Experimental study on beneficiation of a foreign primary ilmenite ore

-

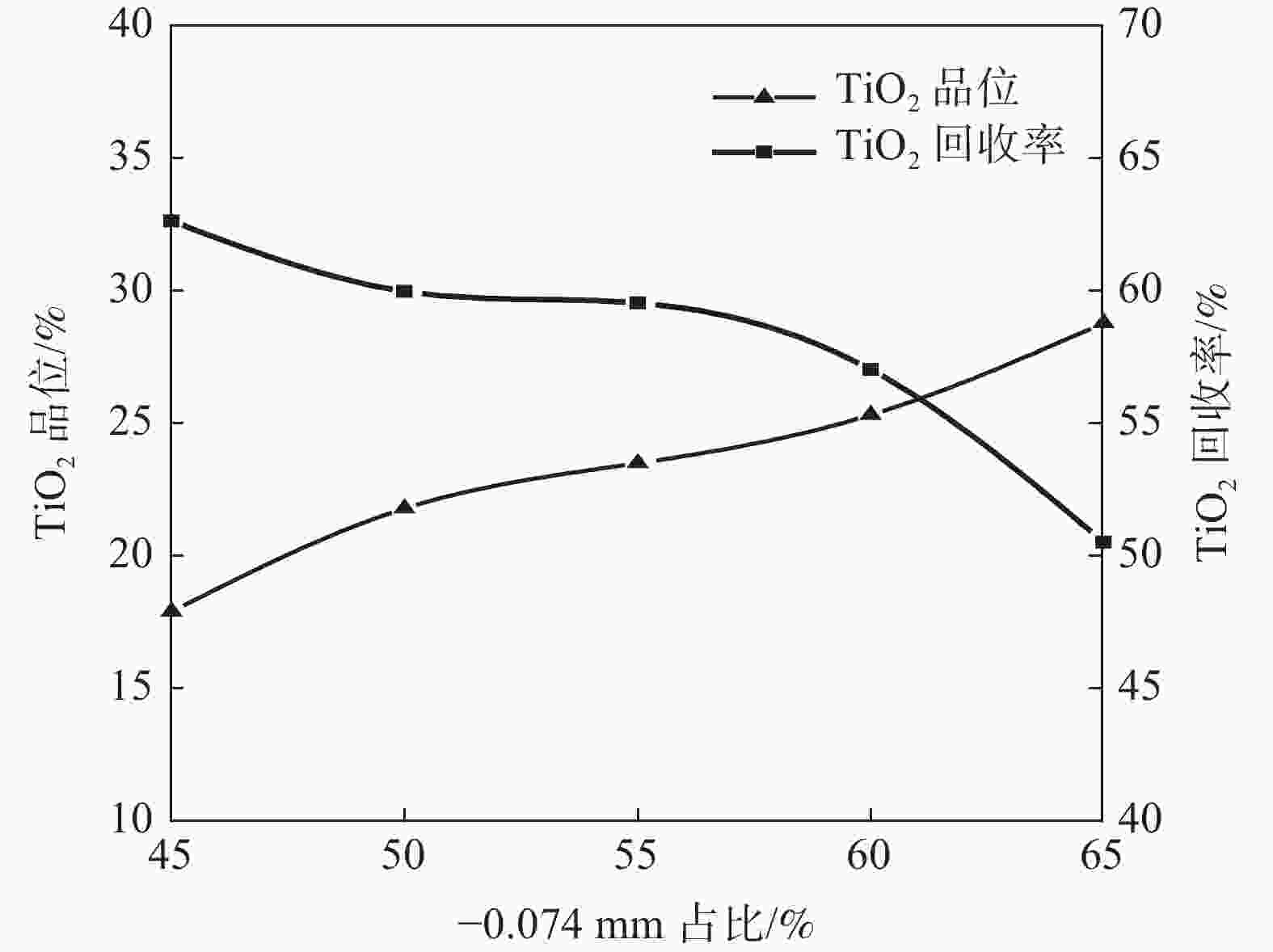

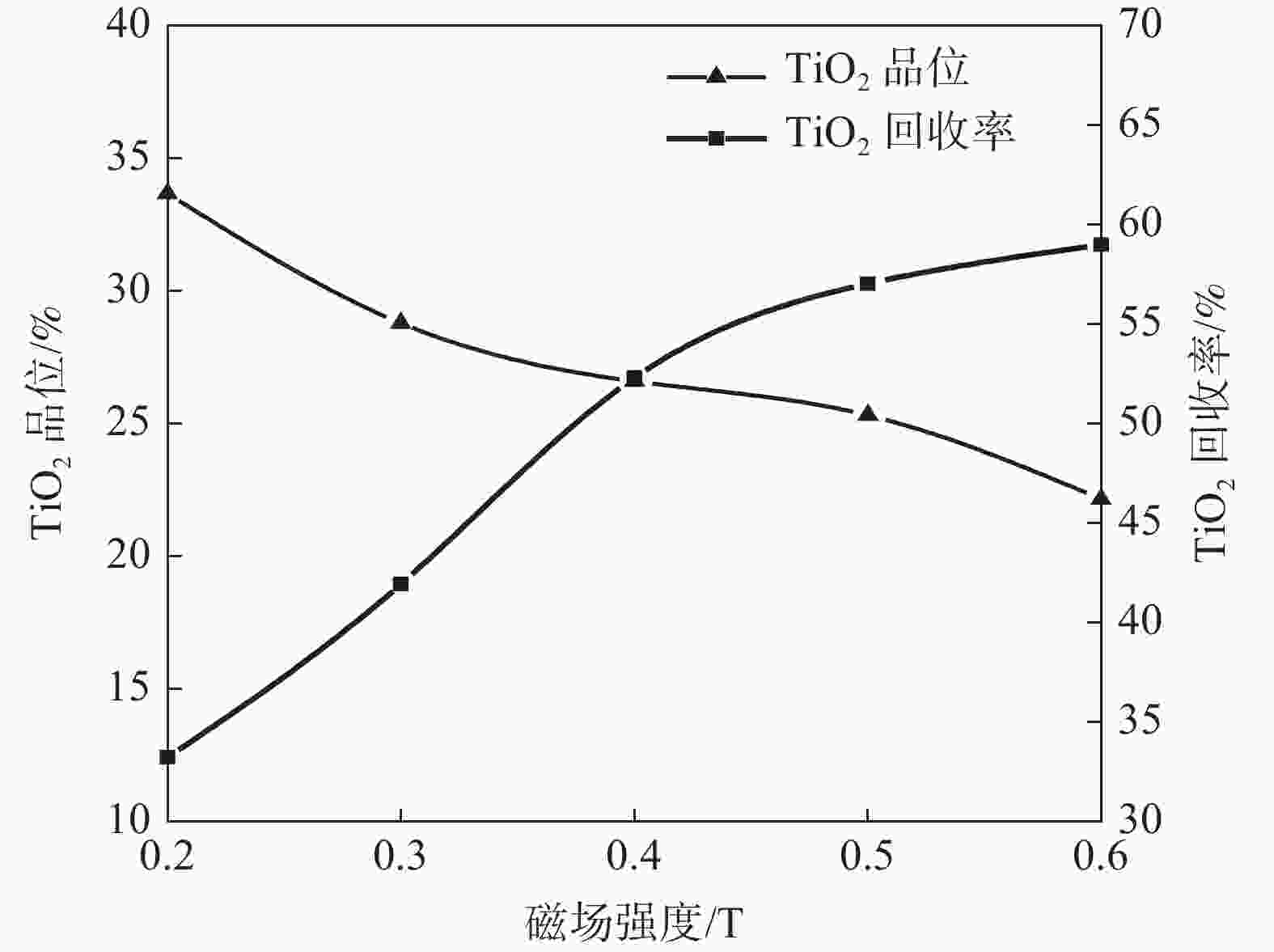

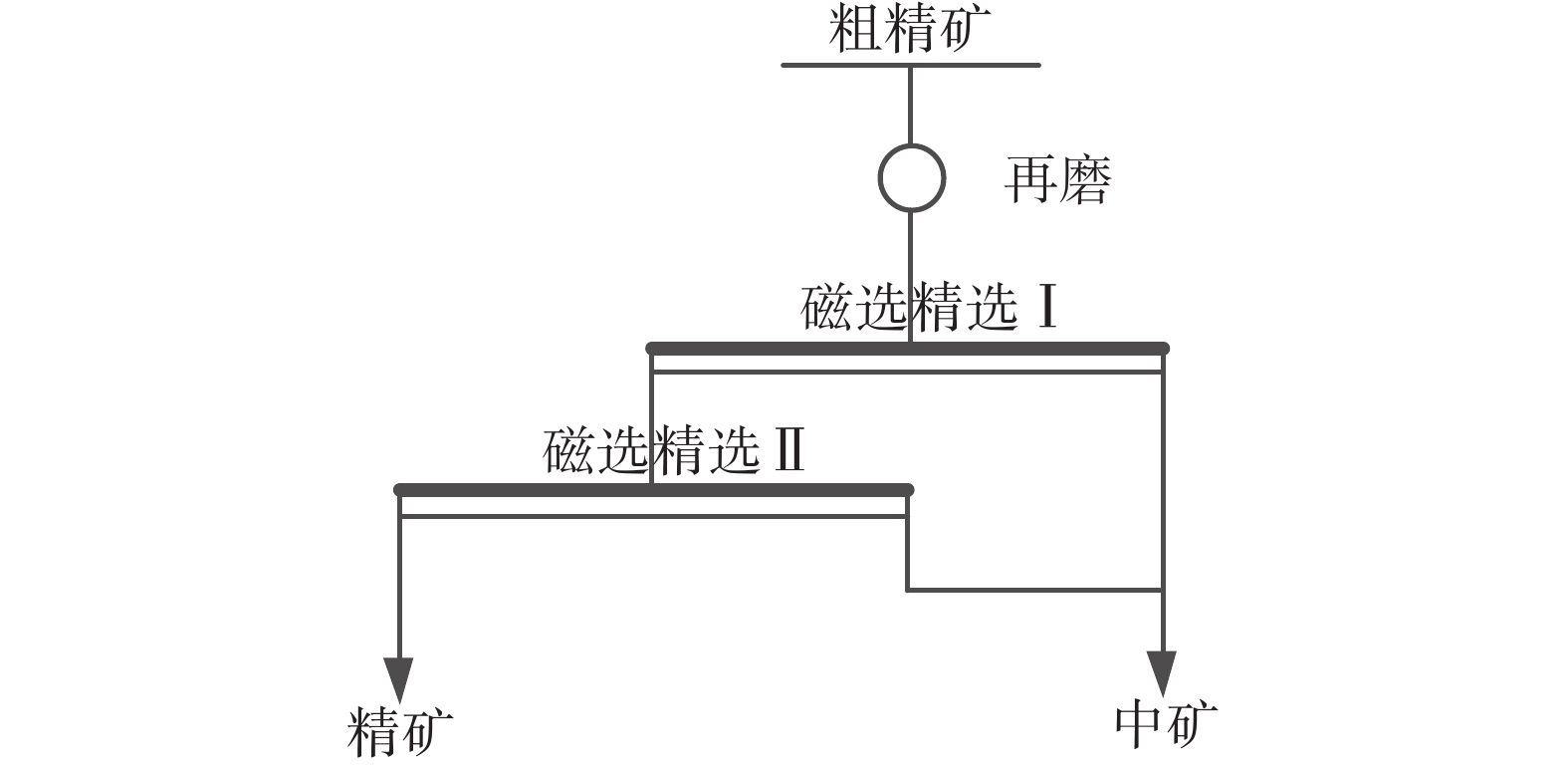

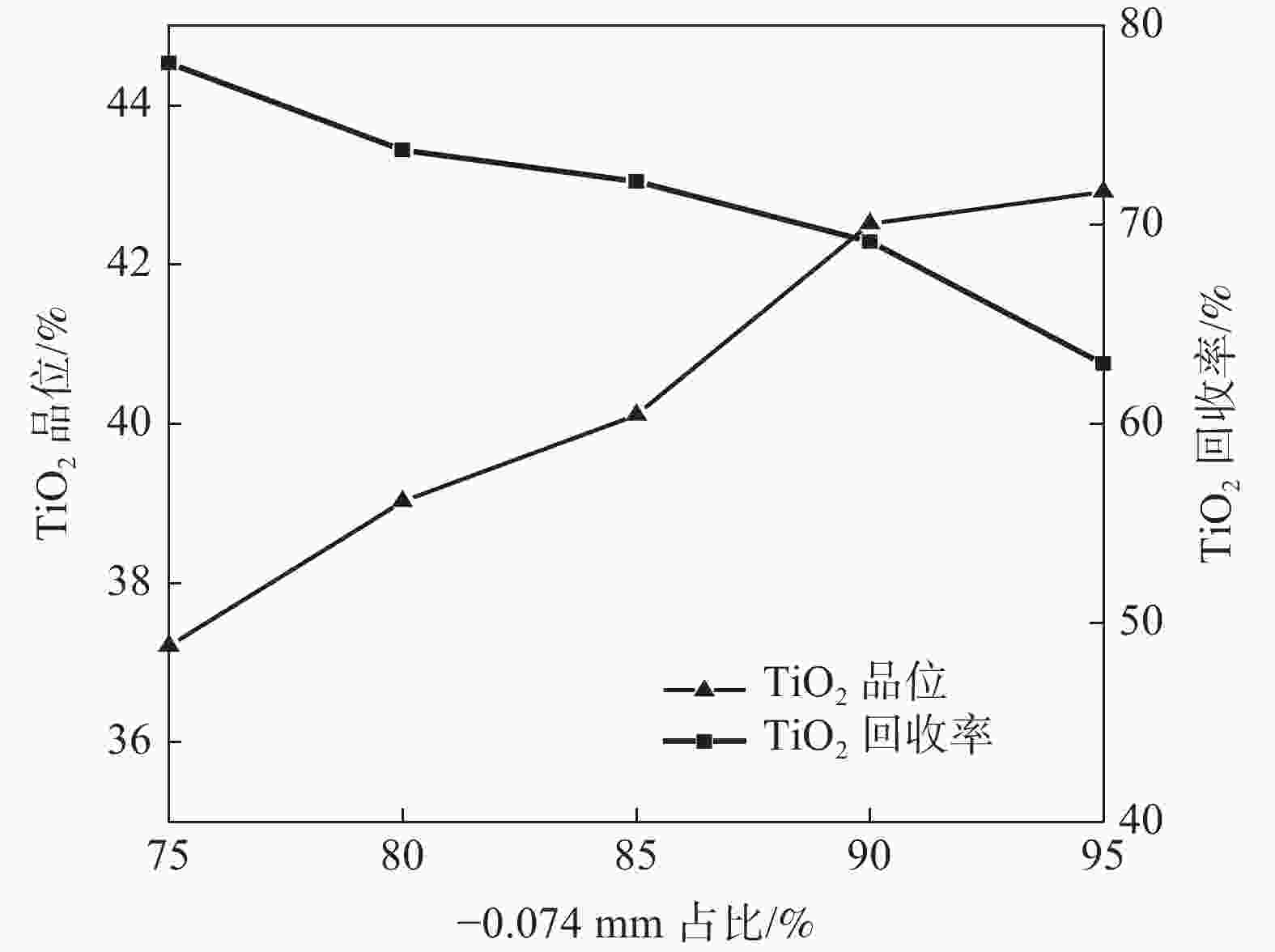

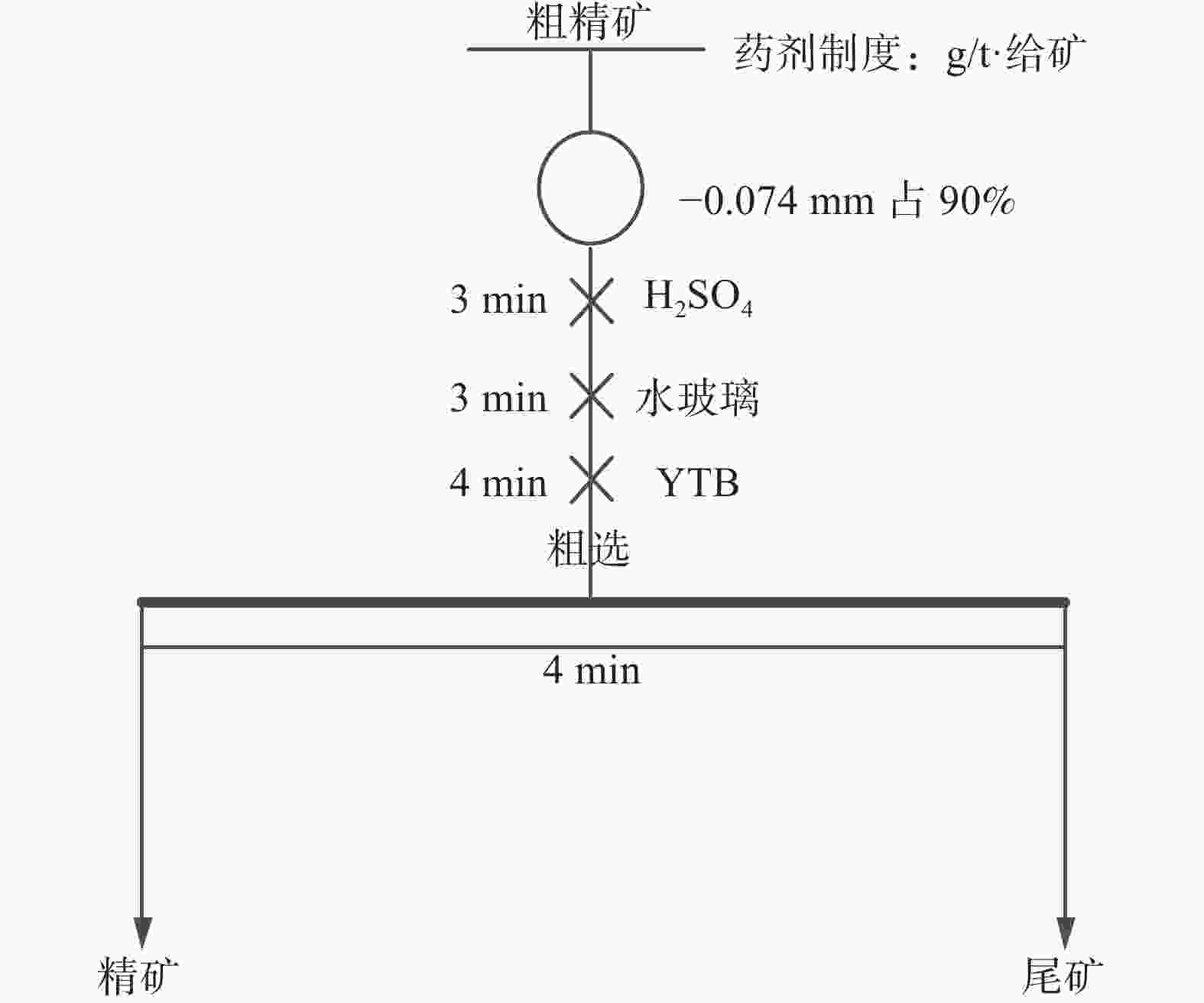

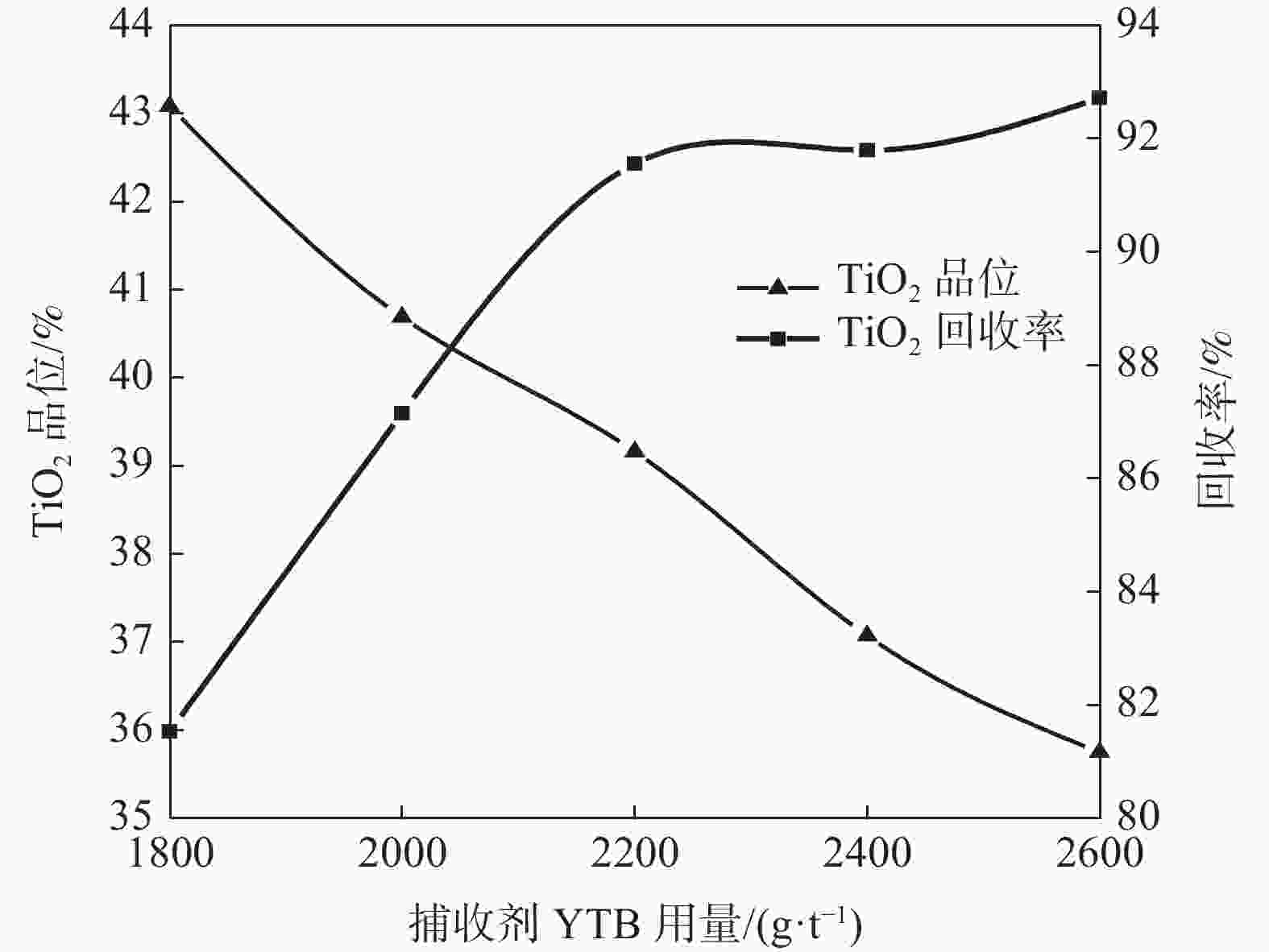

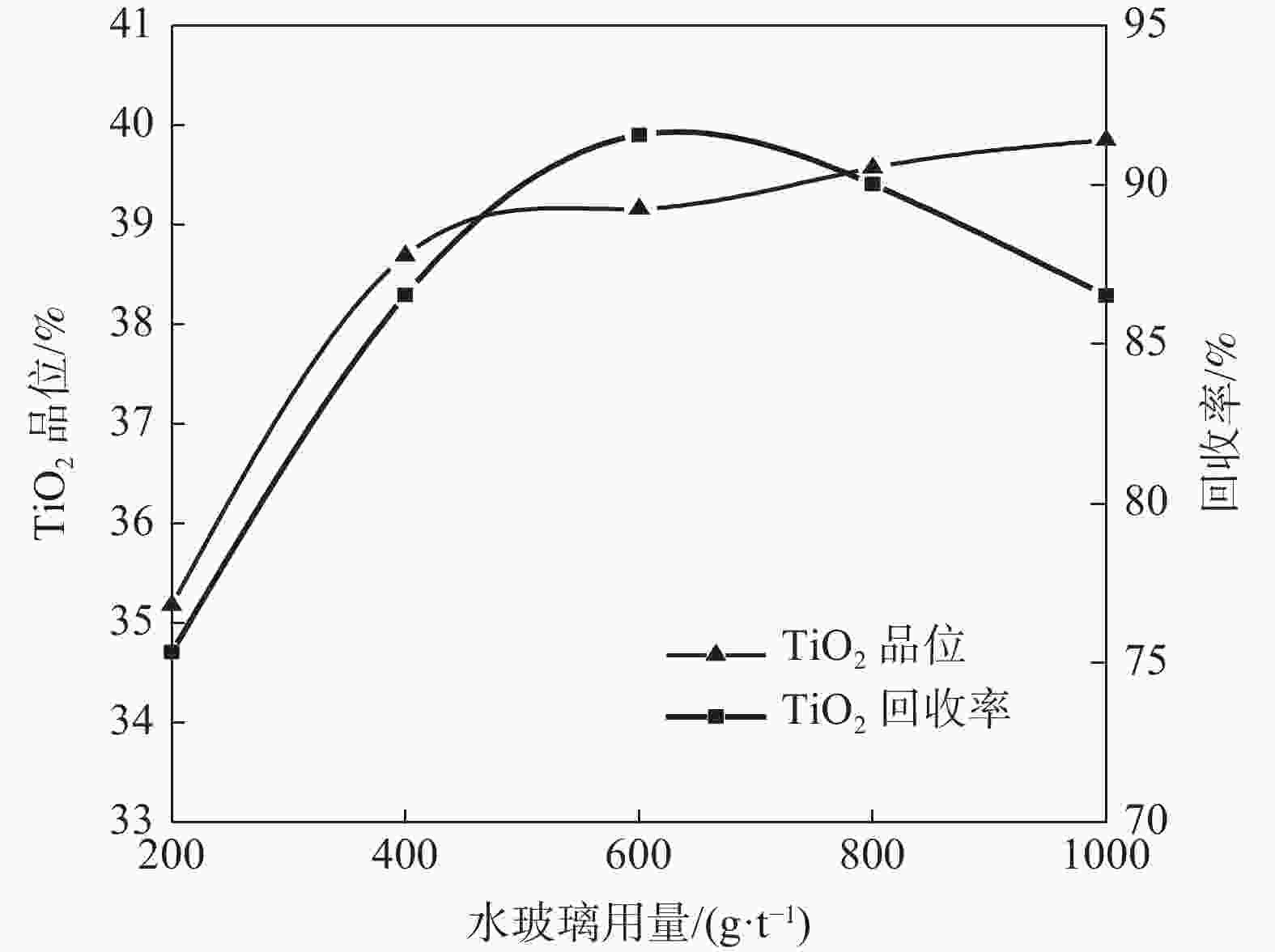

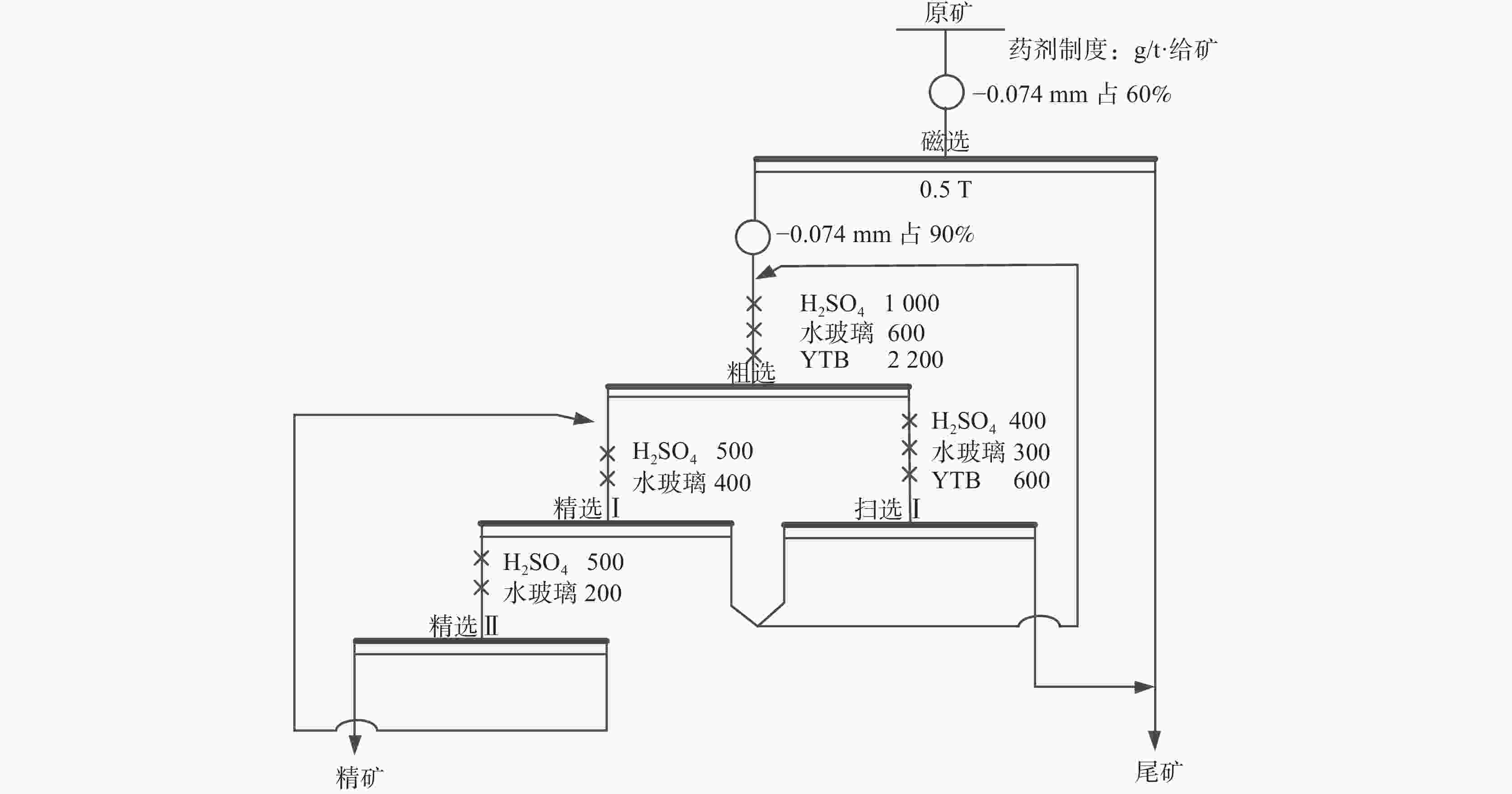

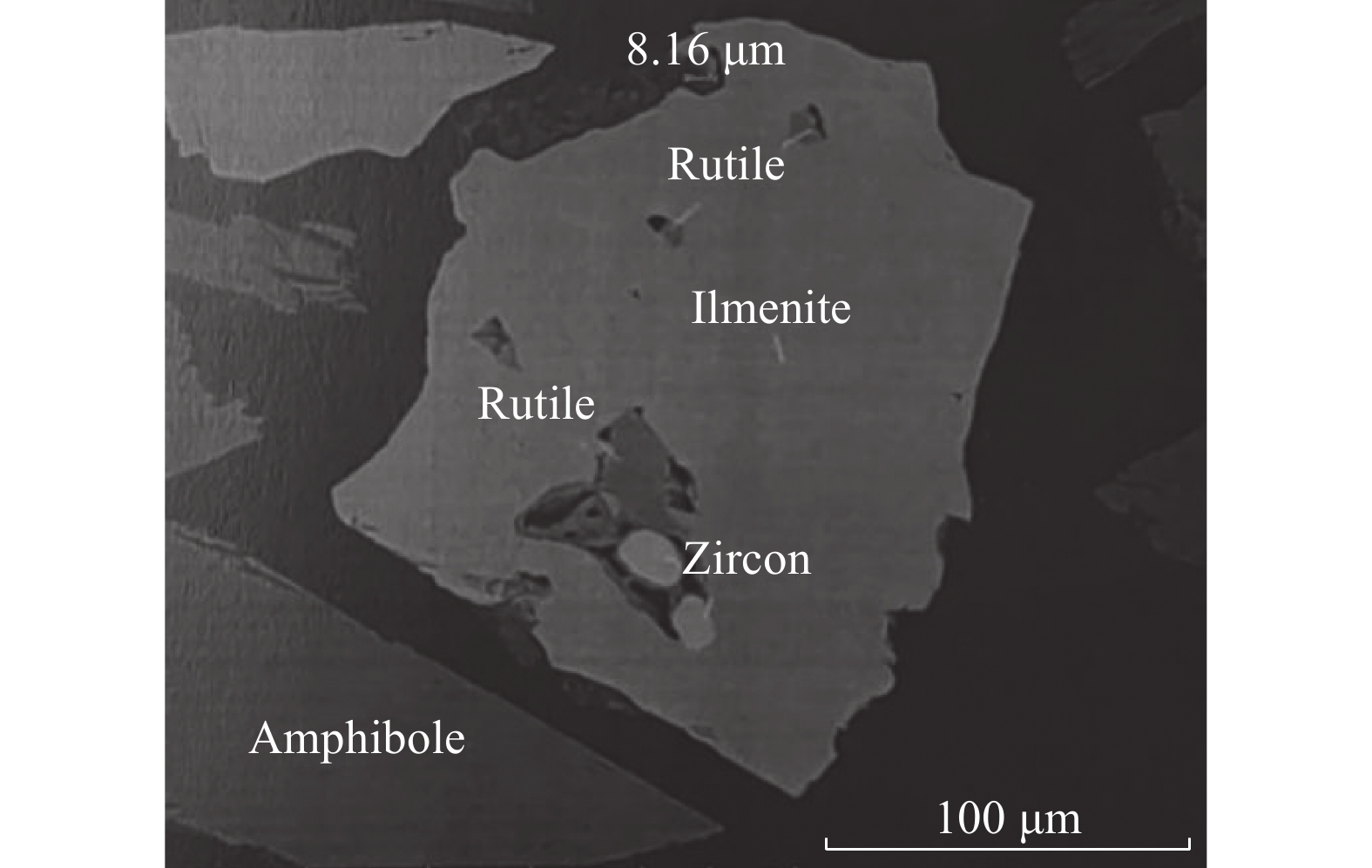

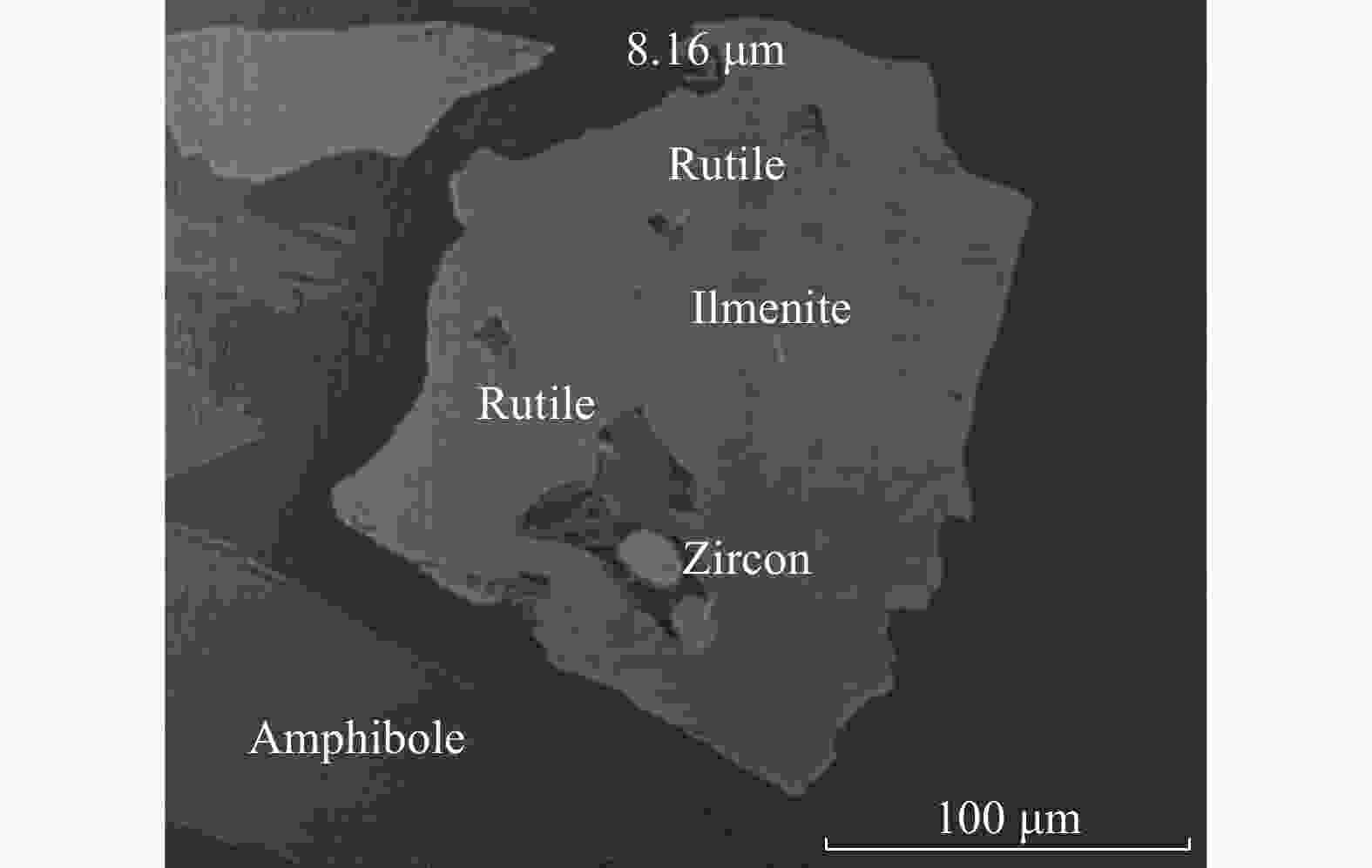

摘要: 国外某原生钛铁矿中TiO2品位8.23%、Fe2O3品位16.47%;主要含钛矿物为钛铁矿、少量金红石和榍石,微量含钛的磁铁矿,脉石矿物主要是角闪石、长石,其次绿泥石、金云母、石英、高岭土等。有价矿物之间嵌布关系复杂,且钛铁矿嵌布粒度细,同时钛铁矿和磁铁矿包裹体包含于角闪石间,增强角闪石磁性,不利于钛铁矿磁选分离。试验采用磁选-粗精矿再磨-浮选工艺流程获得TiO2品位为47.41%、回收率为50.32%的钛精矿。Abstract: A primary ilmenite ore from overseas has a TiO2 grade of 8.23% and a Fe2O3 grade of 16.47%. The mainly titanium-containing minerals contain ilmenite, a small amount of rutile and sphene, and a trace amount of titanium-containing magnetite. The gangue minerals are mainly hornblende and feldspar, followed by chlorite, flogopite, quartz and kaolinite. There exist complex embedded relationship among the valuable minerals and fine disseminated grain size of ilmenite. Ilmenite and magnetite inclusions are contained in hornblende resulting in enhancing the magnetism of hornblende, which is not conducive to the magnetic separation of the ilmenite. In this paper, a flow chart of magnetic separation-rougher concentrate regrinding-flotation was adopted to obtain ilmenite concentrate with a TiO2 grade of 47.41% as well as a recovery of 50.32%.

-

Key words:

- ilmenite /

- magnetic separation /

- hornblende /

- flotation

-

表 1 原矿多元素分析

Table 1. Spectral analysis results of run-of-mine

% TiO2 Fe2O3 Mn Cu Zn Pb Bi CaF2 8.23 16.47 0.026 0.011 0.006 0.012 0.0047 0.32 SiO2 MgO CaO Na2O K2O Al2O3 P S 36.83 5.59 6.53 1.92 0.47 16.87 0.076 0.13 表 2 原矿的矿物组成及含量

Table 2. Mineral compositions and contents in run-of-mine

% 钛铁矿 金红石 榍石 磁铁矿 斜长石 白云母 金云母 角闪石 绿泥石 绿帘石 10.44 0.09 1.00 0.12 25.00 0.51 5.45 38.38 9.79 0.44 高岭石 石英 方解石 萤石 黄铁矿 褐铁矿 磷灰石 锆石 其他 合计 2.90 5.24 0.02 0.01 0.01 0.30 0.07 0.02 0.21 100.00 表 3 钛在主要矿物中的分配

Table 3. Phase analysis of titanium in run-of-mine

矿物 含量/% 含TiO2量/% 分配率/% 钛铁矿 10.44 51.25 65.01 金红石 0.09 96.97 1.06 榍石 1.00 36.18 4.40 磁铁矿 0.12 1.35 0.02 石英/长石等 30.29 0.98 3.61 角闪石 38.82 3.75 17.69 绿泥石/高岭土 12.69 4.17 6.43 金云母 5.96 2.35 1.70 褐铁矿 0.30 0.35 0.01 其他 0.29 0.07 合计 100.00 100.00 表 4 全流程闭路试验结果

Table 4. Results of closed-circuit flotation test

产品名称 产率/% TiO2品位/% TiO2回收率/% 精矿 8.74 47.41 50.32 尾矿 91.26 4.48 49.68 原矿 100.00 8.23 100.00 -

[1] 董天颂. 钛选矿[M]. 北京: 冶金工业出版社, 2009.Dong Tiansong. Beneficiation process of titanium[M]. Beijing: Metallurgical Industry Press, 2009. [2] Chen Lulu. Current situation of vanadium-titanium magnetite resource utilization[J]. China Resources Comprehensive Utilization, 2015,33(10):37−39. (陈露露. 我国钒钛磁铁矿资源利用现状[J]. 中国资源综合利用, 2015,33(10):37−39.Chen Lulu. Current situation of vanadium-titanium magnetite resource utilization[J]. China Resources Comprehensive Utilization, 2015, 33( 10) : 37-39. [3] Wang Hongbin, Meng Changchun. Study on the new recovery technology of coarse ilmenite in Panzhihua Midi titanium concentrator[J]. Mining and Metallurgy Engineering, 2011,31(4):51−52. (王洪彬, 孟长春. 攀枝花密地选钛厂粗粒钛铁矿回收新工艺研究[J]. 矿冶工程, 2011,31(4):51−52. doi: 10.3969/j.issn.0253-6099.2011.04.014Wang Hongbin, MengChangchun. Study on the new recovery technology of coarse ilmenite in Panzhihua Midi titanium concentrator[J]. Mining and Metallurgy Engineering, 2011, 31(4) : 51-52. doi: 10.3969/j.issn.0253-6099.2011.04.014 [4] Yi Yunlai, Wei Qian, Liu Zhongrong. Experimental reaearch on mineral processing of some complicated ilmenite ore from abroad[J]. Mining and Metallurgical Engineering, 2014,34(1):41−43. (易运来, 魏茜, 刘忠荣. 国外某复杂钛铁矿的选矿试验研究[J]. 矿冶工程, 2014,34(1):41−43. doi: 10.3969/j.issn.0253-6099.2014.01.011YiYunlai, Wei Qian, Liu Zhongrong. Experimental reaearch on mineral processing of some complicated ilmenite ore from abroad[J]. Mining and Metallurgical Engineering, 2014, 34(1): 41-43. doi: 10.3969/j.issn.0253-6099.2014.01.011 [5] Wang Fengyu, Yang Zhaojun, Luo Rongfei, et al. Recovery increase of -38 μm ultra fineilmenite using ZQS high gradient magnetic separator[J]. Metal Mine, 2019,(8):93−97. (王丰雨, 杨招君, 罗荣飞, 等. 采用ZQS高梯度磁选机提高超细粒级(-38μm)钛铁矿回收效果[J]. 金属矿山, 2019,(8):93−97.Wang Fengyu, YangZhaojun, Luo Rongfei, et al. Recovery increase of -38 μm ultra fineilmenite using ZQS high gradient magnetic separator[J]. Metal Mine, 2019(8): 93-97. [6] Wang Hongbin, Li Jin, Zhang Guohua. Efficient recovery of ilmenite from vanadium bearing titanomagnetite in Panxi area[J]. Iron Steel Vanadium Titanium, 2020,41(3):23−29. (王洪彬, 李金, 张国华. 攀西钒钛磁铁矿中钛铁矿高效回收工艺研究[J]. 钢铁钒钛, 2020,41(3):23−29. doi: 10.7513/j.issn.1004-7638.2020.03.003Wang Hongbin, Li Jin, Zhang Guohua. Efficient recovery of ilmenite from vanadium bearing titanomagnetite in Panxi area[J]. Iron Steel Vanadium Titanium, 2020, 41(3): 23-29. doi: 10.7513/j.issn.1004-7638.2020.03.003 [7] Liu Chao, Chen Zhiqiang, Lv Haozi, et al. Experimental study on beneficiation of a weathered V-Ti iron from abroad[J]. Iron Steel Vanadium Titanium, 2021,42(2):117−124. (刘超, 陈志强, 吕昊子, 等. 国外某风化型钒钛铁矿选矿试验研究[J]. 钢铁钒钛, 2021,42(2):117−124. doi: 10.7513/j.issn.1004-7638.2021.02.020Liu Chao, Chen Zhiqiang, Lv Haozi, et al. Experimental study on beneficiation of a weathered V-Ti iron from abroad[J]. Iron Steel Vanadium Titanium, 2021, 42(2): 117-124. doi: 10.7513/j.issn.1004-7638.2021.02.020 [8] Xu Xiaoyi, Wang Fengyu, Zhang Chaoda, et al. Optimization of gravity separation flowsheet with spiral chute for collecting fine ilmenite[J]. Mining and Metallurgical Engineering, 2021,41(5):45−48. (徐晓衣, 王丰雨, 张超达, 等. 螺旋溜槽回收某细粒级钛铁矿的试验研究[J]. 矿冶工程, 2021,41(5):45−48. doi: 10.3969/j.issn.0253-6099.2021.05.011Xu Xiaoyi, Wang Fengyu, Zhang Chaoda, et al. Optimization of gravity separation flowsheet with spiral chute for collecting fine ilmenite[J]. Mining and Metallurgical Engineering, 2021, 41(5): 45-48. doi: 10.3969/j.issn.0253-6099.2021.05.011 -

下载:

下载: