Study on dynamic mechanical properties and constitutive model of 022Cr18Ni14Mo2 stainless steel under impact load

-

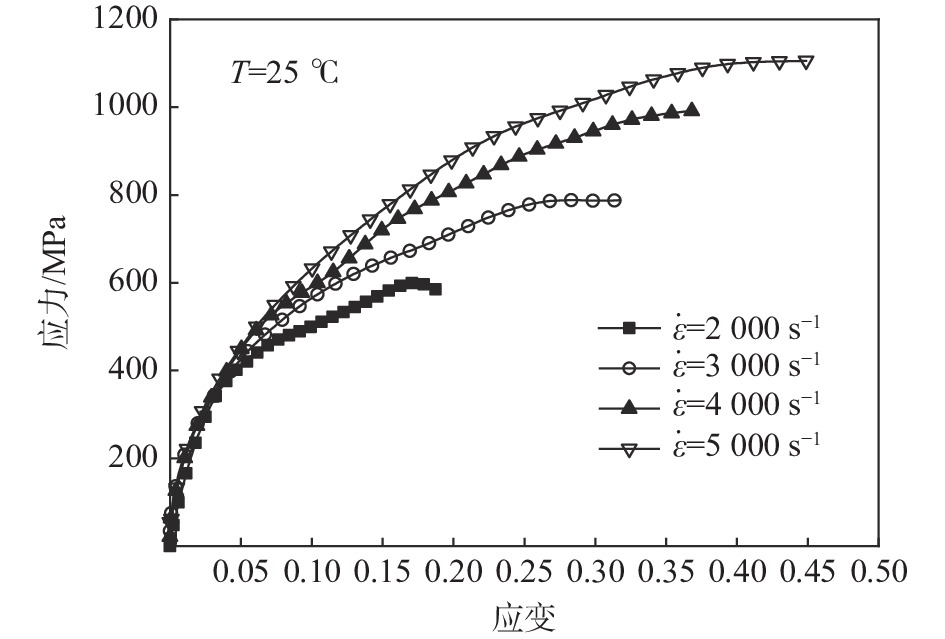

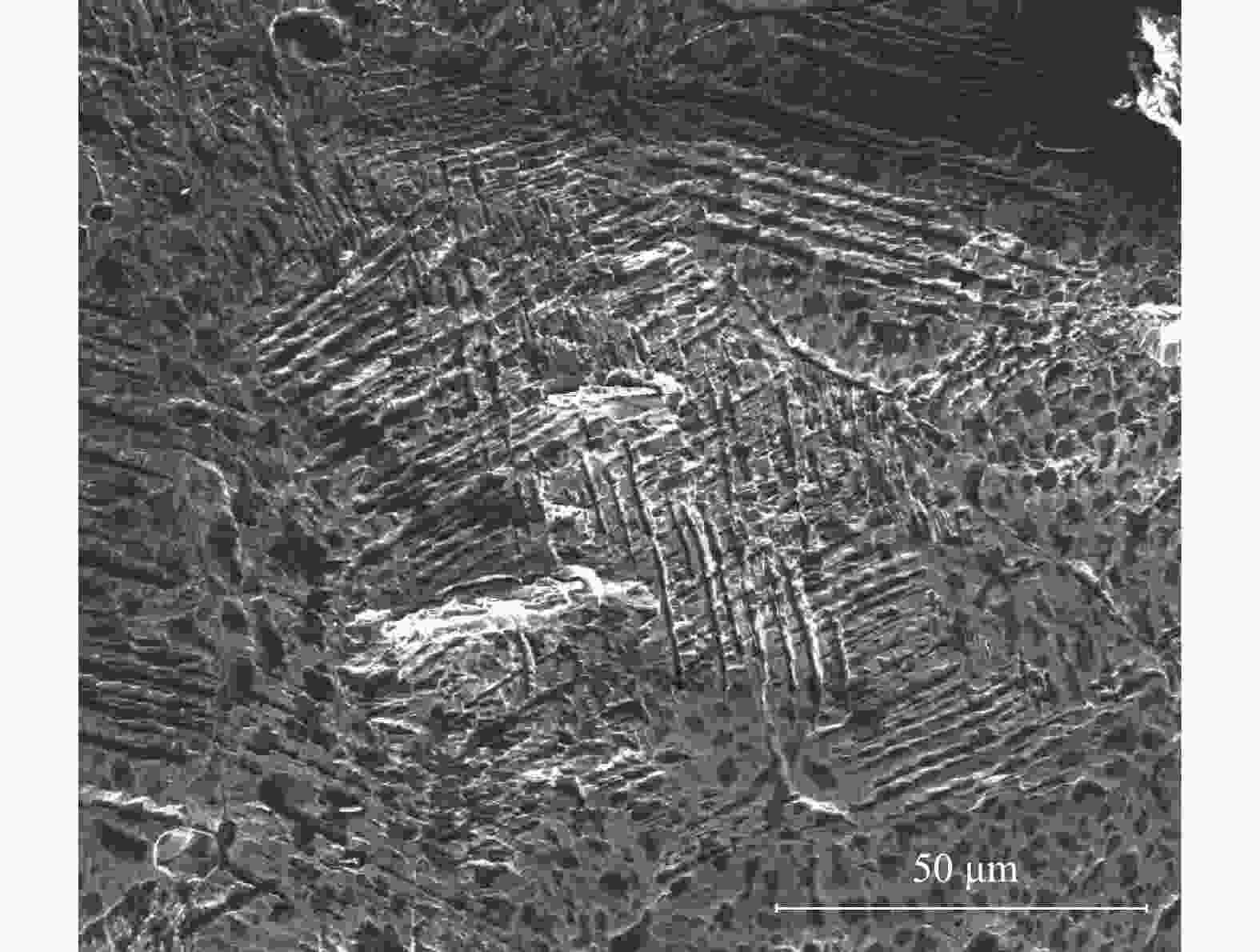

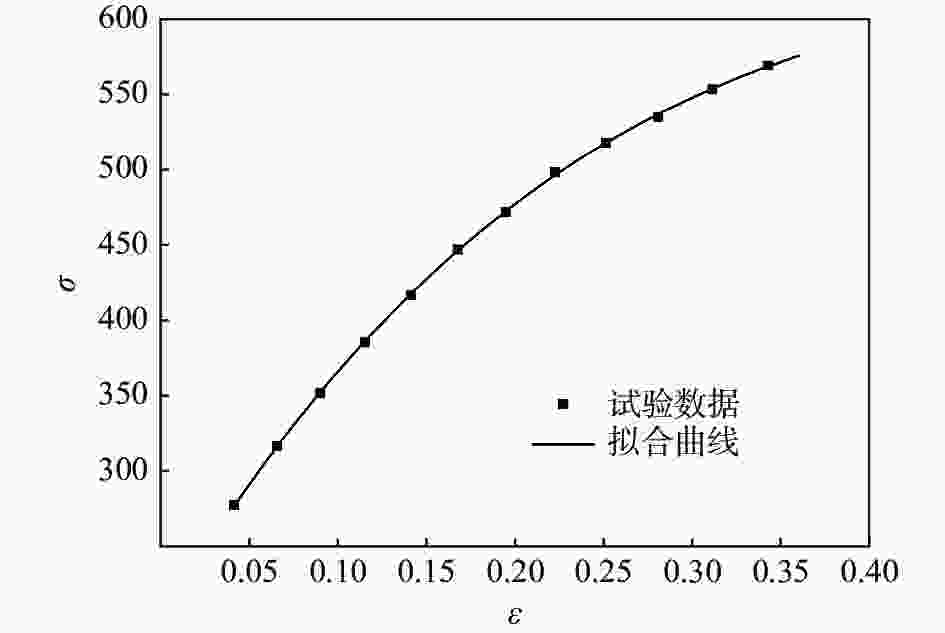

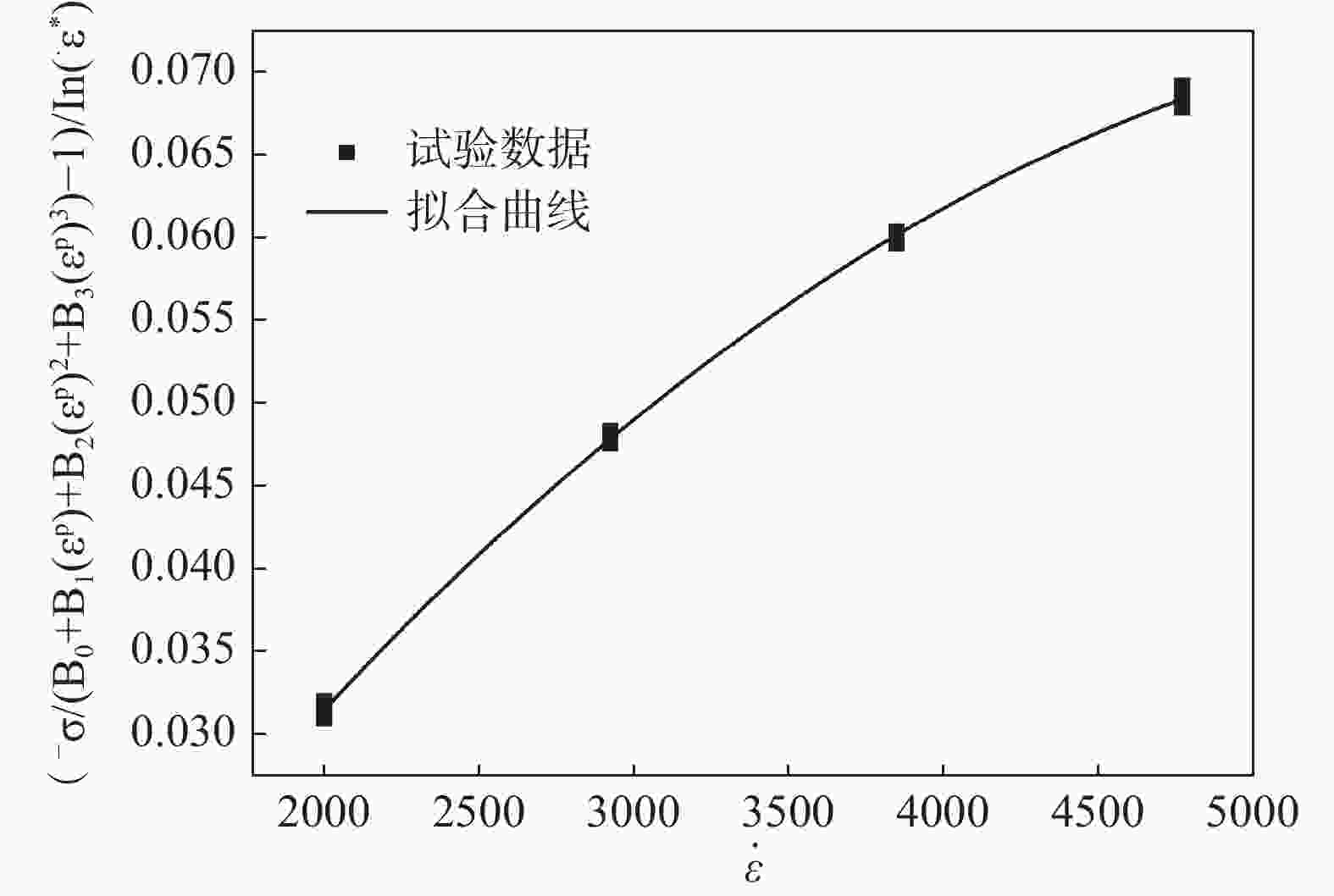

摘要: 利用UTM5305万能试验机和剖分式 Hopkinson 压杆装置,对022Cr18Ni14Mo2不锈钢进行了准静态及动态下的压缩试验研究,探讨了其应变硬化特征及流动应力对应变率的依赖程度,并结合应变强化指数

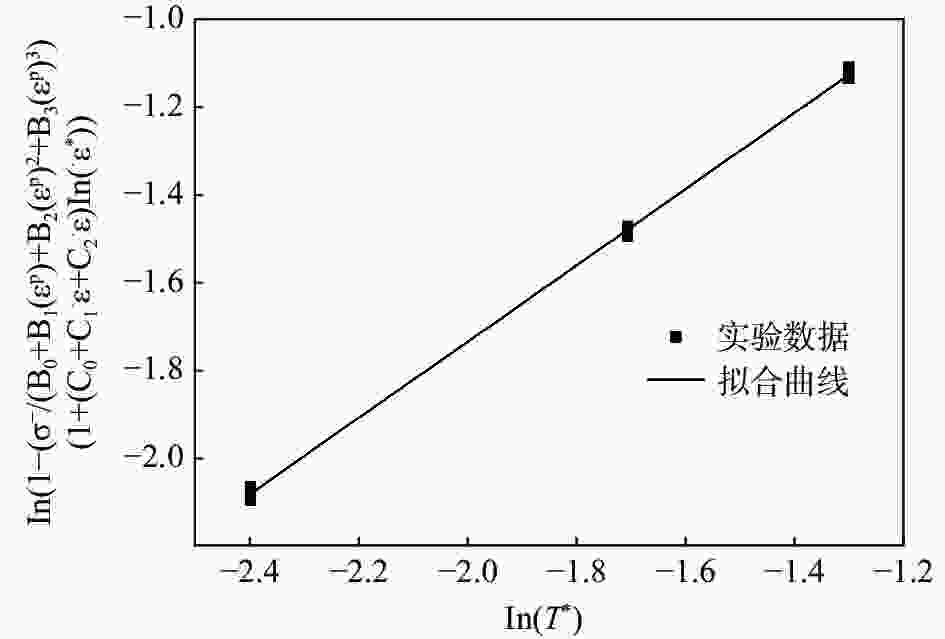

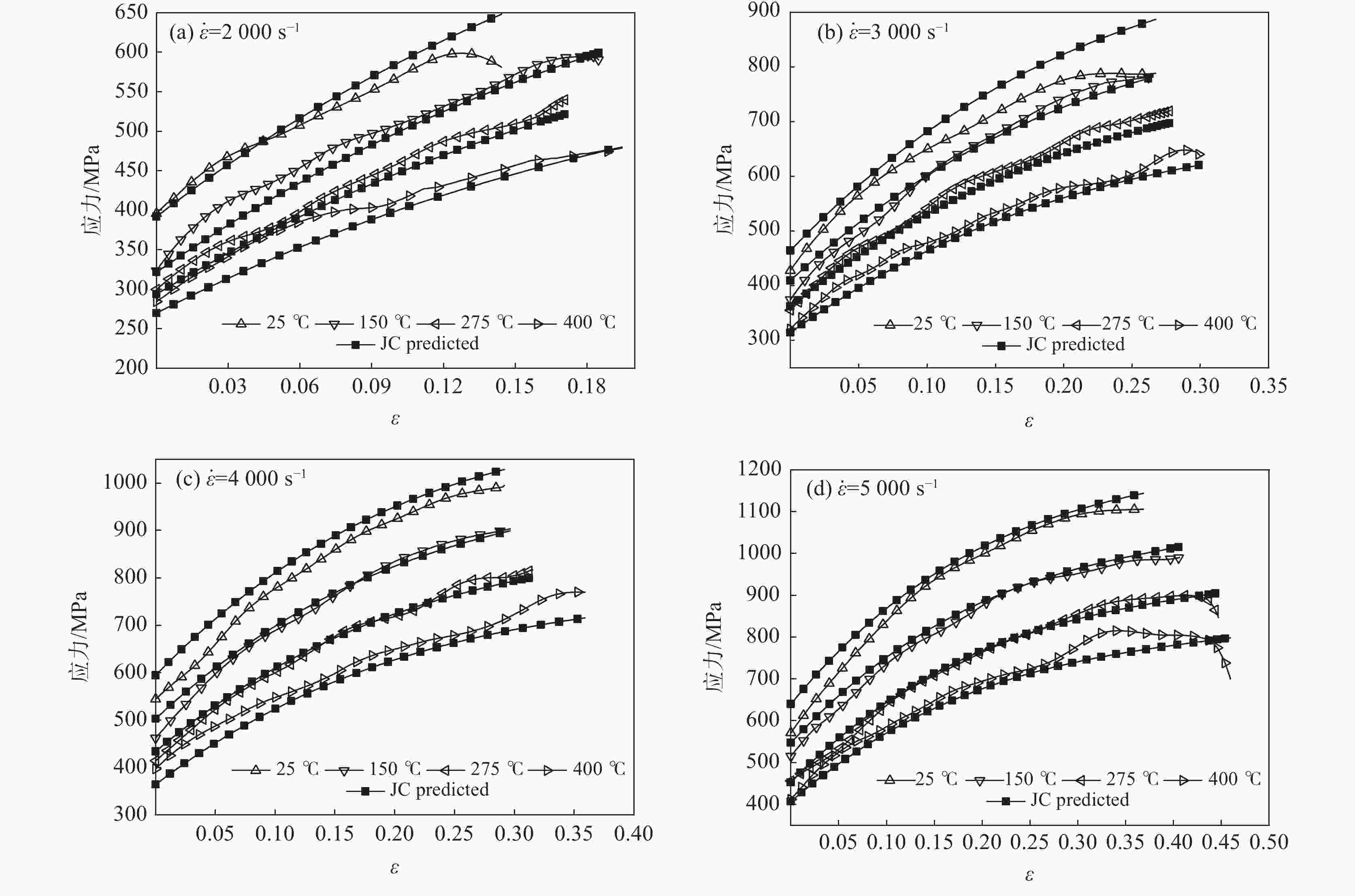

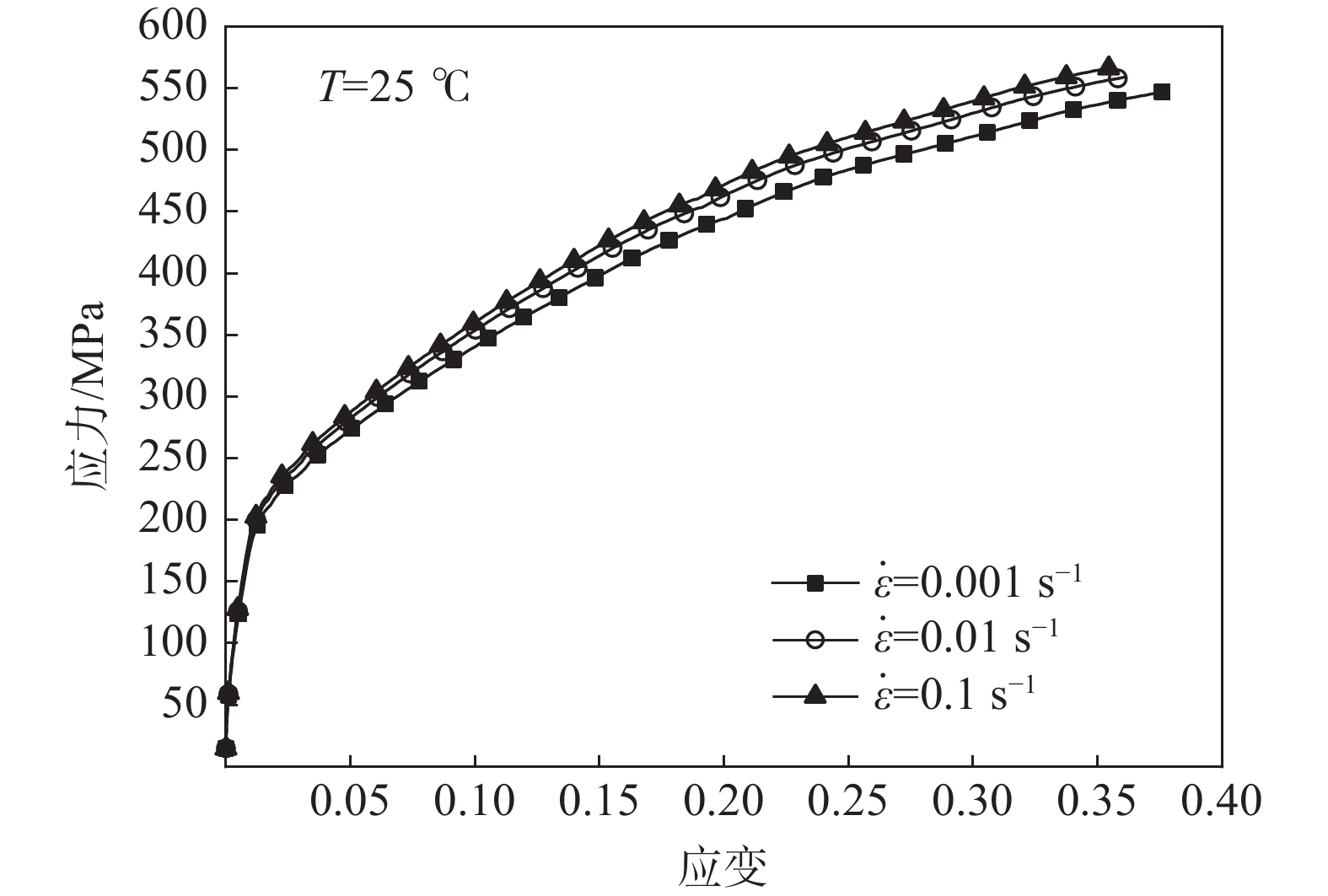

$ n $ 和应变率敏感性系数$ \beta $ 两个参量进行定量分析。依据上述分析结果,对传统的J-C本构模型进行修正,构建了一种新型的本构模型。借助试验数据对修正后的本构模型进行参数识别,将模型预测值与试验值进行对比分析,运用本构模型的相关系数(R)和平均相对误差(AARE)两个参量对其评价。结果表明:该试样具有明显应变硬化特性和显著的应变率敏感性,应变强化指数受应变、应变率的支配,应变率敏感性系数随应变率的增加而增加,且增加的幅度逐渐减小。修正后本构模型的相关系数(R)为0.9896,平均相对误差(AARE)为3.29%,能够较好地描述试样高温、高应变率下的流变行为。Abstract: The quasi-static and dynamic compression tests of 022Cr18Ni14Mo2 stainless steel were performed by using UTM5305 universal testing machine and split Hopkinson compression bar. The strain hardening characteristics and the dependence of flow stress on strain rate were discussed. The quantitative analysis was carried out by taking two parameters of strain hardening index and strain rate sensitivity coefficient into account. Based on the above analysis results, the traditional J-C constitutive model was revised and a new type of constitutive model was constructed. The parameters of the modified constitutive model are identified with the help of experimental data. The predicted values from the model are compared with the experimental values, and the correlation coefficient (R) and average relative error (AARE) of the constitutive model are used to evaluate it. The results show that the sample has obvious strain hardening characteristics and remarkable strain rate sensitivity. The strain hardening index is dominated by strain and strain rate, and the strain rate sensitivity coefficient increases with the increase of strain rate, and the increase amplitude decreases gradually. The correlation coefficient (R) and average relative error (AARE) of the modified constitutive model are 0.9896 and 3.29%, respectively, which can better describe the rheological behavior of specimens at high temperature and high strain rate. -

表 1 022Cr18Ni14Mo2不锈钢主要化学成分

Table 1. Main chemical compositions of 022Cr18Ni14Mo2 stainless steel

% C Si Mn P S Ni Cr 0.08 0.75 2.00 0.045 0.03 8.22 18.89 表 2 不同应变率、应变处的应变硬化指数

Table 2. The strain hardening index of steel impacted at different strain rate and strain

$ \dot \varepsilon $/s−1n ε=0.1 ε=0.15 ε=0.20 ε=0.25 ε=0.30 0.01

2 000

3000

4000

50000.8625

0.8458

0.7946

0.7654

0.75370.8025

0.8679

0.7609

0.7401

0.73070.7258

0.6918

0.6459

0.63290.6984

0.6539

0.6016

0.58460.6127

0.5569

0.5409

0.5284表 3 不同应变率下的应变率敏感性系数

Table 3. Strain rate sensitivity coefficient at different strain rates

$ \dot \varepsilon $/s−1 应变率敏感性系数$ \beta $ 2 000

3000

4000

500011.1538

18.6619

22.9458

25.0159表 4 修正的J-C本构模型平均绝对误差值

Table 4. The average absolute error value of the modified J-C constitutive model

$ \dot \varepsilon $/ s−1 平均绝对误差/MPa 25 ℃ 150 ℃ 275 ℃ 400 ℃ 2 000

3000

4000

500015.66077754

46.80494841

35.88938985

27.7377781614.22130679

13.12439042

12.00604471

16.3348663622.0703322632919

15.3002801865349

10.0440919796945

10.751980414012619.5186443920757

18.3288671876173

29.0687297003203

24.8034712635893 -

[1] Elmesalamy A S, Francis J A, Li L. A comparison of residual stresses in multi pass narrow gap laser welds and gas-tungsten arc welds in AISI 316L stainless steel[J]. International Journal of Pressure Vessels and Piping, 2014,113:49−59. doi: 10.1016/j.ijpvp.2013.11.002 [2] Shang Y, Yuan Y, Li D, et al. Effects of scanning speed on in vitro biocompatibility of 316L stainless steel parts elaborated by selective laser melting[J]. The International Journal of Advanced Manufacturing Technology, 2017,92(9):4379−4285. [3] Otero E, Pardo A, Utrilla M V, et al. Corrosion behaviour of AISI 304 L and AISI 316L stainless steels prepared by powder metallurgy in the presence of sulphuric and phosphoric acid[J]. Corrosion Science, 1998,40(8):1421−1434. doi: 10.1016/S0010-938X(98)00047-X [4] Ehab Ellobody, Ben Young. Structural performance of cold-formed high strength stainless steel columns[J]. Journal of Constructional Steel Research, 2005,61(2):1631−1649. [5] Liu Zhenbao, Liang Jianxiong, Su Jie, et al. Research and development status of high-strength stainless steel[J]. Acta Metallurgica Sinica, 2020,56(4):449−554. (刘振宝, 梁剑雄, 苏杰, 等. 高强度不锈钢的研究及发展现状[J]. 金属学报, 2020,56(4):449−554. [6] Guo Pengcheng, Cao Shufen, Ye Tuo, et al. Mechanical constitutive equation and simulation of AM80 magnesium alloy under high speed impact load[J]. The Chinese Journal of Nonferrous Metals, 2017,27(6):1075−1082. (郭鹏程, 曹淑芬, 叶拓, 等. 高速冲击载荷下AM80镁合金的力学本构及仿真模拟[J]. 中国有色金属学报, 2017,27(6):1075−1082. [7] Noble J P, Goldthorpe B D, Church P. The use of the Hopkinson bar to validate constitutive relations at high rates of strain[J]. Journal of the Mechanics & Physics of Solids, 1999,47(5):1187−1206. [8] Ravichandran G, Subhash G. Critical appraisal of limiting strain rates for compression testing of ceramics in a split hopkinson pressure bar[J]. Journal of the American Ceramic Society, 1994,77(1):263−267. doi: 10.1111/j.1151-2916.1994.tb06987.x [9] Li Yulong, Suo Tao, Guo Weiguo, et al. Hopkinson pressure bar system for determining the dynamic performance of materials at high temperature and high strain rate[J]. Explosion and Shock, 2005,25(6):487−492. (李玉龙, 索涛, 郭伟国, 等. 确定材料在高温高应变率下动态性能的Hopkinson压杆系统[J]. 爆炸与冲击, 2005,25(6):487−492. [10] Yan Qiushi, Sun Bowen, Yang Lu. Study on dynamic mechanical behavior of structural stainless steel at elevated temperature and high strain rate[J]. Journal of Huazhong University of Science and Technology(Natural Science Edition), 2019,47(5):128−132. (闫秋实, 孙博文, 杨璐. 高温高应变率下建筑不锈钢动态力学性能研究[J]. 华中科技大学学报(自然科学版), 2019,47(5):128−132. [11] Wu Liang, Hu Yisen, Ji Xiang, et al. Research on dynamic mechanical properties and constitutive model of martensitic precipitation hardening stainless steel FV520B[J]. Mechanical Strength, 2018,40(3):79−83. (吴亮, 胡毅森, 纪翔, 等. 马氏体沉淀硬化不锈钢FV520B动态力学性能及本构模型的研究[J]. 机械强度, 2018,40(3):79−83. [12] Lee W S, Chen T H, Lin C F, et al. Dynamic mechanical response of biomedical 316L stainless steel as function of strain rate and temperature[J]. Bioinorganic Chemistry and Applications, 2011,2011(8):1−13. [13] He Zhu, Zhao Shougeng, Yang Jialing, et al. Research on dynamic mechanical properties of 0Cr17Ni4Cu4Nb stainless steel[J]. Journal of Materials Science and Engineering, 2007,25(3):418−421. (何著, 赵寿根, 杨嘉陵, 等. 0Cr17Ni4Cu4Nb不锈钢动态力学性能研究[J]. 材料科学与工程学报, 2007,25(3):418−421. doi: 10.3969/j.issn.1673-2812.2007.03.024 [14] Peng J, Li K S, Pei J F, et al. Temperature-dependent SRS behavior of 316 L and its constitutive model[J]. Acta Metallurgica Sinica (English Letters), 2018,31(3):234−244. doi: 10.1007/s40195-017-0697-x [15] 周惠久, 黄明志. 金属材料强度[M]. 北京: 科学出版社, 1989.Zhou Huijiu, Huang Mingzhi. Strength of metal materials[M]. Beijing: Science Press, 1989. [16] 李庆生. 材料强度学[M]. 太原: 山西科学教育出版社, 1990.Li Qingsheng. Material strength[M]. Taiyuan: Shanxi Science Education Press, 1990. [17] Fang Jian, Wei Yijing, Wang Chengzhong. Analytical measurement and mechanical analysis of tensile strain hardening index[J]. Journal of Plasticity Engineering, 2003,10(3):12−17. (方健, 魏毅静, 王承忠. 拉伸应变硬化指数的解析测定及力学分析[J]. 塑性工程学报, 2003,10(3):12−17. doi: 10.3969/j.issn.1007-2012.2003.03.003 [18] Sun Xuewei, Ling Yongzhuo, Sun Jisong, et al. A method of determining strain-hardening exponents[J]. Mechanical Strength, 1995,17(4):27−28. (孙学伟, 令永卓, 孙吉松, 等. 材料硬化指数n的确定方法[J]. 机械强度, 1995,17(4):27−28. [19] 冯端. 金属物理学-金属力学性能[M]. 北京: 科学出版社, 1999.Feng Duan. Metal physics-mechanical properties of metals[M]. Beijing: Science Press, 1999. [20] 史巨元. 钢的动态力学性能及应用[M]. 北京: 冶金工业出版社, 1993.Shi Juyuan. The dynamic mechanical properties and application of steel[M]. Beijing: Metallurgical Industry Press, 1993. [21] Johnson G R, Cook W H. A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures[J]. Engineering Fracture Mechanics, 1983,21:541−548. [22] Shu Chang, Cheng Li, Xu Yu. Research on Johnson-Cook constitutive model parameter estimation[J]. The Chinese Journal of Nonferrous Metals, 2020,30(5):1073−1083. (舒畅, 程礼, 许煜. Johnson-Cook本构模型参数估计研究[J]. 中国有色金属学报, 2020,30(5):1073−1083. [23] Shokry, Abdallah. A modified Johnson–Cook model for flow behavior of alloy 800 H at intermediate strain rates and high temperatures[J]. Journal of Materials Engineering and Performance, 2017,26(12):5723−5730. doi: 10.1007/s11665-017-3076-x [24] Zhang Bing, Yue Lei, Chen Hanfeng, et al. Hot deformation behavior of as-cast GH4169 alloy and comparison of three constitutive models[J]. Rare Metal Materials and Engineering, 2021,50(1):212−222. (张兵, 岳磊, 陈韩锋, 等. 铸态GH4169合金热变形行为及三种本构模型对比[J]. 稀有金属材料与工程, 2021,50(1):212−222. [25] Sheikhali A H, Morakkabati M. Constitutive modeling for hot working behavior of SP-700 titanium alloy[J]. Journal of Materials Engineering and Performance, 2019,28(10):6525−6537. doi: 10.1007/s11665-019-04355-x -

下载:

下载: