Effect of Na2O on the enrichment behavior of phosphorus in the slag system CaO-SiO2-Fe2O3-P2O5

-

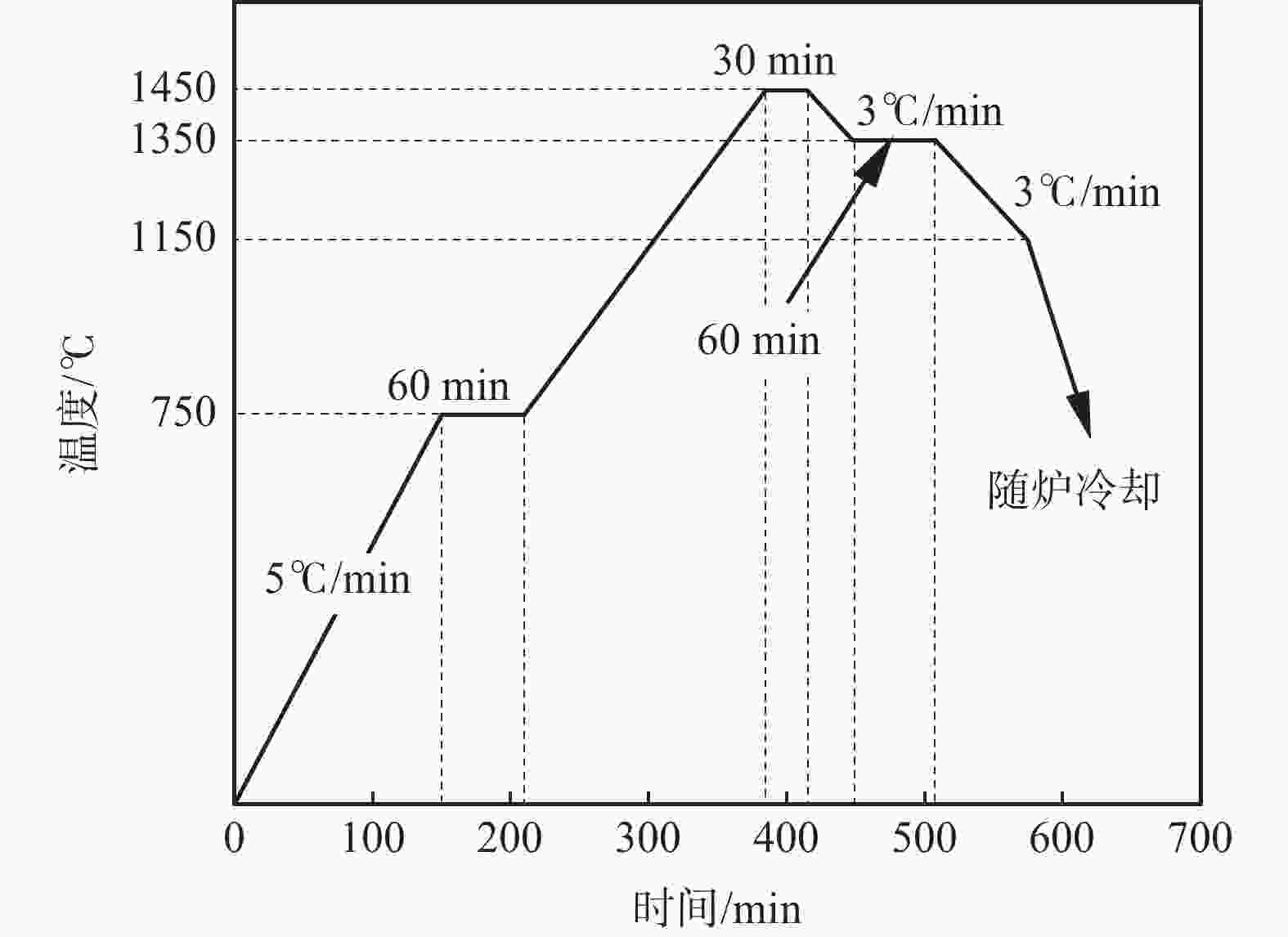

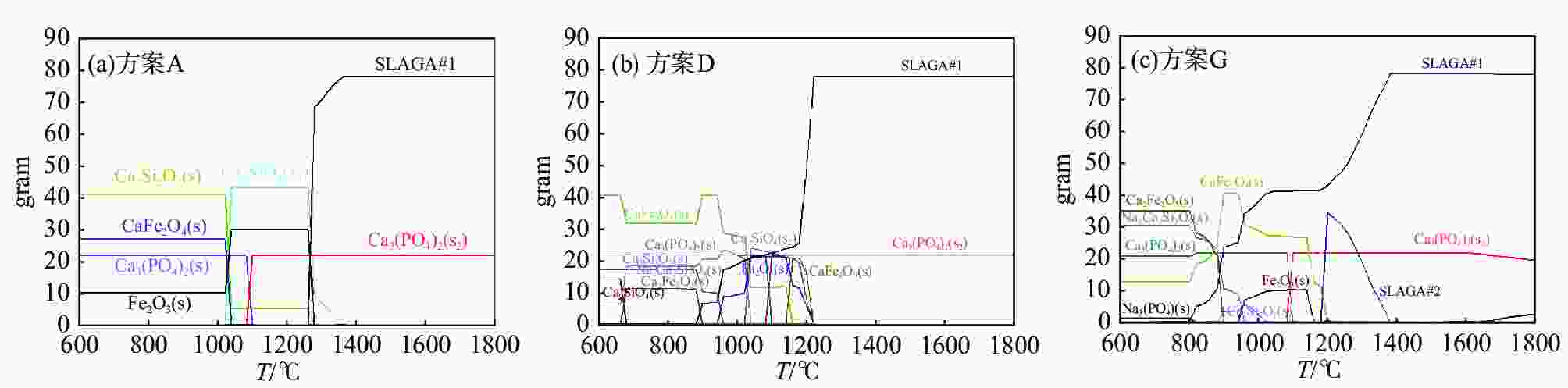

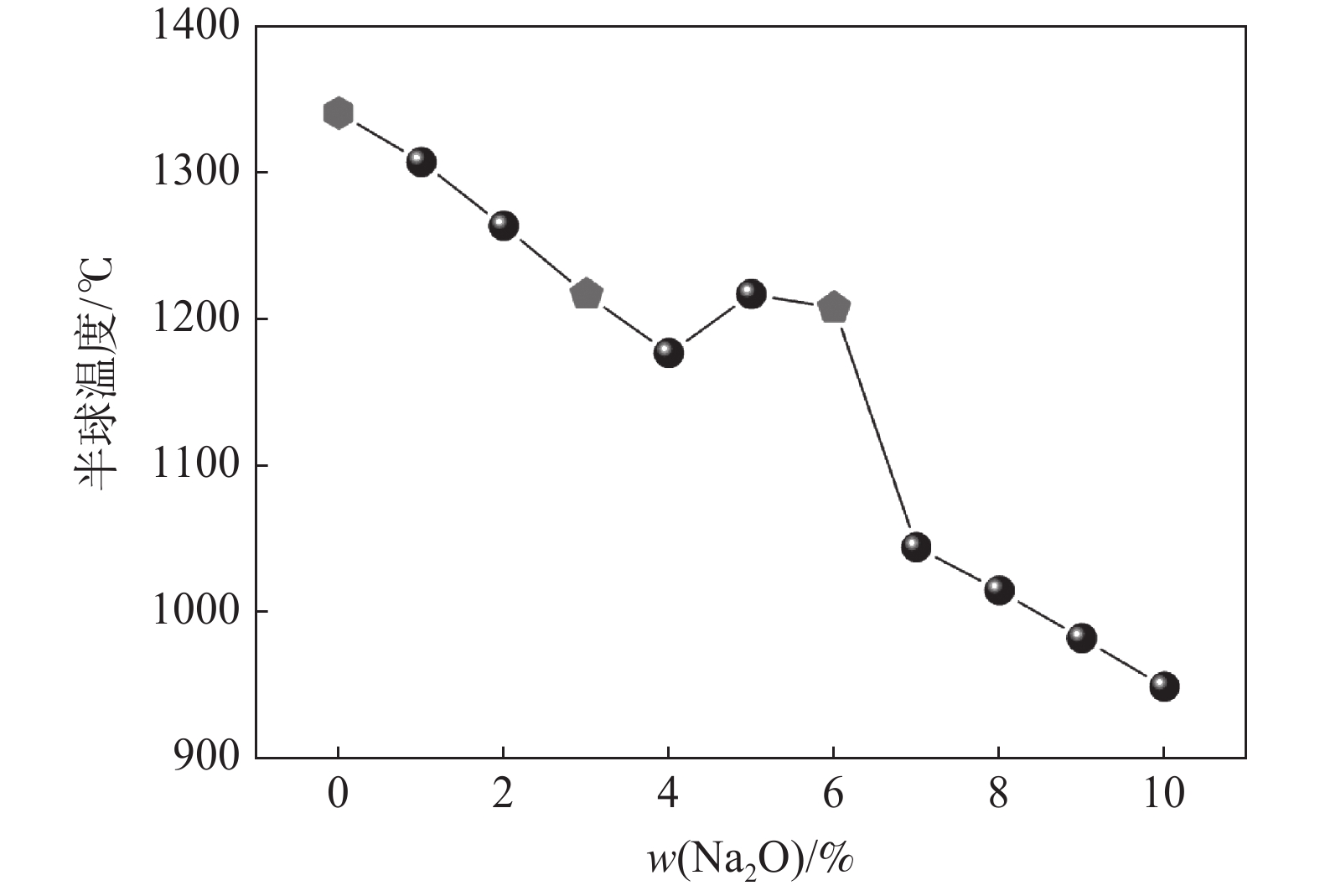

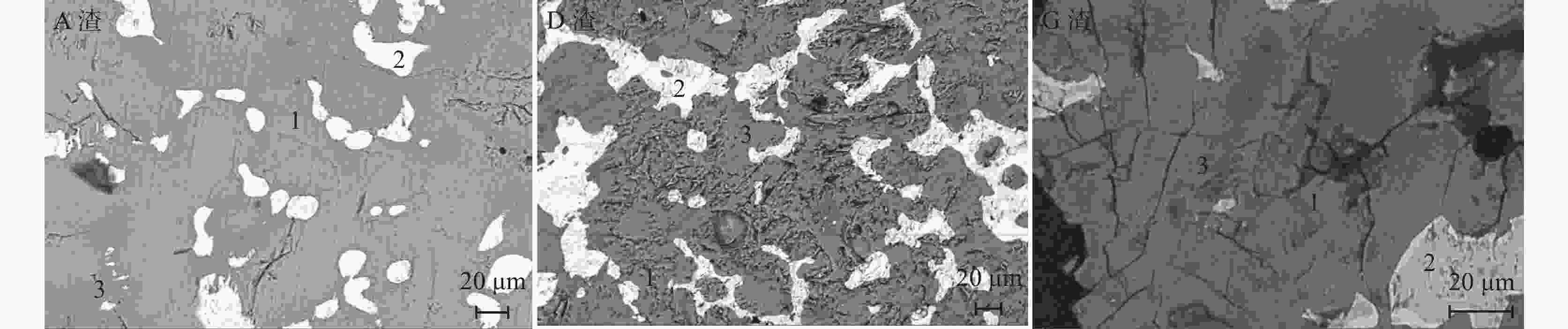

摘要: 通过MoSi2高温箱式炉试验和FactSage、扫描电镜及XRD等分析方法,对渣中Na2O对含磷渣中磷的赋存形式、物相析出规律以及含磷渣中磷的富集行为的影响规律进行系统研究。结果表明:对于CaO-SiO2-Fe2O3-P2O5渣系,Na2O的加入会取代nC2S-C3P固溶体中部分钙,形成Na2Ca4(PO4)2SiO4固溶体,随着Na2O进一步增加直至过量时,前述反应生成的高磷固溶体(Na2Ca4(PO4)2SiO4)中Ca和Si组分的比例进一步降低,逐渐富集成为更高磷固溶体Na3PO4,富磷相中磷的品位得以提高。随着渣中Na2O含量的增加,炉渣熔点明显降低,富磷相中磷含量明显增加,P2O5含量超过30%,完全满足钢渣磷肥对磷含量的要求。因此在炼钢过程加入适量的Na2O(低于6%)代替CaF2作助熔剂造渣,可以促进渣中磷富集,进而改善含磷渣中磷资源回收作磷肥的效果。Abstract: In this paper, the effects of Na2O in slag on the existing forms, the law of phase precipitation and the phosphorus enrichment behavior of phosphorus-containing slag are systematically studied by high-temperature experiments in MoSi2 furnace and analyzed by FactSage, SEM and XRD. The research results show that: for the CaO-SiO2-Fe2O3-P2O5 slag system, the addition of Na2O will replace solid solution calcium of nC2S-C3P, forming Na2Ca4 (PO4)2SiO4 solid solution. As the content of Na2O increases to excess, the content of Ca and Si in P-solid solution (Na2Ca4(PO4)2SiO4) reduces, and the Na3PO4 phase produces the grade of phosphorus in the P-rich phase increases. With the increase of the content of Na2O in slag, the melting point of the slag decreases significantly, the content of phosphorus in the P-rich phase increases significantly, and the content of P2O5 exceeds 30%, which ultimately meets the requirement of phosphorus content in the steel slag phosphate fertilizer. Therefore, adding an appropriate amount of Na2O (less than 6%) in the steel making process instead of CaF2 as the fluxing agent can promote the phosphorus enrichment effect in the slag, and the converter slag can be used as a phosphate fertilizer.

-

表 1 试验渣化学成分

Table 1. Composition of the synthetic slag samples %

渣样 CaO SiO2 Fe2O3 P2O5 Na2O A 42.86 17.14 30 10 0 B 42.15 16.85 30 10 1 C 41.43 16.57 30 10 2 D 40.71 16.29 30 10 3 E 40.00 16.00 30 10 4 F 39.29 15.71 30 10 5 G 38.57 15.43 30 10 6 H 37.86 15.14 30 10 7 I 37.15 14.85 30 10 8 J 36.43 14.57 30 10 9 K 35.72 14.28 30 10 10 表 2 相应合成渣终样EDS结果分析

Table 2. Chemical composition of each phase from the sample in Fig.5 by EDS

% 序号 物相 Na2O MgO SiO2 P2O5 CaO Fe2O3 A 富磷相 0.00 2.95 15.24 20.75 58.90 2.16 RO相 0.00 5.30 0.07 0.17 0.61 93.85 基体相 0.00 11.46 31.29 3.56 53.68 0.00 D 富磷相 2.16 0 14.58 23.63 59.61 0.00 RO相 0.00 10.48 0.00 0.00 0.00 89.52 基体相 1.53 0.00 25.32 3.32 68.80 1.03 G 富磷相 12.31 0.00 8.63 31.74 47.01 0.31 RO相 4.36 0.00 0.38 1.55 0.00 93.71 基体相 3.70 0.00 22.51 2.95 68.31 2.53 -

[1] Yang Jinxing, Lv Ningning, Su Chang, et al. Research process on the recycling of phosphorus resource from conveter steelmaking slag[J]. Applied Chemical Industry, 2019,48(6):1440−1446. (杨金星, 吕宁宁, 苏畅, 等. 转炉钢渣中磷资源回收利用的研究进展[J]. 应用化工, 2019,48(6):1440−1446. doi: 10.16581/j.cnki.issn1671-3206.20190523.025 [2] Bai Xuefeng, Zhang Yimin, Sun Yanhui, et al. Research on recycling of hot slag in dephosphorization furnace of duplex process[J]. Steelmaking, 2018,34(5):31−36. (白雪峰, 张一民, 孙彦辉, 等. 转炉双联炼钢工艺热态渣再利用脱磷的工业试验[J]. 炼钢, 2018,34(5):31−36. [3] Dong Wenliang, Luo Lei, Tian Zhihong, et al. Recycle of decarburization-slag indephosphorization-furnace of duplex processin converter[J]. Iron and Steel, 2017,52(5):36−42. (董文亮, 罗磊, 田志红, 等. “全三脱”工艺流程中脱碳渣返回脱磷转炉利用[J]. 钢铁, 2017,52(5):36−42. doi: 10.13228/j.boyuan.issn0449-749x.20160314 [4] Cui Hongxu, Chen Qingwu, Shen Yingying, et al. Technology research on phosphorus enrichment and application of converter steel slag[J]. China Metallurgy, 2010,20(3):35−38,46. (崔虹旭, 陈庆武, 申莹莹, 等. 转炉钢渣磷富集与应用的技术研究[J]. 中国冶金, 2010,20(3):35−38,46. doi: 10.13228/j.boyuan.issn1006-9356.2010.03.009 [5] Du Chuanming, Yu Yaohui, Yuan Lei, et al. Research status and development trend of phosphorus separation and recovery from steelmaking slag[J]. Iron and Steel, 2020,55(12):1−9. (杜传明, 于耀辉, 袁磊, 等. 钢渣中磷分离及回收的研究现状和发展趋势[J]. 钢铁, 2020,55(12):1−9. doi: 10.13228/j.boyuan.issn0449-749x.20200147 [6] Tong Shuai, Li Chenxiao, Wang Shuhuan, et al. Influence of temperature on dephosphorization of recycling converter gasification dephosphorization slag[J]. Iron Steel Vanadium Titanium, 2021,42(5):109−114. (佟帅, 李晨晓, 王书桓, 等. 温度对转炉气化脱磷渣再利用脱磷的影响[J]. 钢铁钒钛, 2021,42(5):109−114. doi: 10.7513/j.issn.1004-7638.2021.05.017 [7] Boom R, Riaz S, Mills K C. Slags and fluxes entering the new millennium, an analysis of recent trends in research and development[J]. Ironmaking and Steelmaking, 2005,32(1):21−25. doi: 10.1179/174328105X23941 [8] Ji Lipeng. Analysis and discussion on path of phosphorus flow in iron and steel plant[J]. China Metallurgy, 2018,28(6):19−24. (吉立鹏. 钢铁厂磷素流的路径分析及探讨[J]. 中国冶金, 2018,28(6):19−24. doi: 10.13228/j.boyuan.issn1006-9356.20180040 [9] Yang X, Matsuura H, Tsukihashi F. Condensation of P2O5 at the interface between 2CaO•SiO2 and CaO-SiO2-FeOx-P2O5 slag[J]. ISIJ International, 2009,49(9):1298−1307. doi: 10.2355/isijinternational.49.1298 [10] Kitamura S, Saito S, Utagawa K, et al. Mass transfer of P2O5 between liquid slag and solid solution of 2CaO•SiO2 and 3CaO•P2O5[J]. ISIJ International, 2009,49(12):1838−1844. doi: 10.2355/isijinternational.49.1838 [11] Wu X R, Wang P, Li L S, et al. Distribution and enrichment of phosphorus in solidified BOF steelmaking slag[J]. Ironmaking and Steelmaking, 2011,38(3):185−188. doi: 10.1179/030192310X12690127076316 [12] Hironari K, Kazuyo Matsubae-Yokoyama, Tetsuya Nagasaka. Magnetic separation of phosphorus enriched phase from multiphase dephosphorization slag[J]. Tetsu-to-Hagane, 2010,50(1):59−64. doi: 10.2355/isijinternational.50.59 [13] Lin L, Bao Y P, Wang M, et al. Influence of SiO2 modification on phosphorus enrichment in P-bearing steelmaking slag[J]. Ironmaking and Steelmaking, 2013,40(7):521−527. doi: 10.1179/1743281212Y.0000000074 [14] Shimauchi K, Kitamura S, Shibata H. Distribution of P2O5 between solid dicalcium silicate and liquid phases in CaO–SiO2–Fe2O3 system[J]. Tetsu-to-Hagane, 2009,95(3):229−235. doi: 10.2355/tetsutohagane.95.229 [15] Deo B, Halder J, Snoeijer B, et al. Effect of MgO and Al2O3 variations in oxygen steelmaking(BOF) slag on slag morphology and phosphorus distribution[J]. Ironmaking and Steelmaking, 2005,32(1):54−60. doi: 10.1179/174328105X23969 [16] Wang Dazhi, Bao Yanping, Wang Min. Study on the enrichment behavior of phosphorus in high phosphorus converter slag[J]. Chinese Journal of Engineering, 2018,40(S1):65−72. (王达志, 包燕平, 王敏. 高磷转炉渣中磷的富集行为研究[J]. 工程科学学报, 2018,40(S1):65−72. doi: 10.13374/j.issn2095-9389.2018.s1.010 [17] Jiang L, Diao J, Yan X, et al. Effect of Al2O3 on enrichment of phosphorus in hot metal dephosphorization slag[J]. ISIJ International, 2015,55(3):564−569. doi: 10.2355/isijinternational.55.564 [18] Lin Lu, Bao Yanping, Wang Min, et al. Influence of titania modification on phosphorus enrichment in P-bearing steel-making slag[J]. Journal of University of Science and Technology Beijing, 2014,36(8):1013−1019. (林路, 包燕平, 王敏, 等. 二氧化钛改质对含磷转炉渣中磷富集行为的影响[J]. 北京科技大学学报, 2014,36(8):1013−1019. doi: 10.13374/j.issn1001-053x.2014.08.004 [19] Diao Jiang. Effect of Al2O3 and Na2O on dephosphorization of high phosphorus hot metal[J]. Journal of Iron and Steel Research, 2013,25(2):9−13. (刁江. Al2O3和Na2O对高磷铁水脱磷的影响[J]. 钢铁研究学报, 2013,25(2):9−13. doi: 10.13228/j.boyuan.issn1001-0963.2013.02.009 [20] Li Xianpeng, Gao Jintao, Zhang Yanling, et al. Distribution behavior of phosphorus between CaO-FeO-SiO2 -Al2O3/Na2O/TiO2 slags and carbon-saturated iron[J]. Iron and Steel, 2017,52(2):18−23. (李显鹏, 高金涛, 张延玲, 等. CaO-FeO-SiO2-Al2O3/Na2O/TiO2渣系与碳饱和铁水间磷分配行为[J]. 钢铁, 2017,52(2):18−23. doi: 10.13228/j.boyuan.issn0449-749x.20160230 [21] Sun Jiali, Liu Chengjun, Jiang Maofa. Thermodynamic model for dephosphorization of CaO-SiO2-FeO-Al2O3-Na2O-TiO2-P2O5 slag[J]. Iron Steel Vanadium Titanium, 2021,42(2):146−151,178. (孙嘉丽, 刘承军, 姜茂发. CaO-SiO2-FeO-Al2O3-Na2O-TiO2-P2O5渣系的脱磷热力学模型[J]. 钢铁钒钛, 2021,42(2):146−151,178. doi: 10.7513/j.issn.1004-7638.2021.02.024 -

下载:

下载: