Investigation on the effects of V and Ti on continuous cooling transformation behaviour of weathering steel

-

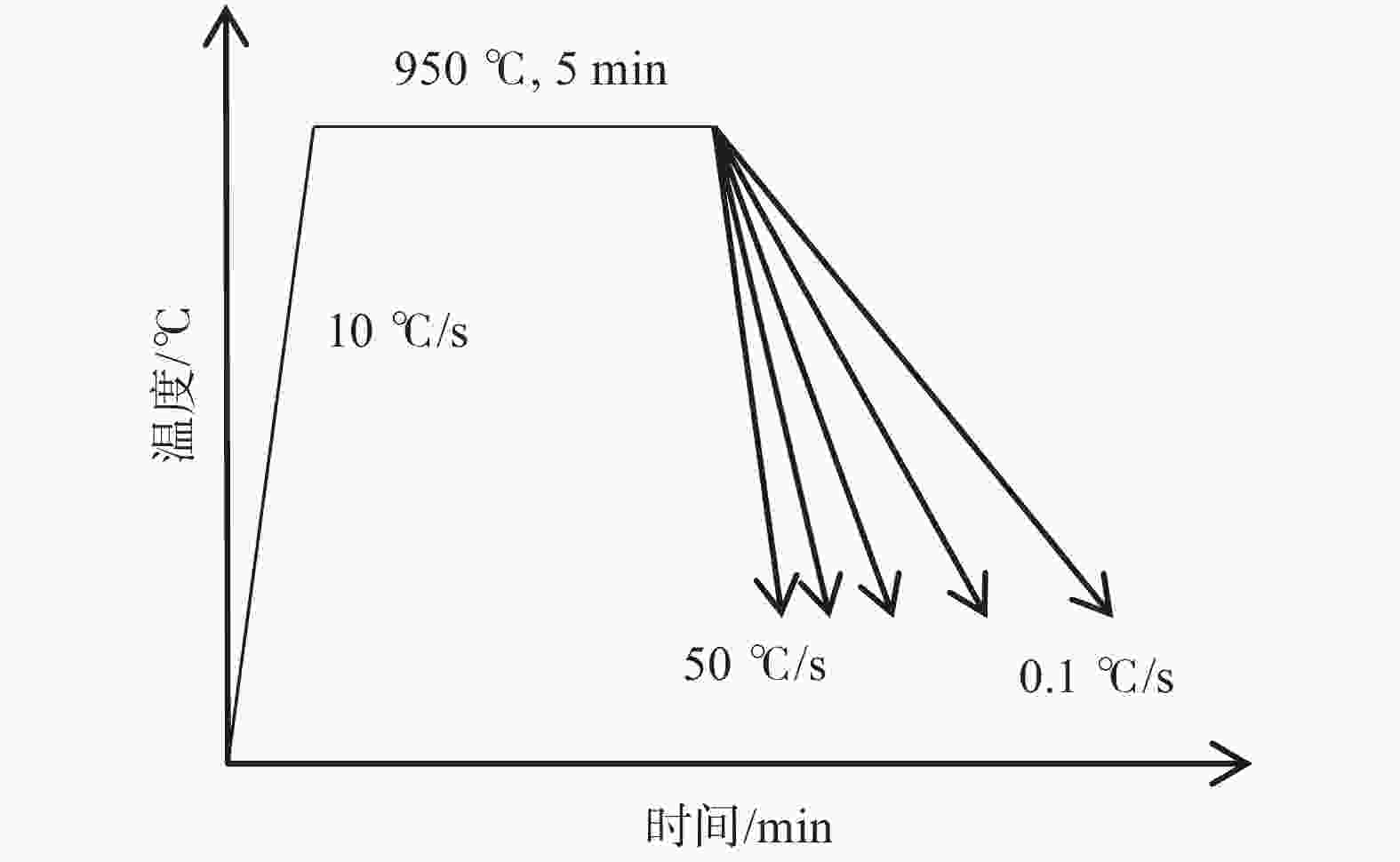

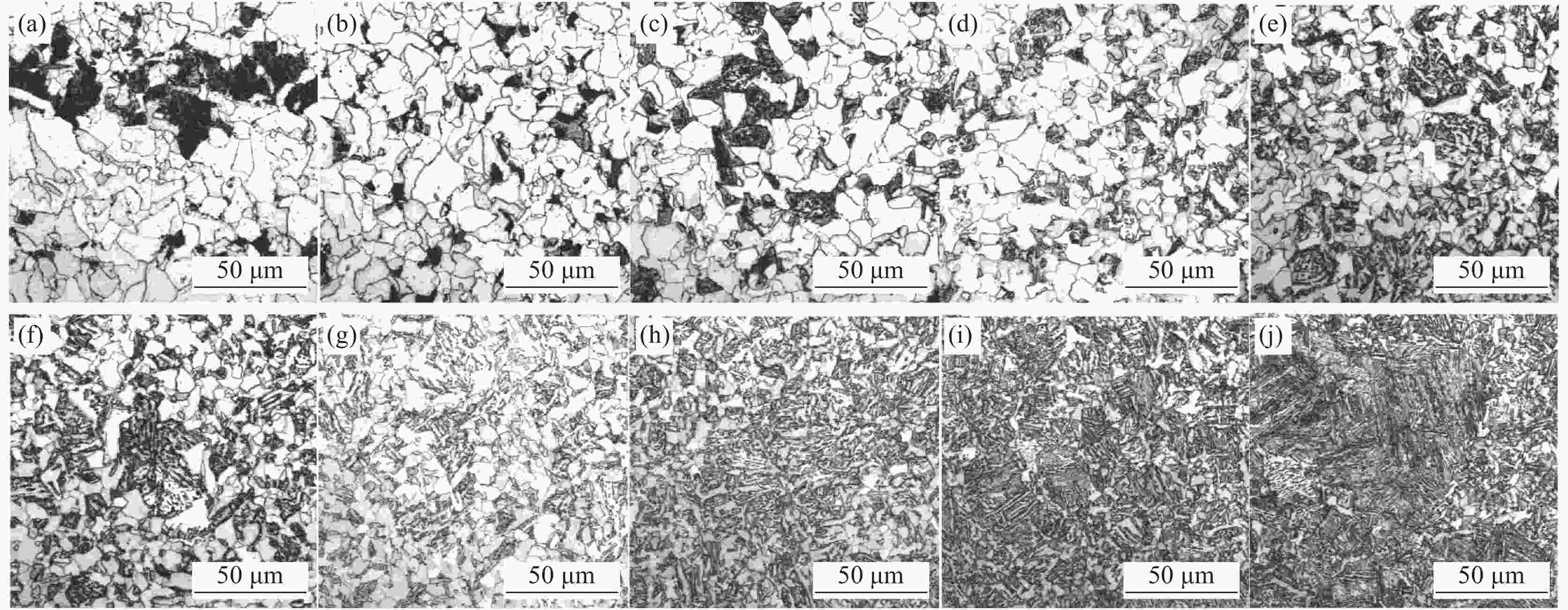

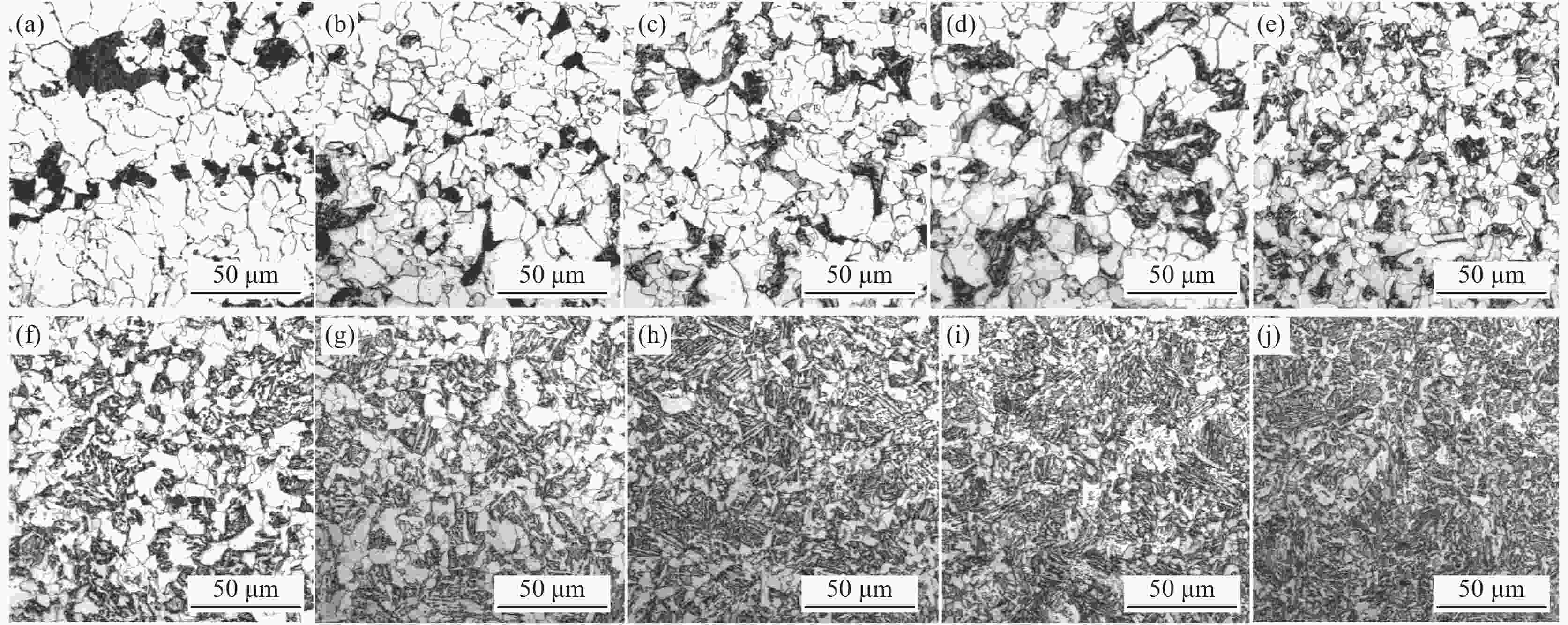

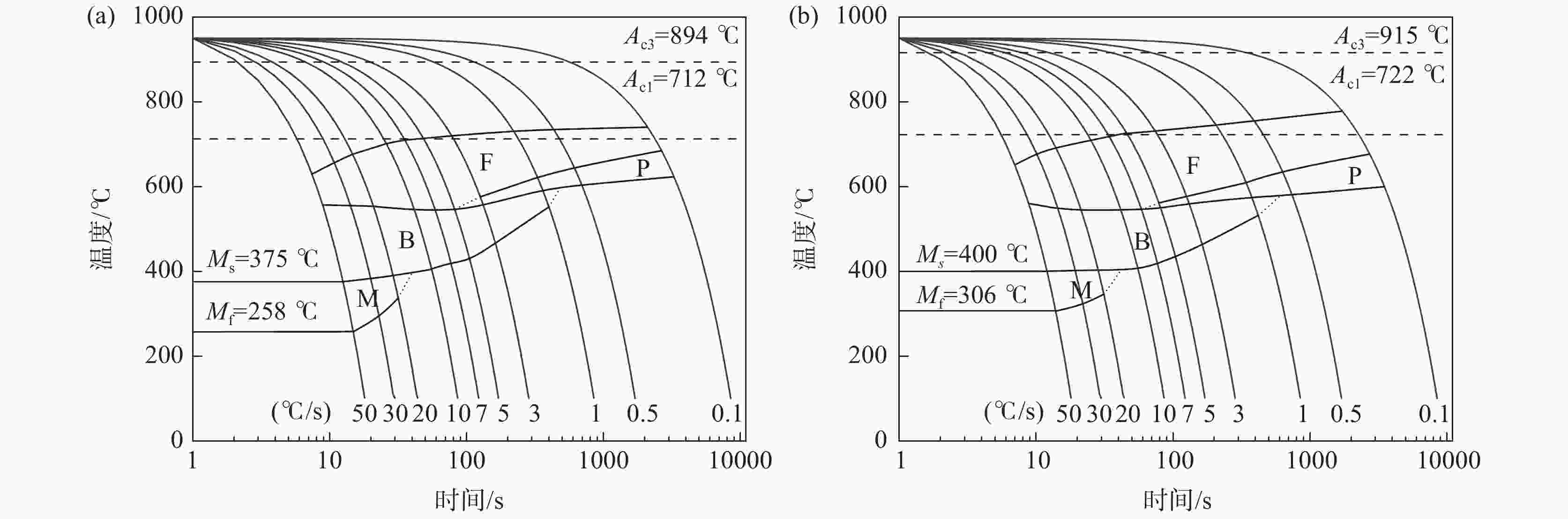

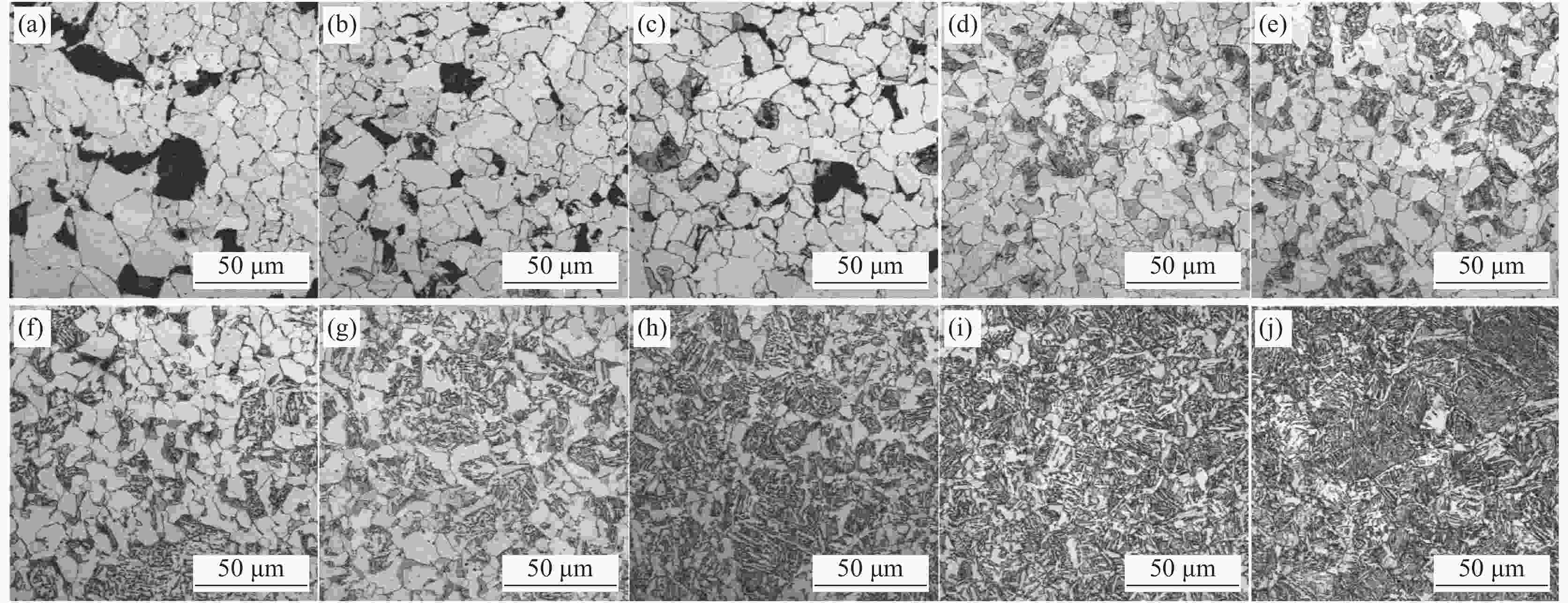

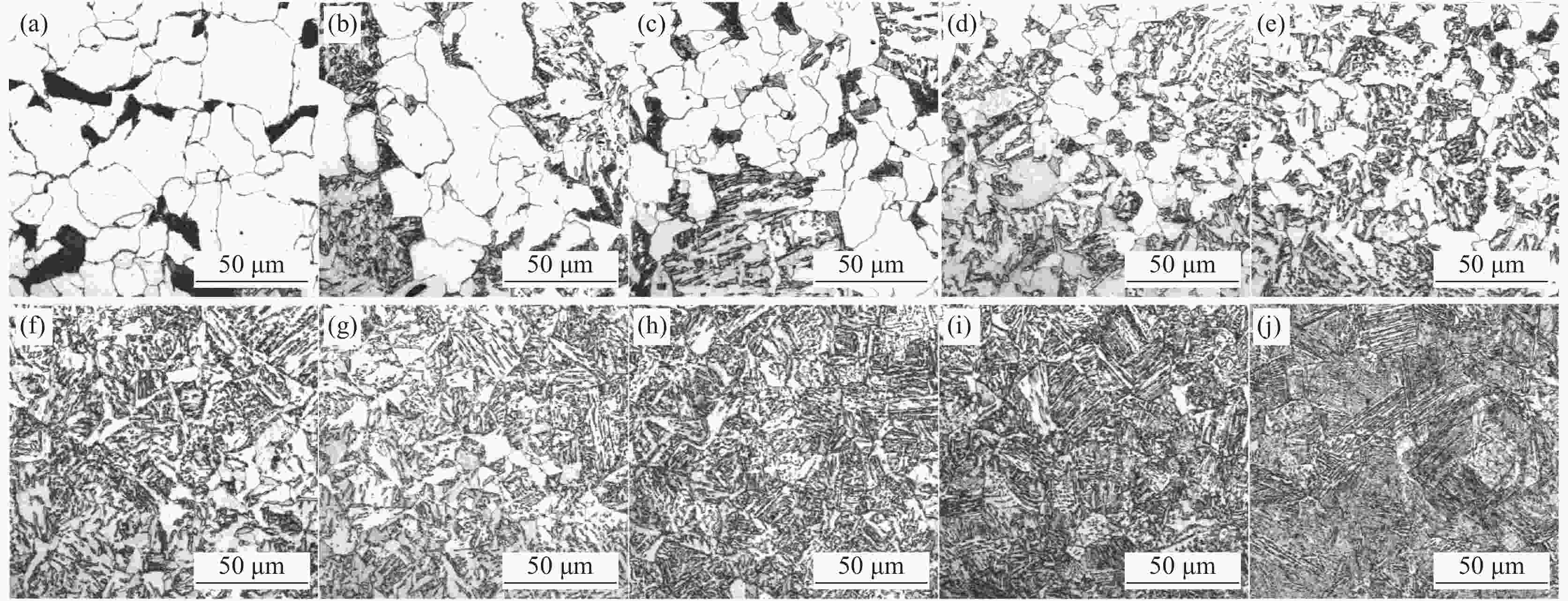

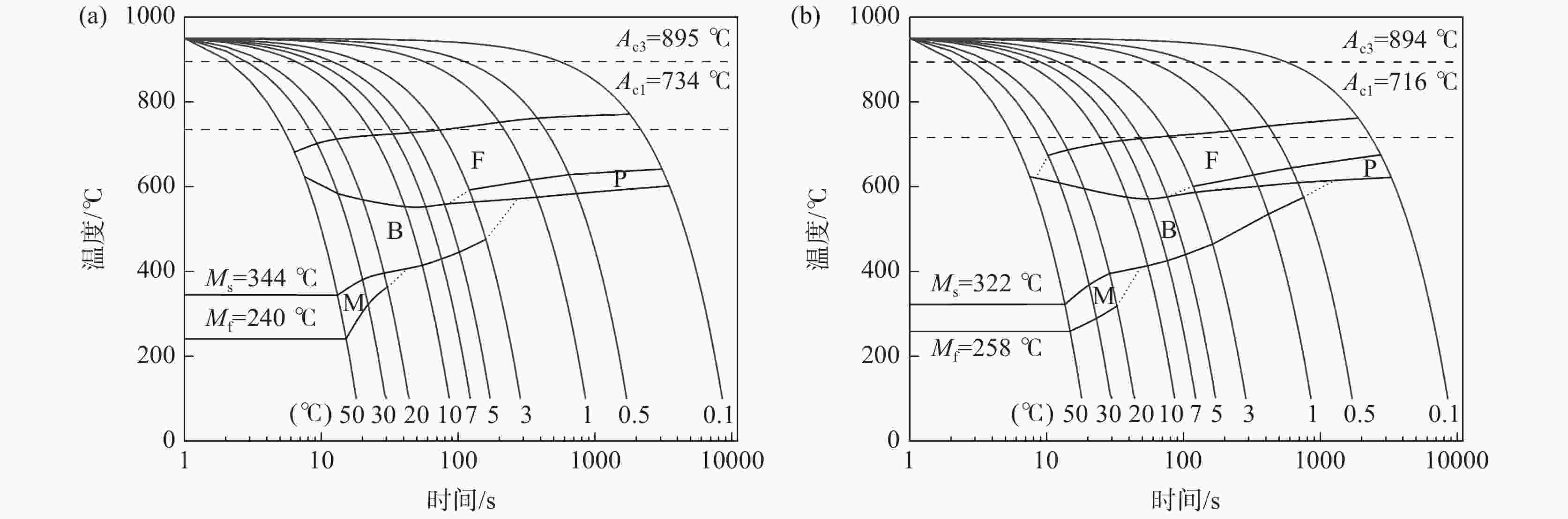

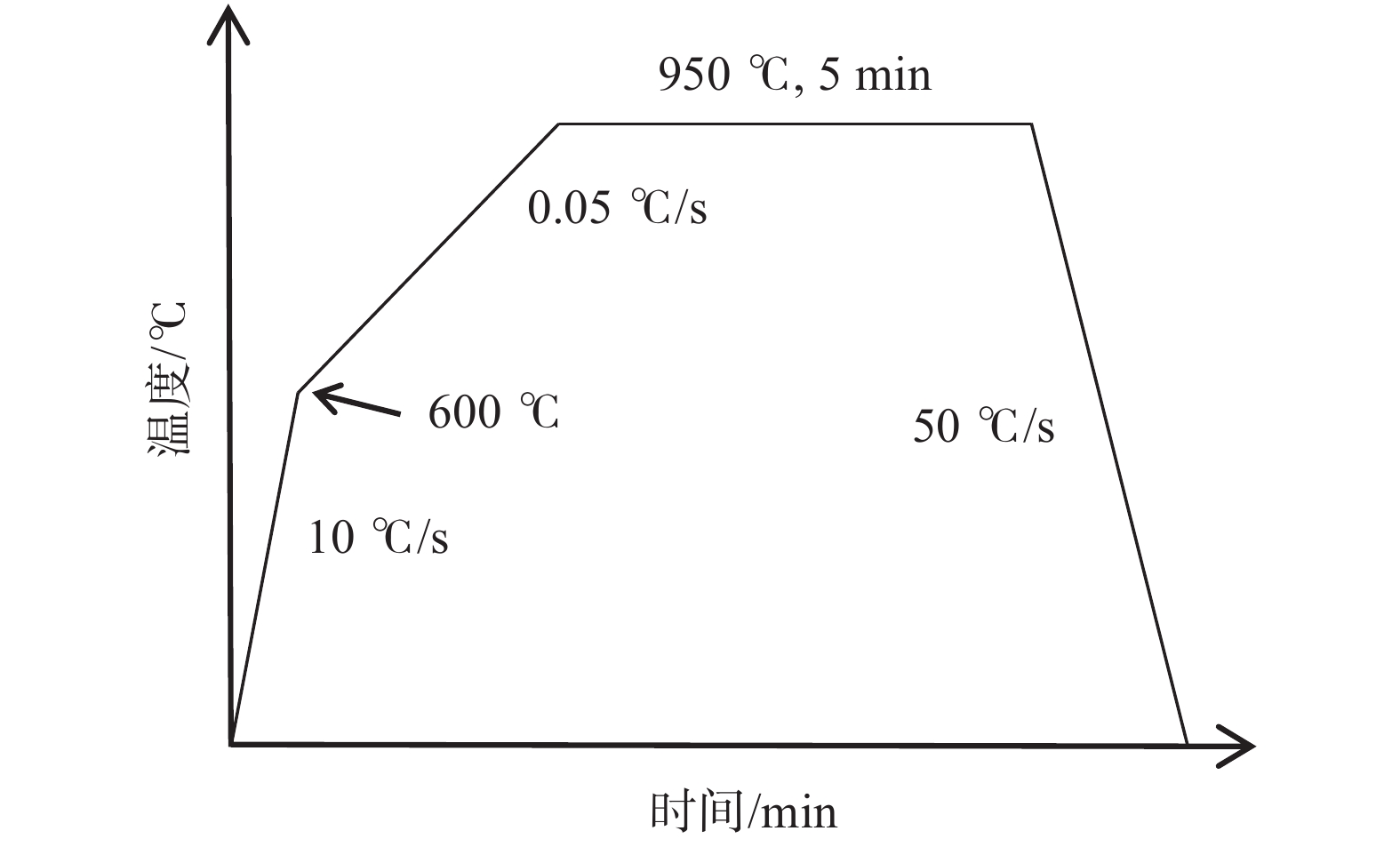

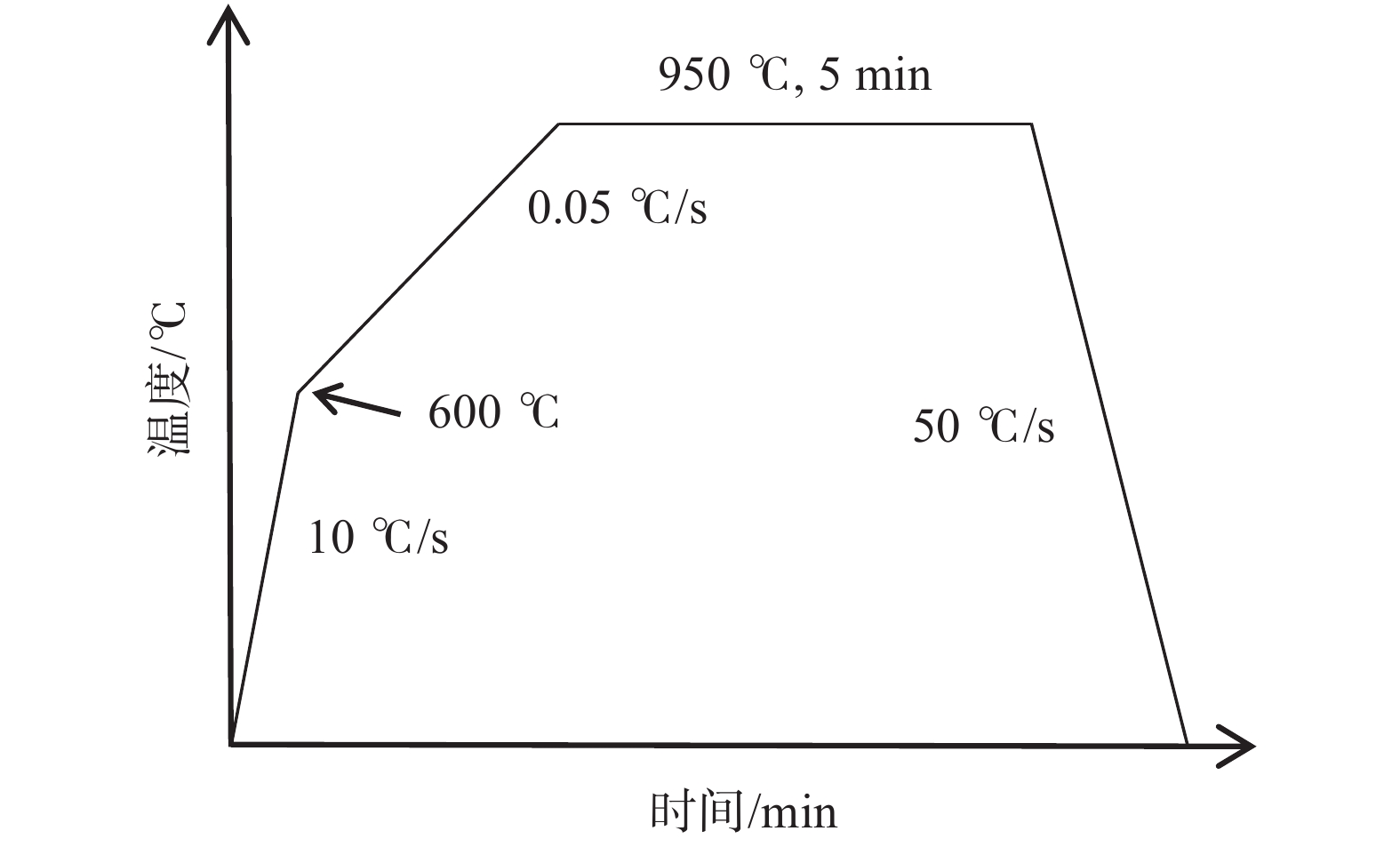

摘要: 进行了V、Ti元素含量不同的耐候钢的过冷奥氏体连续冷却转变热模拟试验并绘制了CCT曲线,研究了不同冷却速度以及V、Ti元素对耐候钢组织转变以及性能的影响。当V含量由0.03%提高至0.07%,马氏体转变开始温度Ms提高25 ℃,促进了马氏体相变。当Ti含量由0.03%提高至0.10%,扩大了贝氏体相变区、降低了贝氏体开始转变冷速,促进了贝氏体转变;同时,马氏体转变开始温度Ms降低22 ℃、马氏体转变终了温度Mf升高18 ℃,马氏体转变区域变窄,抑制了马氏体转变。随着冷却速率的提高,HV0.2硬度值逐渐增加。HV0.2硬度值主要受金相组织的尺寸和形貌影响,V、Ti的第二相析出物对HV0.2硬度值的影响不大。Abstract: Continuous cooling transformation thermal simulation experiment of weathering steel with various V or Ti contents was conducted, and effects of cooling rate and V or Ti element on microstructure transformation and property of weathering steel were investigated. When V content increases from 0.03% to 0.07%, the martensite-start temperature increases 25 ℃, thereby promoting martensitic phase transformation. When Ti content increases from 0.03% to 0.10%, the bainitic phase transformation region expands, and the cooling rate with which bainite transformation starts decreases, thereby promoting bainitic phase transformation; meanwhile, martensite-start temperature decreases 22 ℃, and martensite-finish temperature increases 18 ℃, inducing martensitic phase transformation region shrinks, thereby restraining martensitic phase transformation. With the cooling rate increasing, HV0.2 hardness increases. HV0.2 hardness is mainly affected by the size and morphology of metallographic structure but fewer affected by second phase precipitates of V or Ti.

-

Key words:

- weathering steel /

- CCT curve /

- vanadium /

- titanium /

- bainite /

- martensite /

- hardness

-

表 1 试验钢化学成分

Table 1. Compositions of tested steel

% 编号 C Si Mn P S Cu Ni Cr V Ti Als N 0.03V 0.07 0.39 1.42 0.010 0.002 0.36 0.31 0.64 0.030 0.023 0.0164 0.07V 0.06 0.39 1.43 0.009 0.001 0.35 0.31 0.63 0.070 0.027 0.0163 0.03Ti 0.07 0.40 1.43 0.005 0.002 0.35 0.31 0.63 0.035 0.043 0.0024 0.10Ti 0.07 0.41 1.41 0.005 0.002 0.34 0.31 0.63 0.100 0.035 0.0026 表 2 V含量不同的试验钢硬度(HV0.2)

Table 2. Hardness of tested steel with various V content (HV0.2)

冷速/(℃·s−1) 0.03V试验钢 0.07V试验钢 硬度(HV0.2) 平均值 硬度(HV0.2) 平均值 0.1 160.8 168.6 170.4 166.6 155.7 164.4 159.6 159.9 0.5 180.4 182.3 189.6 184.1 183.2 182.3 184.6 183.4 1 208.3 208.3 209.3 208.6 192.5 190.7 193.6 192.3 3 226.6 220.3 221.6 222.8 219.6 220.6 223.4 221.2 5 228.4 226.6 225.3 226.8 228.4 230.6 232.3 230.4 7 227.2 230.6 232.8 230.2 240.1 238.9 236.4 238.5 10 242.6 240.6 246.6 243.3 240.1 245.1 246.4 243.9 20 269.3 270.0 264.6 268.0 259.6 260.4 262.4 260.8 30 273.9 279.9 275.6 276.5 285.2 281.4 275.4 280.7 50 287.8 290.6 284.6 287.7 283.9 287.8 284.6 285.4 表 3 Ti含量不同的试验钢硬度(HV0.2)

Table 3. Hardness of tested steel with various Ti content (HV0.2)

冷速/(℃·s−1) 0.03Ti试验钢 0.10Ti试验钢 硬度(HV0.2) 平均值 硬度(HV0.2) 平均值 0.1 156.7 153.1 153.5 154.4 147.2 148.6 146.3 147.4 0.5 167.2 161.7 162.3 163.7 188.1 187.3 185.6 187.0 1 175.3 176.3 178.4 176.7 193.8 193.2 197.6 194.9 3 188.1 189.6 186.3 188.0 201.5 200.6 201.4 201.2 5 215.4 210.3 209.6 211.8 215.4 215.4 216.1 215.6 7 217.4 219.6 220 219.0 222.8 223.9 222.4 223.0 10 225 226.1 228.9 226.7 234.1 227.9 230.4 230.8 20 240.6 242.6 243.9 242.4 240.1 252.8 241.4 244.8 30 263.8 266.6 267.9 266.1 269.5 272.4 271.4 271.1 50 294.3 287.8 286.4 289.5 289.4 294.3 290.3 291.3 -

[1] Hou Baorong, Li Xiaogang, Ma Xiumin, et al. The cost of corrosion in China[J]. NPJ Materials Degradation, 2017,1(1):4. doi: 10.1038/s41529-017-0005-2 [2] Liu Kun, Zhang Xudong, Tian Zhihong, et al. Application research of green eco-friendly weathering steel in the field of building structure[J]. Building Science, 2020,36(S2):458−462. (刘锟, 张旭东, 田志红, 等. 绿色环保耐候钢在建筑结构领域中的应用研究[J]. 建筑科学, 2020,36(S2):458−462.Liu K, Zhang X D, Tian Z H, et al. Application research of green eco-friendly weathering steel in the field of building structure[J]. Building Science, 2020, 36(S2): 458-462 (in Chinese). [3] Lin Pengfei, Yang Zhongmin, Chen Ying, et al. Rust layer of weathering steel and its stabilization treatment status[J]. Iron and Steel, 2021,56(3):58−65. (林鹏飞, 杨忠民, 陈颖, 等. 耐候钢锈层及其稳定化处理现状[J]. 钢铁, 2021,56(3):58−65.Lin P F, Yang Z M, Chen Y, et al. Rust layer of weathering steel and its stabilization treatment status[J]. Iron and Steel, 2021, 56(3): 58-65 (in Chinese). [4] Mishra S K, Ranganathan S, Das S K. Investigations on precipitation characteristics in a high strength low alloy (HSLA) steel[J]. Scripta Materialia, 1998,39(2):253−259. doi: 10.1016/S1359-6462(98)00138-9 [5] Cui Kaiyu. Technology practice of increasing impact energy of weathering steel Q550NQR1 at -40 ℃[J]. Special Steel, 2018,39(5):54−57. (崔凯禹. 提高QS50NQRl耐候钢-40 ℃冲击功的工艺实践[J]. 特殊钢, 2018,39(5):54−57. doi: 10.3969/j.issn.1003-8620.2018.05.014Cui K Y. Technology practice of increasing impact energy of weathering steel Q550 NQR1 at -40℃[J]. Special Steel, 2018, 39(5): 54-57 (in Chinese). doi: 10.3969/j.issn.1003-8620.2018.05.014 [6] Wang Chuangwai. Development of high strength weathering steel Q450NQR1 containing vanadium[J]. Iron Steel Vanadium Titanium, 2018,39(3):129−133. (汪创伟. 含钒高强度耐候钢板Q450NQR1开发[J]. 钢铁钒钛, 2018,39(3):129−133. doi: 10.7513/j.issn.1004-7638.2018.03.024Wang C W. Development of high strength weathering steel Q450 NQR1 containing vanadium[J]. Iron Steel Vanadium Titanium, 2018, 39(3): 129-133 (in Chinese). doi: 10.7513/j.issn.1004-7638.2018.03.024 [7] Zhou Cong, Zhang Chenyang, Li Yunxin, et al. Microstructure and properties of Ti microalloyed 700 MPa weathering steel of container[J]. Transactions of Materials and Heat Treatment, 2020,41(7):126−133. (周聪, 张晨洋, 李运鑫, 等. Ti微合金化700 MPa级集装箱用耐候钢的组织性能[J]. 材料热处理学报, 2020,41(7):126−133.Zhou C, Zhang C Y, Li Y X, et al. Microstructure and properties of To microalloyed 700 MPa weathering steel of container[J]. Transactions of Materials and Heat Treatment, 2020, 41(7): 126-133 (in Chinese). [8] Gan Xiaolong, Zhao Gang, Yang Gengwei, et al. Determination and analysis of CCT curve of Ti-V composite microalloyed high stength steel[J]. Hot Working Technology, 2019,48(2):100−103. (甘晓龙, 赵刚, 杨庚蔚, 等. Ti-V复合微合金化高强钢CCT曲线的测定与分析[J]. 热加工工艺, 2019,48(2):100−103.Gan X L, Zhao G, Yang G W, et al. Determination and analysis of CCT curve of Ti-V composite microalloyed high stength steel[J]. Hot Working Technology, 2019, 48(02): 100-103 (in Chinese). [9] Bao Junheng, Zhao Jie, Ning Baoqun, et al. Transformation behavior of austenite continuous cooling for Nb-V micro-alloyed low carbon steel[J]. Journal of Iron and Steel Research, 2013,25(8):28−31. (包俊成, 赵捷, 宁保群, 等. 低碳铌钒微合金化钢奥氏体连续冷却转变行为[J]. 钢铁研究学报, 2013,25(8):28−31.Bao J C, Zhao J, Ning B Q, et al. Transformation behavior of austenite continuous cooling for Nb-V micro-alloyed low carbon steel[J]. Journal of Iron and Steel Research, 2013, 25(8): 28-31 (in Chinese). [10] 蔡珍. 钒微合金化高碳钢形变诱导珠光体相变研究[D]. 武汉: 武汉科技大学, 2019.Cai Zhen. Research on deformation-induced pearlite transformation in vanadium-microalloyed high carbon steel[J]. Wuhan:Wuhan University of Science and Technology, 2019. [11] Siwecki Tadeusz, Eliasson Johan, Lagneborg Rune, et al. Vanadium microalloyed bainitic hot strip steels[J]. ISIJ International, 2010,50(5):760−767. doi: 10.2355/isijinternational.50.760 [12] Wu Hongyan, Du Linxiu, Xue Wenying, et al. Effect of process parameters on continuous cooling transformation for V-Ti microalloyed steel[J]. Iron Steel Vanadium Titanium, 2006,27(1):6−11. (吴红艳, 杜林秀, 薛文颖, 等. 变形工艺对V、Ti微合金钢连续冷却相变的影响[J]. 钢铁钒钛, 2006,27(1):6−11. doi: 10.3969/j.issn.1004-7638.2006.01.002Wu H Y, Du L X, Xue W Y, et al. Effect of process parameters on continuous cooling transformation for V-Ti microalloyed steel[J]. Iron Steel Vanadium Titanium, 2006, 27(1): 6-11 (in Chinese). doi: 10.3969/j.issn.1004-7638.2006.01.002 [13] Liu Meiling, Tang Hengqiang, Zhu Guohui. Continuous cooling transformation an thermal-mechanical simulation of Nb and Nb-Ti microalloy weathering steels[J]. Heat Treatment of Metals, 2019,44(7):138−143. (柳美玲, 汤亨强, 朱国辉. Nb和Nb-Ti系微合金耐候钢的连续冷却转变与形变热模拟[J]. 金属热处理, 2019,44(7):138−143.Liu M L, Tang H Q, Zhu G H. Continuous cooling transformation an thermal-mechanical simulation of Nb and Nb-Ti microalloy weathering steels[J]. Heat Treatment of Metals, 2019, 44(7): 138-143 (in Chinese). -

下载:

下载: