrete[J]. Science Technology and Engineering, 2017,17(27):275−278. (张 扬, 牛荻涛, 李盛斌. 粉煤灰混凝土碳化试验研究[J]. 科学技术与工程, 2017,17(27):275−278. doi: 10.3969/j.issn.1671-1815.2017.27.045 [13] Zhang Lingmao, Jiang Wenhui. Natural carbonization of concrete and its correlation with artificial accelerated carbonization[J]. Journal of Xi 'an University of Building Science and Technology (Natural Science Edition), 1990,(3):207−214. (张令茂, 江文辉. 混凝土自然碳化及其与人工加速碳化的相关性研究[J]. 西安建筑科技大学学报(自然科学版), 1990,(3):207−214. [14] Song Hua, Niu Ditao, Li Chunhui. Experimental study on carbonation performance of concrete with mineral admixtures[J]. Journal of the Chinese Ceramic Society, 2009,37(12):2066−2070. (宋华, 牛荻涛, 李春晖. 矿物掺合料混凝土碳化性能试验研究[J]. 硅酸盐学报, 2009,37(12):2066−2070. doi: 10.3321/j.issn:0454-5648.2009.12.019 [15] Huang Zhonghui, Zhang Shirong, Wang Binghua, et al. Experimental study on carbonation mechanical properties of high performance recyclable concrete with fine aggregates from iron tailings[J]. Journal of Hydraulic and Civil Engineering, 2021,(1):28−33. (黄钟晖, 张世荣, 王炳华, 等. 高性能铁尾矿细骨料再生混凝土碳化力学性能试验研究[J]. 水利与建筑工程学报, 2021,(1):28−33. [16] Zhang Wenjun, Liu Baohua, Zhou Wen, et al. Experimental study on carbonation resistance of rapeseed straw fiber concrete[J]. Journal of Hunan Agricultural University (Natural Science Edition), 2021,47(1):96−100. (张文俊, 刘保华, 周文, 等. 油菜秸秆纤维混凝土抗碳化性能的试验研究[J]. 湖南农业大学学报(自然科学版), 2021,47(1):96−100. [17] Deng Xiao, Li Linze, Zhao Huan, et al. Analysis of carbonization depth and influencing factors of high-titanium type blast furnace slag concrete on site[J]. Sichuan Architecture, 2015,(5):183−184. (邓晓, 李林泽, 赵欢, 等. 现场检测高钛型高炉渣混凝土碳化深度及影响因素分析[J]. 四川建筑, 2015,(5):183−184. doi: 10.3969/j.issn.1007-8983.2015.05.076 [18] Papadakis V G ,Vayenas C G ,Fardis M N. Fundamental modeling and experimental investigation of concrete carbonation[J]. Aci Material Journal, 1991,88(4):363−373. [19] Papadakis V G. Effect of supplementary cementing materials on concrete resistance against carbonation and chloride ingress[J]. Cement&Concrete Research, 2000,30(2):291−299. [20] Van-Loc Ta, Stéphanie Bonnet, Tristan Senga Kiesse, et al. A new meta-model to calculate carbonation front depth within concrete structures[J]. Construction and Building Materials, Elsevier, 2016,129:172−181. doi: 10.1016/j.conbuildmat.2016.10.103 [21] Cui Hongzhi, Tang Waiching, Liu Wei, et al. Experimental study on effects of CO2 concentrations on concrete carbonation and diffusion mechanisms[J]. Construction and Building Materials, 2015,93:522−527. doi: 10.1016/j.conbuildmat.2015.06.007 [22] Xiao Jia, Gou Chengfu. Overview of the research for concrete carbonation[J]. Concrete, 2010,(1):40−44. (肖佳, 勾成福. 混凝土碳化研究综述[J]. 混凝土, 2010,(1):40−44. doi: 10.3969/j.issn.1002-3550.2010.01.014 [23] 牛荻涛. 混凝土结构耐久性与寿命预测[M]. 北京: 科学出版社, 2003.Niu Ditao. Durability and life prediction of concrete structures [M]. Beijing: Science Press, 2003. [24] Zhang Yu, Jiang Lixue. A practical mathematical model of concrete carbonation depth based on the mechanism[J]. Industrial Construction, 1998,28(1):16−19,47. (张誉, 蒋利学. 基于碳化机理的混凝土碳化深度实用数学模型[J]. 工业建筑, 1998,28(1):16−19,47. doi: 10.3321/j.issn:1000-8993.1998.01.005 [25] Ji Y, Wu M, Ding B, et al. The experimental investigation of width of semi-carbonation zone in carbonated concrete[J]. Construction & Building Materials, 2014,65:67−75. [26] Chen Zheng, Hu Yichan, Zhao Yufei, et al. Multi-factor computation model of concrete carbonation depth based on material parameters in standard carbonization environment[J]. Bulletin of the Chinese Ceramic Society, 2019,(6):1681−1687,1693. (陈正, 胡以婵, 赵宇飞, 等. 标准碳化环境下基于材料参数的混凝土碳化深度多因素计算模型[J]. 硅酸盐通报, 2019,(6):1681−1687,1693. [27] Li Guo, Yuan Yingshu, Geng Ou. Influence of climatic conditions on the carbonation rate of concrete[J]. Concrete, 2004,(11):49−51,53. (李果, 袁迎曙, 耿欧. 气候条件对混凝土碳化速度的影响[J]. 混凝土, 2004,(11):49−51,53. doi: 10.3969/j.issn.1002-3550.2004.11.015 [28] Gopinath R, Alexander M, Beushausen H. Predicting depth of carbonation of concrete for varying climatic conditions[C]// 2nd International RILEM/COST Conference on Early Age Cracking and Serviceability in Cement-based Materials and Structures (EAC2). 2014: 515-519. [29] Di Xiaotan, Zhou Yan. Research on concrete carbonization law[J]. China Building Science Research, 1995,(4):31−35. (邸小坛, 周燕. 混凝土碳化规律研究[J]. 中国建筑科学研究, 1995,(4):31−35. -

下载:

下载: