Study on microstructure and properties of high aluminum dual phase steel 980DH with high formability

-

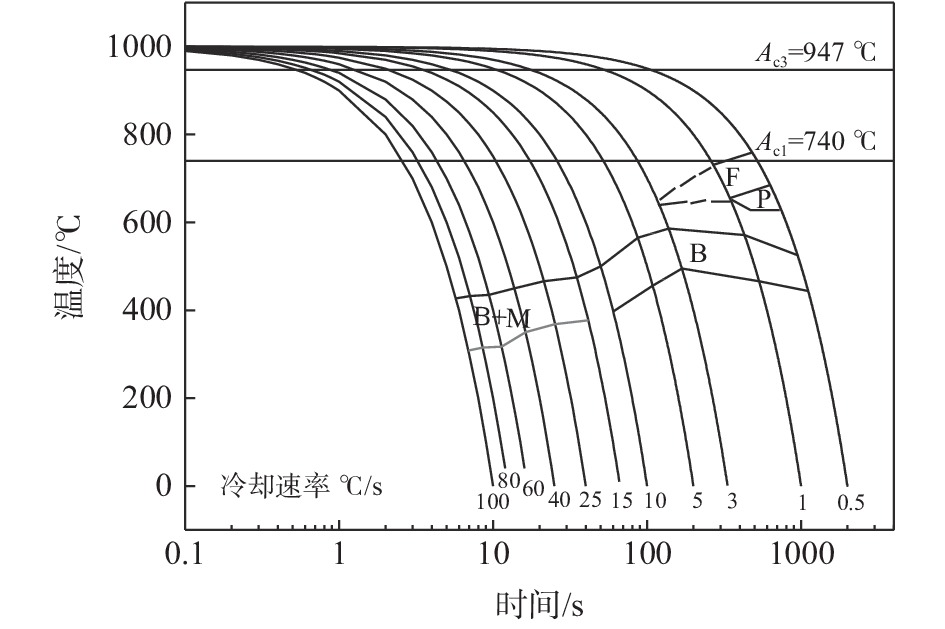

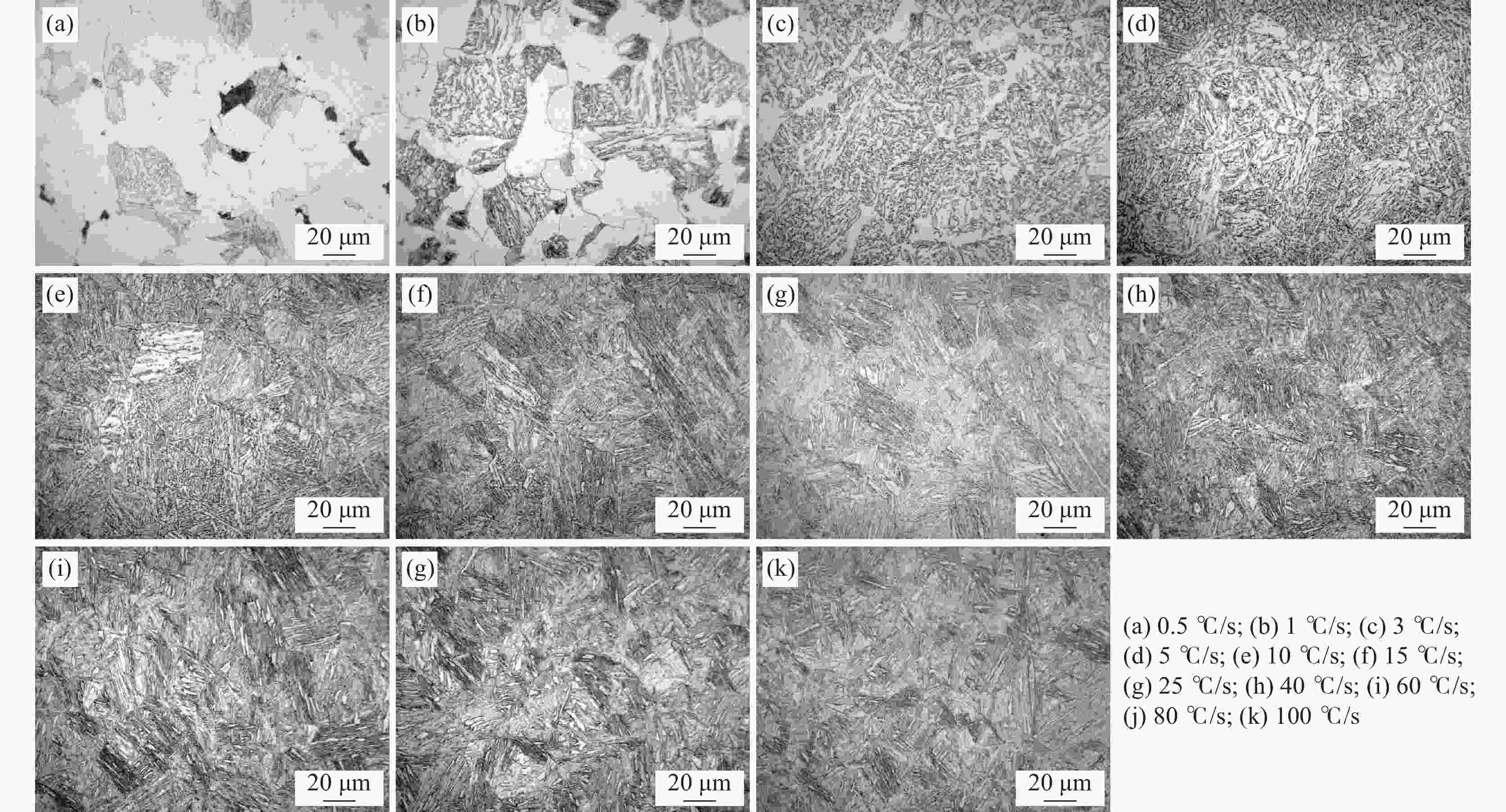

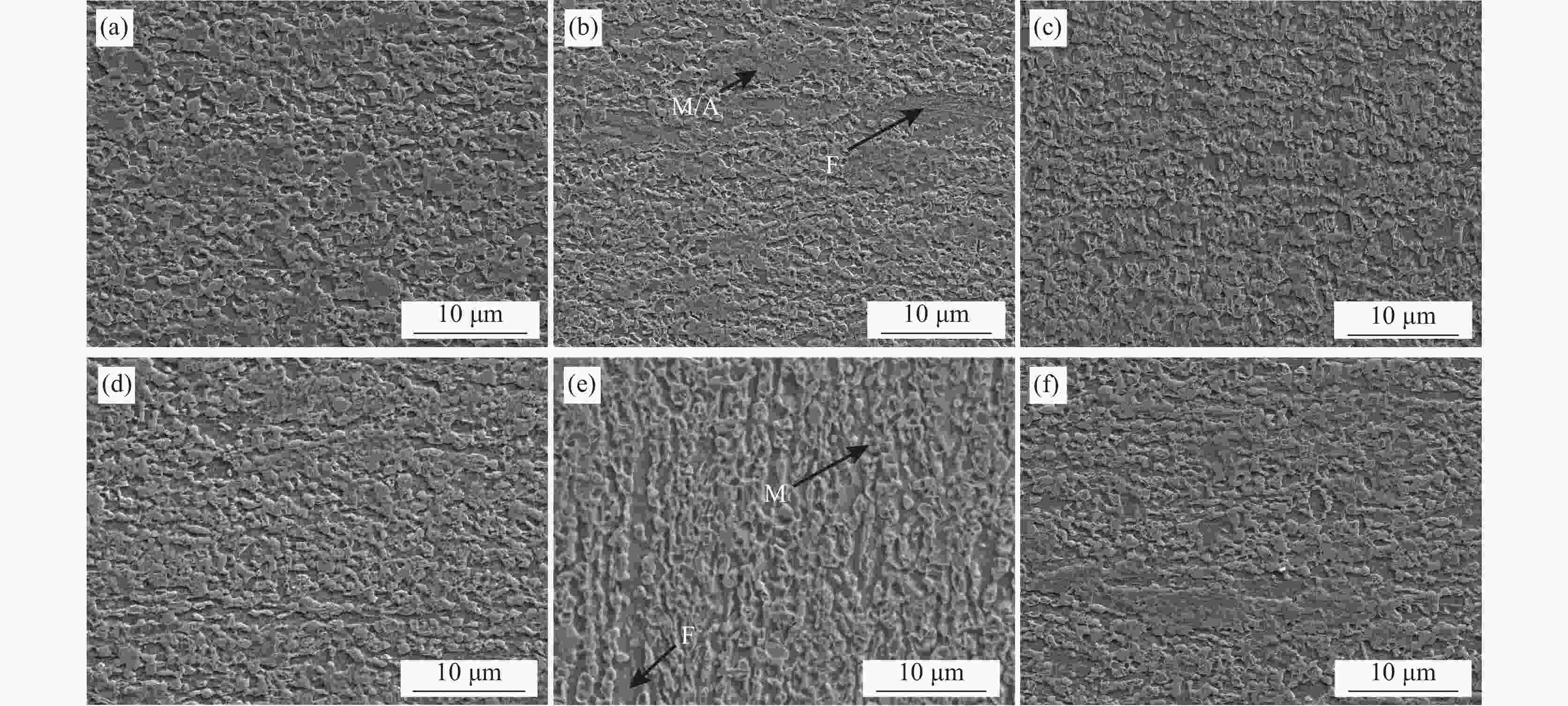

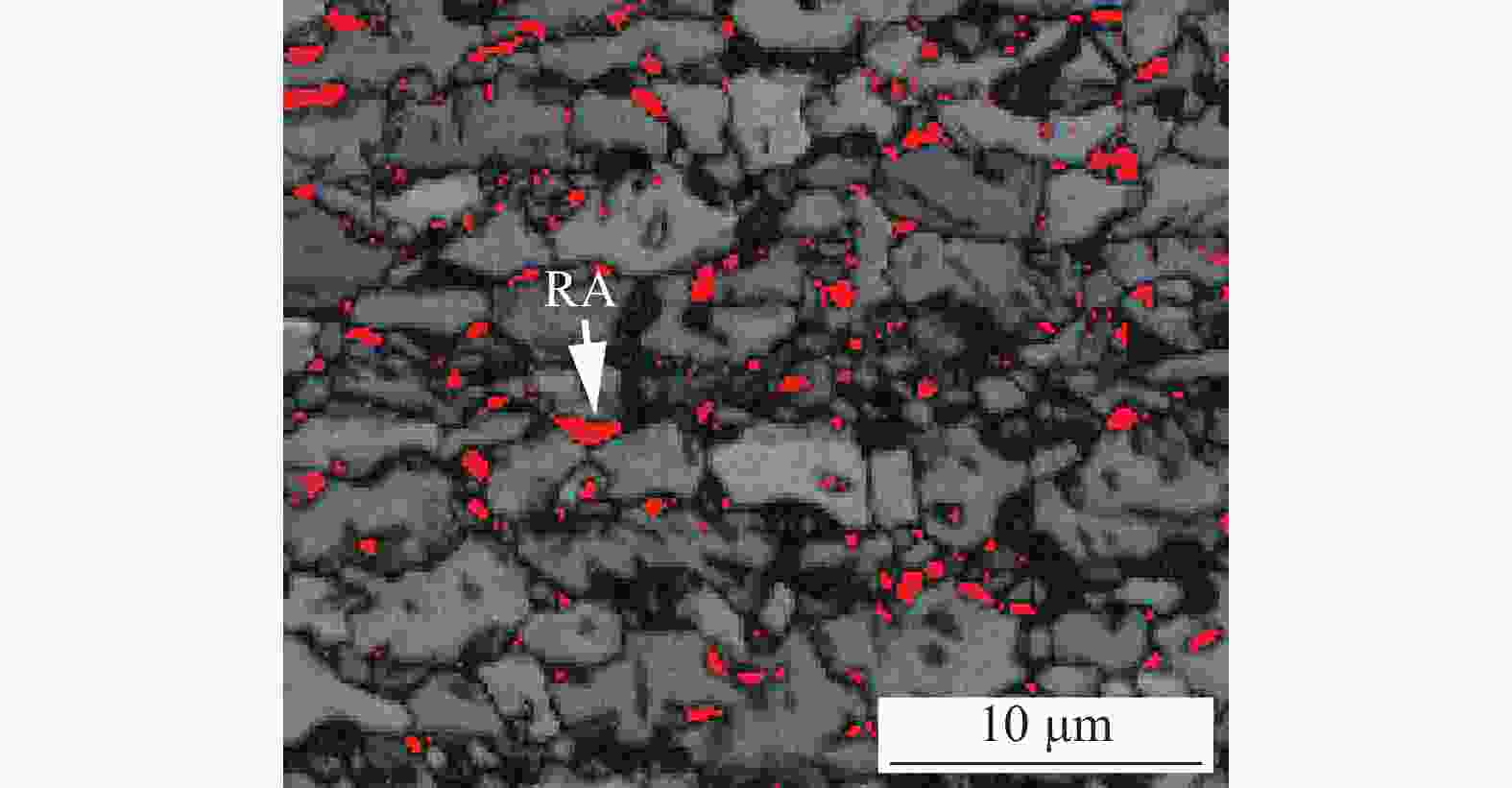

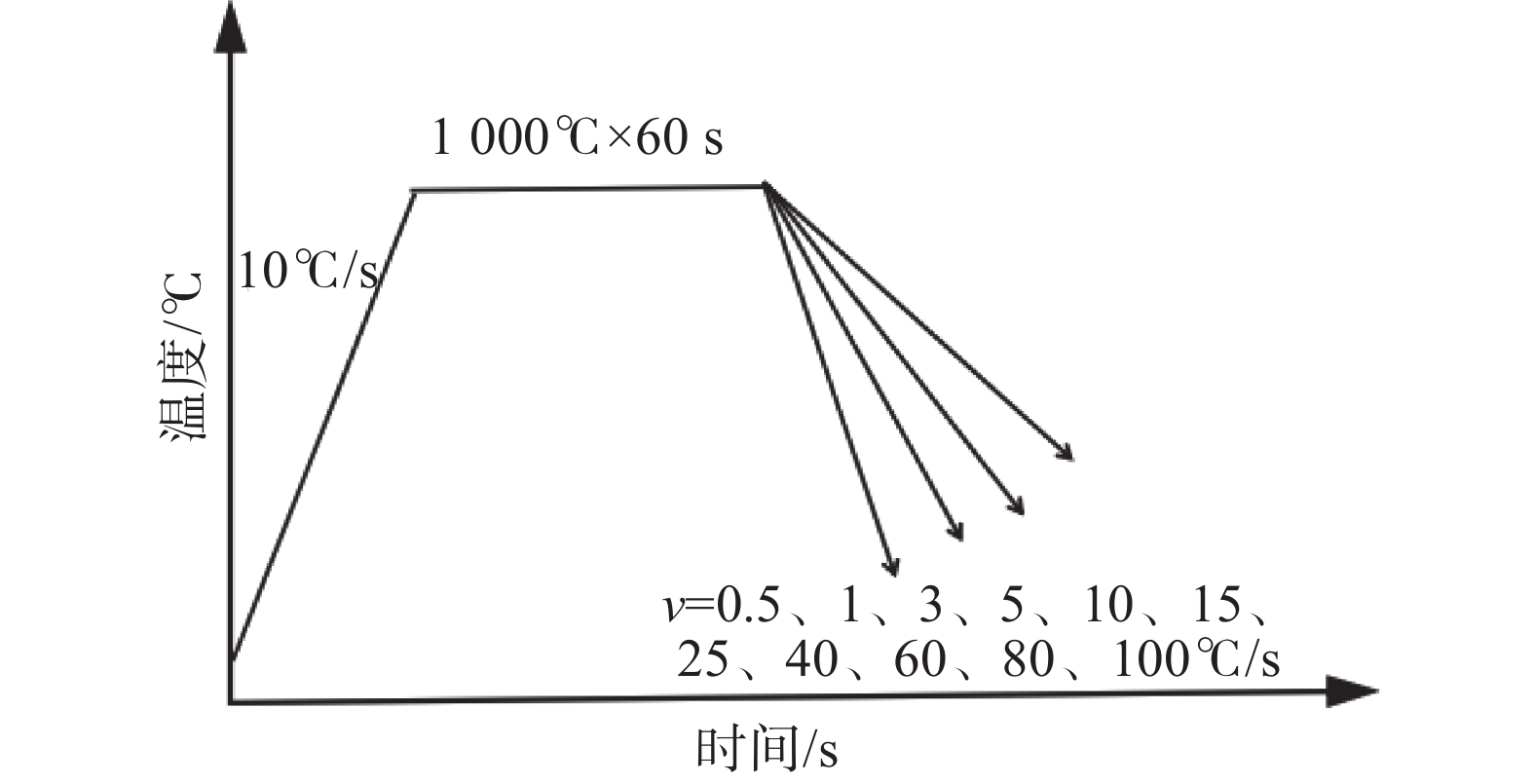

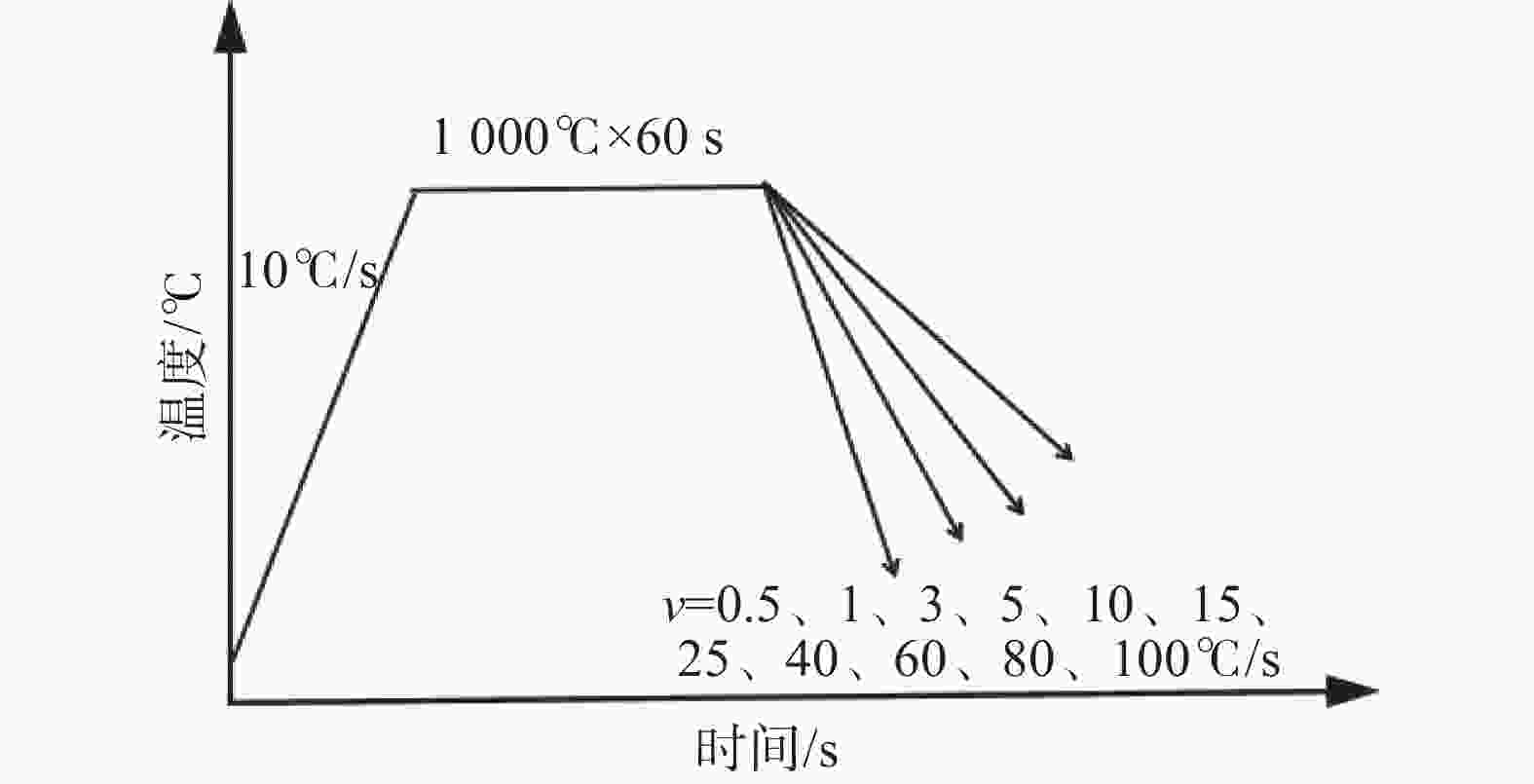

摘要: 采用相变淬火膨胀仪、连退热模拟试验机等开展高铝增强成形性双相钢980DH静态连续冷却转变、连续退火工艺对冷轧板组织、性能的影响规律研究。结果显示:冷却速率在5~10 ℃/s,只发生贝氏体相变;当冷速>15 ℃/s后,随着冷速的提高,贝氏体占比减少,马氏体含量增加;980DH钢基体组织主要为铁素体、马氏体和残余奥氏体;均热温度(780~800 ℃)×160 s、缓冷温度650~700 ℃、冷却速率50 ℃/s快冷至300 ℃,保温5 min时效处理后空冷至室温,可获得性能优异的CR550/980DH。研究结果对工业开发高级别DH钢具有指导意义。Abstract: The influence of static continuous cooling transformation and continuous annealing process on the structure and properties of cold-rolled plates for high aluminum dual phase steel 980DH with high formability were studied by phase transformation quenching dilatometer, continuous annealing simulation tester. The results show that when the cooling rate is between 5 °C/s and 10 °C/s, only bainite transformation occurs. When the cooling rate is greater than 15 °C/s, the proportion of bainite decreases and the fraction of martensite increases as the cooling rate increases. The microstructure of 980DH steel contain mainly ferrite, martensite and retained austenite. Under the processing conditions of soaking temperature at (780~800 ℃)×160 s, slow cooling temperature at 650~700 ℃, cooling rate at 50 ℃/s to 300 ℃ aging treatment for 5 minutes, and then air-cooled to room temperature, CR550/980DH steel plates can achieve excellent performance. It is hoped that this research can be beneficial to the industrial development of high-grade DH steel.

-

Key words:

- dual phase steel /

- 980DH /

- static CCT curve /

- microstructure /

- property /

- retained austenite

-

表 1 试验钢980DH主要化学成分

Table 1. Main chemical compositions of experimental steel 980DH

% C Si Mn P S Als Nb Ti Cr Mo 0.12 0.40 2.0 0.012 0.008 0.55 0.025 0.015 0.25 0.20 表 2 试验方案及力学性能

Table 2. Experimental scheme and mechanical properties

方案 均热温度/℃ 缓冷温度/℃ 快冷温度/℃ Rp0.2/MPa Rm/MPa A/% 1 820 700 300 606 1062 14.51 2 800 700 300 561 1034 16.41 3 780 700 300 638 1075 16.45 4 800 680 300 581.7 1027.5 16.03 5 800 650 300 579.7 1038.8 16.41 6 800 720 300 604 1046.5 14.96 -

[1] 唐荻, 赵征志, 米振莉, 等. 汽车用先进高强板带钢[M]. 北京: 冶金工业出版社, 2016.Tang Di, Zhao Zhengzhi, Mi Zhenli, et al. Advanced high strength strip steel for automobile[M]. Beijing: Metallurgical Industry Press, 2016. [2] Kang Yonglin. Light weight vehicle, advanced high strength steel and energy-saving and emission reduction[J]. Iron and Steel, 2008,43(6):1−7. (康永林. 汽车轻量化先进高强钢与节能减排[J]. 钢铁, 2008,43(6):1−7. doi: 10.3321/j.issn:0449-749X.2008.06.001 [3] 康永林. 现代汽车板工艺及成形理论与技术[M]. 北京: 冶金工业出版社, 2009.Kang Yonglin. Theory and technolog of processing and forming for advanced automobile steel sheets[M]. Beijing: Metallurgical Industry Press, 2009. [4] Liang Jiangtao, Zhao Zhengzhi, Liu Kun, et al. Microstructure and properties of 1300 MPa grade Nb microalloying DH steel[J]. Chinese Journal of Engineering, 2021,43(3):392−399. (梁江涛, 赵征志, 刘锟, 等. 1300 MPa级Nb微合金化DH钢的组织性能[J]. 工程科学学报, 2021,43(3):392−399. [5] 张伟, 李春光, 林兴明, 等. 基于压溃试验增强成形性双相钢吸能特性分析[C]//第十二届中国钢铁年会论文集—5. 金属材料深加工. 中国金属学会, 2019: 7.Zhang Wei, Li Chunguang, Lin Xingming, et al. Analysis of energy absorption characteristics of dual phase steel with high formability based on drop test[C]// Proceedings of the 12th China Iron and Steel Annual Conference – 5: Deep Processing of Metal Materials. Chinese Society of Metals, 2019: 7. [6] Lu Lin, Tang Di, Jiang Haitao. Microstructure and properties of high aluminum 1000 MPa cold rolling hot dip galvanized dual phase steel[J]. Transactions of Materials and Heat Treatment, 2015,36(4):116−120. (卢淋, 唐荻, 江海涛. 高铝1000 MPa级热镀锌双相钢的组织和性能[J]. 材料热处理学报, 2015,36(4):116−120. [7] Wang Xiaojie. Study on surface longitudinal crack of W780QX slab[J]. Hebei Metallurgy, 2020,(4):49−52. (王肖杰. 高铝双相钢W780QX板坯表面纵裂研究[J]. 河北冶金, 2020,(4):49−52. [8] Wang Chang, Yu Yang, Gao Xiaoli, et al. Oxidation characteristic of high aluminum bearing double phase steel[J]. China Metallurgy, 2016,26(9):23−27. (王畅, 于洋, 高小丽, 等. 高铝双相钢氧化特性规律[J]. 中国冶金, 2016,26(9):23−27. [9] Wang Hui, Deng Zhaojun, Lin Chengjiang, et al. Effect of temper-aging temperature on the microstructures and properties of the annealed high aluminum dual phase steel[J]. Rare Metal Materials and Engineering, 2011,40(S2):184−187. (王辉, 邓照军, 林承江, 等. 连退时效温度对高铝双相钢组织及性能的影响[J]. 稀有金属材料与工程, 2011,40(S2):184−187. [10] Deng Zhaojun, Liu Jing, Wang Hui, et al. Influence of annealing temperature on microstructure of a high aluminum dual phase steel[J]. Transactions of Materials and Heat Treatment, 2011,32(3):111−114. (邓照军, 刘静, 王辉, 等. 退火温度对高铝双相钢微观组织的影响[J]. 材料热处理学报, 2011,32(3):111−114. -

下载:

下载: