Experimental study on optimization of flotation reagents for ilmenite froman iron dressing tailing in Panxi area

-

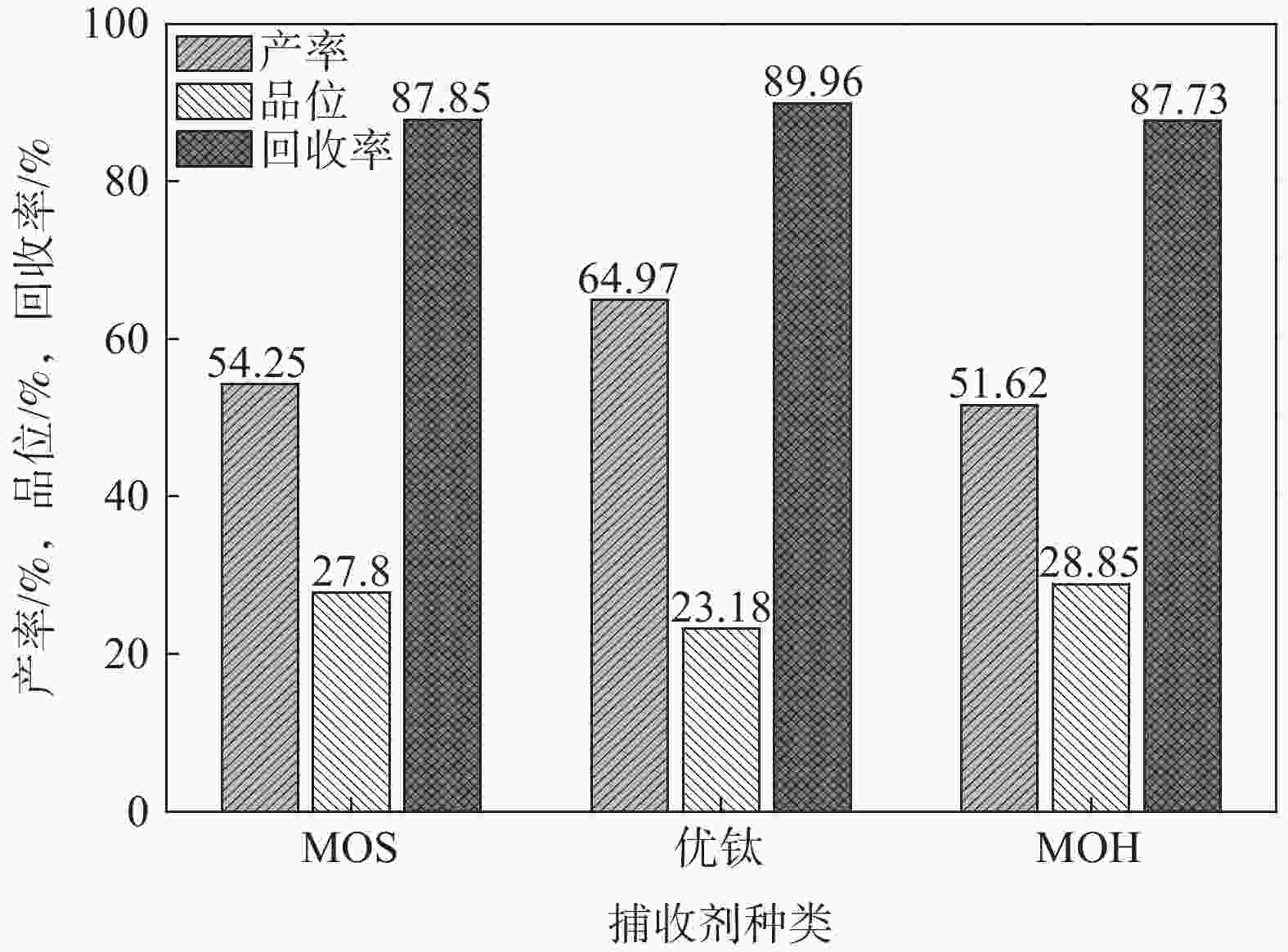

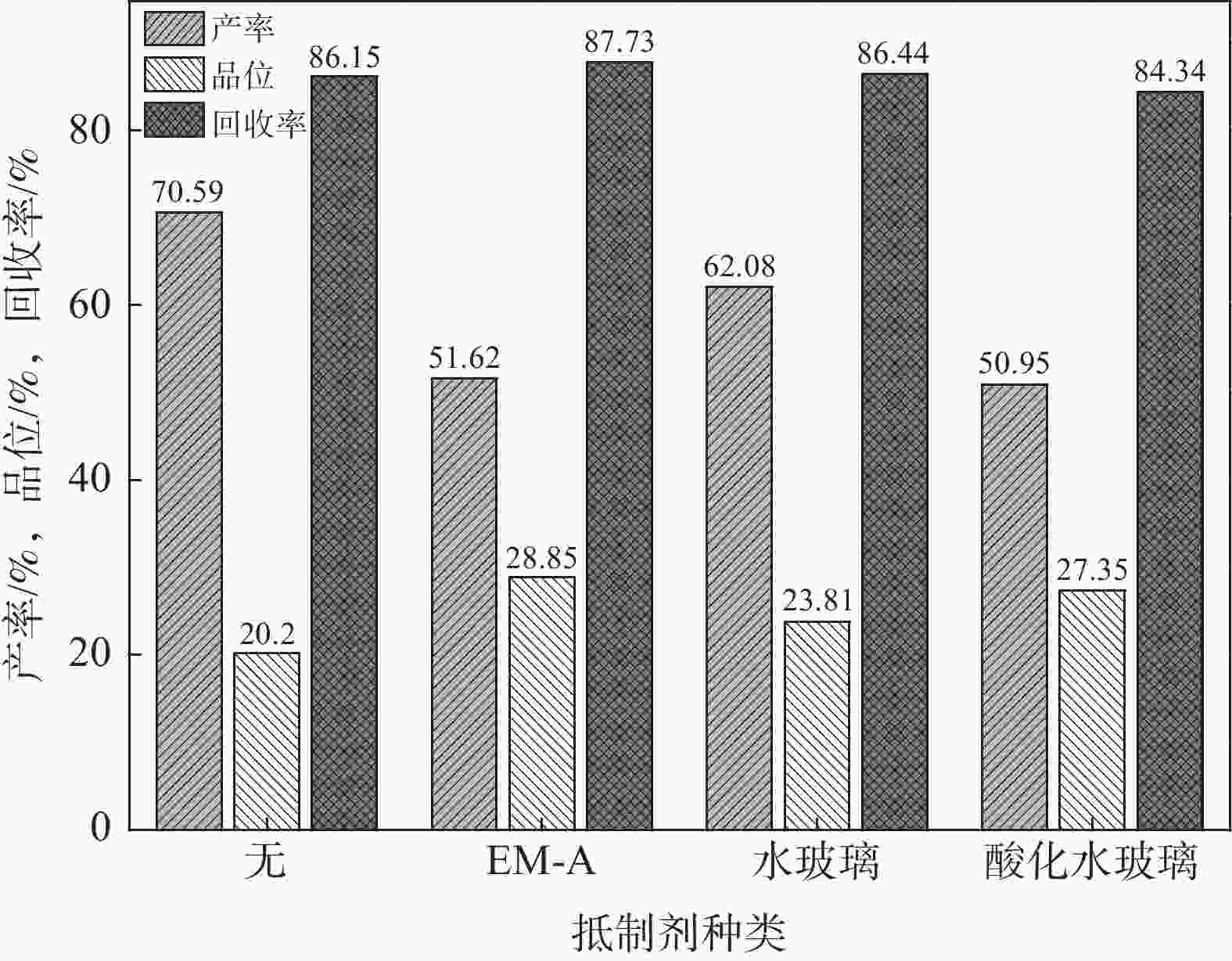

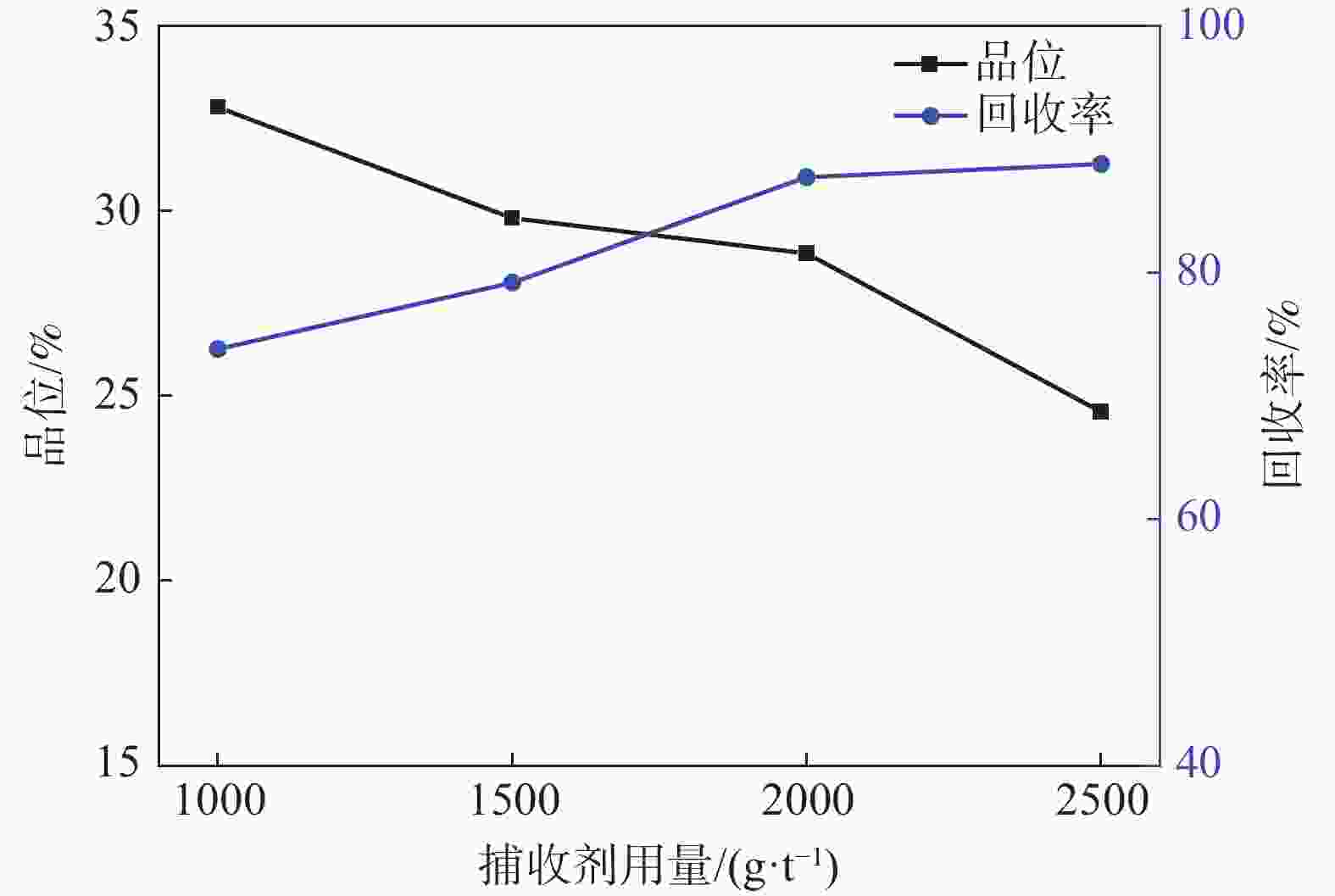

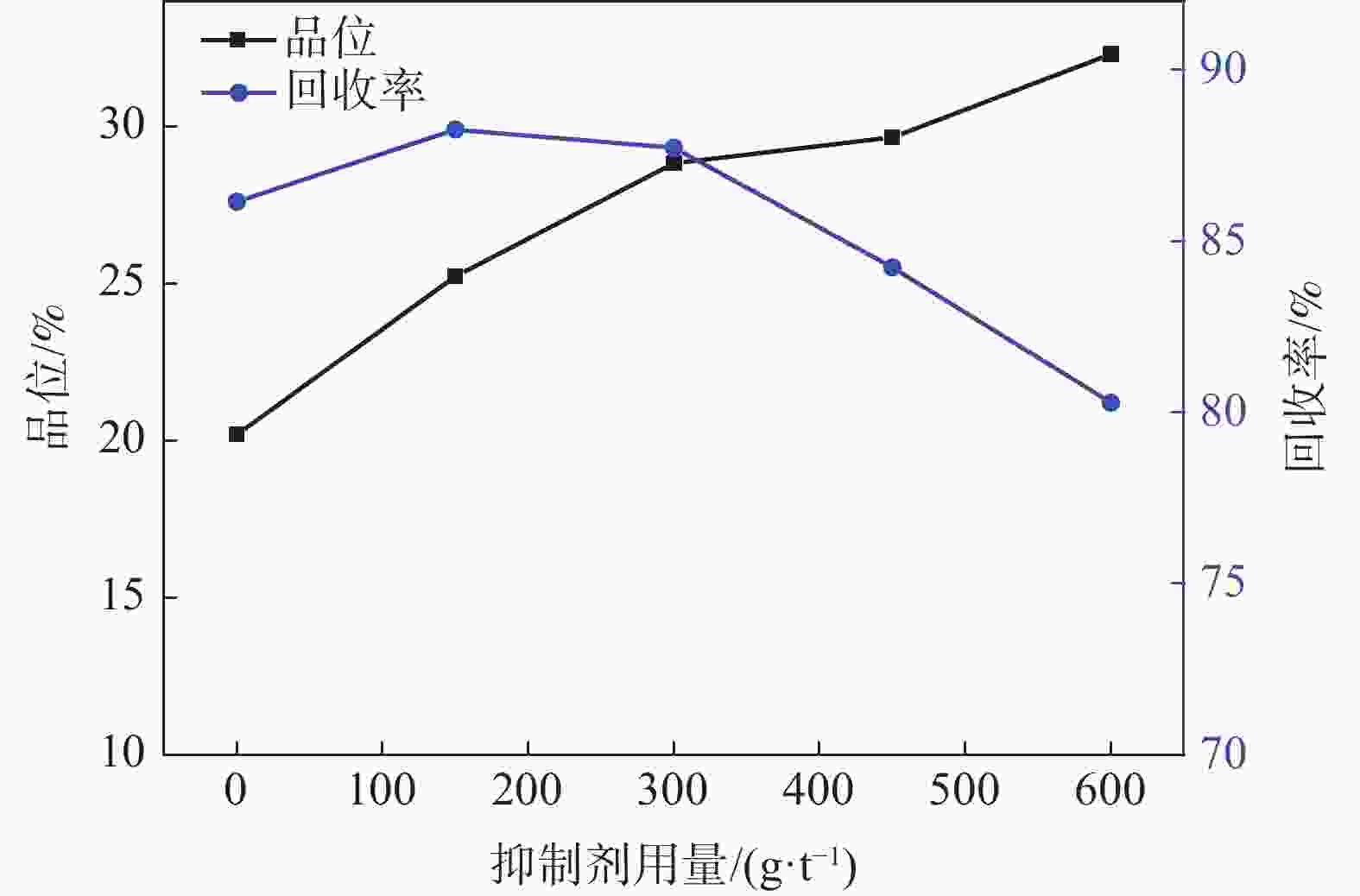

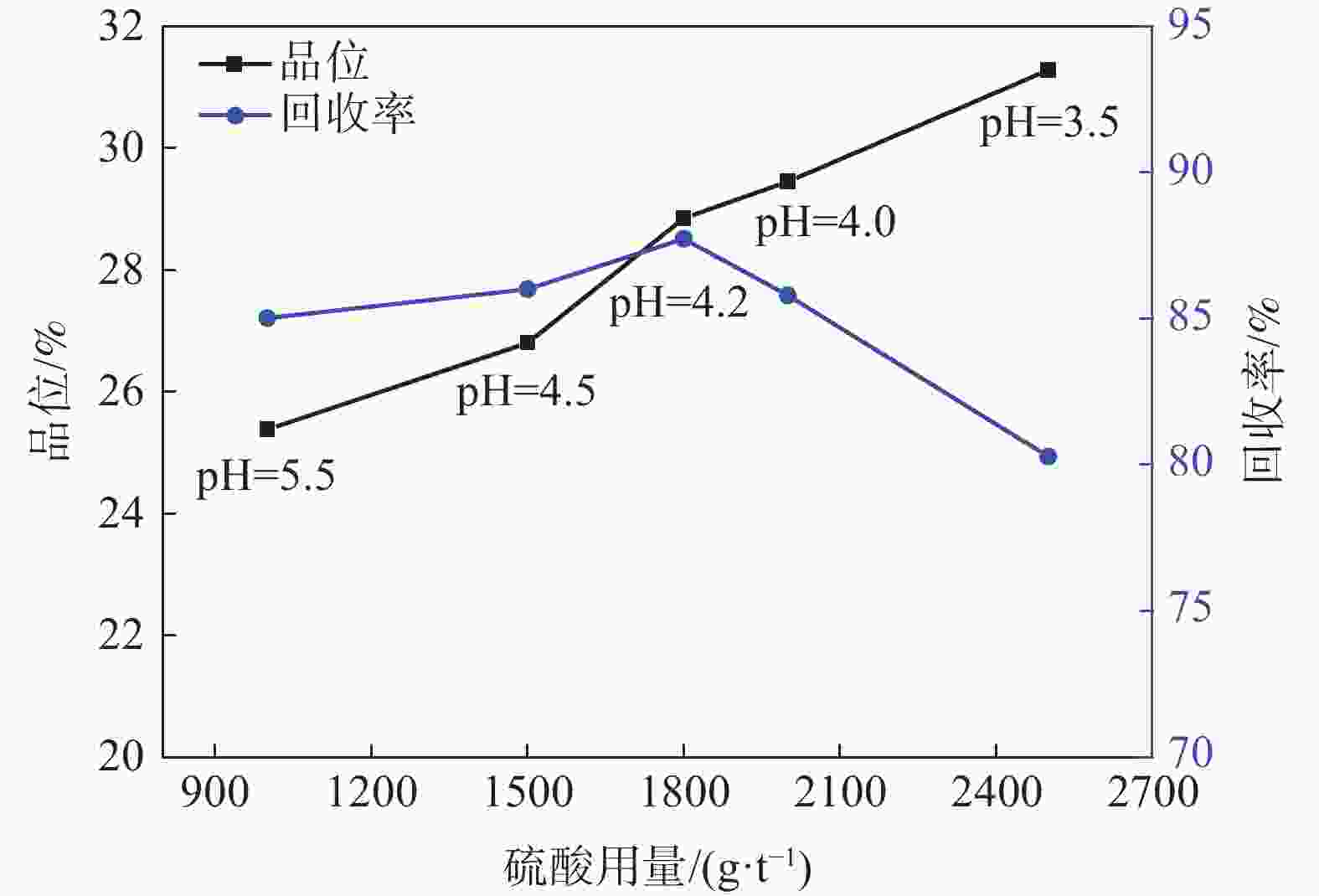

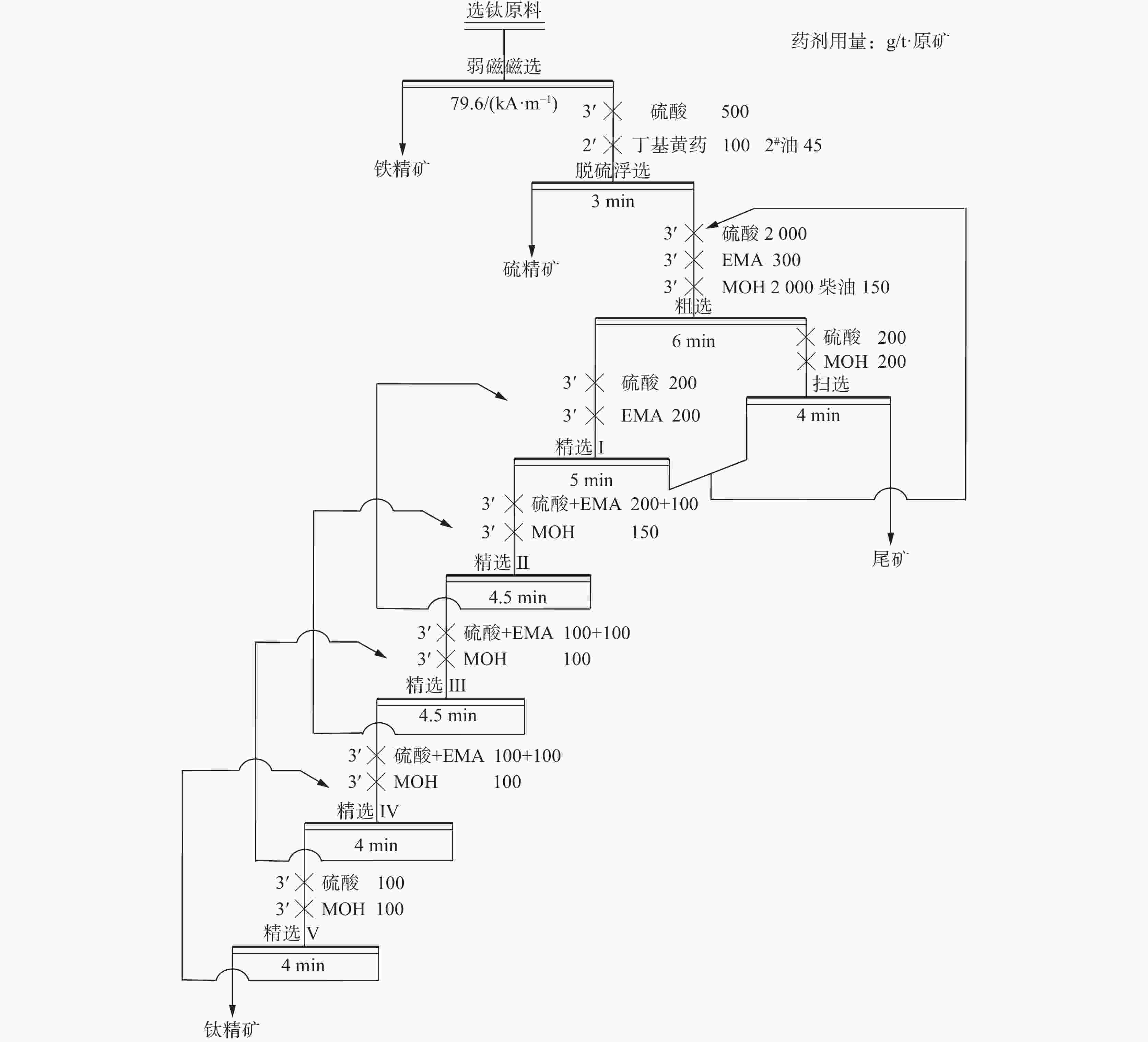

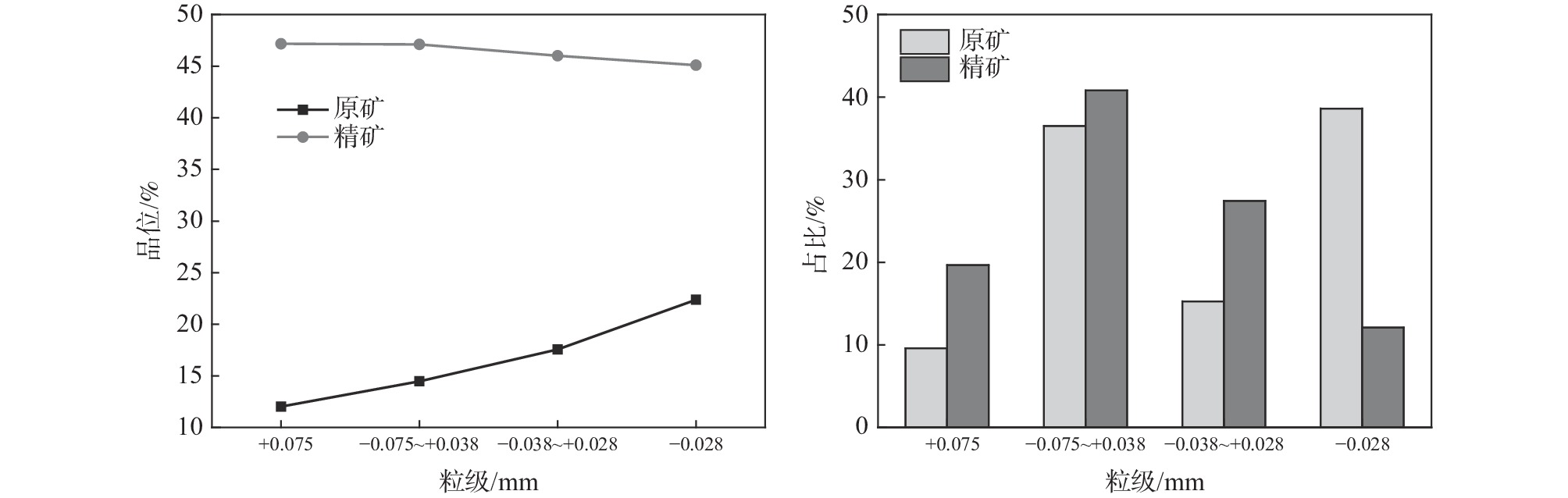

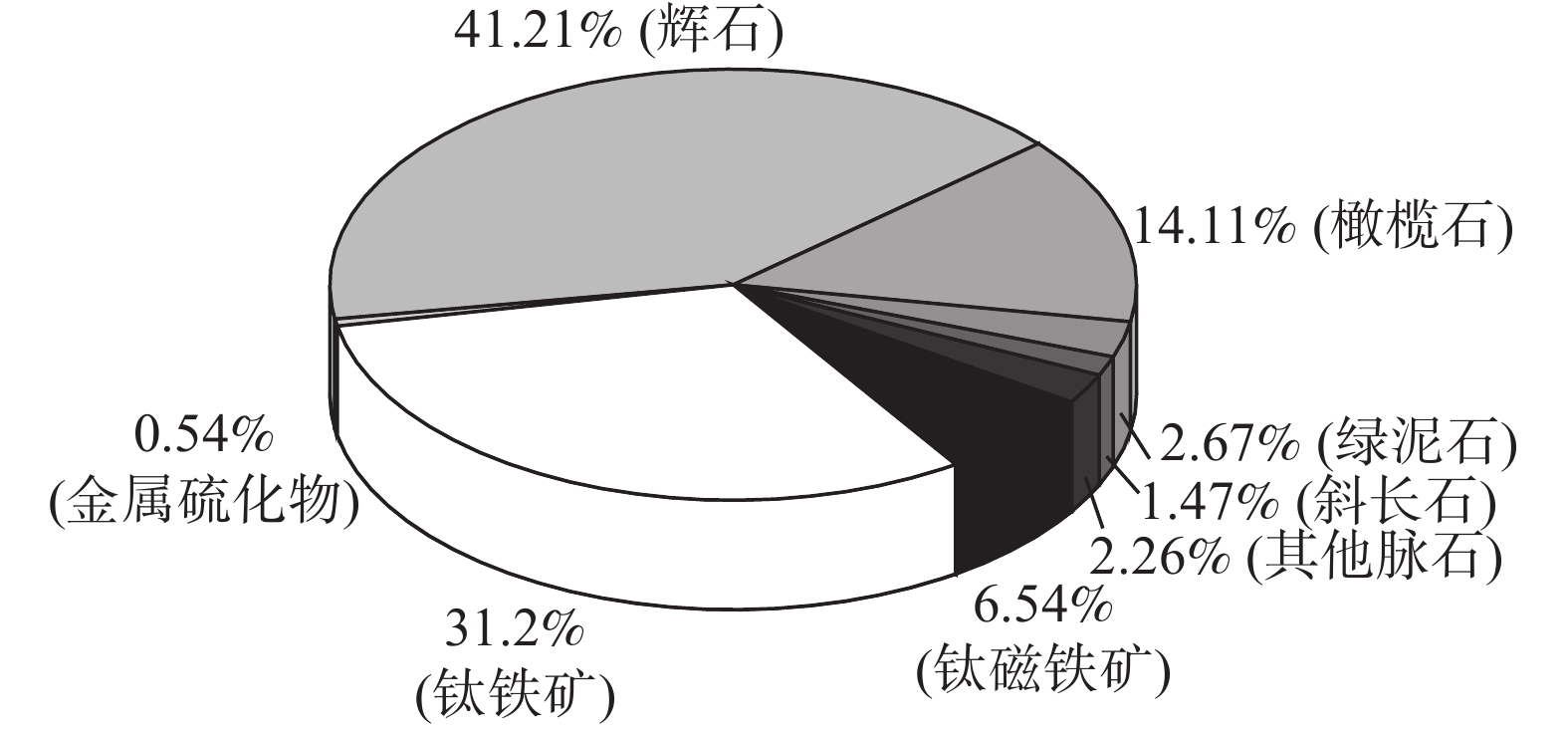

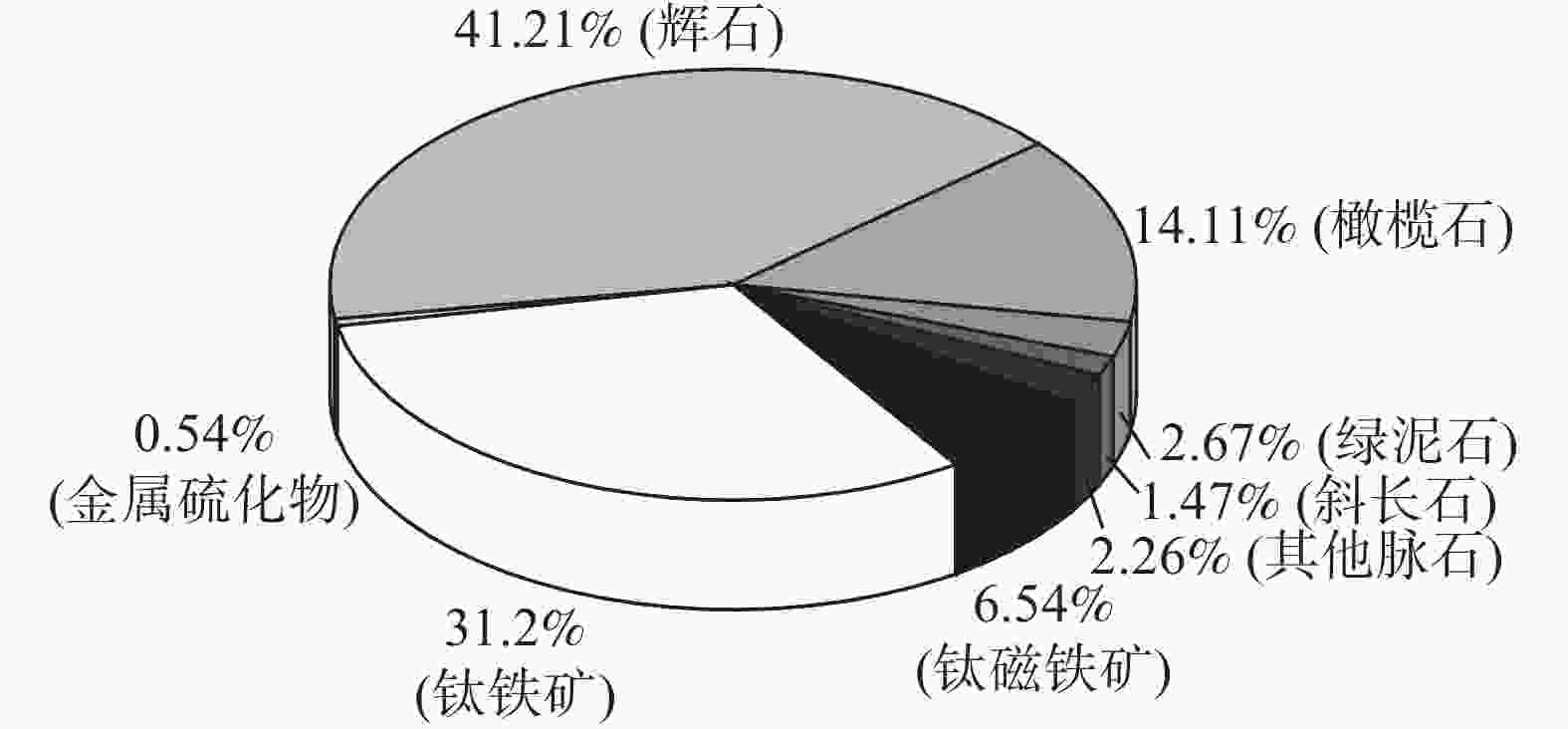

摘要: 针对攀西某选铁尾矿进行了钛铁矿浮选药剂优化试验研究,其TiO2品位为16.6%,主要矿物为钛铁矿、钛磁铁矿、辉石、橄榄石,次要矿物为斜长石、绿泥石。经过捕收剂、抑制剂、硫酸等药剂优化试验,利用硫酸+EMA+MOH,通过磁选除铁-浮选脱硫+一粗一扫五次精选选钛流程,闭路试验可以获得钛精矿产率25.18%,TiO2品位46.48%,回收率71.31%的良好指标,为攀西矿区选铁尾矿中钛铁矿的回收提供技术参考。Abstract: In this paper, the optimization test of ilmenite flotation reagents was carried out for an iron dressing tailing in Panxi. With a TiO2 grade of 16.6%, this tailing is mainly composed of ilmenite, titanomagnetite, pyroxene and olivine, and the secondary minerals are plagioclase and chlorite. The types and dosages of collectors, inhibitors and sulfuric acid were optimized. Using the combination of sulfuric acid, EMA and MOH, a five-time titanium concentration process was obtained, including iron removal by magnetic separation, flotation desulfurization, one rough selection and one sweep selection. Under the optimal conditions, a good index of titanium concentrate yield of 25.18%, TiO2 grade of 46.48% and recovery of 71.31% can be obtained in the closed circuit test, which provides a technical reference for the recovery of ilmenite from iron separation tailings in Panxi mining area.

-

Key words:

- ilmenite /

- iron separation tailings /

- flotation /

- reagent

-

表 1 原矿X荧光光谱(半定量)分析结果

Table 1. XRF analysis results of raw ore (semi quantitative)

% TiO2 Fe MgO SiO2 Al2O3 P2O5 S K2O CaO Na2O 15.839 15.798 15.779 29.132 2.68 0.030 0.216 0.031 9.451 0.125 Ni Co Cu Zn Cr2O3 Mn Nb Sr Zr Cl 0.058 0.033 0.016 0.012 0.124 0.300 0.001 0.006 0.006 0.028 表 2 原矿化学多元素分析结果

Table 2. Chemical multi-element analysis results of raw ore

% TiO2 TFe FeO Fe2O3 Cu Co Ni S P 16.60 16.18 15.78 5.58 0.011 0.030 0.036 0.23 0.016 表 3 浮选原矿筛分分析结果

Table 3. Screening analysis results of flotation raw ore

粒级/mm 产 率/% TiO2品位/% TiO2分布率/% +0.075 13.49 12.03 9.60 −0.075~+0.038 42.63 14.47 36.50 −0.038~+0.028 14.71 17.56 15.28 −0.028~+0.019 11.01 19.36 12.62 −0.019 18.16 24.20 26.00 原 矿 100.00 16.90 100.00 -

[1] Wang Xiangdong, Lu Fusheng, Jia Hong, et al. 2003 China titanium industry development report[J]. Titanium IndustryProgress, 2004,(2):30−36. (王向东, 逯福生, 贾翃, 等. 2003年中国钛工业发展报告[J]. 钛工业进展, 2004,(2):30−36. doi: 10.3969/j.issn.1009-9964.2004.02.005Wang Xiangdong, Lu Fusheng, Jia Hong, et al. 2003 China titanium industry development report [J] . Titanium IndustryProgress, 2004 (2): 30-36. doi: 10.3969/j.issn.1009-9964.2004.02.005 [2] Wang Changsong, Yao Wenjun, Lu Xiaohua. Overview of comprehensive utilization of ilmenite resources[J]. Inorganic Salt Industry, 2014,46(1):4−7. (王昌松, 姚文俊, 陆小华. 钛铁矿资源综合利用概述[J]. 无机盐工业, 2014,46(1):4−7. doi: 10.3969/j.issn.1006-4990.2014.01.002Wang Changshong, Yao Wenjun, Lu Xiaohua . Overview of comprehensive utilization of ilmenite resources [J]. Inorganic Salt Industry, 2014, 46 (1): 4-7. doi: 10.3969/j.issn.1006-4990.2014.01.002 [3] Zhang Xiaowei, Zhang Wanyi, Tong Ying, et al. Current situation and utilization trend of global titanium resources[J]. Mineral Protection and Utilization, 2019,39(5):68−75. (张晓伟, 张万益, 童英, 等. 全球钛矿资源现状与利用趋势[J]. 矿产保护与利用, 2019,39(5):68−75.Zhang Xiaowei, Zhang Wanyi, Tong Ying, et al. Current situation and utilization trend of global titanium resources [J]. Mineral Protection and Utilization, 2019, 39 (5): 68-75. [4] 中华人民共和国国土资源部. 中国矿产资源报告[M]. 北京: 地质出版社, 2017.Ministry of Land and Resources of the People's Republic of China. China mineral resources report [M]. Beijing: Geological Publishing House, 2017. [5] Zhu Fuxing, Jiao Yu, Li Liang, et al. Current situation and development trend of beneficiation technology of Panxi vanadium titanomagnetite[J]. Mining and Metallurgy, 2021,30(4):26−32,40. (朱福兴, 焦钰, 李亮, 等. 攀西钒钛磁铁矿的选矿技术现状及发展趋势[J]. 矿冶, 2021,30(4):26−32,40. doi: 10.3969/j.issn.1005-7854.2021.04.005Zhu Fuxing, Jiao Yu, Li Liang, et al. Current situation and development trend of beneficiation technology of Panxi vanadium titanomagnetite [J]. Mining and Metallurgy, 2021, 30 (4): 26-32, 40. doi: 10.3969/j.issn.1005-7854.2021.04.005 [6] Xu Lijun, Li Liang, Chen Liuxian, et al. Current situation and development direction of comprehensive recovery and utilization of vanadium titanium magnetite in Panxi area[J]. Sichuan Nonferrous Metals, 2011,(1):1−5. (徐丽君, 李亮, 陈六限, 等. 攀西地区钒钛磁铁矿综合回收利用现状及发展方向[J]. 四川有色金属, 2011,(1):1−5.Xu Lijun, Li Liang, Chen Liuxian, et al. Current situation and development direction of comprehensive recovery and utilization of vanadium titanium magnetite in Panxi area [J] Sichuan Nonferrous Metals, 2011 (1): 1-5. [7] Yang Yaohui, Hui Bo, Liao Xiangwen, et al. Beneficiation test of Hongge low-grade refractory olivine pyroxene type vanadium titanium magnetite ore[J]. Metal Mine, 2016,(10):77−82. (杨耀辉, 惠博, 廖祥文, 等. 攀西低品位难选橄辉岩型钒钛磁铁矿石选矿试验[J]. 金属矿山, 2016,(10):77−82. doi: 10.3969/j.issn.1001-1250.2016.10.016Yang Yaohui, Hui Bo, Liao Xiangwen, et al. Beneficiation test of Hongge low-grade refractory olivine pyroxene type vanadium titanium magnetite ore [J] . Metal Mine, 2016 (10): 77-82. doi: 10.3969/j.issn.1001-1250.2016.10.016 [8] Deng Bing, Zhang Yuan, Xu Ming, et al. Iron separation test of a vanadium titanomagnetite deep ore in Panxi[J]. Modern Mining, 2013,29(12):23−26. (邓冰, 张渊, 徐明, 等. 攀西某钒钛磁铁矿深部矿石选铁试验[J]. 现代矿业, 2013,29(12):23−26. doi: 10.3969/j.issn.1674-6082.2013.12.007Deng Bing, Zhang Yuan, Xu Ming, et al. Iron separation test of a vanadium titanomagnetite deep ore in Panxi [J]. Modern Mining, 2013, 29 (12): 23-26. doi: 10.3969/j.issn.1674-6082.2013.12.007 [9] Luo Jinhua. Distribution of main elements of Hongge vanadium titano-magnetite in mineral processing[J]. Comprehensive Utilization of Mineral Resources, 2015,(3):55−58. (罗金华. 红格钒钛磁铁矿主要元素在选矿中的分布[J]. 矿产综合利用, 2015,(3):55−58. doi: 10.3969/j.issn.1000-6532.2015.03.014Luo Jinhua . Distribution of main elements of Hongge vanadium titano-magnetite in mineral processing [J] . Comprehensive Utilization of Mineral Resources, 2015 (3): 55-58. doi: 10.3969/j.issn.1000-6532.2015.03.014 [10] 方帅. 攀西钛铁矿高效清洁浮选分离机制研究[D]. 绵阳: 西南科技大学, 2020.Fang Shuai . Study on efficient and clean flotation separation mechanism of Panxi ilmenite [D] . Mianyang: Southwest University of Science and Technology, 2020. [11] Xiao Wei, Shao Yanhai, Wei Jiayi, et al. Research status and prospect of ilmenite flotation reagent[J]. Mineral Protection and Utilization, 2021,41(5):160−167. (肖玮, 邵延海, 尉佳怡, 等. 钛铁矿浮选药剂研究现状及展望[J]. 矿产保护与利用, 2021,41(5):160−167.Xiao Wei, Shao Yanhai, Wei Jiayi, et al. Research status and prospect of ilmenite flotation reagent [J] . Mineral Protection and Utilization, 2021, 41 (5): 160-167. [12] Dong Wenchao, Liu Jian, Bai Xu, et al. Mechanism and progress of ilmenite flotation reagents[J]. Mineral Protection and Utilization, 2019,39(4):7. (董文超, 刘建, 白旭, 等. 钛铁矿浮选药剂作用机理及进展[J]. 矿产保护与利用, 2019,39(4):7.Dong Wenchao, Liu Jian, Bai Xu, et al. Mechanism and progress of ilmenite flotation reagents [J] . Mineral Protection and Utilization, 2019, 39 (4): 7. [13] Chen Mingjie, Wen Shuming, Hu Tianxi. Current situation and progress of ilmenite flotation research in China[J]. Foreign Metal Ore Dressing, 2005,(7):17−22. (陈名洁, 文书明, 胡天喜. 国内钛铁矿浮选研究的现状与进展[J]. 国外金属矿选矿, 2005,(7):17−22.Chen Mingjie, Wen Ming, Hu Tianxi . Current situation and progress of ilmenite flotation research in China [J] . Foreign Metal Ore Dressing, 2005 (7): 17-22. [14] Feng Qiming, Xi Zhenwei, Zhang Guofan, et al. Study on flotation performance of ilmenite with fatty acid collector[J]. Metal Mine, 2009,(5):46−45. (冯其明, 席振伟, 张国范, 等. 脂肪酸捕收剂浮选钛铁矿性能研究[J]. 金属矿山, 2009,(5):46−45. doi: 10.3321/j.issn:1001-1250.2009.05.012Feng Qiming, Xi Zhenwei, Zhang Guofan, et al. Study on flotation performance of ilmenite with fatty acid collector [J] . Metal Mine, 2009 (5): 46-45. doi: 10.3321/j.issn:1001-1250.2009.05.012 -

下载:

下载: