Experimental study on comprehensive recovery of a beach placer ore abroad

-

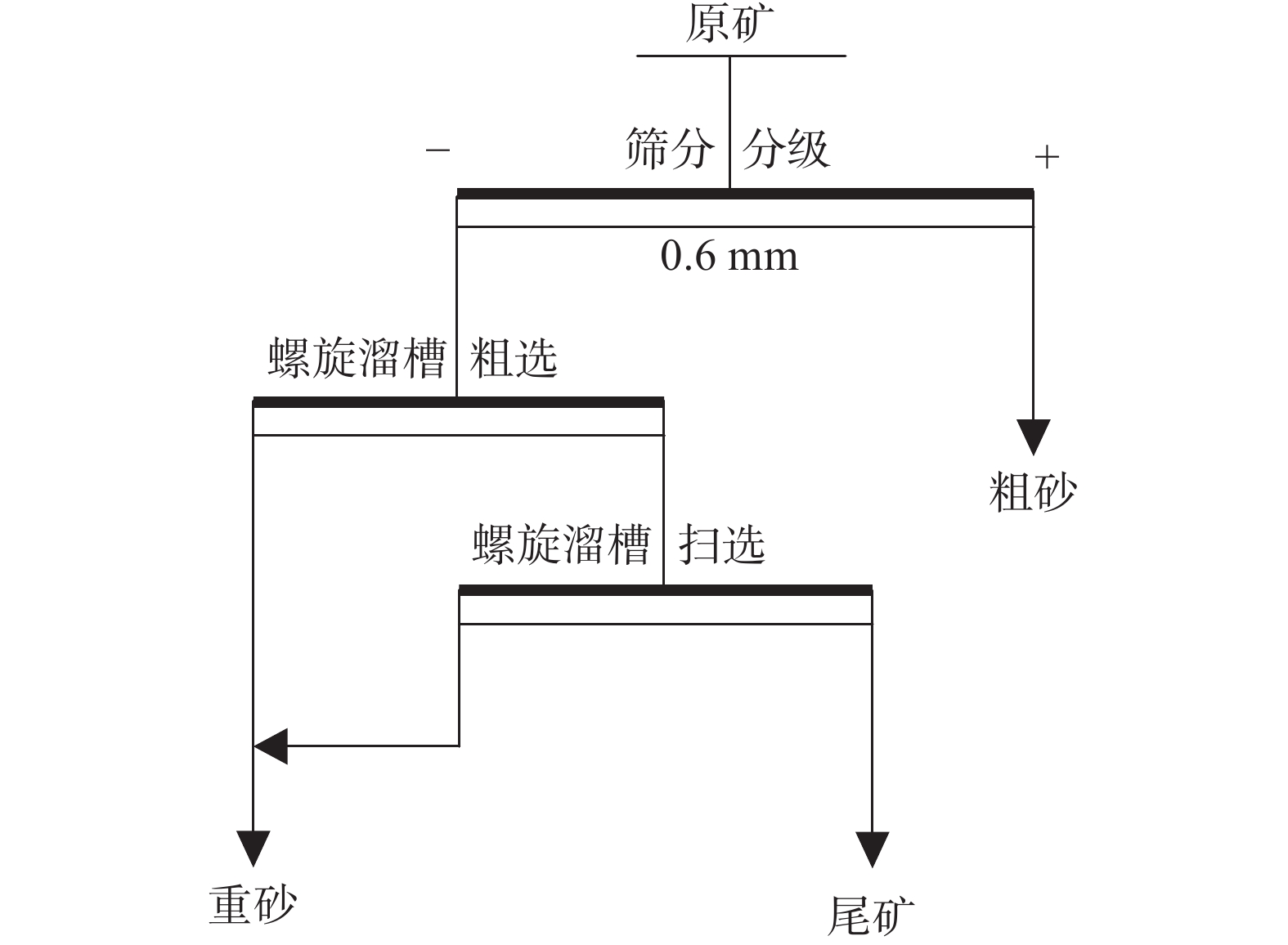

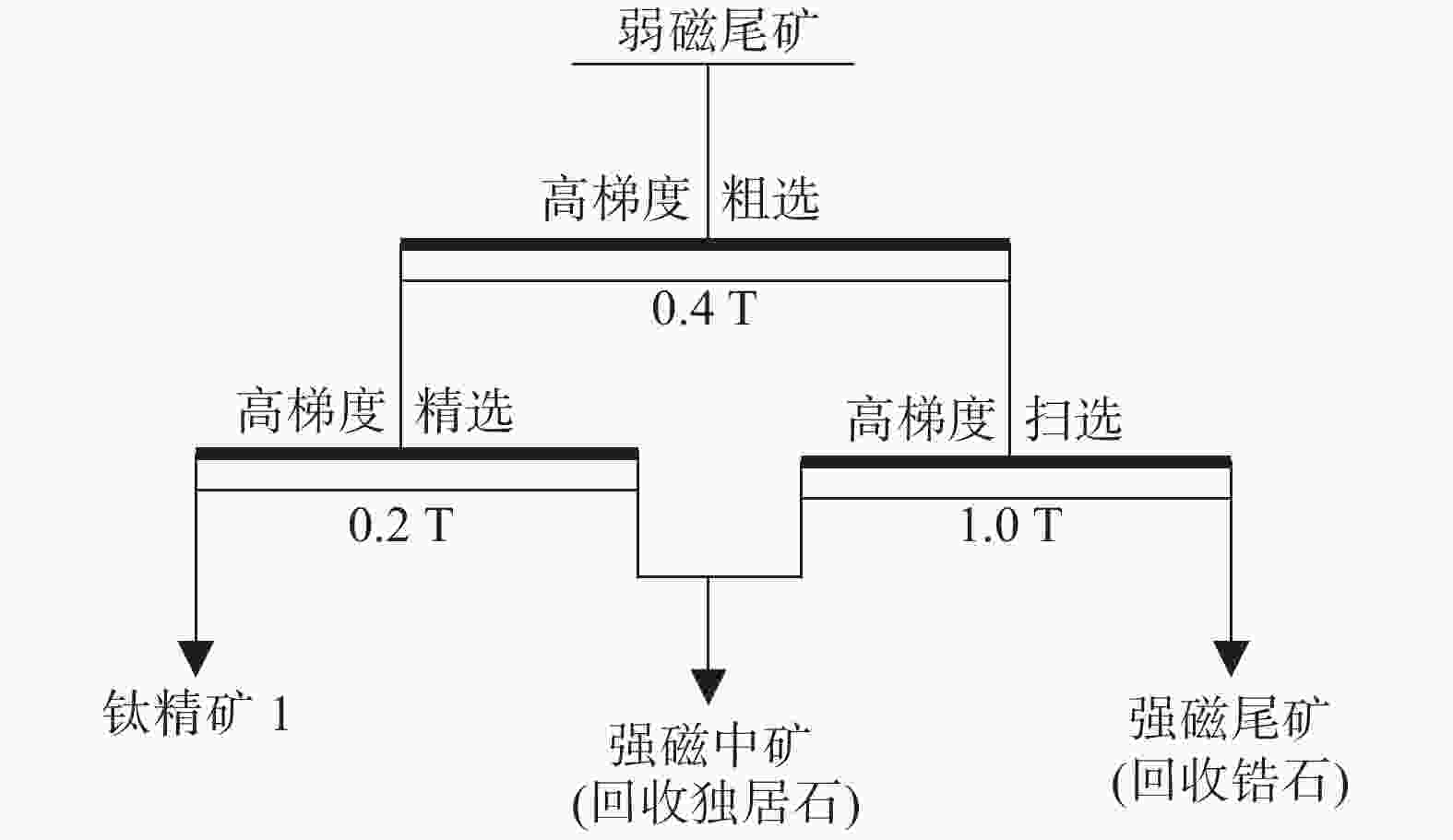

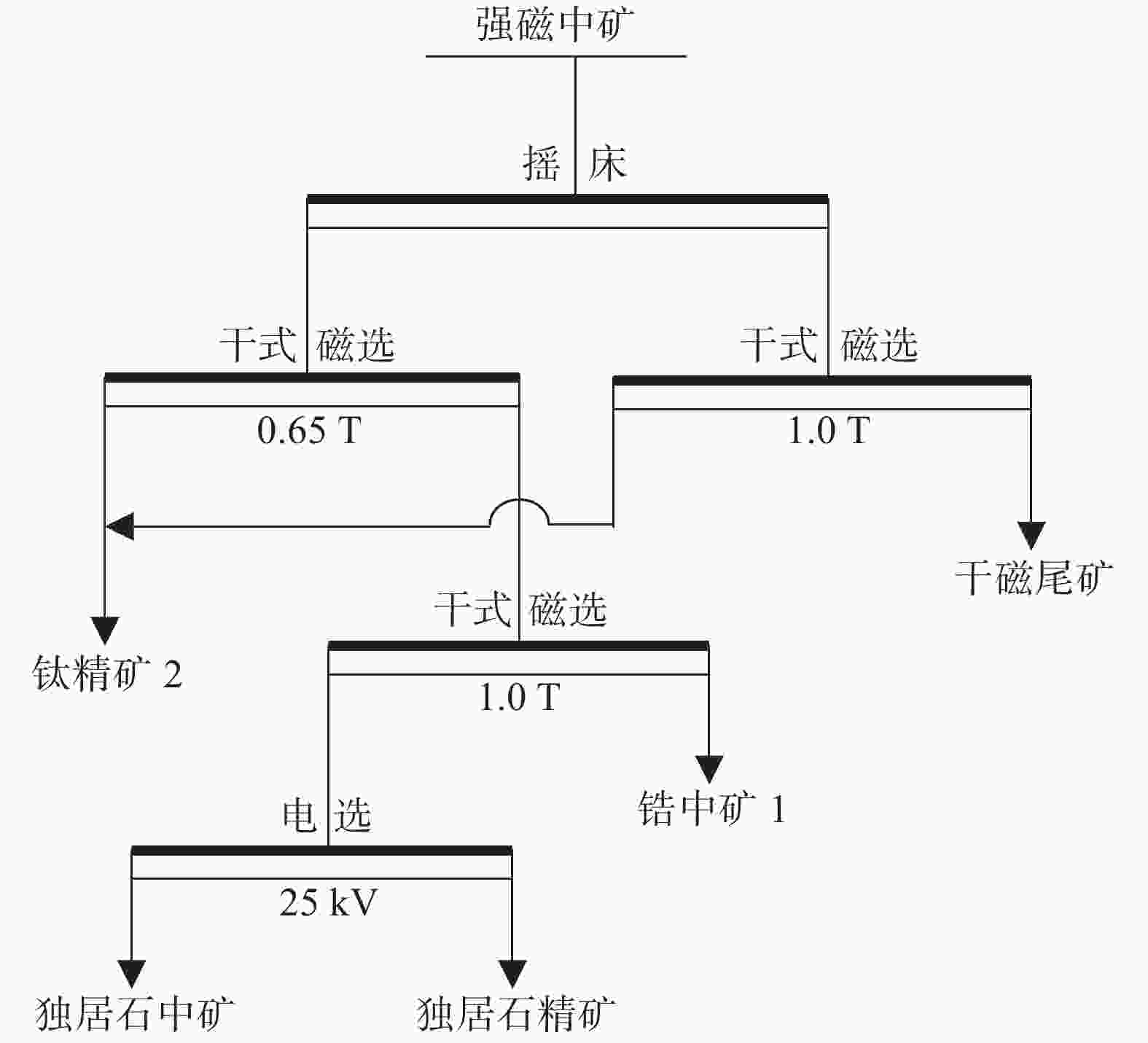

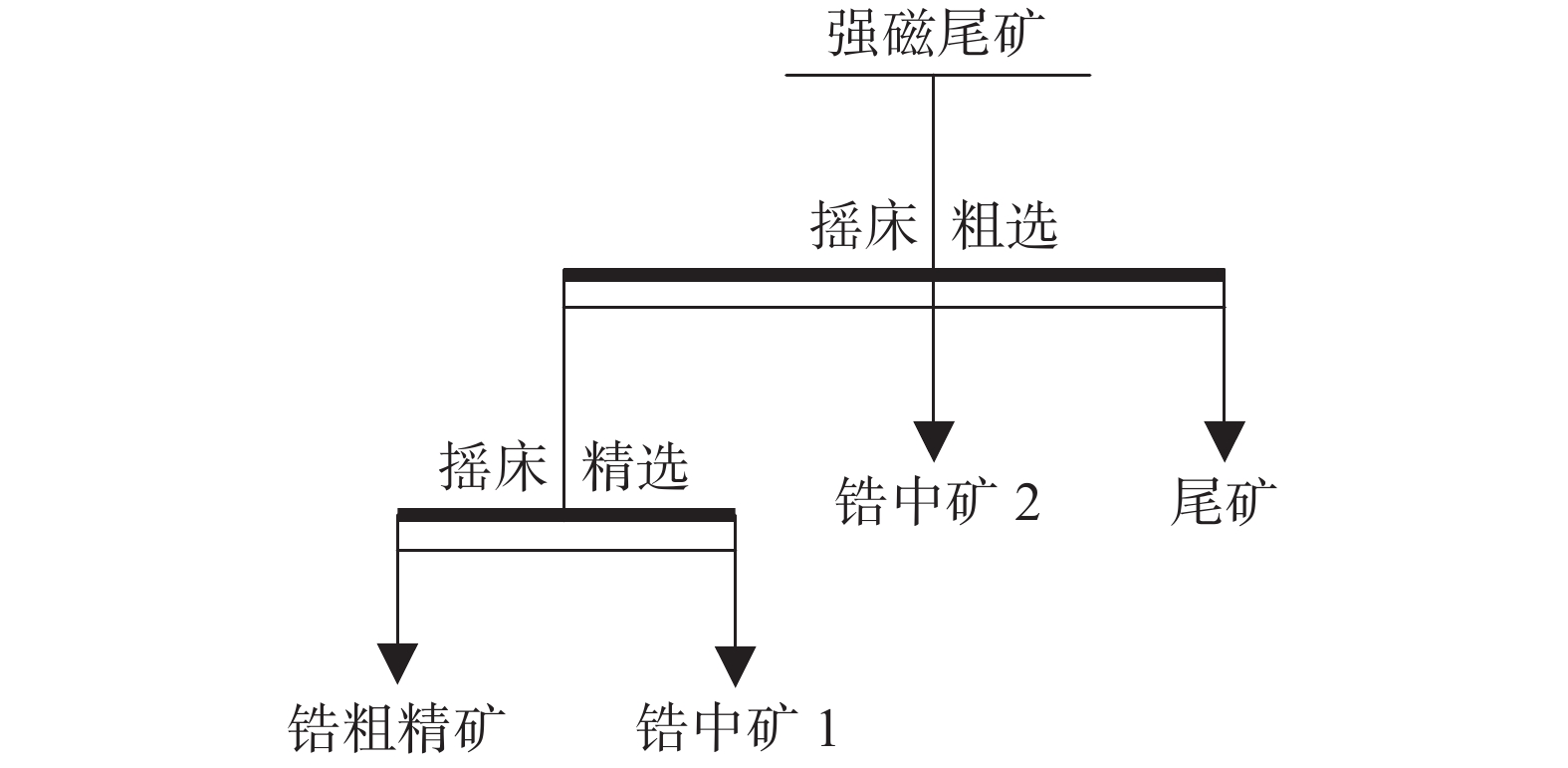

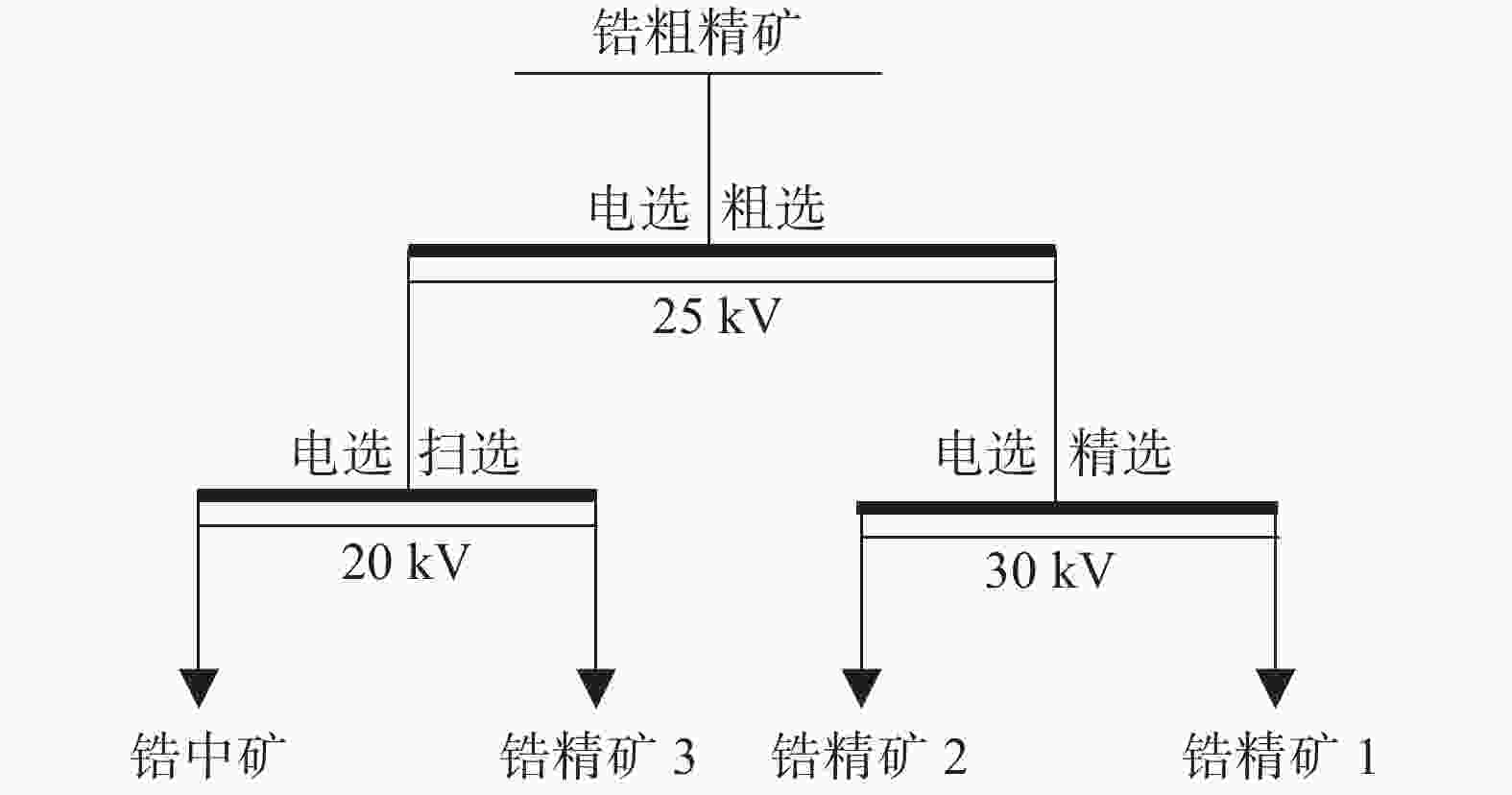

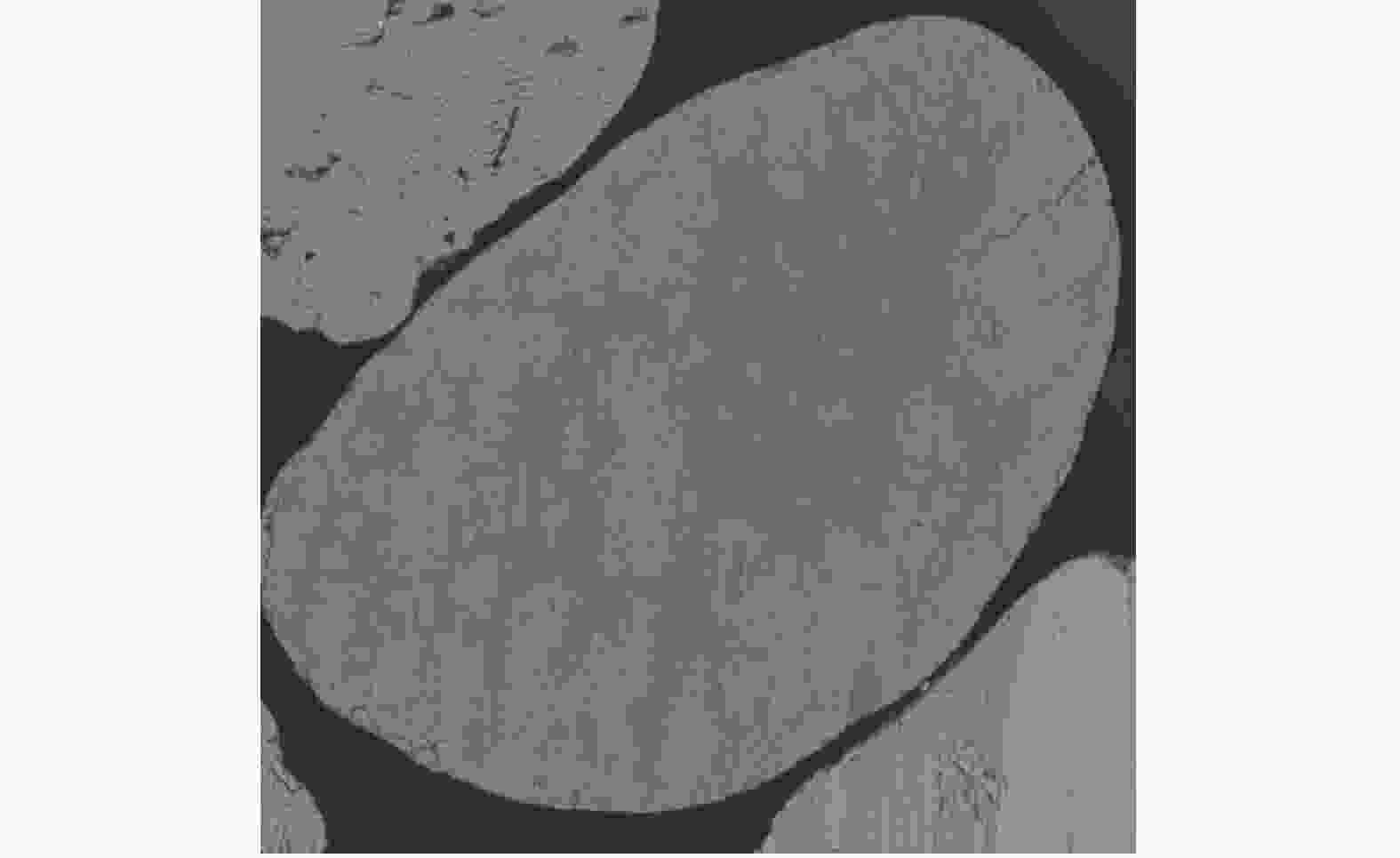

摘要: 国外某海滨砂矿富含钛铁矿、锆石、独居石等多种有用矿物。钛铁矿矿物经历蚀变,部分锆石表面被铁污染,矿物磁、电性质发生变化,较为难选。采用筛选—螺旋溜槽一粗一扫工艺预富集重矿物,获得产率23.78%,Fe、TiO2、REO、Zr(Hf)O2品位分别为25.76%、43.73%、0.44%、2.83%,回收率分别为93.70%、93.11%、78.32%、93.64%的重砂。针对重砂,采用弱磁选铁—高梯度强磁选一粗一精一扫,分离出部分磁性较强钛精矿,强磁中矿采用摇床—干式磁选—电选流程分离出独居石精矿和另一部分磁性较弱钛精矿,强磁尾矿进行摇床选锆—锆粗精矿进行电选除杂,从而分离出铁精矿、钛精矿、独居石精矿和锆精矿产品。相对重砂,精矿与中矿中TiO2、REO、Zr(Hf)O2综合回收率分别为99.16%、67.71%、89.56%,实现了有用矿物的综合回收。研究结果可为类似海滨砂矿的开发和综合回收提供参考。Abstract: There is a beach placer ore abroad, which is rich in ilmenite, zircon, monazite and other valuable minerals. Oxidation alteration of ilmenite and some contaminated zircon surface with iron change the magnetic and electrical properties of the minerals, which makes it difficult to separate. In view of the complex characteristics of raw ore, a process of sieve and one rough-one sweep with spiral chute was carried out to enrich the heavy minerals in a 23.78% yield concentrate, in which the grade of Fe, TiO2, REO and Zr(Hf)O2 were 25.76%, 43.73%, 0.44%, 2.83%, while the recovery were 93.70%, 93.11%, 78.32%, 93.64%, respectively. Based on the heavy minerals concentrate, a process including low-intensity magnetic separation of iron, then one rough one fine and one sweep with high-intensity magnetic separation (WHIMS) was applied to separate ilmenite and enrich monazite. Part of stronger magnetic ilmenite was separated in WHIMS final concentrate, monazite and another part of weaker magnetic ilmenite in WHIMS middling were separated by a process of table separation, dry magnetic separation and high-tension separation. Zircon in WHIMS tailings was separated by a process of table separation and then high-tension separation for impurities removal of rough zircon concentrate. The separation of magnetite concentrate, ilmenite concentrate, monazite concentrate and zirconium concentrate were finally achieved. The total TiO2, REO and Zr(Hf)O2 recovery rate of heavy minerals concentrate were 99.16%, 67.71% and 89.56% respectively. The comprehensive recovery of valuable minerals was realized. This research could be a reference for the exploitation of similar beach placer ores.

-

Key words:

- beach placer ores /

- comprehensive recovery /

- ilmenite /

- zircon /

- monazite

-

表 1 原矿多元素分析

Table 1. Multi-elemental analysis results of raw ore

% Fe TiO2 Zr(Hf)O2 REO MgO Al2O3 SiO2 6.39 10.96 0.70 0.13 0.32 0.85 77.81 表 2 原矿主要矿物组成

Table 2. Main mineral compositions and content in raw ore

% 钛铁矿 金红石 白钛石 锆石 独居石 磁铁矿 钛赤铁矿 褐铁矿 榍石 18.52 0.03 0.27 1.06 0.23 0.13 0.66 0.12 0.04 石英 长石 角闪石 尖晶石 三水铝石 蓝晶石 高岭石 其他 合计 76.64 0.52 0.19 0.35 0.25 0.47 0.12 0.41 100 表 3 原矿主要金属粒度分布

Table 3. Grain size of main valuable metal elements in raw ore

粒级/mm 产率/% 品位/% 占有率/% Fe TiO2 Zr(Hf)O2 Fe TiO2 Zr(Hf)O2 +1.25 1.58 1.46 2.04 0.15 0.37 0.31 0.33 −1.25~+1.0 1.50 0.19 0.17 0.035 0.05 0.02 0.07 −1.0~+0.5 20.59 0.17 0.23 0.057 0.57 0.45 1.61 −0.5~+0.25 52.58 3.05 5.57 0.28 26.00 25.58 20.19 −0.25~+0.1 22.58 20.03 33.25 2.39 71.13 72.04 74.03 −0.1~+0.075 0.36 16.28 24.41 5.38 0.96 0.85 2.68 −0.075~+0.038 0.25 9.36 5.78 1.98 0.37 0.14 0.67 −0.038 0.55 6.18 11.61 0.57 0.55 0.61 0.43 合计 100.00 6.30 10.69 0.73 100.00 100.00 100.00 表 4 原矿重选预富集试验结果

Table 4. Results of heavy minerals preconcentration from the raw ores by gravity separation

产品

名称产率/% 品位/% 回收率/% Fe TiO2 REO Zr(Hf)O2 Fe TiO2 REO Zr(Hf)O2 重砂 23.78 25.76 43.73 0.44 2.83 93.70 93.11 78.32 93.64 尾矿 55.24 0.66 1.28 0.044 0.066 5.56 6.33 18.22 5.08 粗砂 20.98 0.23 0.30 0.022 0.044 0.74 0.56 3.46 1.28 原矿 100.00 6.54 11.17 0.13 0.72 100.00 100.00 100.00 100.00 表 5 弱磁选铁试验结果

Table 5. Results of magnetite separation from heavy concentrate by low-intensity magnetic separation

产品名称 对重砂产率/% 品位/% 对重砂回收率/% Fe TiO2 Fe TiO2 铁精矿 0.19 45.48 8.04 0.34 0.03 尾矿 99.81 25.72 43.80 99.66 99.97 重砂 100.00 25.76 43.73 100.00 100.00 表 6 高梯度磁场强度条件试验结果

Table 6. Experimental results of high gradient magnetic field intensity

场强/

T产品

名称作业

产率/%品位/% 作业回收率/% TiO2 REO Zr(Hf)O2 TiO2 REO Zr(Hf)O2 0.2 精矿 51.26 51.92 0.12 0.15 60.77 14.08 2.72 尾矿 48.74 35.25 0.77 5.64 39.23 85.92 97.28 弱磁尾矿 100.00 43.80 0.44 2.83 100.00 100.00 100.00 0.3 精矿 68.57 52.47 0.16 0.25 82.14 24.99 6.06 尾矿 31.43 24.89 1.05 8.45 17.86 75.01 93.94 弱磁尾矿 100.00 43.80 0.44 2.83 100.00 100.00 100.00 0.4 精矿 75.97 52.70 0.21 0.31 91.41 36.20 8.29 尾矿 24.03 15.65 1.17 10.84 8.59 63.80 91.71 弱磁尾矿 100.00 43.80 0.44 2.84 100.00 100.00 100.00 0.5 精矿 77.69 53.32 0.35 0.47 94.58 61.91 12.91 尾矿 22.31 10.65 0.75 11.04 5.42 38.09 87.09 弱磁尾矿 100.00 43.80 0.44 2.83 100.00 100.00 100.00 0.6 精矿 79.26 53.31 0.39 0.52 96.46 69.96 14.60 尾矿 20.74 7.48 0.64 11.62 3.54 30.04 85.40 弱磁尾矿 100.00 43.80 0.44 2.82 100.00 100.00 100.00 0.8 精矿 80.21 53.16 0.42 0.55 97.35 76.56 15.64 尾矿 19.79 5.86 0.52 12.02 2.65 23.44 84.36 弱磁尾矿 100.00 43.80 0.44 2.82 100.00 100.00 100.00 1.0 精矿 82.26 52.71 0.43 0.60 98.99 80.39 17.50 尾矿 17.74 2.48 0.49 13.11 1.01 19.61 82.50 弱磁尾矿 100.00 43.80 0.44 2.82 100.00 100.00 100.00 表 7 高梯度磁选回收钛、稀土试验结果

Table 7. Results of high gradient magnetic separation of ilmenite and monazite from tailingS of low intensity magnetic separation

产品

名称产率/% 品位/% 回收率/% TiO2 REO Zr(Hf)O2 TiO2 REO Zr(Hf)O2 钛精矿1 52.34 52.35 0.06 0.11 62.66 7.19 2.03 强磁中矿 32.87 49.13 1.10 1.45 36.93 82.79 16.81 强磁尾矿 14.6 1.13 0.30 15.74 0.38 10.02 81.16 弱磁尾矿 99.81 43.80 0.44 2.84 99.97 100.00 100.00 表 8 强磁中矿独居石精选分离试验结果

Table 8. Results of monazite separation from high intensity magnetic middlings

产品

名称产率/% 品位/% 回收率/% TiO2 REO Zr(Hf)O2 TiO2 REO Zr(Hf)O2 钛精矿2 28.91 55.21 0.05 0.04 36.50 3.97 0.84 锆中矿1 1.02 6.48 3.34 42.25 0.15 7.8 15.22 独居石精矿 0.53 0.18 52.74 1.18 0.00 63.96 0.22 独居石中矿 0.07 21.49 23.4 0.44 0.04 3.75 0.01 干磁尾矿 2.34 4.43 0.62 0.63 0.24 3.32 0.52 强磁中矿 32.87 49.13 1.10 1.45 36.93 82.80 16.81 表 9 强磁尾矿摇床选锆试验结果

Table 9. Table separation results of Zr from high intensity magnetic tailings

产品名称 产率/% 品位/% 回收率/% Fe TiO2 REO Zr(Hf)O2 TiO2 REO Zr(Hf)O2 锆粗精矿 3.11 0.46 2.29 0.13 63.03 0.16 0.93 69.23 锆中矿1 0.12 0.48 2.45 0.26 55.56 0.01 0.07 2.35 锆中矿2 0.87 0.35 1.43 0.42 24.65 0.03 0.84 7.58 尾矿 10.50 0.32 0.75 0.34 0.54 0.18 8.18 2.00 强磁尾矿 14.60 0.15 1.13 0.30 15.74 0.38 10.02 81.16 表 10 锆粗精矿电选试验结果

Table 10. High-tension separation results of rough zircon concentrate

产品名称 产率/% 品位/% 回收率/% Fe TiO2 Zr(Hf)O2 TiO2 Zr(Hf)O2 锆中矿 0.32 2.43 20.8 42.22 0.15 4.83 锆精矿3 0.31 0.36 0.26 65.04 0.00 7.16 锆精矿2 0.77 0.40 0.22 65.12 0.00 17.74 锆精矿1 1.70 0.13 0.08 65.67 0.00 39.51 锆粗精矿 3.11 0.46 2.29 63.03 0.16 69.23 表 11 重砂精选试验指标汇总

Table 11. Results of concentrate and middlings recovered from heavy minerals preconcentrate

元素 产品名称 对重砂产率/% 品位/% 对重砂回收率/% Fe 铁精矿 0.19 45.48 0.33 TiO2 钛精矿 81.25 53.37 99.16 REO 独居石精矿 0.53 52.74 63.96 独居石中矿 0.07 23.40 3.75 小计 67.71 Zr(Hf)O2 锆精矿1 1.7 65.67 39.51 锆精矿2+3 1.08 65.10 24.90 锆中矿合计 2.21 35.98 25.15 小计 89.56 -

[1] 周乐光. 矿石学基础[M]. 北京: 冶金工业出版社, 2007.Zhou Leguang. Fundamentals of minerals[M]. Beijing: Metallurgical Industry Press, 2007. [2] Liao Qian, Gong Wenyong, Zhang Jianwen, et al. Experimental study on pre-enrichment by gravity separation in a beach placer[J]. Hunan Nonferrous Metals, 2020,36(1):15−17,51. (廖乾, 龚文勇, 张建文, 等. 某海滨砂矿重选预富集试验研究[J]. 湖南有色金属, 2020,36(1):15−17,51.Liao Qian, Gong Wenyong, Zhang Jianwen, et al. Experimental study on pre-enrichment by gravity separation in a beach placer[J]. Hunan Nonferrous Metals, 2020, 36(1): 15-17, 51. [3] 王正铤. 中国滨海砂矿分布规律[C]//中国地质科学院天津地质矿产研究所所刊(21). 天津: 1989: 124-133.Wang Zhengting. The distributive regularity of sea beach placer in China[C]// Journal of Bulletin Tianjin Institute Geol. Mjn. Res. No. 21. Tianjin: Bulletin Tianjin Institute Geol. Mjn. Res. 1989: 124-133. [4] Sun Yan, Han Changfu. Distribution and exploitation of placer deposit resources in China[J]. Marine Geology & Quaternary Geology, 1999,(1):123−127. (孙岩, 韩昌甫. 我国滨海砂矿资源的分布及开发[J]. 海洋地质与第四纪地质, 1999,(1):123−127.Sun Yan, Han Changfu. Distribution and exploitation of placer deposit resources in China[J]. Marine Geology & Quaternary Geology, 1999(1): 123-127. [5] Long Yunbo, Zhang Yushu, Zhou Mangeng, et al. Experimental research on mineral processing of beach placer from Wanning in Hainan province[J]. Multipurpose Utilization of Mineral Resources, 2011,(4):14−17. (龙运波, 张裕书, 周满赓, 等. 海南万宁海滨砂矿选矿试验研究[J]. 矿产综合利用, 2011,(4):14−17.Long Yunbo, Zhang Yushu, Zhou Mangeng, et al. Experimental research on mineral processing of beach placer from Wanning in Hainan province[J]. Multipurpose Utilization of Mineral Resources, 2011(4): 14-17. [6] Zhang Jianwen, Wang Haidong, Gong Wenyong, et al. Analysis on the development and utilization situation of zirconium resource in China[J]. Conservation and Utilization of Mineral Resources, 2019,39(5):106−110. (张建文, 王海东, 龚文勇, 等. 中国锆矿资源开发利用形势分析[J]. 矿产保护与利用, 2019,39(5):106−110.Zhang Jianwen, Wang Haidong, Gong Wenyong, et al. Analysis on the development and utilization situation of zirconium resource in China[J]. Conservation and Utilization of Mineral Resources, 2019, 39(5): 106-110. [7] Li Kai, Deng Xingcai, Ye Zhiping. Development and utilization of shore sand minerals in Madagascar[J]. Resources & Industries, 2009,11(5):30−34. (李恺, 邓杏才, 叶志平. 马达加斯加海滨砂矿的开发利用[J]. 资源与产业, 2009,11(5):30−34.Li Kai, Deng Xingcai, Ye Zhiping. Development and utilization of Shore sand minerals in Madagascar[J]. Resources & Industries, 2009, 11(5): 30-34. [8] Liu Chengzong. Study on the new process of screen—spiral separation for beach placers[J]. Journal of Guangdong Non-Ferrous Metals, 1992,(2):102−107. (刘承宗. 海滨砂矿筛选-螺旋选矿新工艺的研究[J]. 广东有色金属学报, 1992,(2):102−107.Liu Chengzong. Study on the new process of screen—spiral separation for beach placers[J]. Journal of Guangdong Non-Ferrous Metals, 1992(2): 102-107. -

下载:

下载: