Effect of holding time on solid solution behavior of inhibitors in rare earth oriented silicon steel during reheating

-

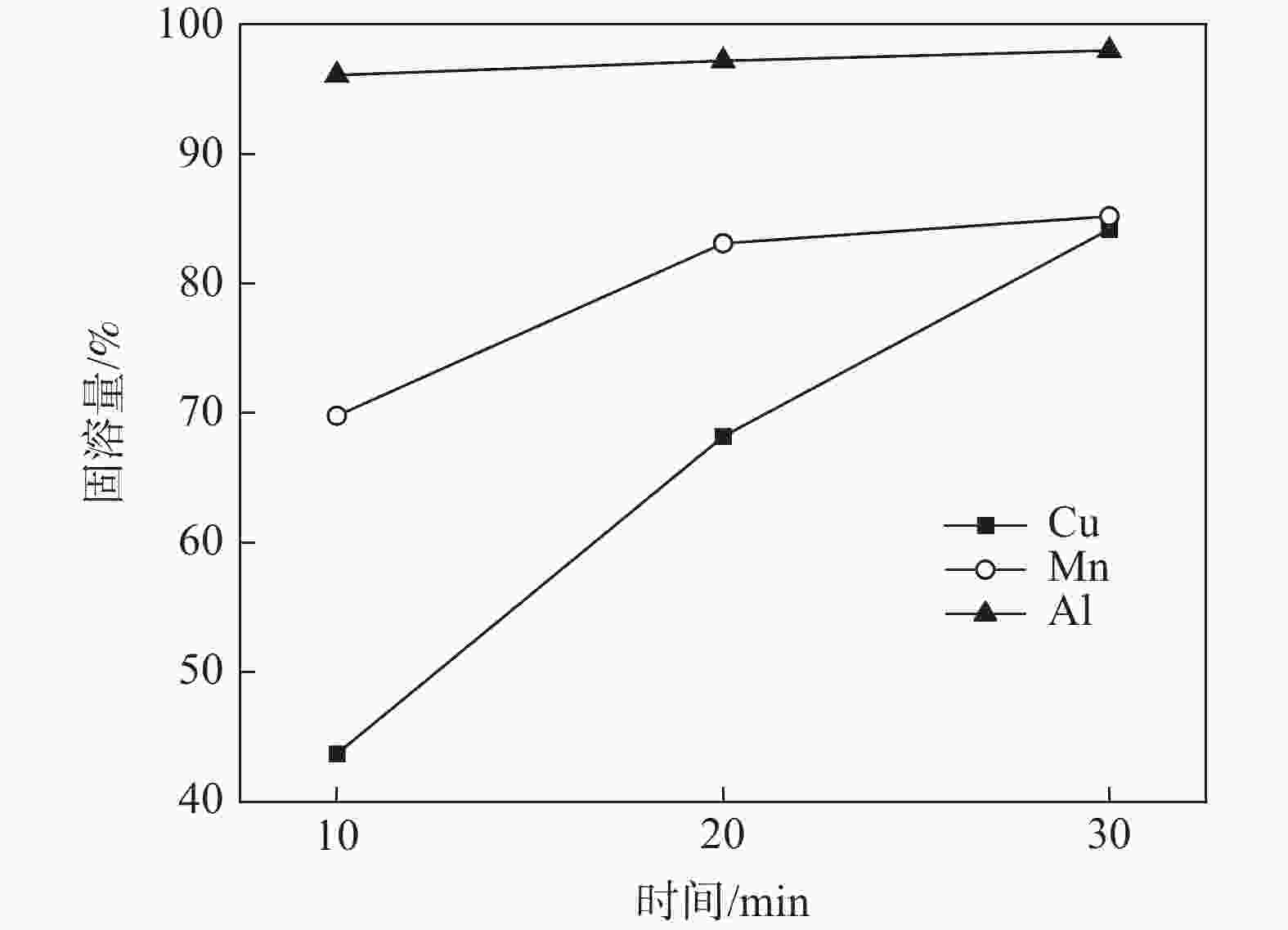

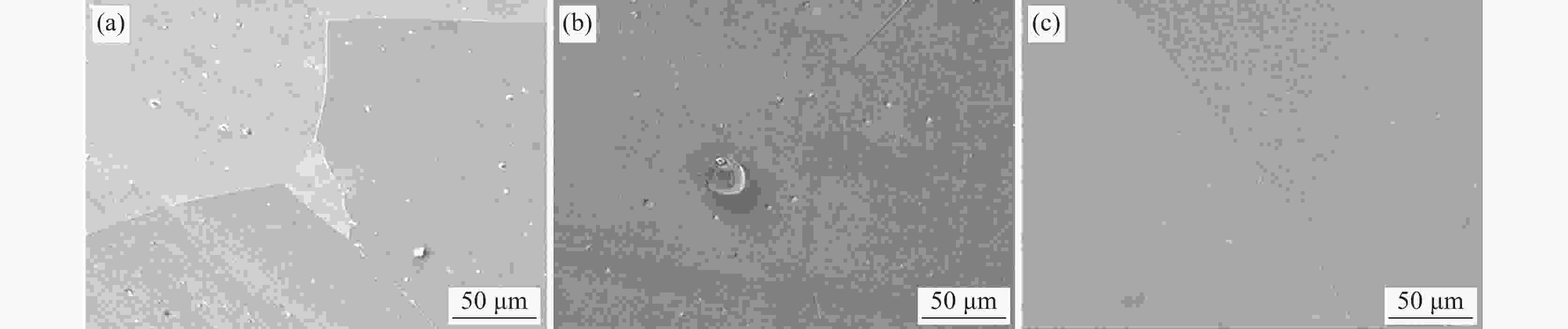

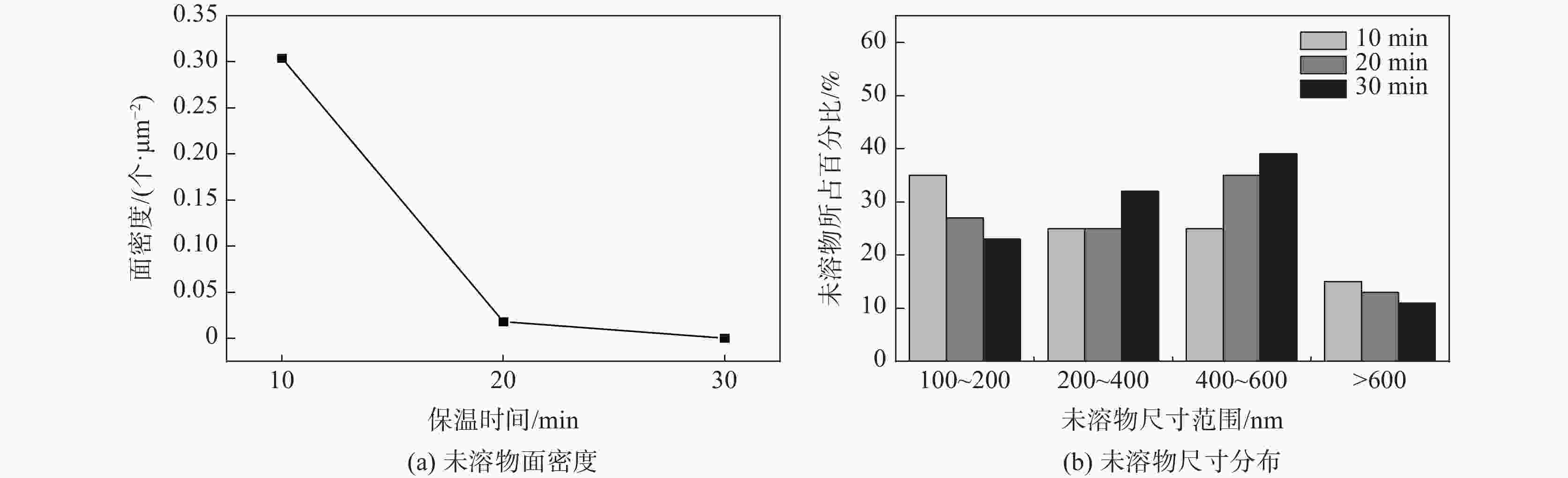

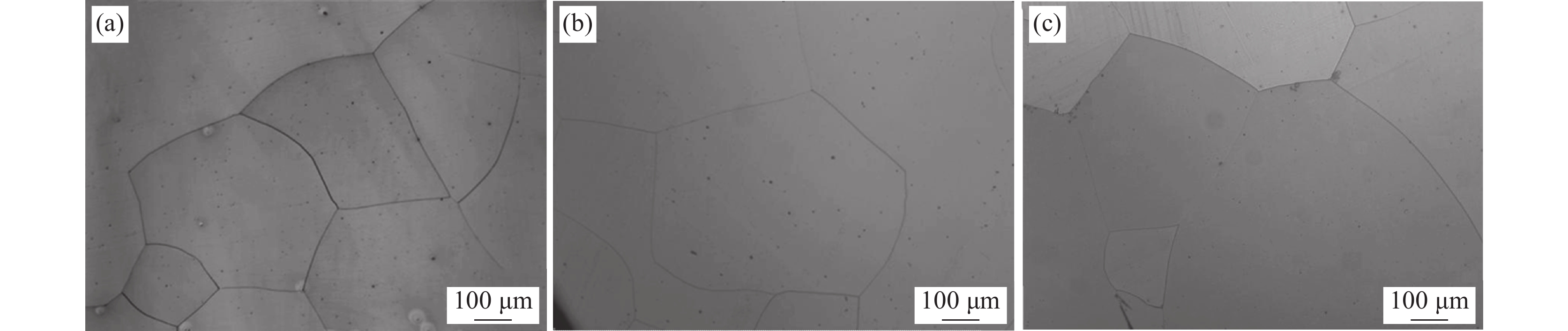

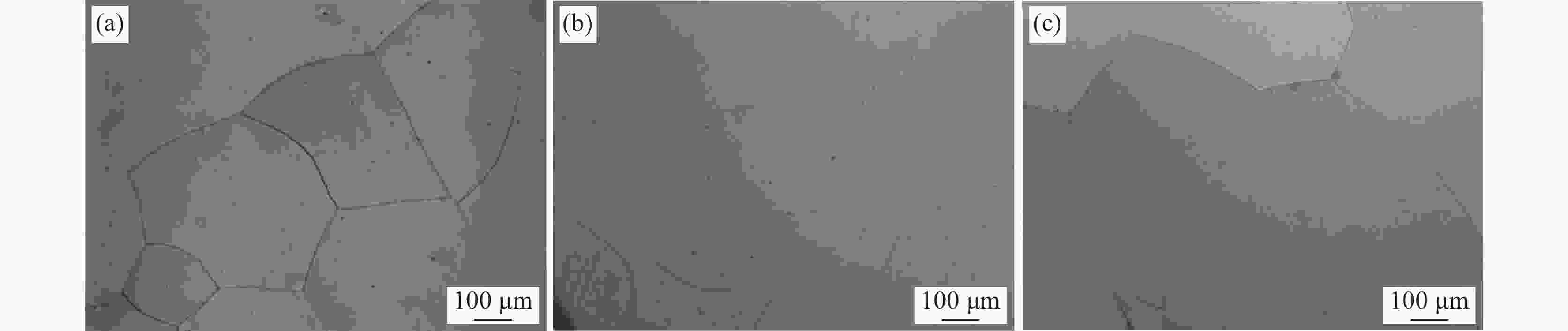

摘要: 借助OM、激光共聚焦显微镜、质谱仪和电解萃取等设备和方法,研究了添加微量稀土La(质量分数0.0011%)的取向硅钢在轧制前采用不同加热保温时间对抑制剂固溶行为的影响。结果表明:当稀土取向硅钢在1250 ℃分别保温10、20、30 min后,试验钢晶粒尺寸随保温时间延长有先快后慢的长大趋势;三种抑制剂元素Mn、Cu和Al均发生固溶,保温时间对Mn和Cu两种元素的固溶影响明显,固溶量分别由69.8%和43.7%增加至84.2%和85.2%;随着保温时间的延长,稀土取向硅钢中抑制剂的小尺寸未溶物逐渐减少直至消失,较大尺寸未溶物(300~600 nm)逐渐转变为小尺寸未溶物逐步溶入基体中,数量减少且未溶物的类型由复杂逐渐转变为单一。Abstract: In this paper the solid solution behavior of the inhibitor under various holding time in 0.001 1 % La oriented silicon steel during reheating had been investigated by using OM, LM, methods of electrolytic extraction and mass spectrometer. The results showed that grain size of the test steel increased significantly with the holding time prolonging when the rare earth oriented silicon steel was heated to 1 250 ℃ and held for 10, 20 min and 30 min respectively, and the growth trend slowed down after holding time more than 20 minutes. As inhibitor elements, Mn, Cu and Al were all dissolving back, and holding time greatly influenced dissolution of Mn and Cu. The solid solubility of Mn and Cu increased from 69.8% and 43.7% to 84.2% and 85.2% respectively. Furthermore, with the prolongation of holding time, the insoluble small size inhibitors gradually decreased or even disappeared, and those larger ones gradually changed into small size insoluble substances and gradually dissolved into matrix in RE oriented silicon steel. The quantity decreased and the type of insoluble matter changed from complex to single gradually.

-

Key words:

- oriented silicon steel with rare earth La /

- heating time /

- inhibitor /

- solid solution

-

表 1 试验钢主要化学成分

Table 1. Main chemical compositions of the tested steel

% Si Mn Cu Ti Nb Alt C N S P La 3.04 0.21 0.52 0.0099 0.0090 0.076 0.038 0.0033 0.018 0.007 0.0011 -

[1] 何忠治, 赵宇, 罗海文. 电工钢[M]. 北京: 冶金工业出版社, 2012.He Zhongzhi, Zhao Yu, Luo Haiwen. Electrical steel[M]. Beijing: Metallurgical Industry Press, 2012. [2] 毛卫民, 杨平. 电工钢的材料学原理[M]. 北京: 高等教育出版社, 2013.Mao Weimin, Yang Ping. Material science principles on electrical steels[M]. Beijing: Higher Education Press, 2013. [3] Dong Lili, Lu Xiaoyu, Ma Yonglin. Influence of rare-earth element Ce on microstructure and texture of hot rolled oriented silicon steel[J]. Heat Treatment of Metals, 2020,45(9):220−223. (董丽丽, 卢晓禹, 麻永林. 稀土元素Ce对取向硅钢热轧钢带组织和织构的影响[J]. 金属热处理, 2020,45(9):220−223. [4] Lu Jiadong, Wu Shengjie, Yue Chongxiang, et al. Effect of secondary annealing temperature on microstructure and magnetic properties of non-oriented silicon steel[J]. Heat Treatment of Metals, 2021,46(3):67−71. (陆佳栋, 吴圣杰, 岳重祥, 等. 二次退火温度对无取向硅钢组织和磁性能的影响[J]. 金属热处理, 2021,46(3):67−71. [5] Zhang Bo, Meng Li, Zhang Ning, et al. Research progress of ultra-thin grain-oriented silicon steel[J]. Iron and Steel, 2020,55(10):96−102. (张波, 孟利, 张宁, 等. 超薄取向硅钢的研究进展[J]. 钢铁, 2020,55(10):96−102. [6] Qu Meiqing, Ren Huiping, Jin Zili, et al. Effect of Ce on microstructure and inhibitor evolution for 3% grain-oriented steel[J]. Heat Treatment of Metals, 2017,42(7):26−30. (渠美清, 任慧平, 金自力, 等. 稀土Ce对3%取向硅钢组织及抑制剂演变规律的影响[J]. 金属热处理, 2017,42(7):26−30. [7] Zhang Xin, Jin Zili, Ren Huiping, et al. Effect of rare earth Ce on as-cast precipitates of Cu-containing low-temperature grain-oriented silicon steel[J]. Heat Treatment of Metals, 2020,45(10):135−139. (张欣, 金自力, 任慧平, 等. 稀土Ce对含Cu低温取向硅钢铸态析出物的影响[J]. 金属热处理, 2020,45(10):135−139. [8] Suzuki S, Ushigami Y, Homma H, et al. Influence of metallurgical factors on secondary recrystallization of silicon steel[J]. Materials Transactiongs, 2001,42(6):994−1006. doi: 10.2320/matertrans.42.994 [9] Kumano T, Haratani T, Ushigami Y. The improvement of primary texture for sharp goss orientation on grain oriented silicon steel[J]. ISIJ International, 2007,43(5):736−745. [10] Zhou Bowen, Li Guangqiang, Zhu Chengyi, et al. The evolution of precipitate and microstructure during hot band annealing of grain-oriented silicon steel[J]. Journal of Chongqing University, 2017,40(10):70−78. (周博文, 李光强, 朱诚意, 等. 取向硅钢常化过程析出物和组织演变规律[J]. 重庆大学学报, 2017,40(10):70−78. doi: 10.11835/j.issn.1000-582X.2017.10.008 -

下载:

下载: