Study on the microstructure and mechanical properties of the automotive titanium alloy based on friction stir processing

-

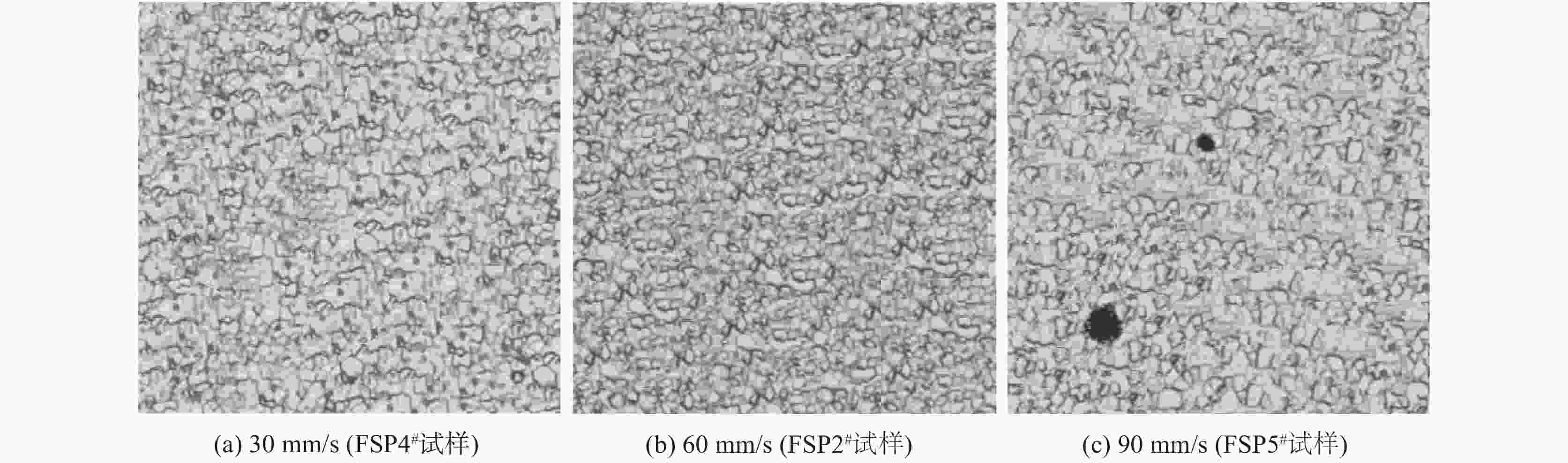

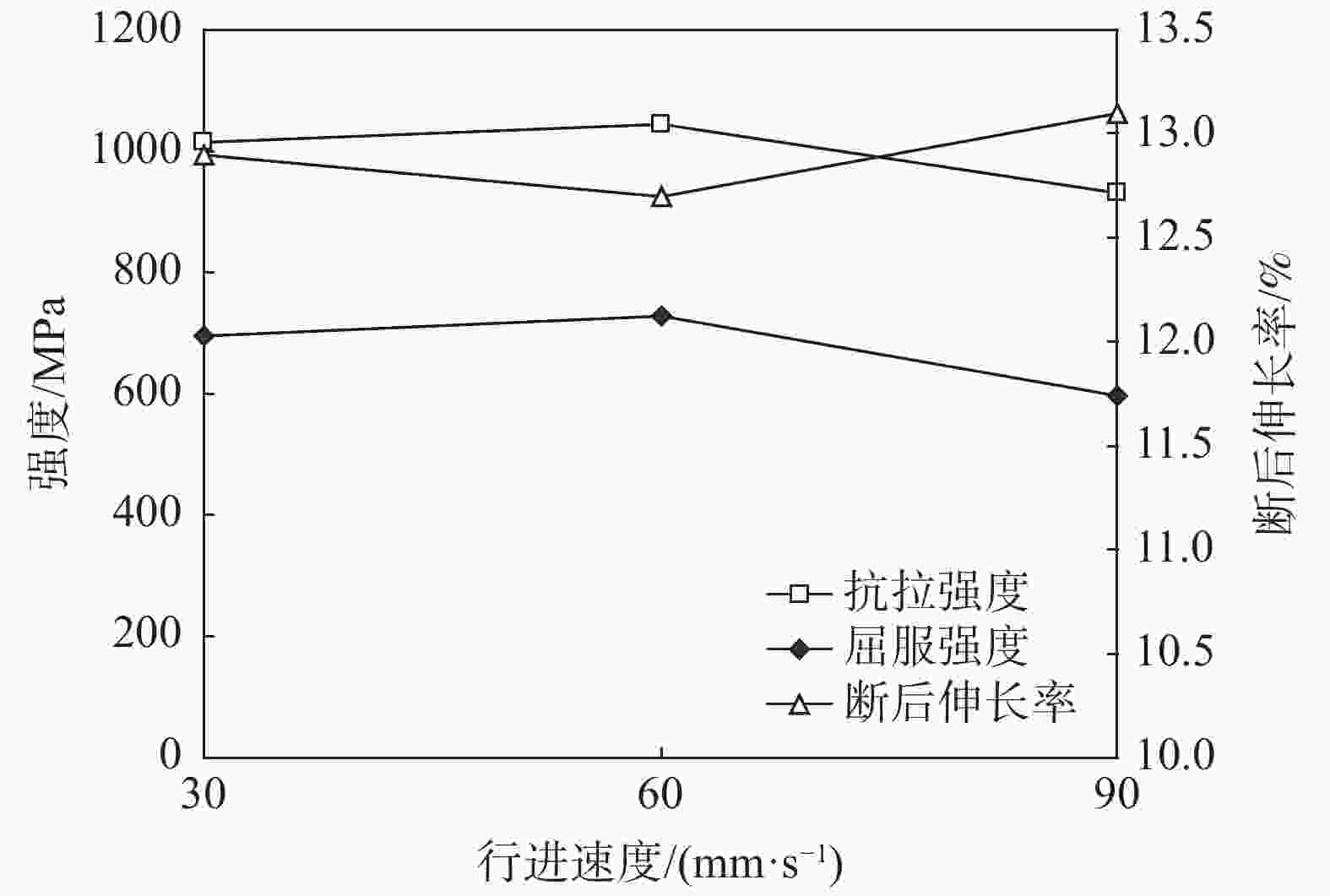

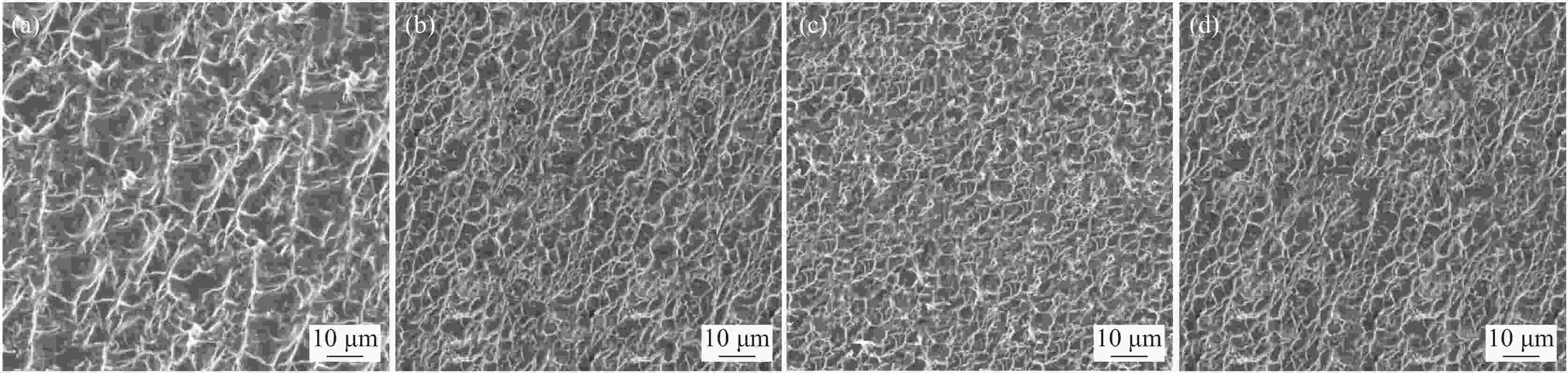

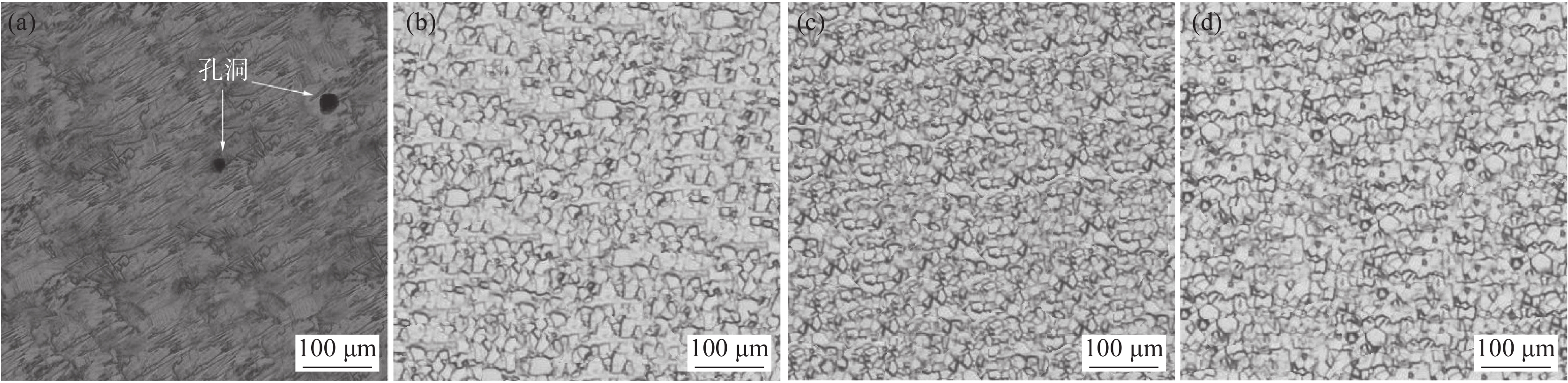

摘要: 采用不同的主轴旋转速度和行进速度对铸态Ti8LC汽车钛合金进行了搅拌摩擦加工改性试验,并测试和对比分析了合金试样的显微组织和力学性能。结果表明,改性后合金内部晶粒明显细化、组织分布均匀性得到改善、力学性能显著提高。在轴肩下压量0.2 mm和主轴倾斜角度2.5°不变的情况下,随主轴旋转速度从200 r/min增大到400 r/min或行进速度从30 mm/s加快到90 mm/s,改性钛合金试样的晶粒先细化后粗化、力学性能先提高后下降。主轴旋转速度300 r/min,行进速度60 mm/s时改性钛合金试样的力学性能最佳,抗拉强度和屈服强度分别为1 046、729 MPa,延伸率为12.7%;与铸态Ti8LC汽车钛合金相比,改性后试样的抗拉强度和屈服强度分别增大118、125 MPa,其增幅分别达12.7%、20.7%。Abstract: In this investigation, the friction stir processing (FSP) method was used to modify the surface layer of an as-cast Ti8LC automotive titanium alloy using different spindle rotation speeds and travel speeds. In addition, the microstructure and mechanical properties of the alloy samples were tested and compared. The results show that the internal grains of the alloy are refined, and the uniformity of microstructure distribution and the mechanical properties are improved after FSP modification. When the shoulder depression is 0.2 mm, and the spindle inclination angle is 2.5°, the spindle rotation speed increases from 200 r/min to 400 r/min or travel speed from 30 mm/s to 90 mm/s. Meanwhile, the grains of FSP alloy samples are refined first and then coarsened, and the mechanical properties are improved first and then decreased. The best mechanical properties of the modified alloy samples can be obtained with the spindle rotation speed of 300 r/min and the travel speed of 60 mm/s. The tensile strength, yield strength and elongation are 1 046, 729 MPa and 12.7%, respectively. Compared with the as-cast Ti8LC automotive titanium alloy, the tensile strength and yield strength of FSP modified alloy samples are increased by 118 MPa and 125 MPa (with a 12.7% and 20.7% amplitude), respectively.

-

表 1 Ti8LC合金试样化学成分

Table 1. Chemical composition of the Ti8LC alloy specimen

% Al Mo Fe C N H O 其它杂质元素 Ti 5.958 2.016 1.492 0.022 0.015 0.011 0.106 <0.150 余量 表 2 合金试样FSP工艺参数

Table 2. FSP Process parameters of the alloy specimen

试样编号 主轴旋转速度/(r·min−1) 行进速度/(mm·s−1) 轴肩下压量/mm 主轴倾斜角度/(°) FSP1# 200 60 0.2 2.5 FSP2# 300 60 0.2 2.5 FSP3# 400 60 0.2 2.5 FSP4# 300 30 0.2 2.5 FSP5# 300 90 0.2 2.5 表 3 金相腐蚀液组成

Table 3. Ratio of the metallographic corrosion agent

mL 氢氟酸 硝酸 无水乙醇 去离子水 15 10 20 105 -

[1] Zhang Yan, Pang Youjun, Li Yang. Titanium alloy and automobile lightweight technology[J]. Auto Time, 2019,(19):12−14. (张妍, 庞有俊, 李杨. 钛合金与汽车轻量化技术[J]. 时代汽车, 2019,(19):12−14.Zhang Yan, Pang Youjun, Li Yang. Titanium alloy and automobile lightweight technology[J]. Auto Time, 2019(19): 12-14. [2] Chen Zhenglong, Yang Xiao. Application of titanium alloy in modern automobile industry[J]. Modern Components, 2017,(9):46−47. (陈政龙, 杨晓. 钛合金在现代汽车工业中的应用[J]. 汽车工艺师, 2017,(9):46−47. doi: 10.3969/j.issn.1672-657X.2017.09.013Chen Zhenglong, Yang Xiao. Application of titanium alloy in modern automobile industry[J]. Modern Components, 2017(9): 46-47. doi: 10.3969/j.issn.1672-657X.2017.09.013 [3] Sun Feng, Yin Xiaoli, Zhao Da. Rolling process optimization of vanadium microalloyed automobile titanium alloy[J]. Iron Steel Vanadium Titanium, 2020,41(3):59−63. (孙凤, 尹晓丽, 赵达. 钒微合金化汽车钛合金的轧制工艺优化[J]. 钢铁钒钛, 2020,41(3):59−63. doi: 10.7513/j.issn.1004-7638.2020.03.009Sun Feng, Yin Xiaoli, Zhao Da. Rolling process optimization of vanadium microalloyed automobile titanium alloy[J]. Iron Steel Vanadium Titanium, 2020, 41(3): 59-63. doi: 10.7513/j.issn.1004-7638.2020.03.009 [4] Gan Wei, Xiang Junfeng, Huang Fang. Effect of forging temperature on properties of new titanium alloys for automobiles[J]. Ordnance Material Science and Engineering, 2019,42(5):70−73. (甘伟, 项俊锋, 黄芳. 锻造温度对汽车用新型钛合金性能的影响[J]. 兵器材料科学与工程, 2019,42(5):70−73.Gan Wei, Xiang Junfeng, Huang Fang. Effect of forging temperature on properties of new titanium alloys for automobiles [J]. Ordnance Material Science and Engineering, 2019, 42(5): 70-73. [5] Song Wei. Optimization of casting process for automobile titanium alloy air valves[J]. Hot Working Technology, 2018,47(7):102−104,111. (宋纬. 汽车钛合金气阀的铸造工艺优化[J]. 热加工工艺, 2018,47(7):102−104,111.Song Wei. Optimization of casting process for automobile titanium alloy air valves[J]. Hot Working Technology, 2018, 47(7): 102-104, 111. [6] Wang Hongguang. Influence of forging temperature on performance of a new type niobium-containing titanium alloy bar used in car[J]. Forging & Stamping Technology, 2018,43(8):13−16. (王洪广. 锻造温度对新型含铌汽车钛合金棒材性能的影响[J]. 锻压技术, 2018,43(8):13−16.Wang Hongguang. Influence of forging temperature on performance of a new type niobium-containing titanium alloy bar used in car[J]. Forging & Stamping Technology, 2018, 43(8): 13-16. [7] Zhang Huifang. Preparation of Mo alloy coating on titanium alloy used in cars by double glow plasma alloying process and its friction and wear performance[J]. Materials Protection, 2017,50(6):88−90. (张慧芳. 汽车用钛合金表面双辉等离子Mo合金化层的制备及其摩擦磨损性能[J]. 材料保护, 2017,50(6):88−90.Zhang Huifang. Preparation of Mo alloy coating on titanium alloy used in cars by double glow plasma alloying process and its friction and wear performance[J]. Materials Protection, 2017, 50(6): 88-90. [8] Ren Lihong, Xu Ying. Application of titanium alloy 3D printing technology in automobile engine parts manufacturing[J]. Internal Combustion Engine & Parts, 2021,(2):213−214. (任丽宏, 徐英. 钛合金3D打印技术在汽车发动机零部件制作中的应用[J]. 内燃机与配件, 2021,(2):213−214.Ren Lihong, Xu Ying. Application of titanium alloy 3D printing technology in automobile engine parts manufacturing[J]. Internal Combustion Engine & Parts, 2021(2): 213-214. [9] Jia Weiju, Zeng Weidong, Duan Fengchuan, et al. Study on fatigue crack propagation behavior of low cost titanium alloy Ti8LC[J]. Rare Metal Materials and Engineering, 2009,38(12):2171−2174. (贾蔚菊, 曾卫东, 段风川, 等. Ti8LC低成本钛合金疲劳裂纹扩展行为研究[J]. 稀有金属材料与工程, 2009,38(12):2171−2174. doi: 10.3321/j.issn:1002-185X.2009.12.022Jia Weiju, Zeng Weidong, Duan Fengchuan, et al. Study on fatigue crack propagation behavior of low cost titanium alloy Ti8 LC[J]. Rare Metal Materials and Engineering, 2009, 38(12): 2171-2174. doi: 10.3321/j.issn:1002-185X.2009.12.022 [10] Lv Yuting, Nie Bin, Liu Guohao, et al. Effect of friction stir processing (FSP) tool on microstructures and mechanical properties of NiAl bronze alloy[J]. Surface Technology, 2019,48(12):102−107. (吕玉廷, 聂彬, 刘国浩, 等. 搅拌摩擦加工工具对镍铝青铜合金显微组织和机械性能的影响[J]. 表面技术, 2019,48(12):102−107.Lv Yuting, Nie Bin, Liu Guohao, et al. Effect of friction stir processing (FSP) tool on microstructures and mechanical properties of NiAl bronze alloy[J]. Surface Technology, 2019, 48(12): 102-107. [11] Shi Qingyu, Cao Xiong, Li Jiyuan, et al. Improved mechanical properties in friction stir processed carbon fiber reinforced aluminum composites[J]. Journal of Tsinghua University(Science and Technology), 2017,57(8):792−797. (史清宇, 曹雄, 李积元, 等. FSP制备碳纤维增强铝基复合材料的强韧化机理[J]. 清华大学学报(自然科学版), 2017,57(8):792−797.Shi Qingyu, Cao Xiong, Li Jiyuan, et al. Improved mechanical properties in friction stir processed carbon fiber reinforced aluminum composites[J]. Journal of Tsinghua University(Science and Technology), 2017, 57(8): 792-797. [12] Wang Saixiang, Zhang Datong. Microstructure and mechanical properties of frictional stirring processed (FSP) MB8 magnesium alloy[J]. Special Casting & Nonferrous Alloys, 2011,31(1):83−86. (王赛香, 张大童. 搅拌摩擦加工MB8镁合金的组织与力学性能分析[J]. 特种铸造及有色合金, 2011,31(1):83−86. doi: 10.3870/tzzz.2011.01.027Wang Saixiang, Zhang Datong. Microstructure and mechanical properties of frictional stirring processed (FSP) MB8 magnesium alloy[J]. Special Casting & Nonferrous Alloys, 2011, 31(1): 83-86. doi: 10.3870/tzzz.2011.01.027 -

下载:

下载: