Influence of vanadium-microalloying on microstructure and property of 5CrNiMo die steel

-

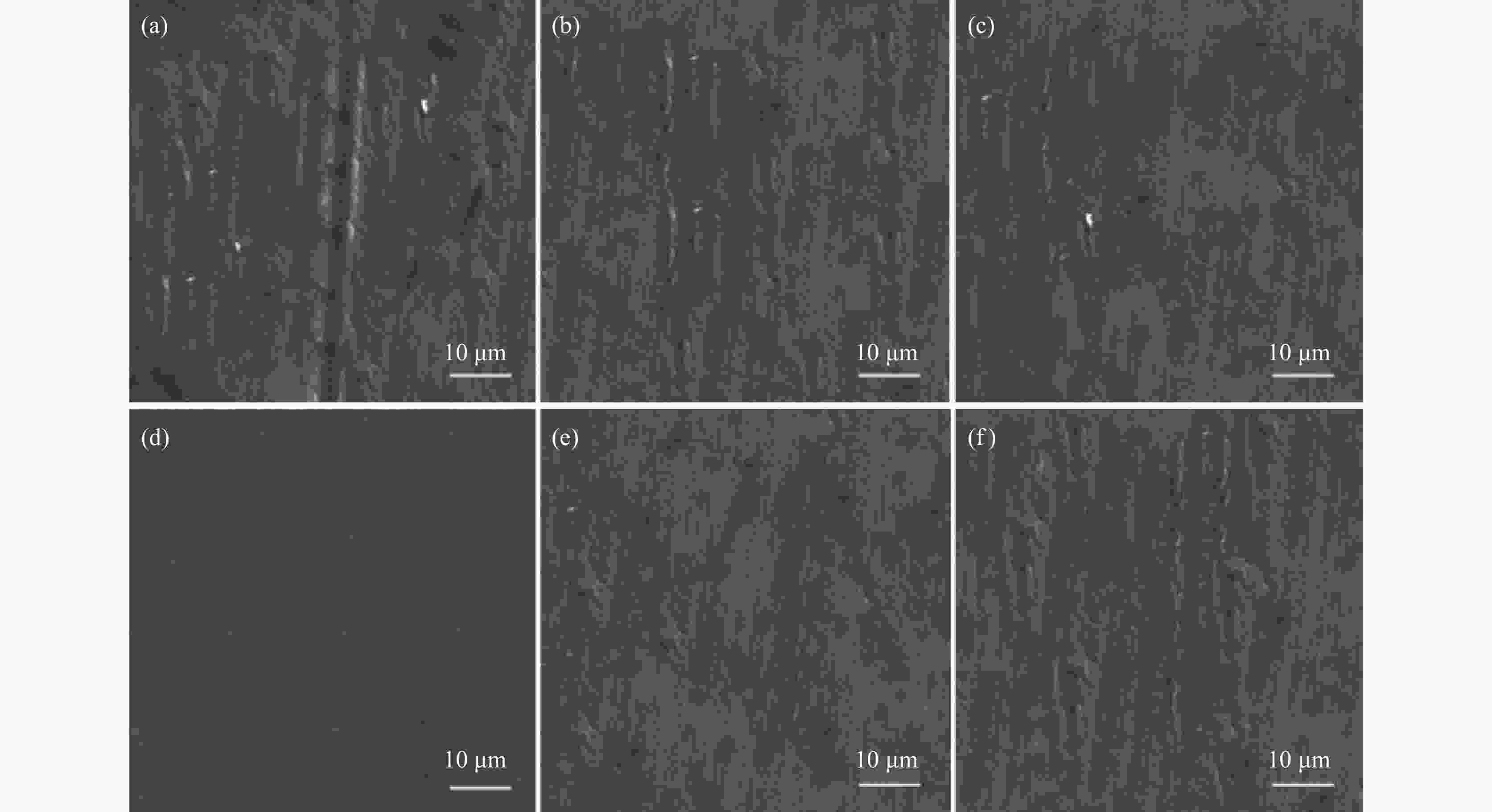

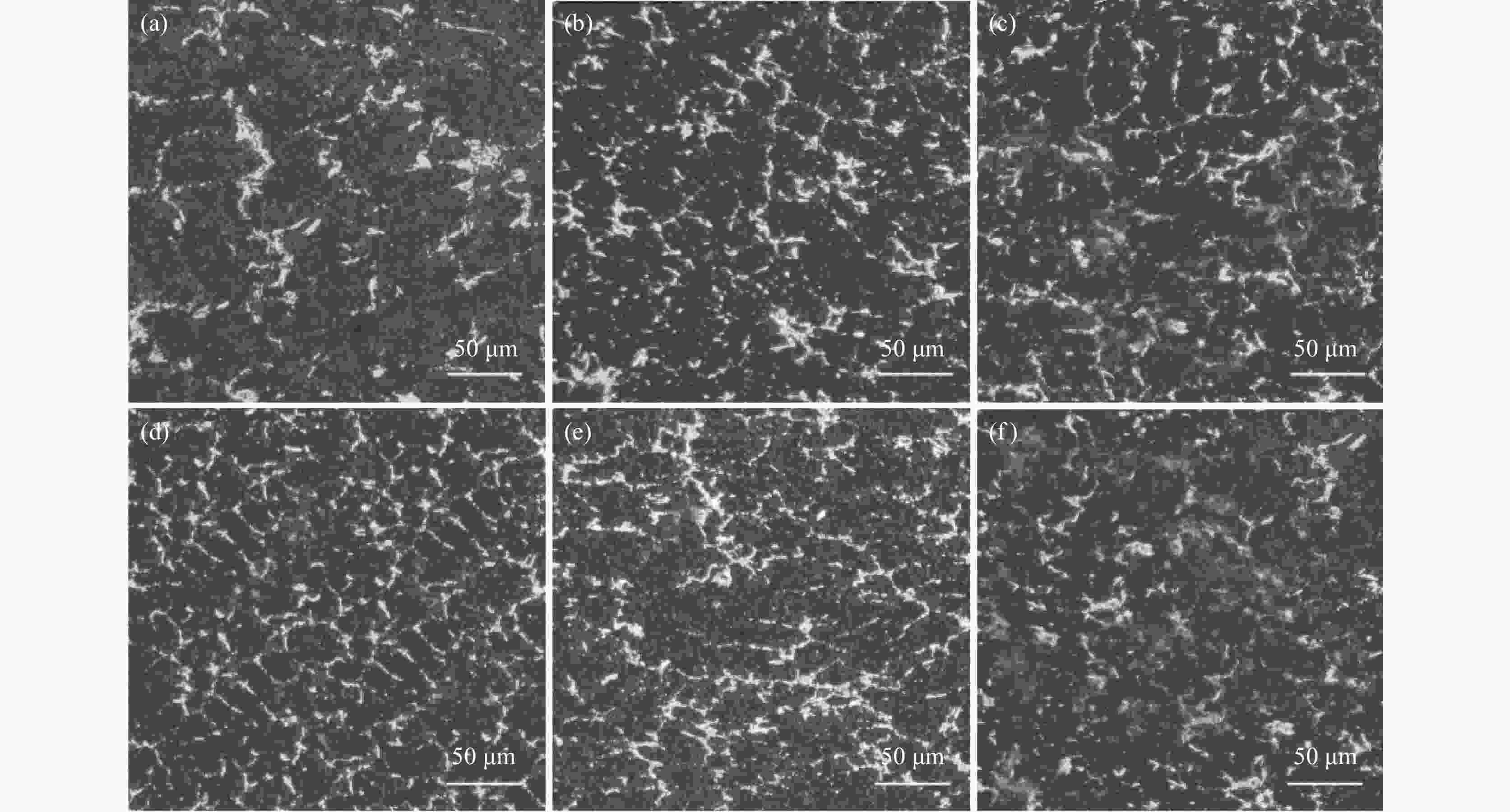

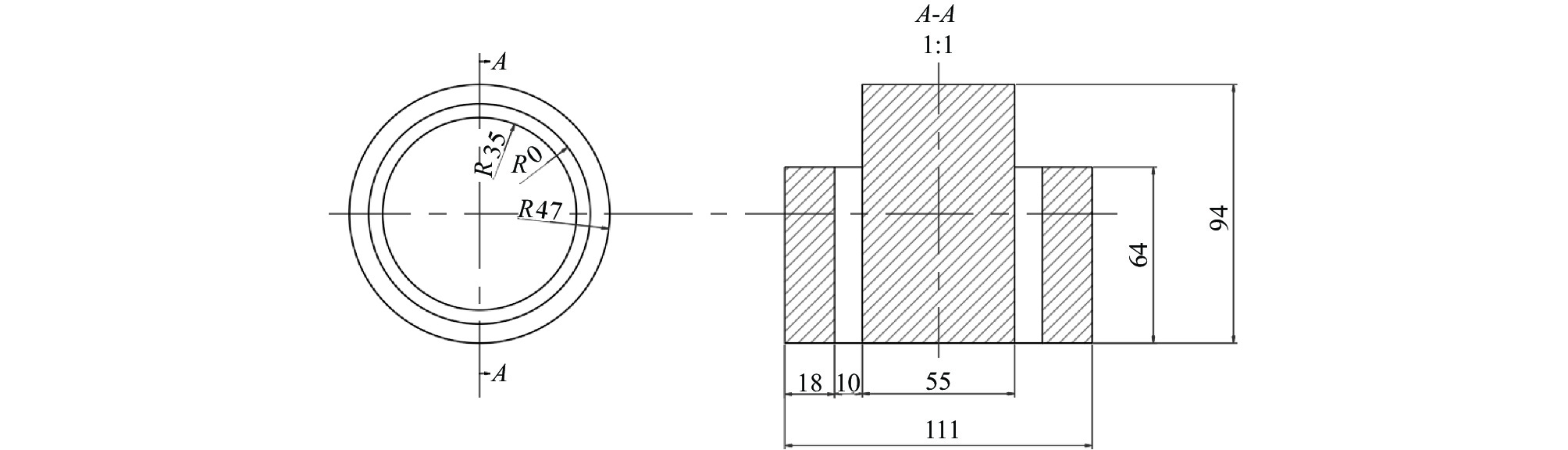

摘要: 在5CrNiMoV模具钢试样中添加了不同含量的合金元素钒,制备了不同钒含量的5CrNiMoVx(x=0, 0.1, 0.2, 0.3, 0.4, 0.5)模具钢试样,并采用金相和扫描电镜对试样显微组织进行分析,测试了试样的抗热裂性能和耐高温磨损性能。结果表明,添加合金元素钒有助于细化5CrNiMoV模具钢试样的显微组织,提高其抗热裂性能和耐高温磨损性能。随钒含量逐渐增加,模具钢试样的显微组织先细化后粗化,抗热裂性能和耐高温磨损性能先提高后下降。与不添加钒(x=0)相比,当钒含量x=0.3%时,5CrNiMoVx模具钢试样的裂纹长度减小3.4 mm、磨损体积减小16×10−3 mm3,模具钢试样的抗热裂性能和耐高温磨损性能显著提高。5CrNiMoVx (x=0, 0.1, 0.2, 0.3, 0.4, 0.5)模具钢试样的钒含量优选为x=0.3%。

-

关键词:

- 5CrNiMoV模具钢 /

- 钒微合金化 /

- 抗热裂性 /

- 耐高温磨损性能

Abstract: 5CrNiMoVx (x = 0, 0.1, 0.2, 0.3, 0.4, 0.5) with different vanadium contents were prepared by adding different amounts of alloying element vanadium into the 5CrNiMoV die steel. The microstructure of the sample was analyzed by optical and scanning electron microscopes, and the hot cracking resistance and high temperature wear resistance of the sample were tested. The results show that the addition of vanadium helps refine the microstructure of 5CrNiMo die steel and improves its hot cracking resistance and high temperature wear resistance. With the increase of vanadium content, the microstructure of die steel samples is refined first and then coarsened, and the hot cracking resistance and high temperature wear resistance are improved first and then decreased. When the vanadium content is 0.3%, the crack length and wear volume of 5CrNiMoVx die steel are reduced by 3.4 mm and 16×10−3 mm3, respectively. The optimum vanadium content of 5CrNiMoVx (x = 0, 0.1, 0.2, 0.3, 0.4, 0.5) die steel sample is x = 0.3%. -

表 1 5CrNiMoVx(x=0,0.1,0.2,0.3,0.4,0.5) 模具钢试样化学成分

Table 1. Chemical compositions of 5CrNiMoVx(x=0,0.1,0.2,0.3,0.4,0.5) die steel specimens

% 编号(钒含量) C Mn Cr Ni Mo Si V S P Fe 试样1(x=0) 0.55 0.68 0.71 1.65 0.18 0.22 0 <0.02 <0.02 Bal. 试样2(x=0.1) 0.55 0.67 0.72 1.64 0.18 0.22 0.1 <0.02 <0.02 Bal. 试样3(x=0.2) 0.54 0.68 0.71 1.66 0.19 0.23 0.2 <0.02 <0.02 Bal. 试样4(x=0.3) 0.55 0.69 0.72 1.65 0.19 0.22 0.3 <0.02 <0.02 Bal. 试样5(x=0.4) 0.56 0.68 0.72 1.65 0.19 0.23 0.4 <0.02 <0.02 Bal. 试样6(x=0.5) 0.55 0.68 0.71 1.65 0.18 0.23 0.5 <0.02 <0.02 Bal. 表 2 5CrNiMoVx(x=0,0.1,0.2,0.3,0.4,0.5)模具钢试样抗热裂性能

Table 2. Hot cracking resistance of 5CrNiMoVx (x=0, 0.1, 0.2,0.3,0.4,0.5) die steel samples

试样编号 钒含量/% 裂纹长度/mm 试样1 x=0 3.46 试样2 x=0.1 1.67 试样3 x=0.2 0.95 试样4 x=0.3 0.03 试样5 x=0.4 0.82 试样6 x=0.5 1.77 表 3 模具钢试样耐高温磨损性能

Table 3. Wear resistance of die steel specimens at high temperature

试样编号 钒含量/% 高温磨损体积×103/mm3 试样1 x=0 27 试样2 x=0.1 30 试样3 x=0.2 22 试样4 x=0.3 19 试样5 x=0.4 23 试样6 x=0.5 29 -

[1] Zhang Yan, Wang Zhenxu, Xu Yu, et al. Effect of quenching temperature on corrosion resistance of 40Cr13 plastic die steel[J]. Materials for Mechanical Engineering, 2021,45(1):80−84. (张艳, 王振旭, 徐豫, 等. 淬火温度对40Cr13塑料模具钢耐腐蚀性能的影响[J]. 机械工程材料, 2021,45(1):80−84. doi: 10.11973/jxgccl202101013Zhang Yan, Wang Zhenxu, Xu Yu, et al. Effect of quenching temperature on corrosion resistance of 40 Cr13 plastic die steel[J]. Materials for Mechanical Engineering, 2021, 45(1): 80-84 doi: 10.11973/jxgccl202101013 [2] Huang Biaocai, Ning Bo, Chen Yuye, et al. Effect of heat treatment processes on microstructure and properties of P20 die steel[J]. Heat Treatment of Metals, 2021,46(1):88−91. (黄标彩, 宁博, 陈玉叶, 等. 热处理工艺对P20模具钢组织和性能的影响[J]. 金属热处理, 2021,46(1):88−91.Huang Biaocai, Ning Bo, Chen Yuye, et al. Effect of heat treatment processes on microstructure and properties of P20 die steel[J]. Heat Treatment of Metals, 2021, 46(1): 88-91 [3] Wang Zhiguo, He Zhenfeng, Zhao Jibin, et al. Microstructure transformation and difference of 316L stainless steel by laser depositionon surface of mold steel[J]. Journal of Materials Engineering, 2021,49(2):105−113. (王志国, 何振丰, 赵吉宾, 等. 模具钢表面激光沉积316L不锈钢的组织转变及差异性[J]. 材料工程, 2021,49(2):105−113. doi: 10.11868/j.issn.1001-4381.2020.000186Wang Zhiguo, He Zhenfeng, Zhao Jibing, et al. Microstructure transformation and difference of 316 L stainless steel by laser depositionon surface of mold steel[J]. Journal of Materials Engineering, 2021, 49(2): 105-113 doi: 10.11868/j.issn.1001-4381.2020.000186 [4] Qiu Yu, Yuan Fei, Zeng Yuansong, et al. Hot deformation behavior and hot processing maps of 4Cr5MoSiV1 hot working die steel[J]. Materials for Mechanical Engineering, 2021,45(2):71−77. (邱宇, 袁飞, 曾元松, 等. 4Cr5MoSiV1热作模具钢的热变形行为与热加工图[J]. 机械工程材料, 2021,45(2):71−77. doi: 10.11973/jxgccl202102013Qiu Yu, Yuan Fei, Zeng Yuansong, et al. Hot Deformation Behavior and Hot Processing Maps of 4 Cr5 MoSiV1 Hot Working Die Steel[J]. Materials for Mechanical Engineering, 2021, 45(2): 71-77 doi: 10.11973/jxgccl202102013 [5] Sun Ruibao. Effect of preheating temperature on performance of 3Cr2W8VSr new type of die casting die steel[J]. Hot Working Technology, 2020,49(10):153−155. (孙瑞宝. 预热温度对3Cr2W8VSr新型压铸模具钢性能的影响[J]. 热加工工艺, 2020,49(10):153−155.Sun Ruibao. Effect of preheating temperature on performance of 3 Cr2 W8 VSr new type of die casting die steel[J]. Hot Working Technology, 2020, 49(10): 153-155 [6] Sun Xiaoming, Wei Huacheng, Du Xiaozhong, et al. Application of DEFORM-3D in cavity analysis of pre-forging mold for integral steel wheel[J]. Forging & Stamping Technology, 2020,45(8):23−31. (孙晓明, 魏华成, 杜晓钟, 等. DEFORM-3D在整体辗钢车轮预锻模具型腔分析中的应用[J]. 锻压技术, 2020,45(8):23−31.Sun Xiaoming, Hua Cheng, Du Xiaozhong, et al. Application of DEFORM-3 D in cavity analysis of pre-forging mold for integral steel wheel[J]. Forging & Stamping Technology, 2020, 45(8): 23-31 [7] Zhang Yongqiang, Xu Guocai, Zuo Pengpeng, et al. Prediction of thermo-mechanical fatigue damage and life for H13 hot-work die steel[J]. Shanghai Metals, 2020,42(3):12−16,20. (张永强, 徐国财, 左鹏鹏, 等. H13热作模具钢热-机械疲劳损伤和寿命的预测[J]. 上海金属, 2020,42(3):12−16,20.Zhang Yongqiang, Xu Guocai, Zuo Pengpeng, et al. Prediction of thermo-mechanical fatigue damage and life for H13 hot-work die steel[J]. Shanghai Metals, 2020, 42(3): 12-16, 20 [8] Yuan Changwang, Huang Jiajin, Li Shengci, et al. Influence of die and temperature on microstructure and properties of 1500 MPa thermoforming steel[J]. Nonferrous Metals Science and Engineering, 2020,11(4):37−43. (袁昌望, 黄加进, 李声慈, 等. 模具及温度对1500 MPa级热成形钢组织性能的影响[J]. 有色金属科学与工程, 2020,11(4):37−43.Yuan Changwang, Huang Jiajin, Li Shengci, et al. Influence of die and temperature on microstructure and properties of 1500 MPa thermoforming steel[J]. Nonferrous Metals Science and Engineering, 2020, 11(4): 37-43 [9] Ding Xiangqin, Ji Shijun. Study on the properties of a new type of mechanical die steel containing titanium[J]. Iron Steel Vanadium Titanium, 2020,41(6):170−174. (丁向琴, 冀世军. 新型含钛机械模具钢的性能研究[J]. 钢铁钒钛, 2020,41(6):170−174. doi: 10.7513/j.issn.1004-7638.2020.06.029Ding Xiangqin, Ji Beijun. Study on the properties of a new type of mechanical die steel containing titanium[J]. Iron Steel Vanadium Titanium, 2020, 41(6): 170-174 doi: 10.7513/j.issn.1004-7638.2020.06.029 [10] Yu Shujing, Li Jiming. Effect of vanadium content on the properties of 40Cr die steel[J]. Iron Steel Vanadium Titanium, 2020,41(5):166−170. (于淑静, 李纪明. 钒添加量对40Cr模具钢性能的影响[J]. 钢铁钒钛, 2020,41(5):166−170. doi: 10.7513/j.issn.1004-7638.2020.05.028Yu Shujing, Li Jiming. Effect of Vanadium Content on the Properties of 40 Cr Die Steel[J]. Iron Steel Vanadium Titanium, 2020, 41(5): 166-170 doi: 10.7513/j.issn.1004-7638.2020.05.028 -

下载:

下载: