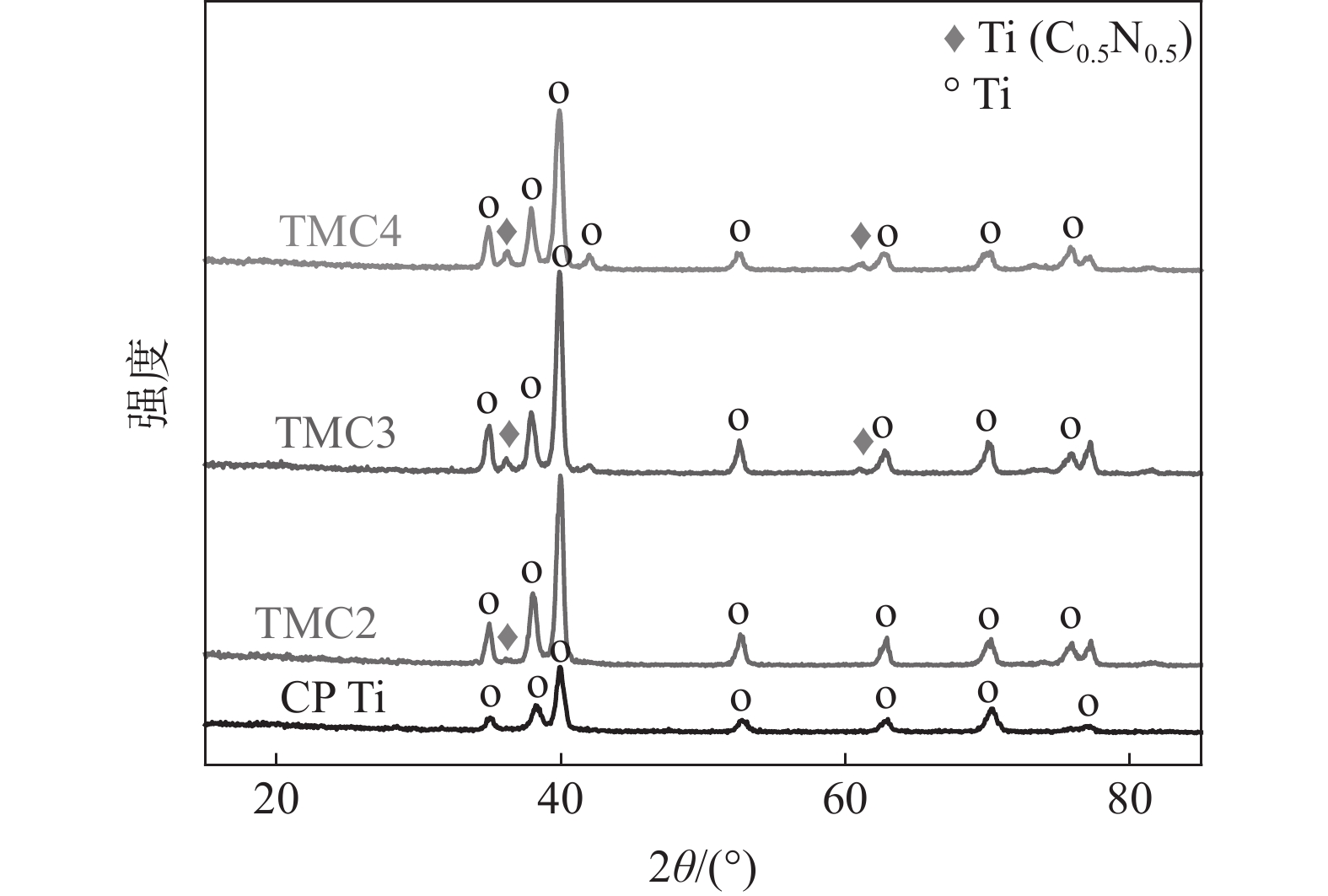

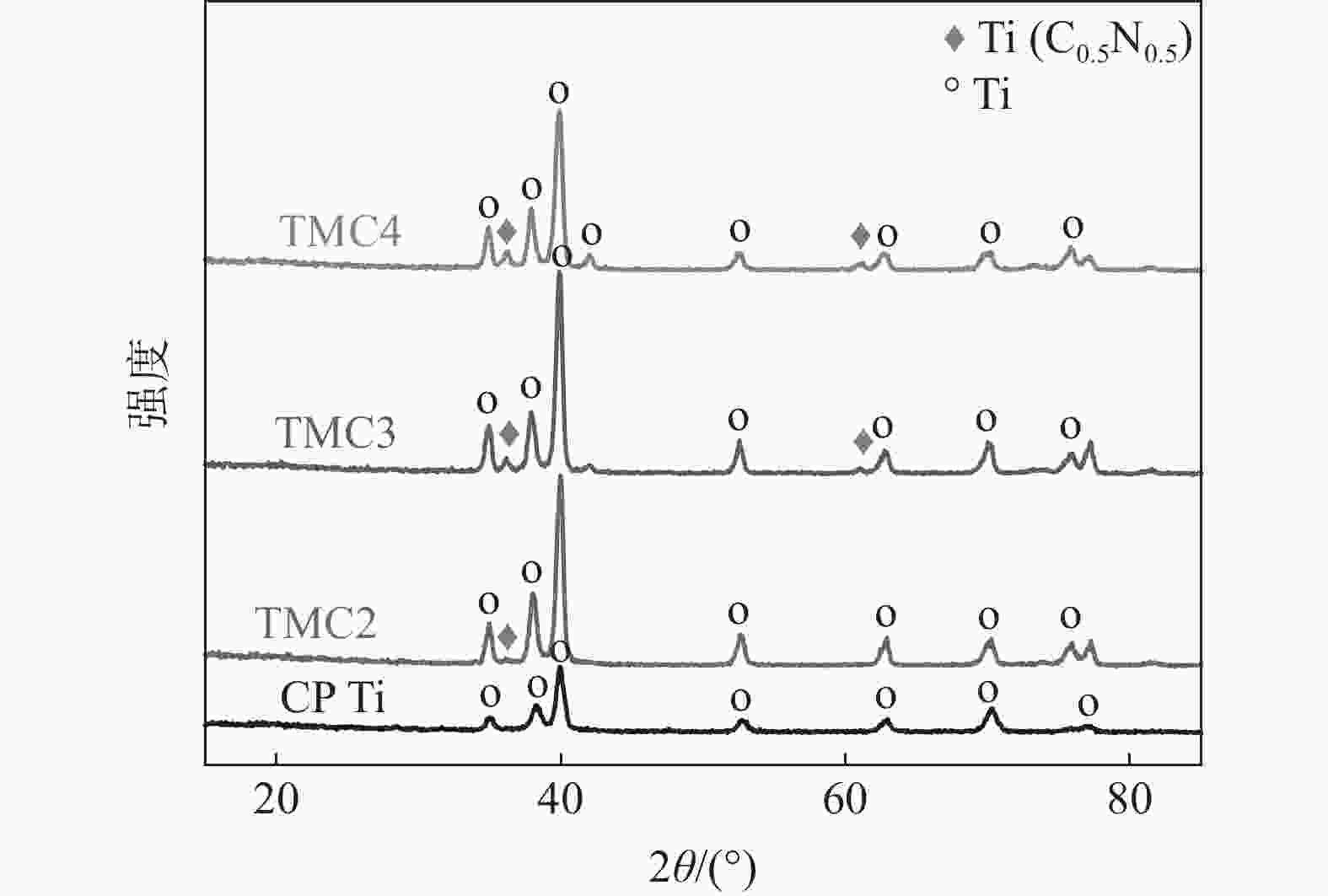

Research on microstructure and mechanical properties of Ti(C0.5N0.5) particle reinforced Ti matrix composites

-

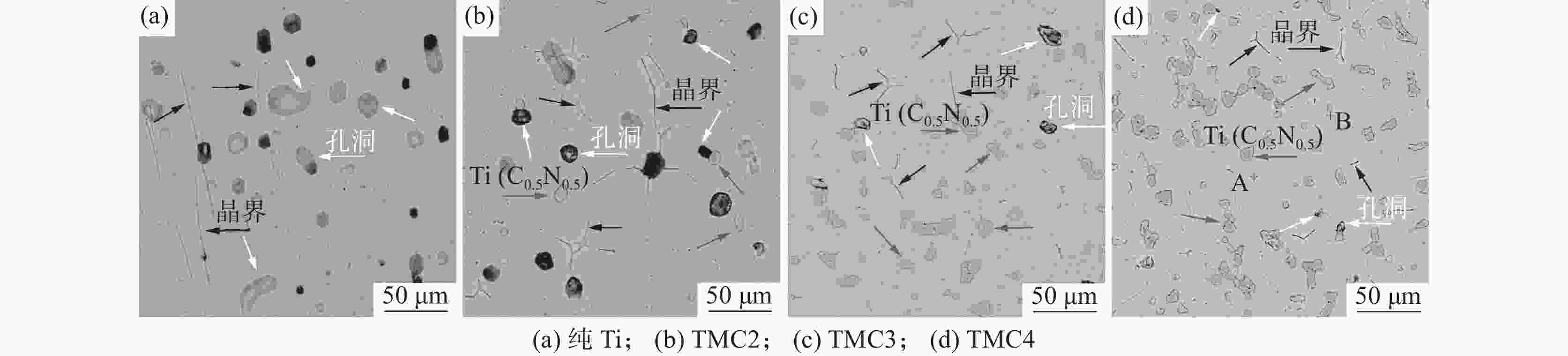

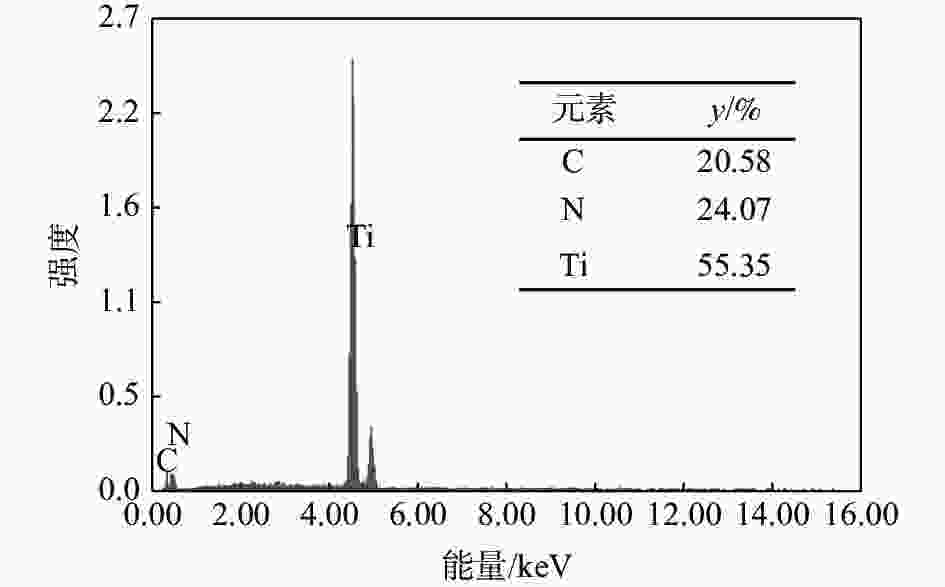

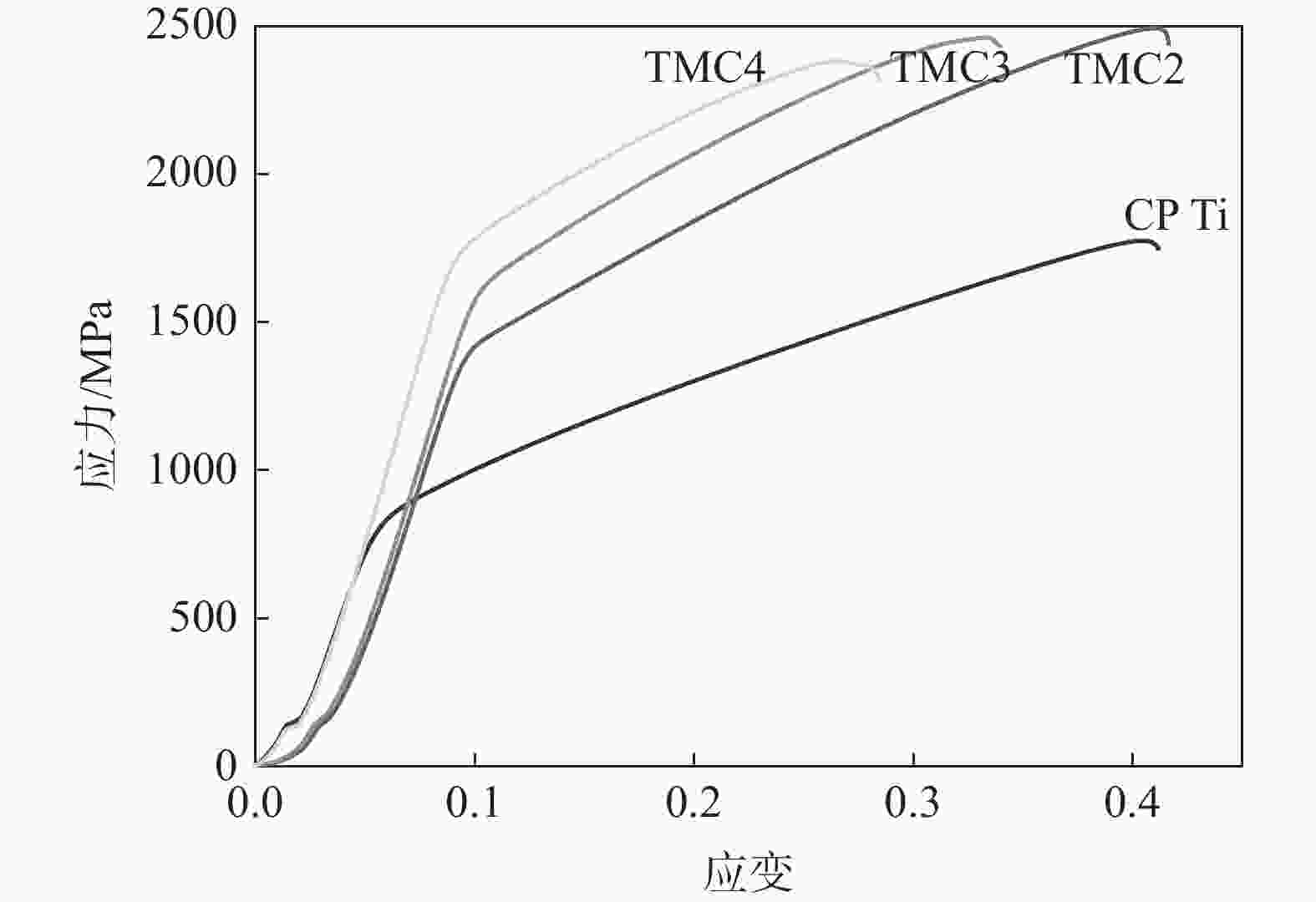

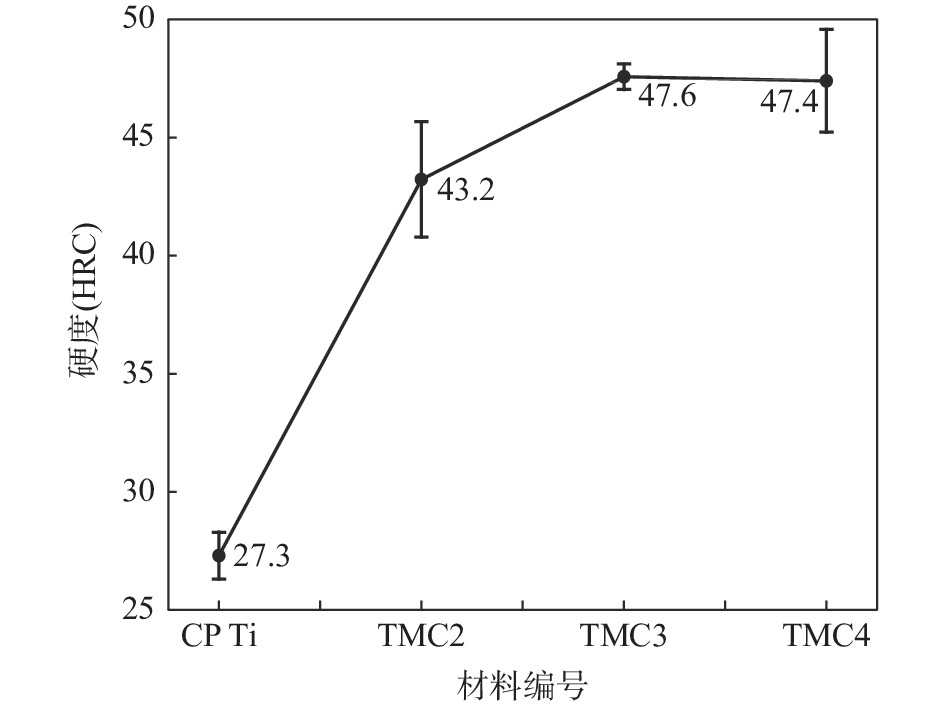

摘要: 以纯Ti粉、Ti(C0.5N0.5) 颗粒为原料,采用粉末冶金工艺,制备了Ti(C0.5N0.5)颗粒增强钛基复合材料,研究了Ti(C0.5N0.5) 含量对钛基复合材料组织和力学性能的影响。结果表明:Ti(C0.5N0.5) 颗粒的添加,显著细化了钛基体的晶粒,晶粒形貌由粗大的柱状晶转变为细小的等轴晶;随着Ti(C0.5N0.5) 含量的增加,钛基复合材料的孔隙明显减少,致密度提高,钛基复合材料的硬度和屈服强度逐渐增加,但压缩应变逐渐减小。

-

关键词:

- 钛基复合材料 /

- Ti(C0.5N0.5) 颗粒 /

- 粉末冶金 /

- 显微组织 /

- 力学性能

Abstract: Using pure Ti powder and Ti(C0.5N0.5) particles as raw materials, Ti(C0.5N0.5) particle reinforced Ti matrix composites were prepared by powder metallurgy process. The effects of Ti(C0.5N0.5) content on the microstructure and mechanical properties of titanium matrix composites were studied. The results show that the addition of Ti(C0.5N0.5) particles significantly refines the grain size of Ti matrix, and the grain morphology changes from coarse columnar grain to fine equiaxed grain. With the increase of Ti(C0.5N0.5) content, the porosity of Ti matrix composites decreases obviously, the density increases, and the hardness and yield strength of Ti matrix composites increase gradually, but the compressive strain decreases gradually. -

表 1 纯钛和钛基复合材料的原料配比

Table 1. Raw materials ratio of pure titanium and titanium matrix composites

材料编号 w(Ti)/% w(碳氮化钛)/% A(CP Ti) 100.0 0 B(TMC2) 97.0 3 C(TMC3) 94.0 6 D(TMC4) 91.0 9 表 2 不同Ti(C0.5N0.5) 含量的钛基复合材料实际密度和理论密度

Table 2. The actual density and theoretical density of Ti matrix composites with different Ti(C0.5N0.5) contents

材料编号 实际密度/(g·cm−3) 理论密度/(g·cm−3) 致密度/% A(CP Ti) 4.34 4.50 96.48 B(TMC2) 4.44 4.52 98.20 C(TMC3) 4.46 4.53 98.60 D(TMC4) 4.48 4.54 98.53 表 3 不同Ti(C0.5N0.5) 含量的钛基复合材料的压缩性能

Table 3. Compression properties of titanium matrix composites with different Ti(C0.5N0.5) contents

材料编号 抗压屈服强度/MPa 抗压强度/MPa 压缩应变/% CP Ti 850.0 1849.3 41.2 TMC2 1430.2 2498.1 41.6 TMC3 1603.3 2473.3 33.9 TMC4 1710.1 2444.0 28.4 -

[1] Ji Bo, Huang Guangfa, Mao Jianwei. Effect of isothermal extrusion deformation on microstructure and mechanical properties of (TiB+TiC) reinforced titanium matrix composites at room temperature[J]. Titanium Industry Progress, 2018,35(3):16−21. (计波, 黄光法, 毛建伟. 等温挤压变形量对(TiB+TiC)增强钛基复合材料组织和室温力学性能的影响[J]. 钛工业进展, 2018,35(3):16−21.Ji Bo, Huang Guangfa, Mao Jianwei. Effect of isothermal extrusion deformation on microstructure and mechanical properties of (TiB+TiC)reinforced titanium matrix composites at room temperature [J]. Titanium Industry Progress, 2018, 35(3): 16-21. [2] 孙亮. 原位自生(TiC+TiB)增强钛基复合材料组织调控与耐磨性[D]. 沈阳: 沈阳工业大学, 2018.Sun Liang. In situ (TiC+TiB) enhanced microstructure regulation and wear resistance of titanium matrix composites[D]. Shenyang: Shenyang University of Technology, 2018. [3] Han Yuanfei, Le Jianwen, Fang Minghan, et al. Preparation, processing and aerospace application of high performance in-situ titanium matrix composites[J]. Progress of Materials in China, 2020,39(12):945−954. (韩远飞, 乐建温, 方旻翰, 等. 高性能原位自生钛基复合材料制备加工与航天应用探索[J]. 中国材料进展, 2020,39(12):945−954.Han Yuanfei, Le Jianwen, Fang Minghan, et al. Preparation, processing and aerospace application of high performance in-situ titanium matrix composites[J]. Progress of Materials in China, 2020, 39(12): 945-954. [4] Han Yuanfei, Sun Xianglong, Qiu Peikun, et al. Research and progress on advanced processing technology of particle reinforced titanium matrix composites[J]. Journal of Composite Materials, 2017,34(8):1625−1635. (韩远飞, 孙相龙, 邱培坤, 等. 颗粒增强钛基复合材料先进加工技术研究与进展[J]. 复合材料学报, 2017,34(8):1625−1635.Han Yuanfei, Sun Xianglong, Qiu Peikun, et al. Research and progress on advanced processing technology of particle reinforced titanium matrix composites[J]. Journal of Composite Materials, 2017, 34(8): 1625-1635. [5] Fu Binguo, Li Chaozhi, Liu Jinhai, et al. Application and prospect of in-situ synthesis technology in discontinuous reinforced titanium matrix composites[J]. Casting, 2018,67(4):312−316. (付彬国, 李朝志, 刘金海, 等. 原位合成技术在非连续增强钛基复合材料中的应用及展望[J]. 铸造, 2018,67(4):312−316. doi: 10.3969/j.issn.1001-4977.2018.04.005Fu Binguo, Li Chaozhi, Liu Jinhai, et al. Application and prospect of in-situ synthesis technology in discontinuous reinforced titanium matrix composites [J]. Casting, 2018, 67(4): 312-316. doi: 10.3969/j.issn.1001-4977.2018.04.005 [6] Lai Xiaojun, Li Shaopeng, Han Yuanfei, et al. Research progress on composite design and advanced machining technology of multi-dimensional and multi-scale reinforced titanium matrix composites[J]. Titanium IndustryProgress, 2020,37(3):40−48. (来晓君, 李劭鹏, 韩远飞, 等. 多元多尺度增强钛基复合材料复合设计与先进加工技术研究进展[J]. 钛工业进展, 2020,37(3):40−48.Lai Xiaojun, Li Shaopeng, Han Yuanfei, et al. Research progress on composite design and advanced machining technology of multi-dimensional and multi-scale reinforced titanium matrix composites [J]. Titanium IndustryProgress, 2020, 37(3): 40-48. [7] Liu Shifeng, Song Xi, Xue Tong, et al. Application and development of titanium alloy and titanium matrix composites in aerospace[J]. Journal of Aeronautical Materials, 2020,40(3):77−94. (刘世锋, 宋玺, 薛彤, 等. 钛合金及钛基复合材料在航空航天的应用和发展[J]. 航空材料学报, 2020,40(3):77−94. doi: 10.11868/j.issn.1005-5053.2020.000061Liu Shifeng, Song Xi, Xue Tong, et al. Application and development of titanium alloy and titanium matrix composites in aerospace [J]. Journal of Aeronautical Materials, 2020, 40(3): 77-94. doi: 10.11868/j.issn.1005-5053.2020.000061 [8] Zhou Haitao, Kong Fantao, Chen Yuyong. Progress in powder metallurgy of TiAl intermetallic compounds[J]. Rare Metal Materials and Engineering, 2016,45(9):2466−2472. (周海涛, 孔凡涛, 陈玉勇. TiAl金属间化合物粉末冶金技术研究进展[J]. 稀有金属材料与工程, 2016,45(9):2466−2472.Zhou Haitao, Kong Fantao, Chen Yuyong. Progress in powder metallurgy of TiAl intermetallic compounds [J]. Rare Metal Materials and Engineering, 2016, 45(9): 2466-2472. [9] Lin Xuejian, Dong Fuyu, Zhang Shixin, et al. Effect of (TiC+TiB) content on microstructure and mechanical properties of TC4 alloy[J]. Hot Working Technology, 2019,(6):133−137. (林雪健, 董福宇, 张世鑫, 等. 不同含量(TiC+TiB)对TC4合金组织和力学性能的影响[J]. 热加工工艺, 2019,(6):133−137.Lin Xuejian, Dong Fuyu, Zhang Shixin, et al. Effect of (TiC+TiB) content on microstructure and mechanical properties of TC4 alloy [J]. Hot Working Technology, 2019(6): 133-137. [10] Ma F, Zhou J, Liu P, et al. Strengthening effects of TiC particles and microstructure refinement in in situ TiC-reinforced Ti matrix composites[J]. Materials Characterization, 2017,127:27−34. doi: 10.1016/j.matchar.2017.02.004 [11] Jiao Y, Huang L, Geng L. Progress on discontinuously reinforced titanium matrix composites[J]. Journal of Alloys and Compounds, 2018,767:1196−1215. doi: 10.1016/j.jallcom.2018.07.100 [12] Vasanthakumar K, Ghosh S, Koundinya N, et al. Synthesis and mechanical properties of TiCx and Ti (C, N) reinforced titanium matrix in situ composites by reactive spark plasma sintering[J]. Materials Science and Engineering:A, 2019,759:30−39. doi: 10.1016/j.msea.2019.05.021 [13] 冯俊. 原位生成(TiC、TiB)/Ti基复合材料的组织与性能研究[D]. 重庆: 西南大学, 2020.Feng Jun. Study on microstructure and properties of in situ (TiC, TiB)/Ti matrix composites[D]. Chongqing: Southwest University, 2020. [14] Zhang X, Song F, Wei Z, et al. Microstructural and mechanical characterization of in-situ TiC/Ti titanium matrix composites fabricated by graphene/Ti sintering reaction[J]. Materials Science and Engineering:A, 2017,705:153−159. doi: 10.1016/j.msea.2017.08.079 [15] 毛小南. TiC颗粒增强钛基复合材料的内应力对材料机械性能的影响[D]. 西安: 西北工业大学, 2004.Mao Xiaonan. Effect of internal stress on mechanical properties of TiC particle reinforced titanium matrix composites[D]. Xi, an: Northwestern Polytechnical University, 2004. [16] 任伟玮. TiCN复合陶瓷的制备及性能探究[D]. 广州: 广东工业大学, 2018.Ren Weiwei. Preparation and properties of TiCN composite ceramics[D]. Guangzhou: Guangdong University of Technology, 2018. [17] Lagos M A, Agote I, Atxaga G, et al. Fabrication and characterisation of titanium matrix composites obtained using a combination of self propagating high temperature synthesis and spark plasma sintering[J]. Materials Science and Engineering:A, 2016,655:44−49. doi: 10.1016/j.msea.2015.12.050 [18] Li Ziyang, Wang Sijia, Deng Wenju. Research progress of ceramic particle reinforced metal matrix composites[J]. Light Industry Science and Technology, 2021,37(4):41−44. (李滋阳, 王思佳, 邓文举. 陶瓷颗粒增强金属基复合材料研究进展[J]. 轻工科技, 2021,37(4):41−44.Li Ziyang, Wang Sijia, Deng Wenju. Research progress of ceramic particle reinforced metal matrix composites [J]. Light Industry Science and Technology, 2021, 37(4): 41-44. [19] 刘嘉威. 碳氮化钛粉末的合成及其成型工艺研究[D]. 厦门: 厦门理工学院, 2020.Liu Jiawei. Carbon titanium nitride powder synthesis and molding process of the research[D]. Xiamen: Xiamen institute of technology, 2020. [20] 杜康鸿,柳中强,张建涛,等.基于高通量的原位制备网状结构TiC增强TC4复合材料的组织与性能[J/OL].粉末冶金材料科学与工程:1−10.[2021-12-29].DOI: 10.19976/j.cnki.43-1448/TF.2021070.Du Kanghong, Liu Zhongqiang, Zhang Jiantao, et al. Microstructure and properties of TiC reinforced TC4 composites prepared in situ based on high throughput [J/OL]. Powder Metallurgy Materials Science and Engineering: 1−10. [2021-12-29]. DOI:10.19976/j.cnki.43-1448/ TF.2021070. -

下载:

下载: