Study on vacuum electron beam welding process of 50 mm thick plate TC4 and TA17 titanium alloys

-

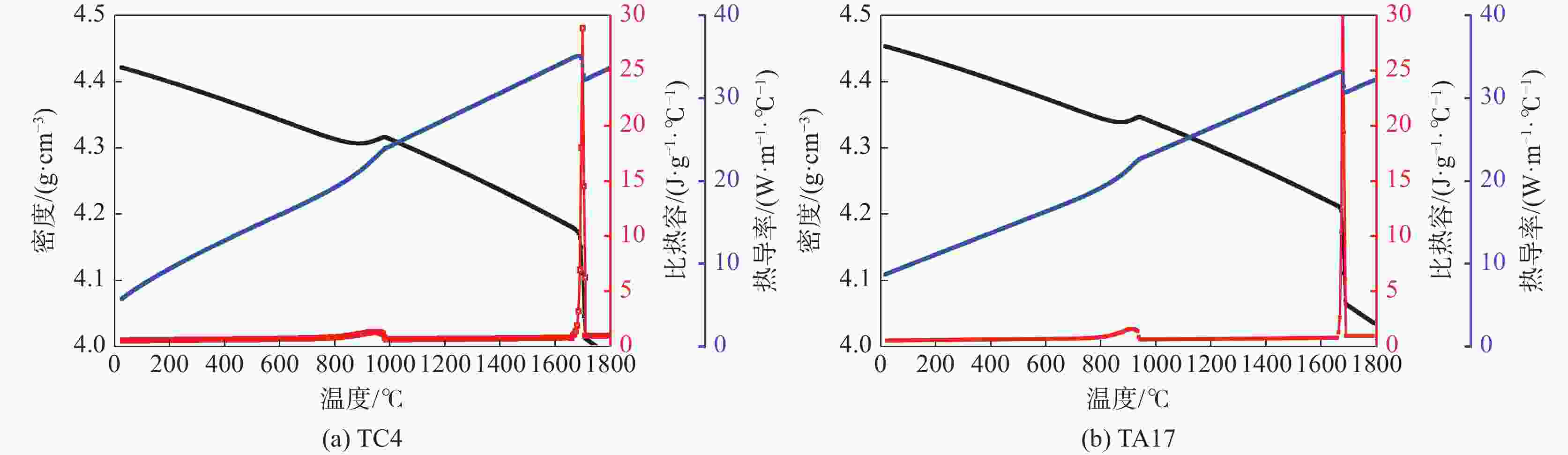

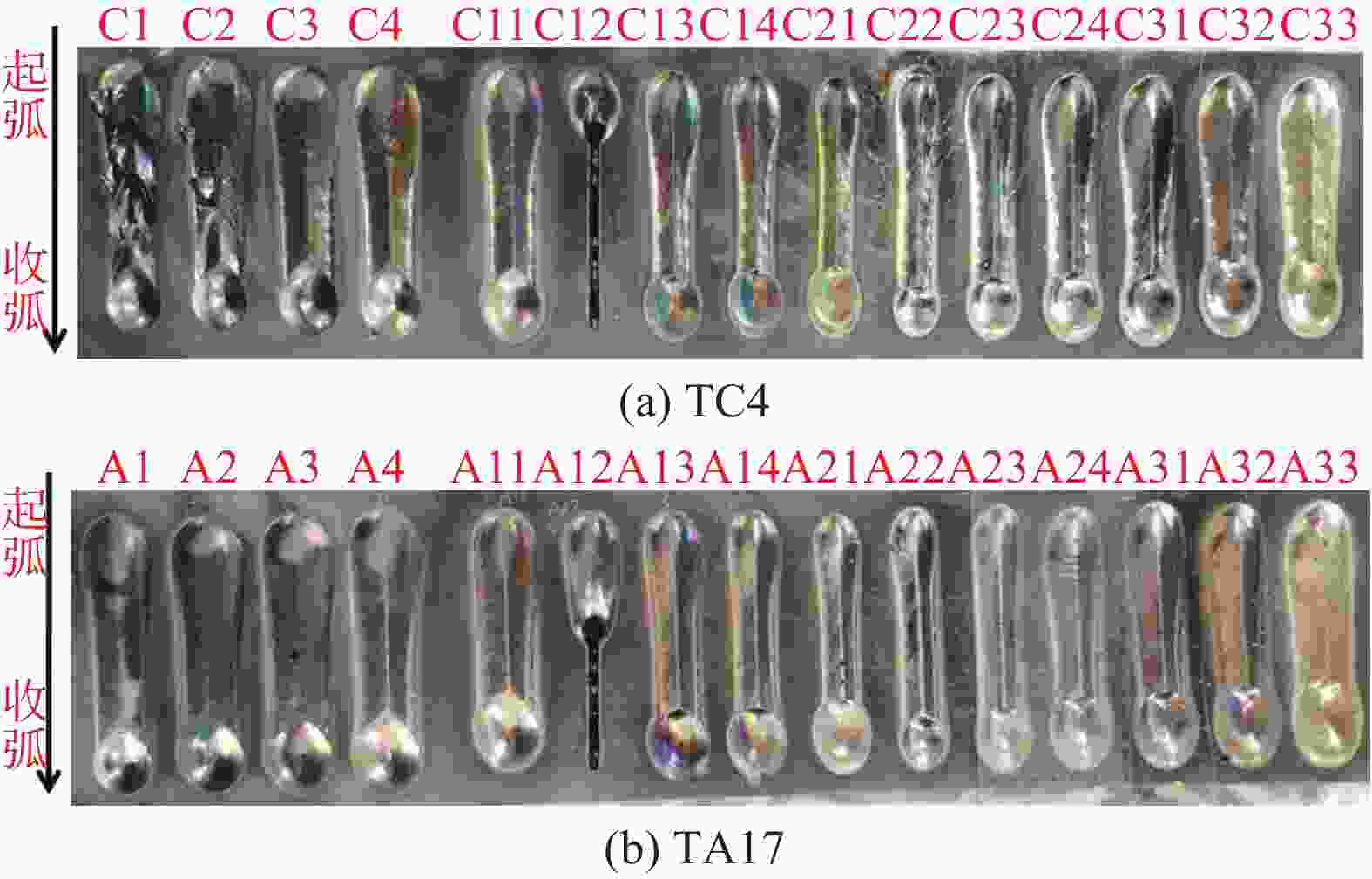

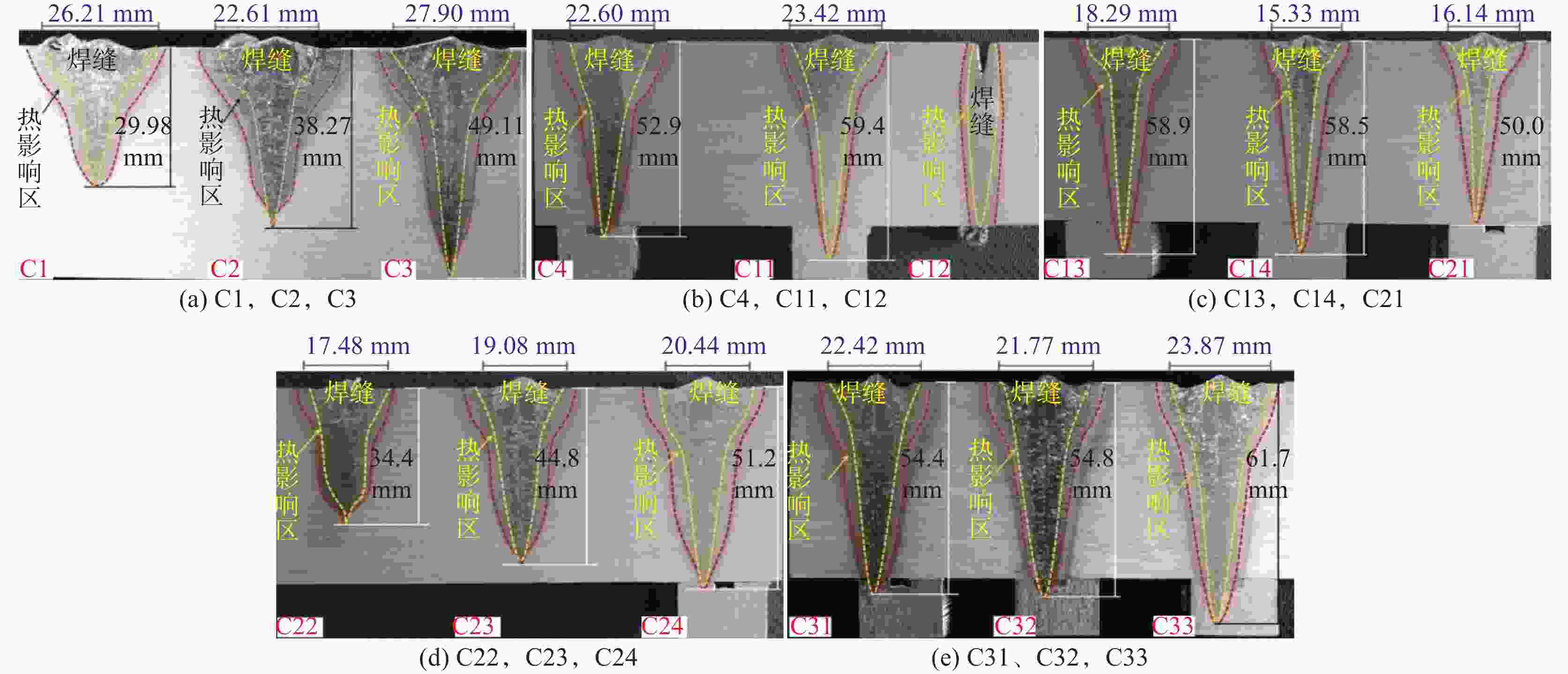

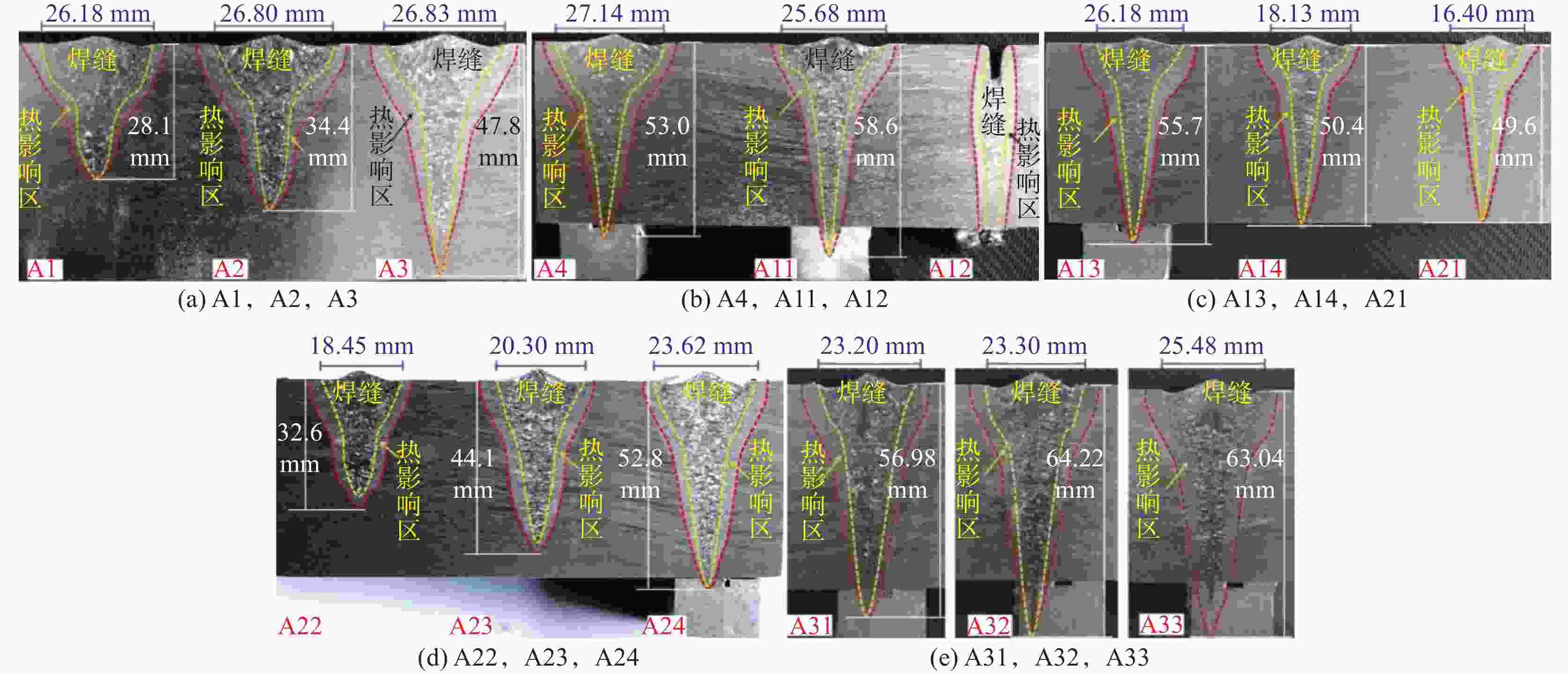

摘要: 采用JMATPRO热力学软件,在分析TC4和TA17钛合金的密度、比热和导热率等特性的基础上,开展了厚度50 mm的TC4和TA17钛合金真空电子束焊接试验,设计了高压和中压加速电压,不同焊接束流和焊接速度的参数变化,研究了焊接工艺参数对焊缝熔宽和熔深及焊缝成形系数的影响作用。试验结果表明,相同焊接工艺参数条件下TC4钛合金的熔深和焊缝成形系数较TA17高,焊接束流对熔深和焊缝成形系数影响能力最为突出,加速电压150 kV的高压更适合于大厚板钛合金的真空电子束焊接。Abstract: Based on the analysis of the density, specific heat and thermal conductivity of TC4 and TA17 titanium alloys by using JMATPRO thermodynamic software, the vacuum electron beam welding experiments of TC4 and TA17 titanium alloys with a thickness of 50 mm were carried out. The parameters of high and medium voltage accelerating voltage, different welding beam current and welding speed were designed. The effects of welding process parameters on weld width, penetration and weld forming coefficient were studied. The test results show that the penetration and weld forming coefficient of TC4 titanium alloy are higher than TA17 under the same welding process parameters. The influence of welding beam current on penetration and weld forming coefficient is the most prominent. The high voltage of accelerating voltage 150 kV is more suitable for vacuum electron beam welding of large and thick titanium alloys.

-

Key words:

- titanium alloys /

- TC4 /

- TA17 /

- vacuum electron beam welding

-

表 1 TC4和TA17钛合金化学成分分析结果

Table 1. Chemical compositions of TC4 and TA17 titanium alloys

% 牌号 Al V C Fe O H N Ti TC4 6.26 4.02 0.016 0.110 0.120 0.0006 0.0066 余量 TA17 3.90 2.57 0.012 0.026 0.070 0.0006 0.0060 余量 表 2 25~1800 ℃温度区间内钛合金热物理参数对比

Table 2. Comparison of thermophysical parameters of titanium alloys in the temperature range of 25~1800 ℃

材料 温度/℃ 密度/(g·cm−3) 比热/(J·g−1·℃−1) 热导率/(W·m−1·℃−1) TC4 25 4.42 0.55 5.75 500 4.36 0.67 14.39 1000 4.31 0.66 24.21 1500 4.22 0.77 32.23 1670 4.18 1.14 34.96 1800 3.99 0.98 33.67 TA17 25 4.45 0.54 8.72 500 4.39 0.66 14.92 1000 4.34 0.65 23.41 1500 4.25 0.76 30.68 1670 4.21 1.28 33.18 1800 4.04 0.97 32.22 表 3 TC4及TA17电子束焊接工艺参数及焊缝成形情况

Table 3. EBW process parameters and weld forming situation of TC4 and TA17

试样

编号加速电压/

kV束流/

mA上聚焦电流/

mA下聚焦电流/

mA焊接速度/

(mm·min−1)热输入/

(kJ·cm−1)焊件背面成形情况 C1 150 60 400 510 150 36.0 试板背面未焊透 A1 C2 150 70 400 510 150 42.0 试板背面未焊透 A2 C3 150 80 400 510 150 48.0 垫板敲掉,垫板无匙孔 A3 C4 150 85 400 510 150 51.0 垫板与试板焊为一体,垫板无匙孔 A4 C11 150 90 400 510 150 54.0 垫板与试板焊为一体,垫板上有密集匙孔 A11 垫板与试板焊为一体,垫板上未出现匙孔 C12 150 90 400 510 200 40.5 无垫板,试板焊漏长度95 mm A12 无垫板,焊漏长度65 mm C13 150 90 400 510 200 40.5 垫板与试板焊为一体,垫板上有一个匙孔 A13 垫板与试板焊为一体,垫板上无匙孔 C14 150 90 400 510 250 32.4 垫板与试板焊为一体,垫板无匙孔 A14 垫板敲掉,试板上有密集匙孔 C21 150 90 400 510 300 27.0 垫板与试板焊为一体,无匙孔 A21 垫板脱离,试板后段密集匙孔 C22 85 90 370 330 150 30.6 垫板取掉,试板背面未焊透 A22 C23 85 120 370 330 150 40.8 垫板取掉,试板背面未焊透 A23 C24 85 140 370 330 150 47.6 垫板与试板焊为一体,无匙孔 A24 C31 85 150 370 330 150 51.0 垫板与试板焊为一体,无匙孔 A31 C32 85 160 370 330 150 54.4 垫板与试板焊为一体,垫板上有少量匙孔 A32 垫板与试板焊为一体,垫板上有几个匙孔 C33 85 170 370 330 150 57.8 垫板与试板焊为一体,垫板后端有密集匙孔 A33 垫板与试板焊为一体,垫板后端有几处匙孔 表 4 TC4和TA17电子束焊接不同焊接流速下的熔宽、熔深及焊缝系数

Table 4. Weld width, penetration and weld forming coefficient of TC4 and TA17 using EBW at different welding beam current

材料 加速电压

/kV焊接速度/(mm·min−1) 焊接束流

/mA熔宽

/mm熔深

/mm焊缝成形系数 TC4 150 150 60 26.21 29.98 1.14 70 22.61 38.27 1.69 80 27.90 49.11 1.76 85 22.60 52.90 2.34 90 23.42 59.40 2.54 85 150 90 17.48 34.40 1.97 120 19.08 44.80 2.35 140 20.44 49.20 2.41 150 22.42 54.40 2.43 160 21.77 54.80 2.52 170 23.87 61.70 2.58 TA17 150 150 60 26.18 28.10 1.07 70 26.80 34.40 1.28 80 26.83 47.80 1.78 85 27.14 53.0 1.95 90 25.68 58.60 2.28 85 150 90 18.45 32.60 1.77 120 20.30 44.10 2.17 140 23.62 52.80 2.24 150 23.20 56.98 2.46 160 23.30 64.22 2.76 170 25.48 63.04 2.47 表 5 TC4和TA17电子束焊接不同焊接速度下的熔宽、熔深及焊缝系数

Table 5. Weld width, penetration and weld forming coefficient of TC4 and TA17 using EBW at different welding speed

材料 加速电压

/kV焊接束流

/mA焊接速度/(mm·min−1) 熔宽

/mm熔深

/mm焊缝成形系数 TC4 150 90 150 23.42 59.40 2.54 200 18.29 58.90 3.22 250 15.33 58.50 3.82 300 16.14 50.0 3.10 TA17 150 90 150 25.68 58.60 2.28 200 26.18 55.70 2.13 250 18.13 50.40 2.78 300 16.40 49.60 3.02 -

[1] Zhao Yongqing. Current situation and development trend of titanium alloys[J]. Materials China, 2010,29(5):1−8. (赵永庆. 国内外钛合金研究的发展现状及趋势[J]. 中国材料进展, 2010,29(5):1−8.Zhao Yongqing. Current situation and development trend of titanium alloys [J]. Materials China, 2010, 29(5): 1-8. [2] Wang Yating, Lin Naiming, Tang Bin. Development of thermal oxidation of titanium and titanium alloys[J]. Corrosion & Protection, 2014,35(10):965−970. (王娅婷, 林乃明, 唐宾. 钛及钛合金热氧化工艺的研究现状[J]. 腐蚀与防护, 2014,35(10):965−970.Wang Yating, Lin Naiming, Tang Bin. Development of thermal oxidation of titanium and titanium alloys [J]. Corrosion & Protection, 2014, 35(10): 965-970. [3] Zhang Binggang, Wu Lin, Feng Jicai. Development status of EBW technology both at home and abroad[J]. Welding & Joining, 2004,(2):5−8. (张秉刚, 吴林, 冯吉才. 国内外电子束焊接技术研究现状[J]. 焊接, 2004,(2):5−8. doi: 10.3969/j.issn.1001-1382.2004.02.001Zhang Binggang, Wu Lin, Feng Jicai. Development status of EBW technology both at home and abroad [J]. Welding & Joining, 2004(2): 5-8. doi: 10.3969/j.issn.1001-1382.2004.02.001 [4] Li Yajiang, Liu Kun. Application and advanced bonding technology of titanium alloy in aviation industry[J]. Aeronautical Manufacturing Technology, 2015,(16):34−37. (李亚江, 刘坤. 钛合金在航空领域的应用及其先进连接技术[J]. 航空制造技术, 2015,(16):34−37.Li Yajiang, Liu Kun. Application and advanced bonding technology of titanium alloy in aviation industry [J]. Aeronautical Manufacturing Technology, 2015, (16): 34-37. -

下载:

下载: