Effect of TiO2 on physicochemical properties and structure of high-alumina blast furnace slag

-

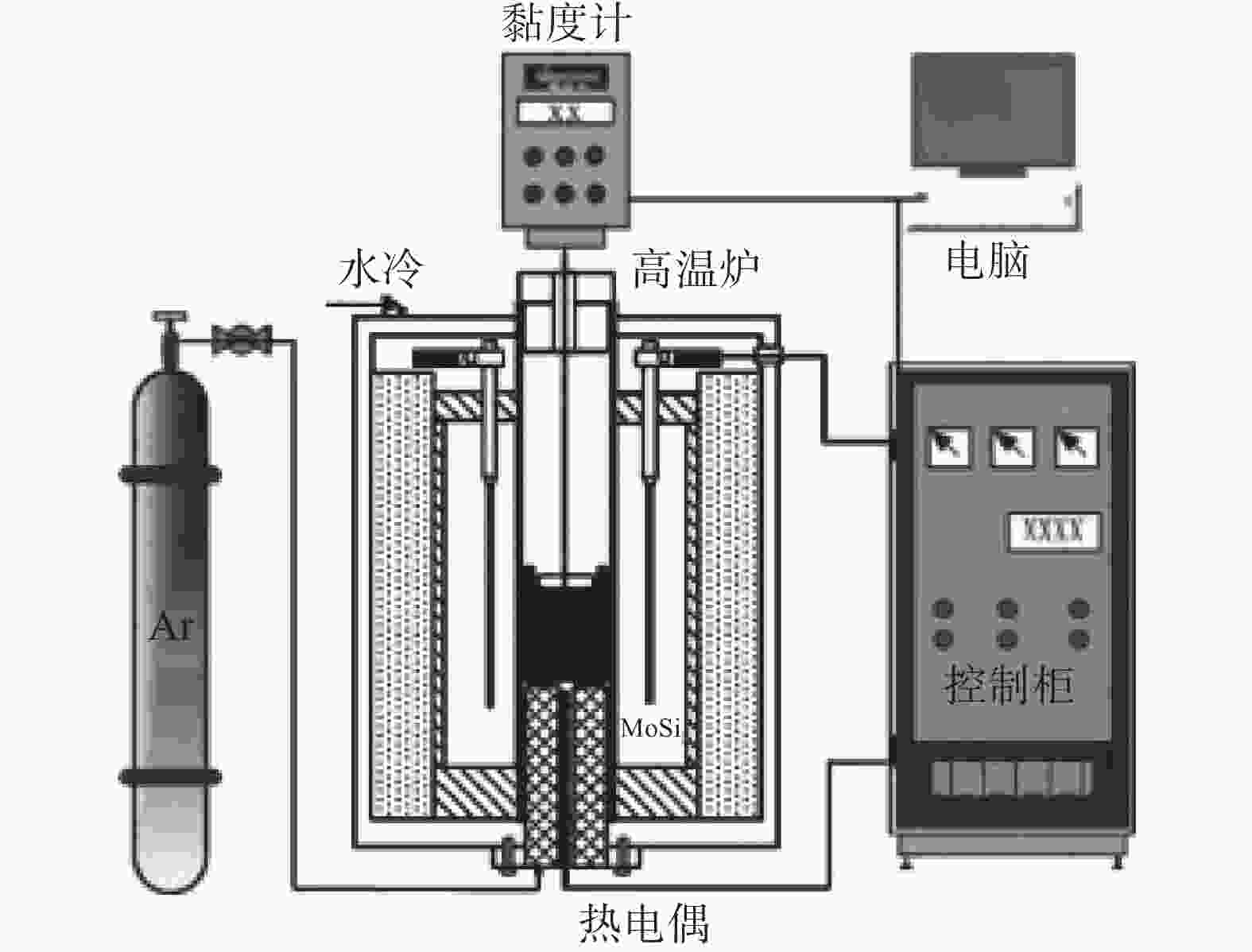

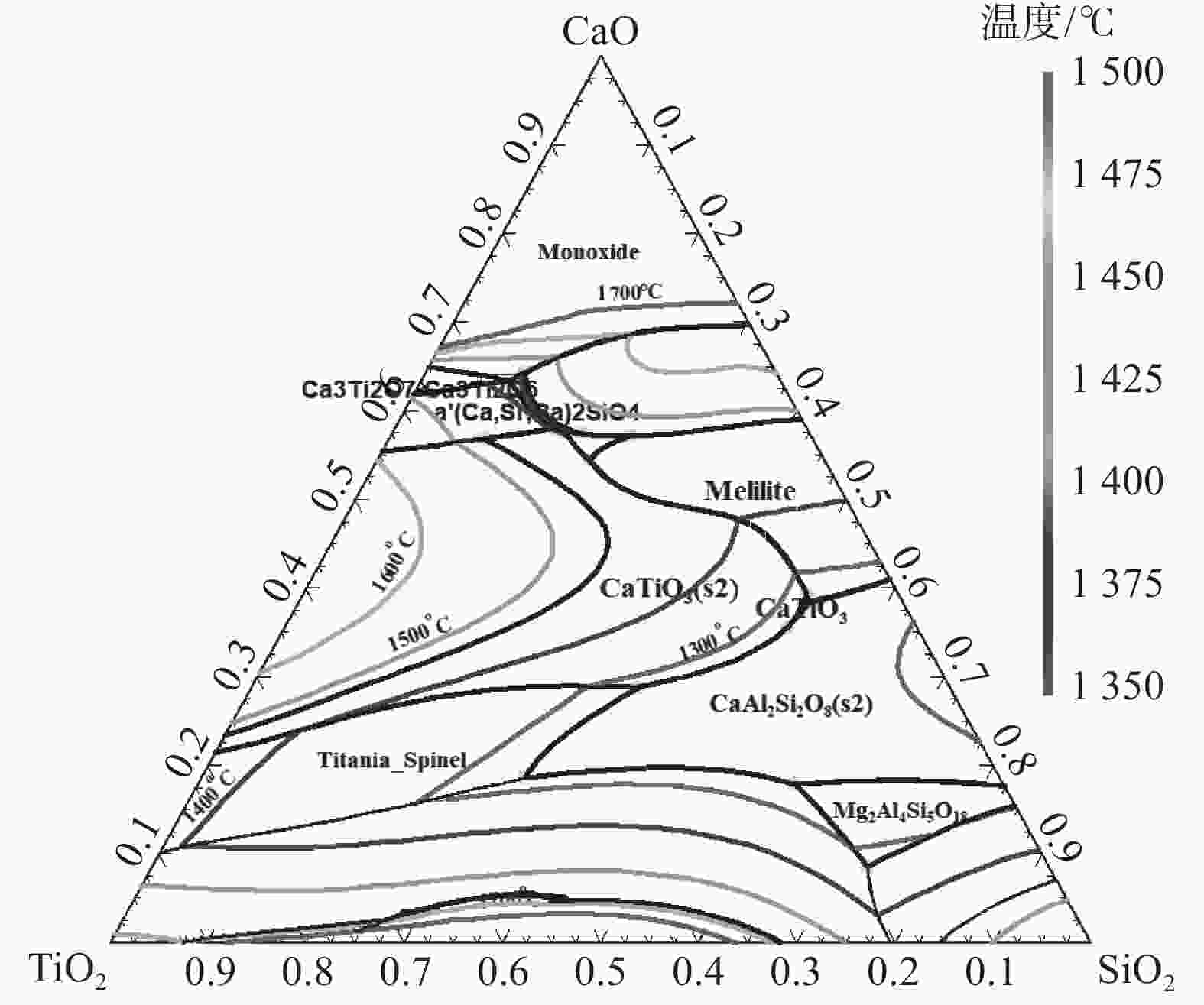

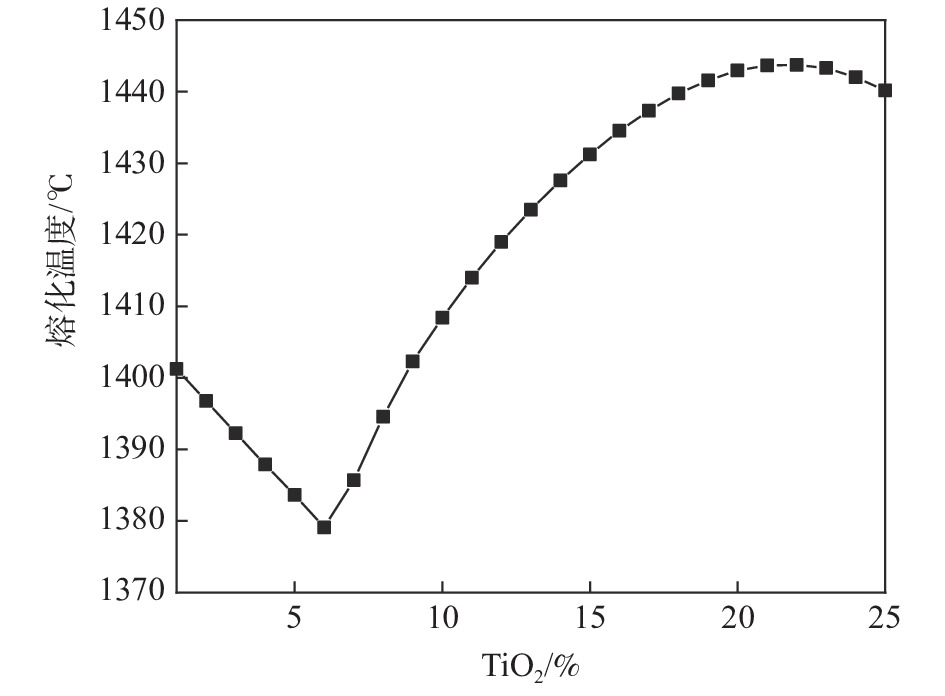

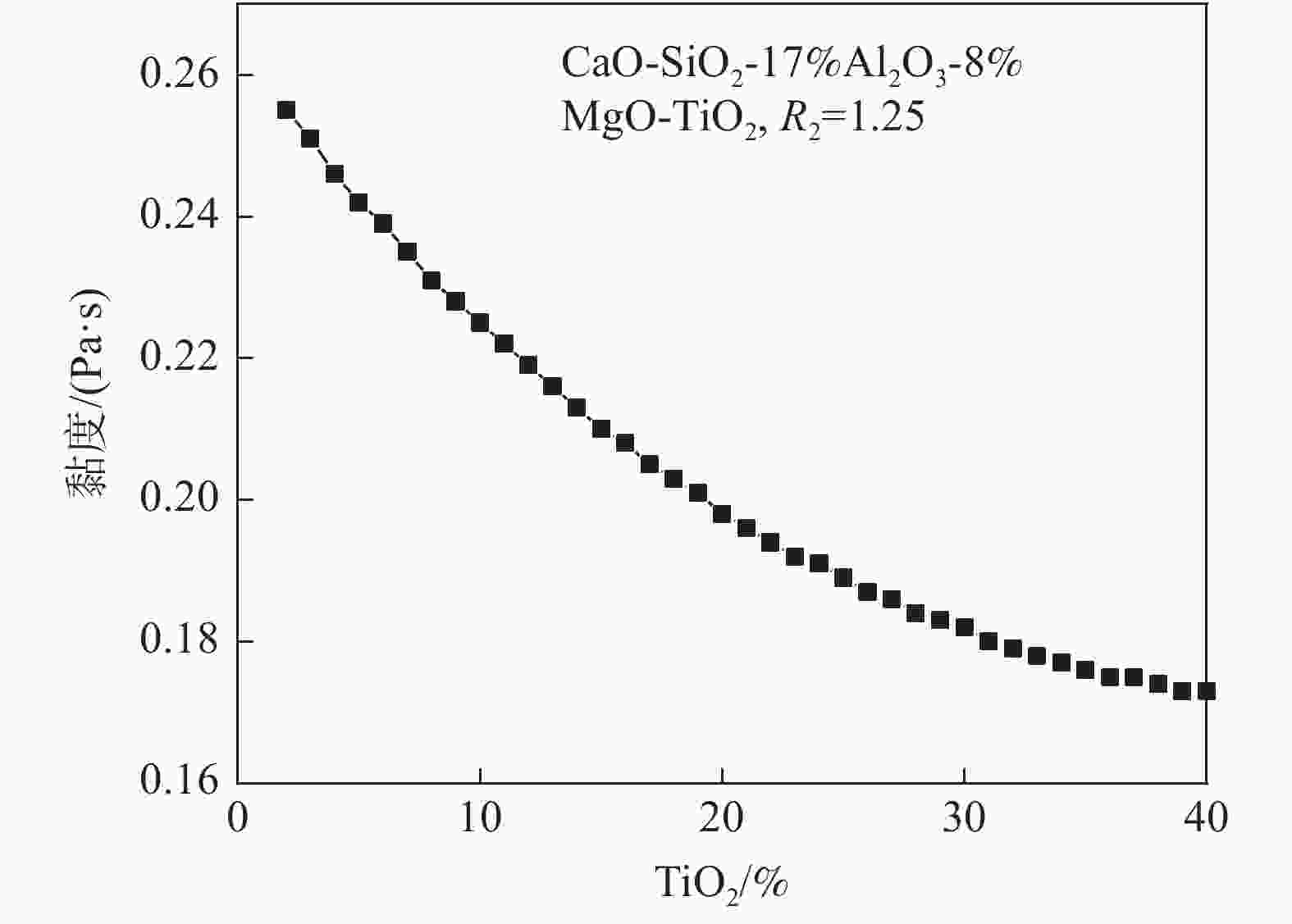

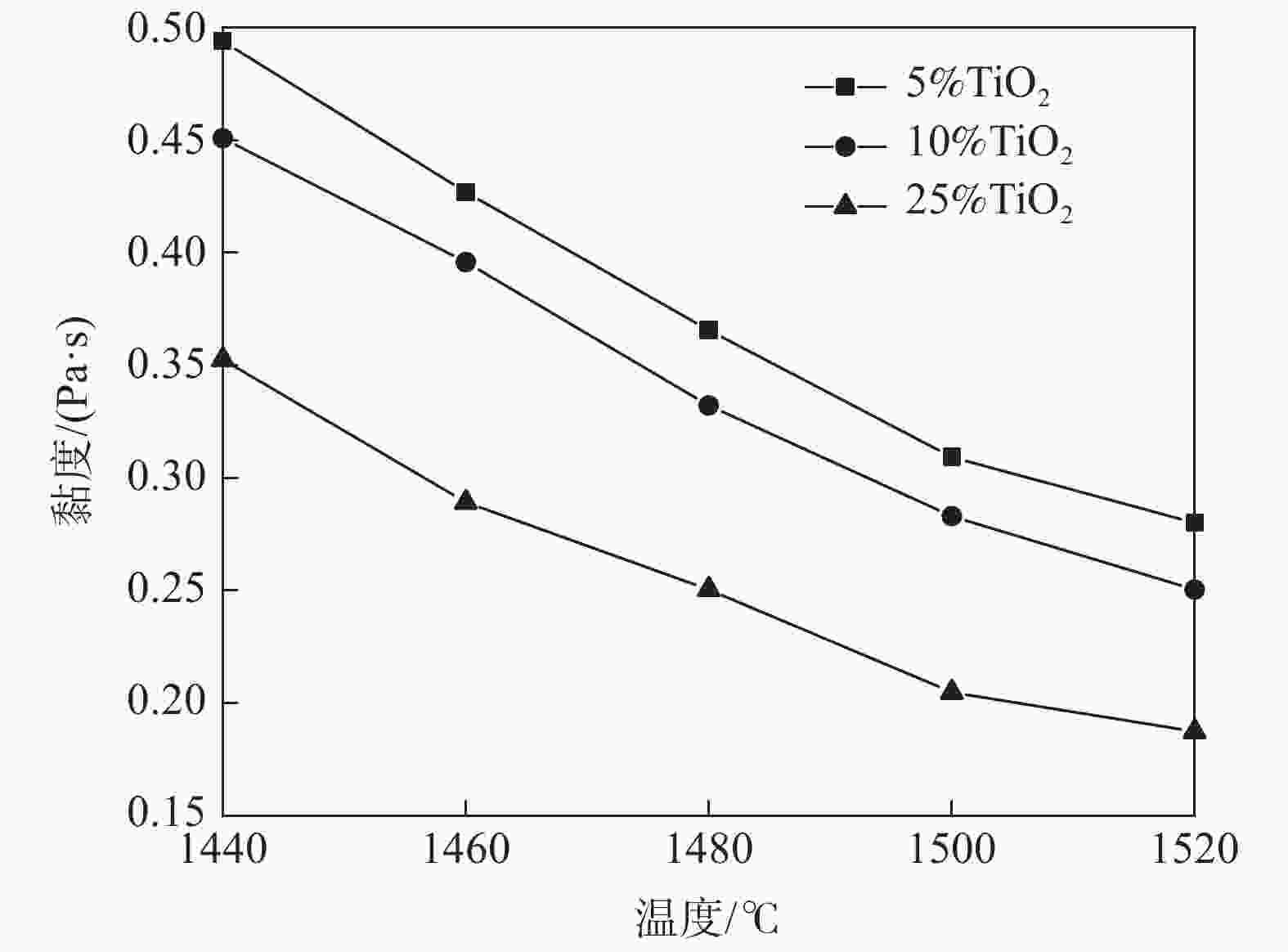

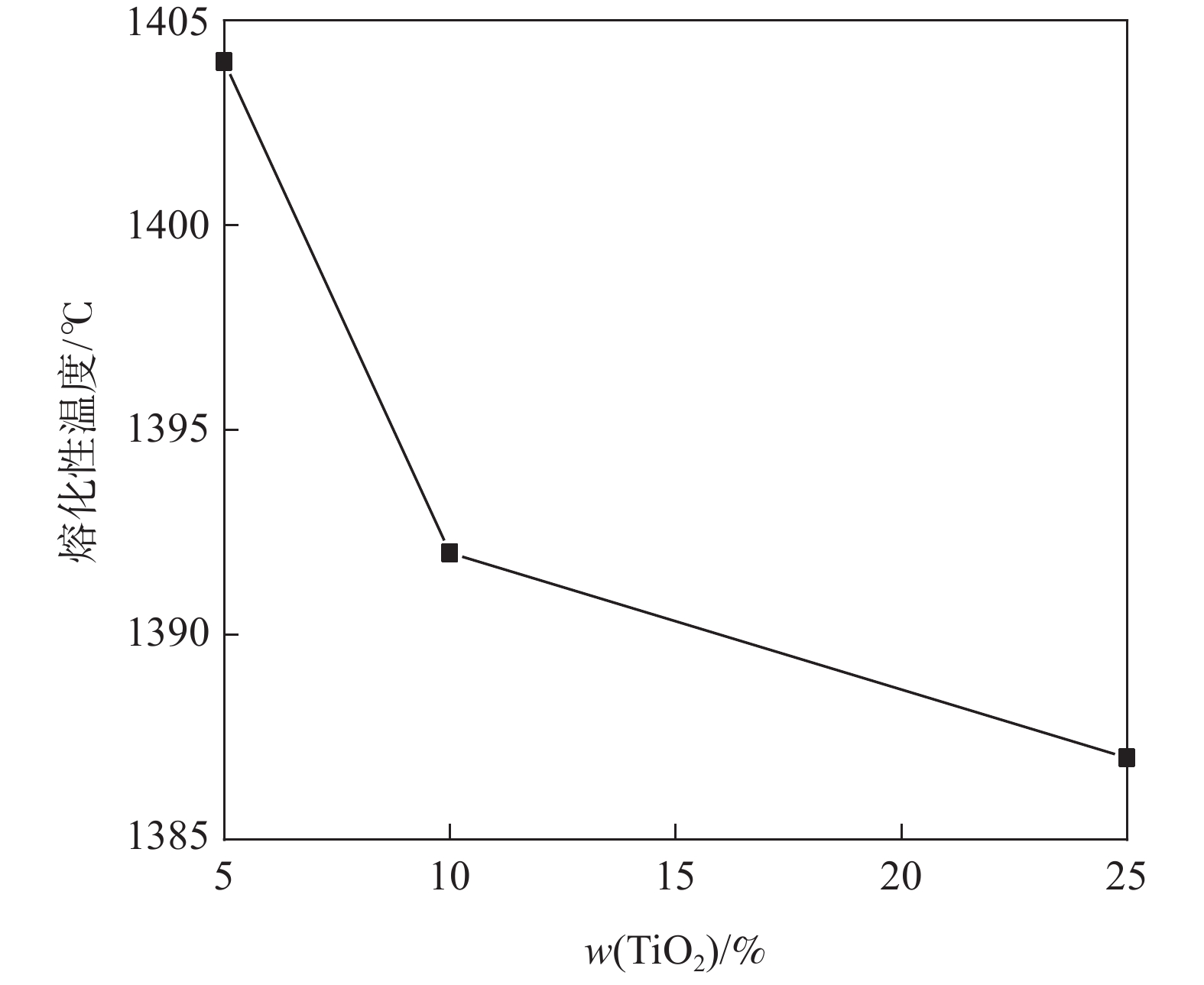

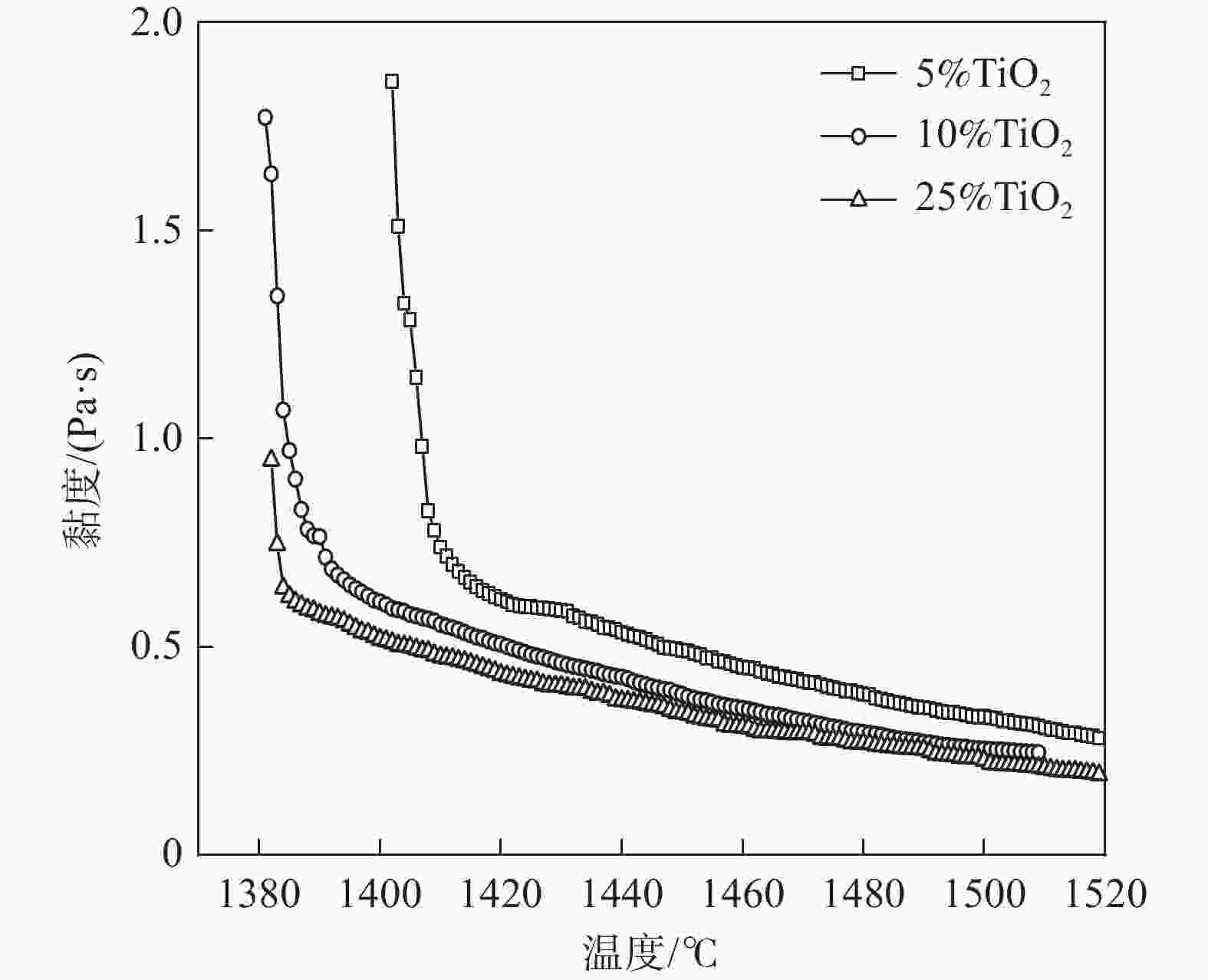

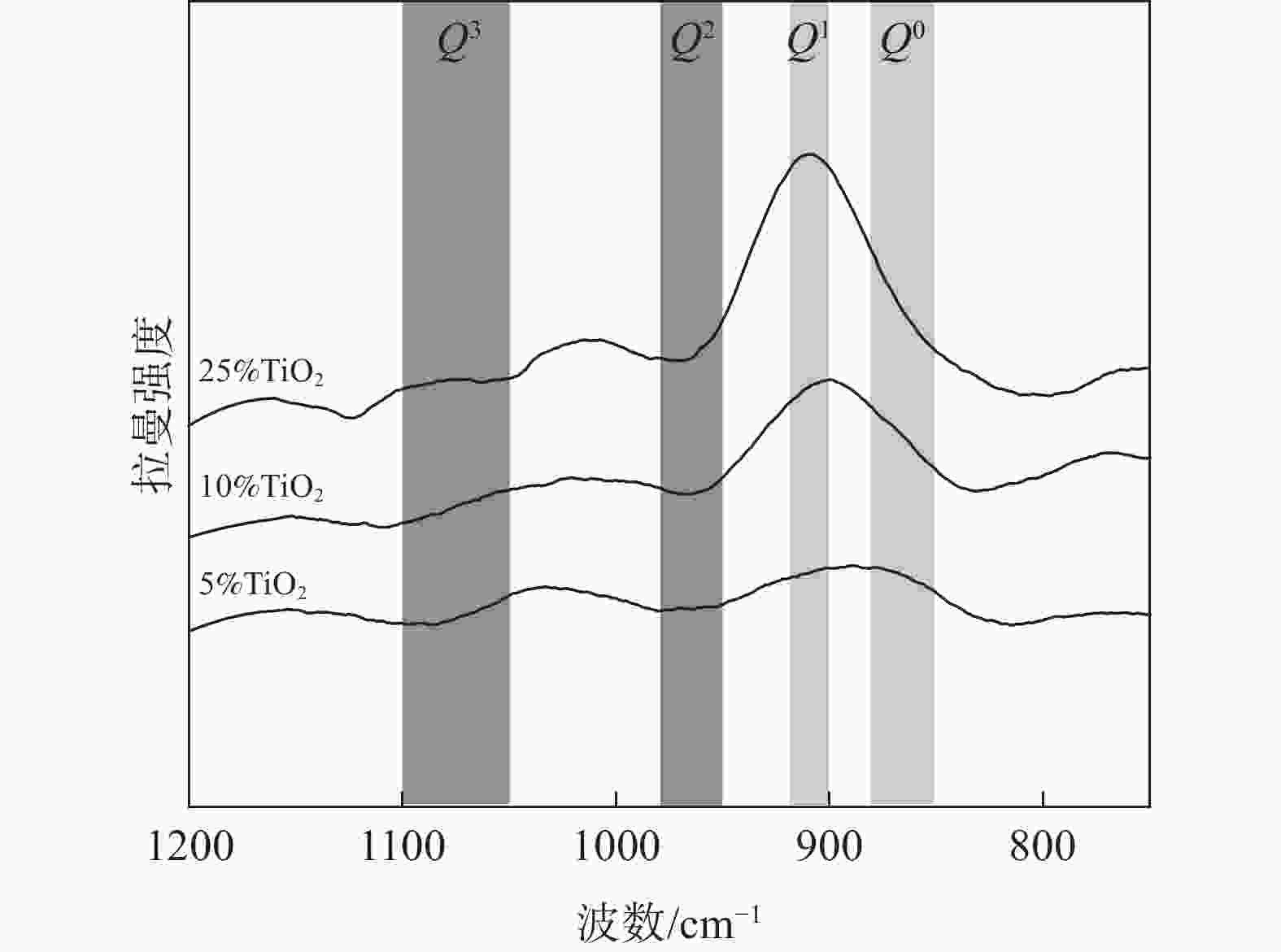

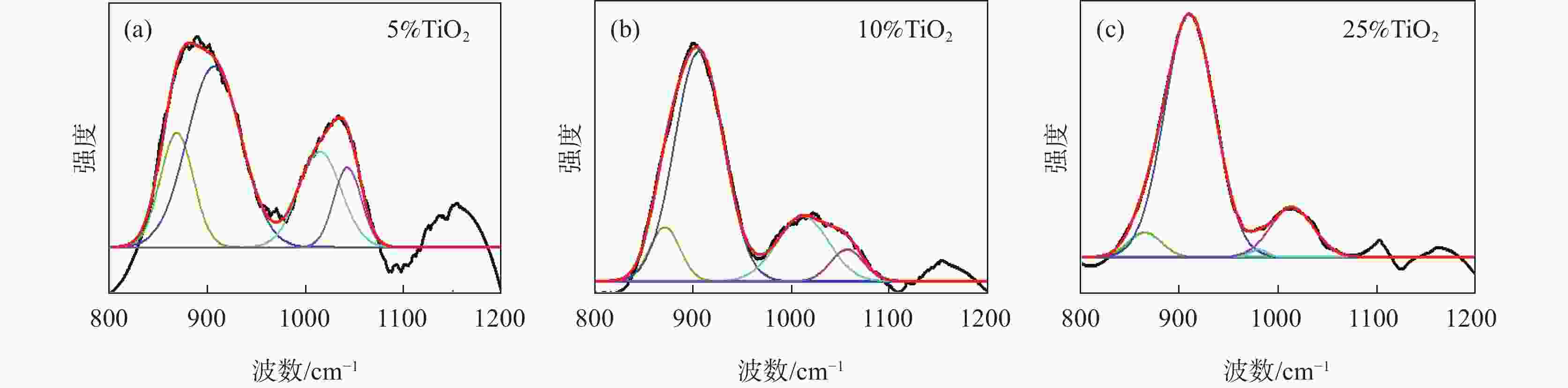

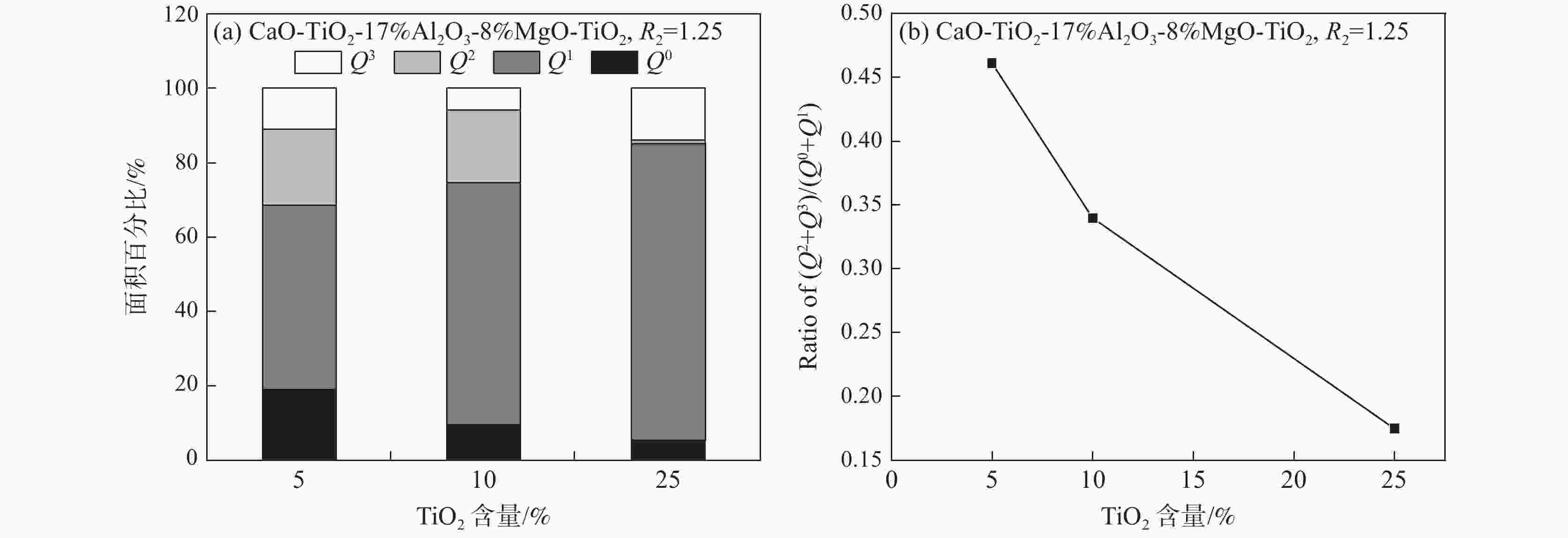

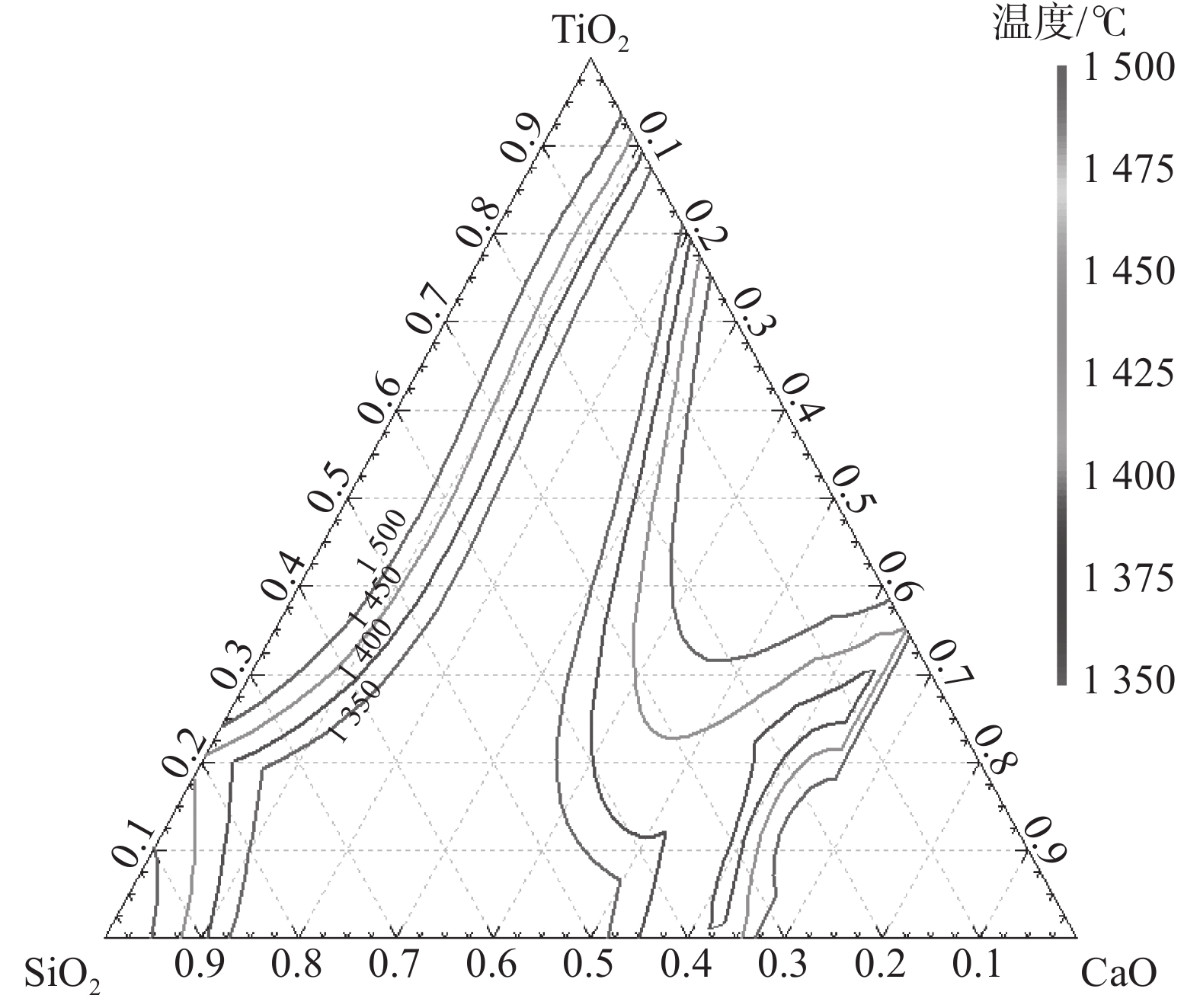

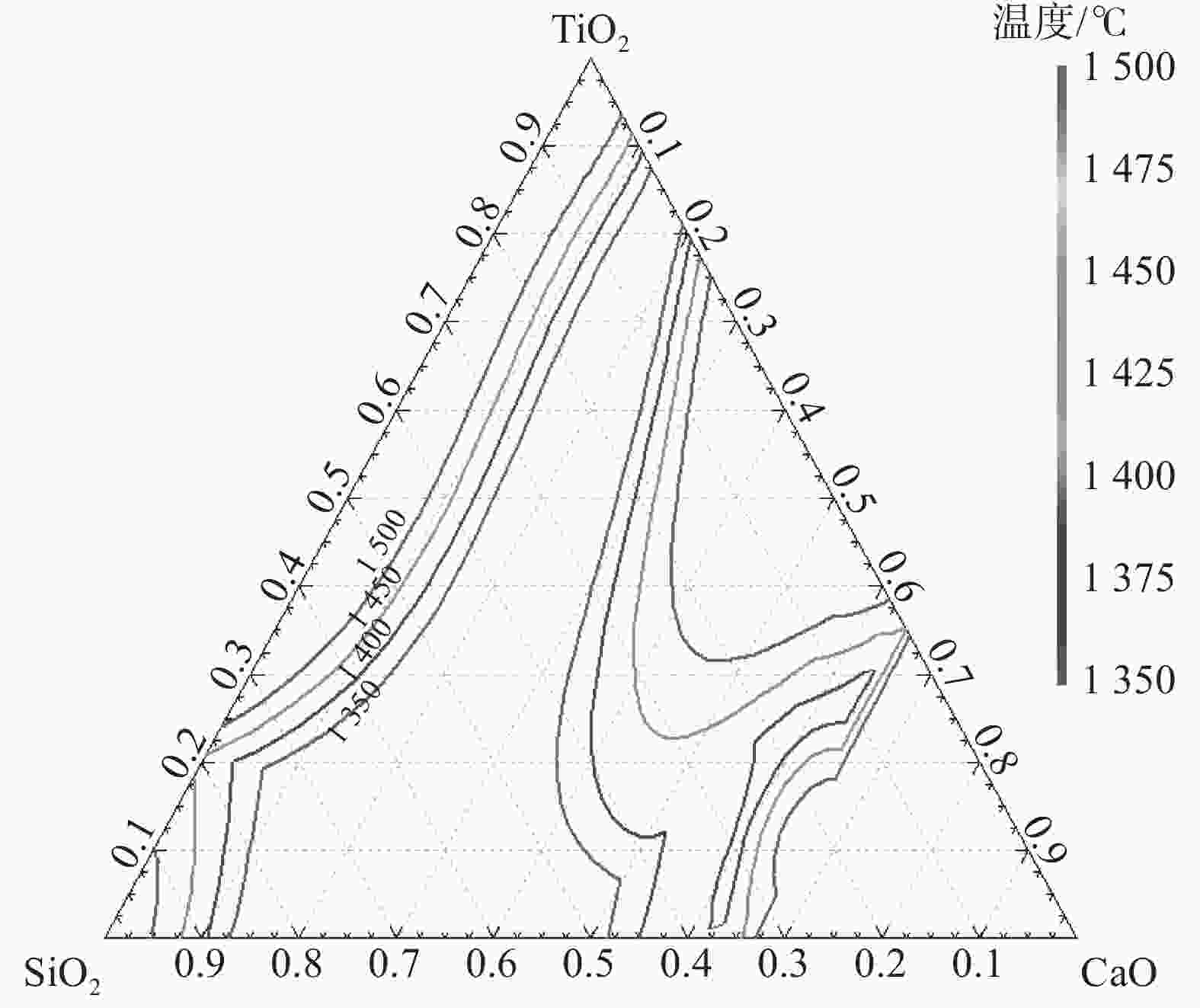

摘要: 随着国内各钢铁企业高炉配加经济性较高的高铝原料的增加,炉渣中Al2O3含量增加,渣铁流动性变差,给高炉冶炼带来一系列问题。以CaO-SiO2-Al2O3-MgO-TiO2五元渣系为研究对象,通过相图理论计算结合试验研究和炉渣结构分析,研究了高铝渣中不同TiO2含量(低钛:5%,中钛:15%,高钛:25%)对高铝高炉渣黏度、熔化性温度的影响,并通过炉渣结构研究解析了影响炉渣物化性能的原因。结果表明:固定碱度R2为1.25,TiO2质量分数增加至25%过程中,炉渣熔化温度先下降后增高,当TiO2质量分数为7%时,炉渣液相析出相由斜长石类的钙铝硅酸盐(Ca2Al2SiO7)转变为高熔点钛酸钙(CaTiO3),其熔点为1975 ℃,炉渣熔化温度增加;TiO2含量由低钛5%增加至高钛25%时,炉渣黏度和熔化性温度均降低。温度越高,炉渣流动性越好,渣中TiO2以[TiO6]8-八面体结构存在,可使渣中复杂硅氧网状结构解体;TiO2含量由5%增加至25%时,炉渣中复杂结构单元Si(Q2 + Q3)的含量降低,简单结构单元Si(Q0 + Q1)的含量升高,Si(Q2 + Q3)/Si (Q0 + Q1)降低,炉渣结构简单化,即炉渣中无论是在低钛、中钛、还是高钛含量,TiO2在炉渣中起炉渣修饰子作用,对降低炉渣黏度、改善炉渣流动性有积极作用,可作为高铝冶炼调控手段之一。Abstract: With the increase of the high-alumina raw materials with high economy in blast furnace (BF) of domestic iron and steel enterprises, the content of Al2O3 in slag increases and the fluidity of the slag iron becomes worse, which brings a series of problems to BF smelting. Taking five-component CaO-SiO2-Al2O3-MgO-TiO2 slag system as the research object, through phase diagram theoretical calculation, experimental research and slag structure analysis, the effects of different TiO2 content (low titanium 5%, medium titanium 15%, and high titanium 25%) in high-alumina slag on the viscosity and melting temperature of high-alumina BF slag were studied, The reasons affecting the physicochemical properties of slag are analyzed by slag structure. The results show that the fixed alkalinity R2 is 1.25, the mass fraction of TiO2 increases from 1% to 25% and the melting temperature of slag in the phase diagram first decreases and then increases. When the mass fraction of TiO2 is 7%, the liquid phase of slag first precipitates from plagioclase calcium aluminosilicate (Ca2Al2SiO7 ) to calcium titanate (CaTiO3) with melting point of 1975 ℃, and the melting temperature of slag increases. When the TiO2 content increases from 5% (low titanium) to 25% (high titanium) the slag viscosity and melting temperature decrease. The higher the temperature, the better the fluidity of slag, that is, TiO2 in slag exists in [TiO6]8- octahedron structure, which can disintegrate the complex silica network structure in slag. When the content of TiO2 increases from 5% to 25%, the content of complex structural unit Si(Q2+Q3) in the slag decreases, the content of simple structural unit Si(Q0+Q1) increases, Si(Q2+Q3 )/Si(Q0+Q1) decreases, and the slag structure is simplified, that is, TiO2 acts as a slag modifier in the slag whether in low, medium or high titanium content, which is helpful to reduce the viscosity and it plays a positive role in improving slag fluidity.

-

Key words:

- high-alumina blast furnace slag /

- TiO2 /

- physicochemical properties /

- slag structure

-

表 1 CaO-SiO2-17 %Al2O3-8 %MgO-TiO2渣系黏度和熔化性温度测试结果

Table 1. Viscosity and melting temperature test results of CaO-SiO2-17 %Al2O3-8 %MgO-TiO2 slag system

编号 R2 w/% CaO SiO2 MgO TiO2 Al2O3 1 1.25 38.89 31.11 8 5 17 2 1.25 36.11 28.89 8 10 17 3 1.25 27.78 22.22 8 25 17 表 2 熔渣结构单元拉曼光谱特征峰

Table 2. Raman-active vibrations for various structure units of slag

结构单元 NBO/T[Qn] 波数/cm−1 [SiO4]4− 4(Q0) 850~880 [Si2O7]6− 3(Q1) 900~920 [SiO3]2− 2(Q2) 950~980 [Si2O7]2− 1(Q3) 1050~1100 -

[1] Yu Wen, Ding Guoxuan, Fan Xiaopeng, et al. Study on mine geological ecological environment evaluation based on analytic hierarchy process fuzzy comprehensive model[J]. Three Gorges Ecological Environment Monitoring, 2021,6(2):26−35. (郁文, 丁国轩, 樊小鹏, 等. 基于层次分析-模糊综合模型的矿山地质生态环境评价研究[J]. 三峡生态环境监测, 2021,6(2):26−35. [2] Sun Changyu, Chen Yachun, Li Jing, et al. The effect of MgO on the desulfurization of high-aluminum blast furnace slag and its kinetic analysis[J]. Journal of Chongqing University, 2016,39(4):82−87. (孙长余, 陈亚春, 李静, 等. MgO对高铝高炉渣脱硫的影响及其动力学分析[J]. 重庆大学学报, 2016,39(4):82−87. doi: 10.11835/j.issn.1000-582X.2016.04.010 [3] Kim J R, Lee Y S, Dong J M, et al. Influence of MgO and Al2O3 contents on viscosity of blast furnace type slags containing FeO[J]. ISIJ International, 2004,44(8):1291−1297. doi: 10.2355/isijinternational.44.1291 [4] Kim G H, Sohn I. Effect of Al2O3 on the viscosity and structure of calcium silicate-based melts containing Na2O and CaF2[J]. Journal of Non-Crystalline Solids, 2012,358(12-13):1530−1537. doi: 10.1016/j.jnoncrysol.2012.04.009 [5] Machin J S, Yee T B, Hanna D L. Viscosity studies of system CaO–MgO–Al2O3–SiO2: III, 35, 45, and 50% SiO2[J]. Journal of the American Ceramic Society, 1952,35(12):322−325. doi: 10.1111/j.1151-2916.1952.tb13057.x [6] Tang X L, Zhang Z T, Guo M, et al. Viscosities behavior of CaO-SiO2-MgO-Al2O3 slag with low mass ratio of CaO to SiO2 and wide range of Al2O3 content[J]. Journal of Iron & Steel Research International, 2011,(2):1−17. [7] Kurunov I F, Loginov V N, Lyapin S S, et al. New technological solutions to protect the lining of blast-furnace hearths[J]. Metallurgist, 2007,51:425−433. doi: 10.1007/s11015-007-0077-2 [8] Zhao Y. The impact of titanium on Skull formation in the blast furnace hearth[C]//In: AIST. org, editor. AISTech-2013. Pittsburgh, Pa, USA. 2014: 95-103. [9] Yuan Xiang, Zhang Jianliang, Mao Rui, et al. Viscosity and melting properties of blast furnace low titanium slag[J]. Journal of Process Engineering, 2014,14(4):664−670. (袁骧, 张建良, 毛瑞, 等. 高炉低钛渣粘度和熔化性能[J]. 过程工程学报, 2014,14(4):664−670. [10] Shi Lili, Li Rong, Long Ping, et al. Effect of Al2O3 and TiO2 content on viscous flow characteristics and mineral composition of titanium bearing blast furnace slag[J]. Shanxi Metallurgy, 2017,40(5):1−3. (施丽丽, 李容, 隆平, 等. Al2O3和TiO2含量对含钛高炉渣黏流特性及矿物组成的影响[J]. 山西冶金, 2017,40(5):1−3. [11] Yan Z, Pang Z, Lv X W, et al. Effect of TiO2 on the viscous behavior of high alumina blast furnace slag[C]//9th International Symposium on High-Temperature Metallurgical Processing. 2018: 725-733. [12] Wang Z, Shu Q F, Chou K. Viscosity of fluoride-free mold fluxes containing B2O3 and TiO2[J]. Steel Research International, 2013,84(8):766−776. doi: 10.1002/srin.201200256 [13] Park H, Park J Y, Kim J H, et al. Effect of TiO2 on the viscosity and slag structure in blast furnace type slags[J]. Steel Research International, 2012,83(2):150−156. doi: 10.1002/srin.201100249 [14] Xu Renze, Zhang Jianliang, Zhang Heshun, et al. Effect of TiO2 on properties of Jingtang blast furnace slag and thermodynamic analysis[J]. Iron and steel, 2017,52(9):104−109. (许仁泽, 张建良, 张贺顺, 等. TiO2对京唐高炉渣性能的影响及热力学分析[J]. 钢铁, 2017,52(9):104−109. [15] Nakamoto M, Tsugawa Y, Kiyose A, et al. Effect of TiO2 on the viscosity of molten slag in SiO2-CaO-MgO system[J]. Journal of High Temperature Society, 2007,32(1):74−77. [16] Chang Z Y, Jiao K X, Zhang J L, et al. Effect of TiO2 and MnO on viscosity of blast furnace slag and thermodynamic analysis[J]. ISIJ International, 2018,58(12):2173−2179. doi: 10.2355/isijinternational.ISIJINT-2018-379 [17] Zhang S, Zhang X, Peng H, et al. Structure analysis of CaO-SiO2-Al2O3-TiO2 slag by molecular dynamics simulation and FT-IR spectroscopy[J]. Transactions of the Iron & Steel Institute of Japan, 2014,54(4):734−742. [18] Shi Chengbin, Zheng Dingli, Shin Seungho, et al. Effect of TiO2 on the viscosity and structure of low-fluoride slag used for electroslag remelting of Ti-containing steels[J]. International Journal of Minerals Metallurgy and Materials, 2017,24(1):18−24. doi: 10.1007/s12613-017-1374-9 [19] Liang Xiaoping, Lu Dongxu, Wang Yu, et al. Computational simulation on the coordination structure of CaO-B2O3-SiO2-TiO2 mold fluxes system[J]. Journal of Chongqing University, 2015,38(5):135−141. (梁小平, 陆东旭, 王雨, 等. CaO-B2O3-SiO2-TiO2系保护渣配位结构的计算模拟[J]. 重庆大学学报, 2015,38(5):135−141. doi: 10.11835/j.issn.1000-582X.2015.05.020 [20] Pang Zhengde, Lv Xuewei, Yan Zhiming, et al. Viscosity and free running temperature of ultra-high TiO2 bearing blast furnace slag[J]. Iron and Steel, 2020,55(8):181−186. (庞正德, 吕学伟, 严志明, 等. 超高TiO2高炉渣黏度及熔化性温度[J]. 钢铁, 2020,55(8):181−186. doi: 10.13228/j.boyuan.issn0449-749x.20200201 -

下载:

下载: