Research on multi-condition synchronous heating of titanium billet in large billet heating furnace

-

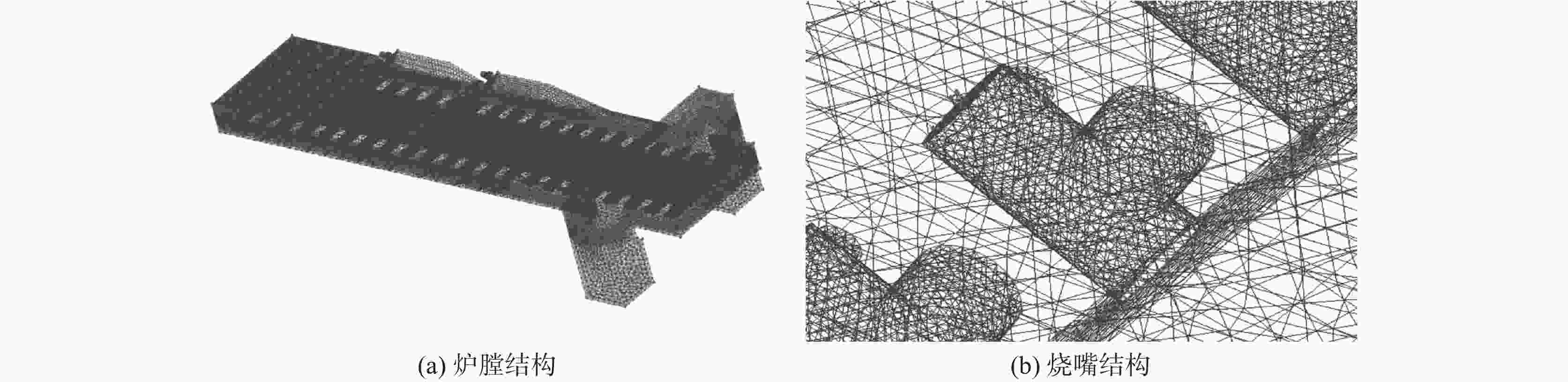

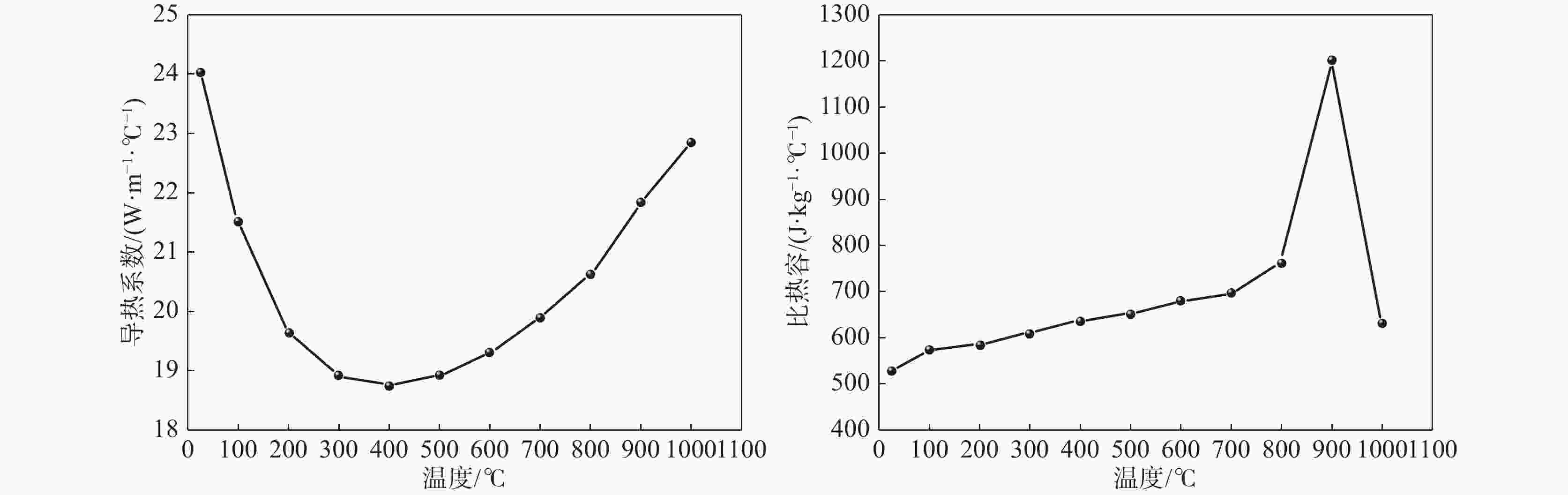

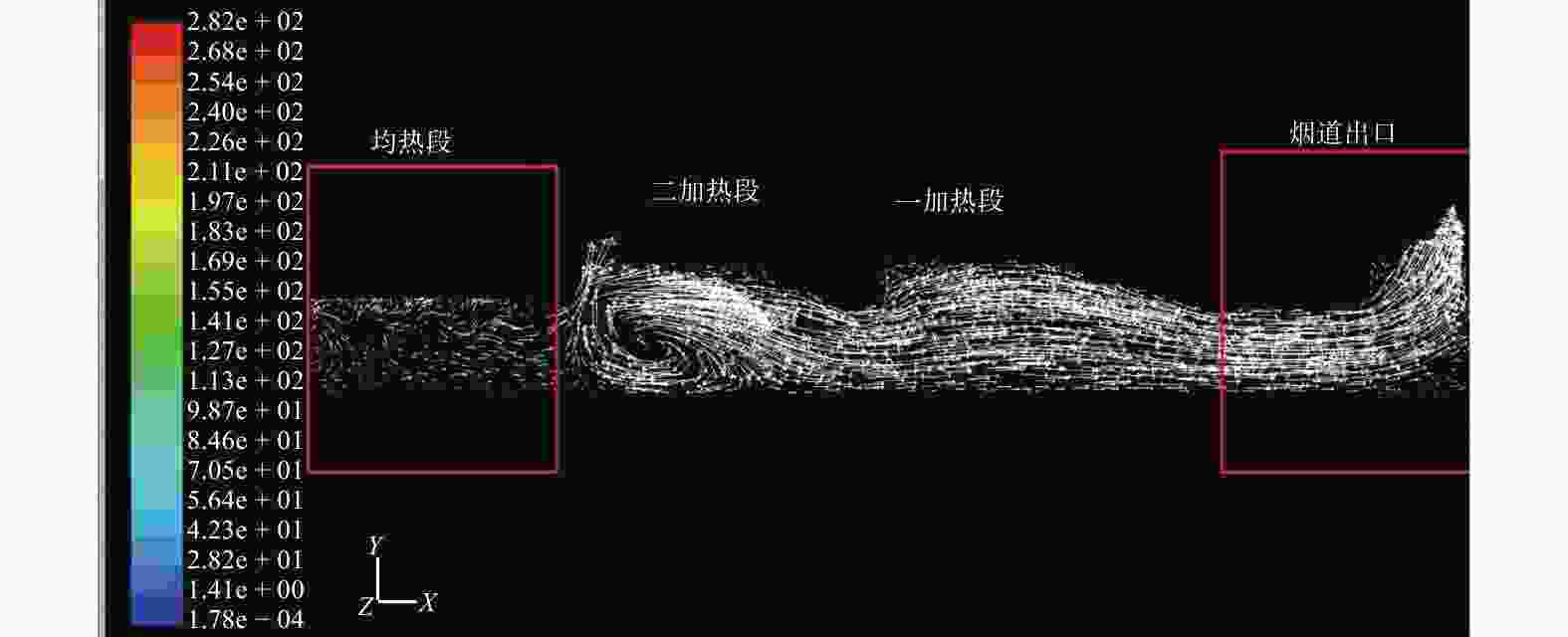

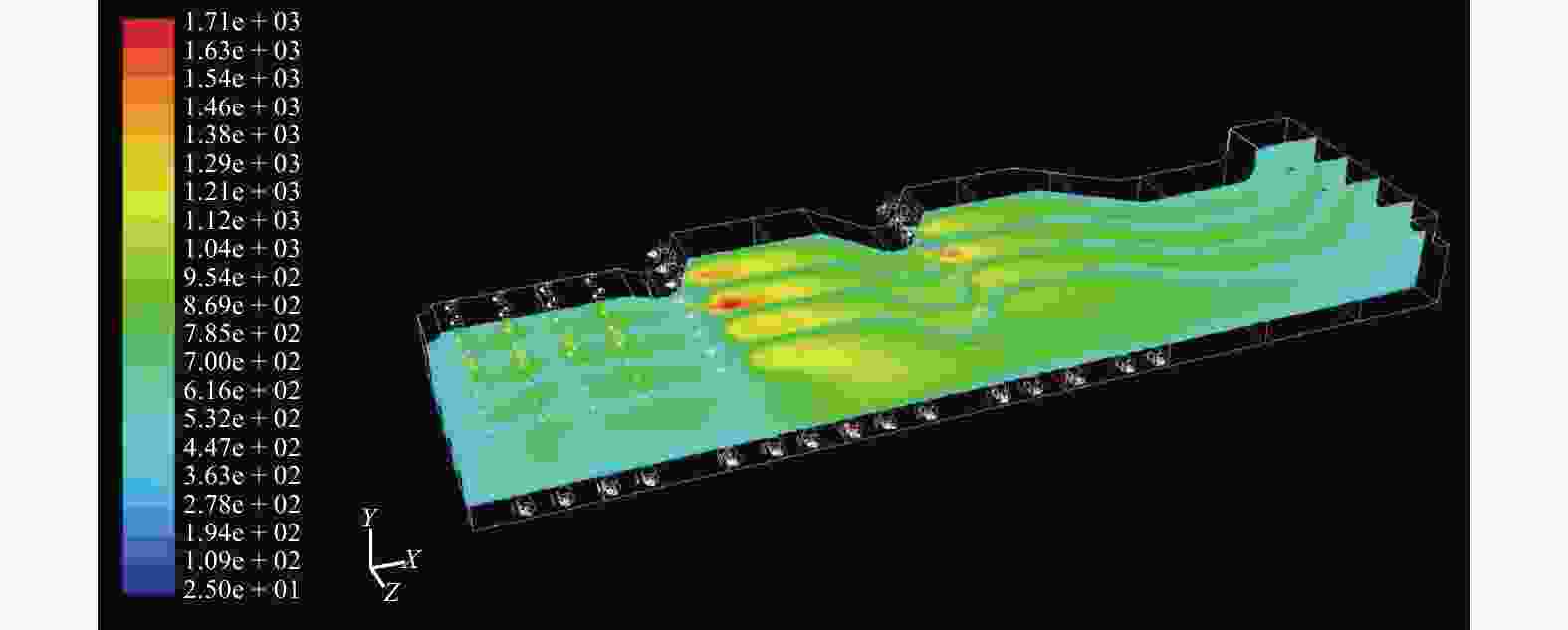

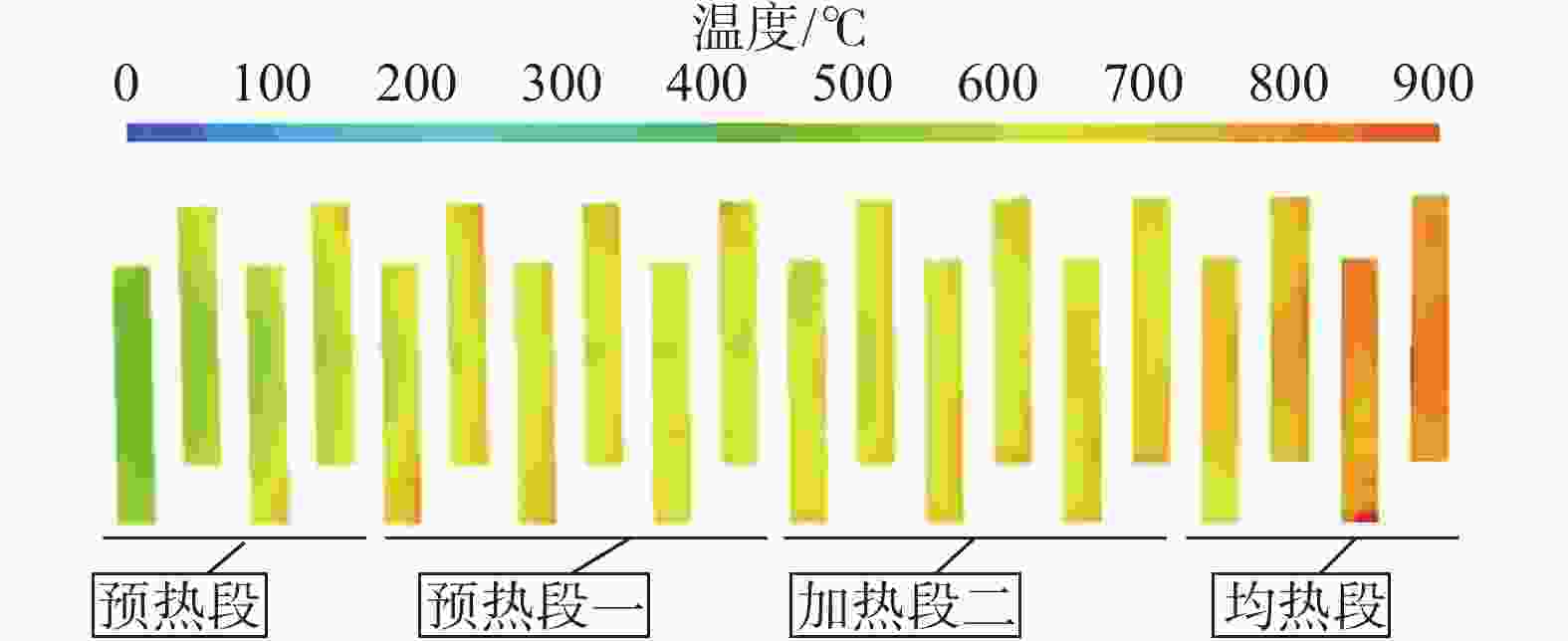

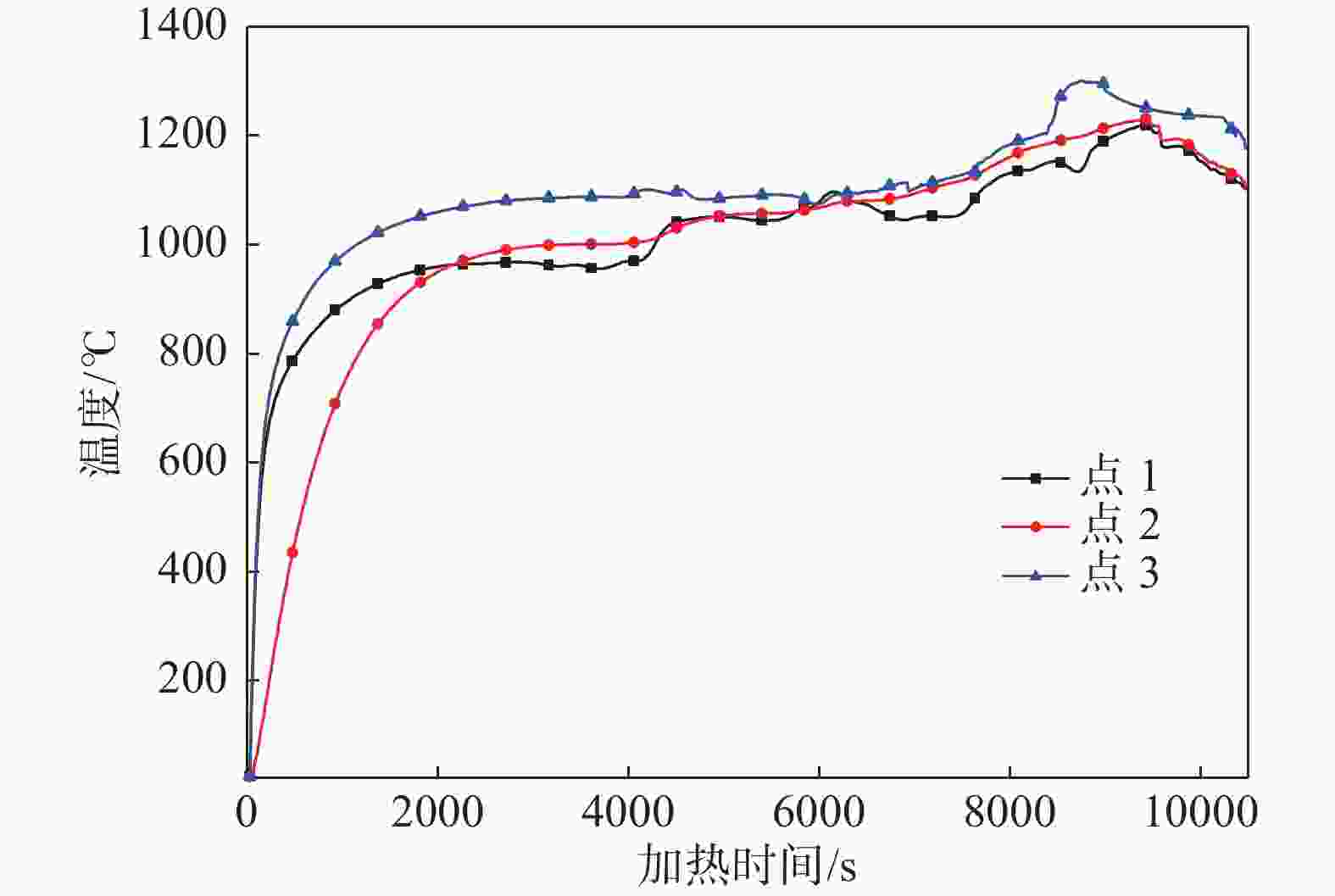

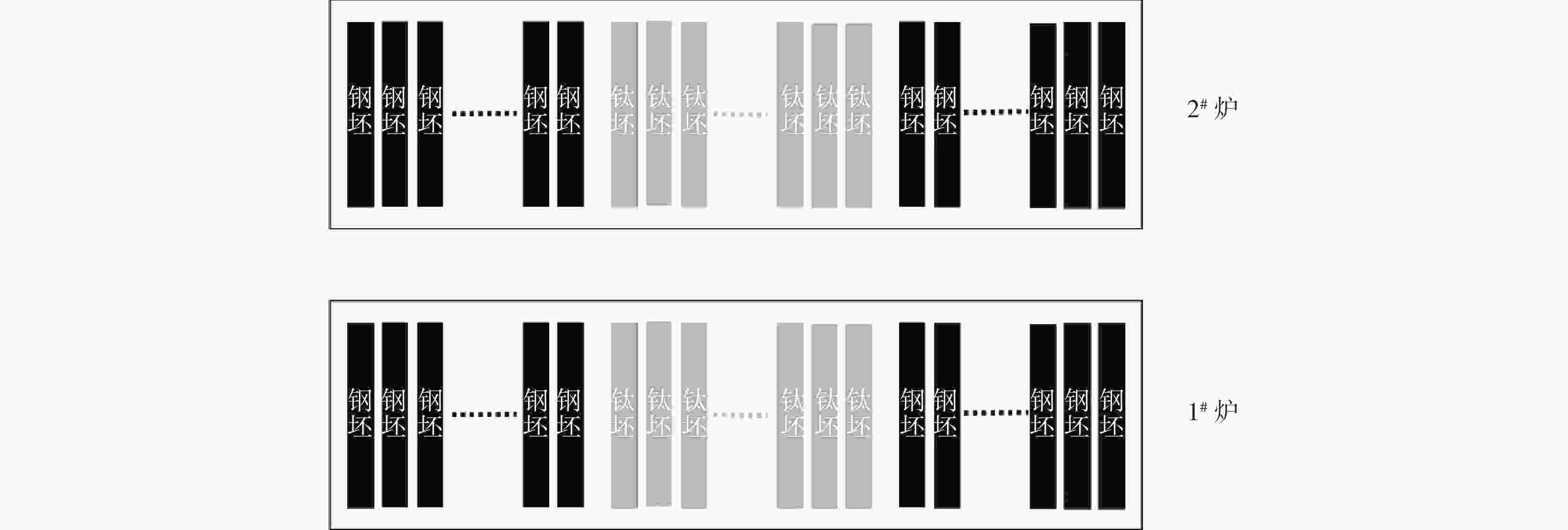

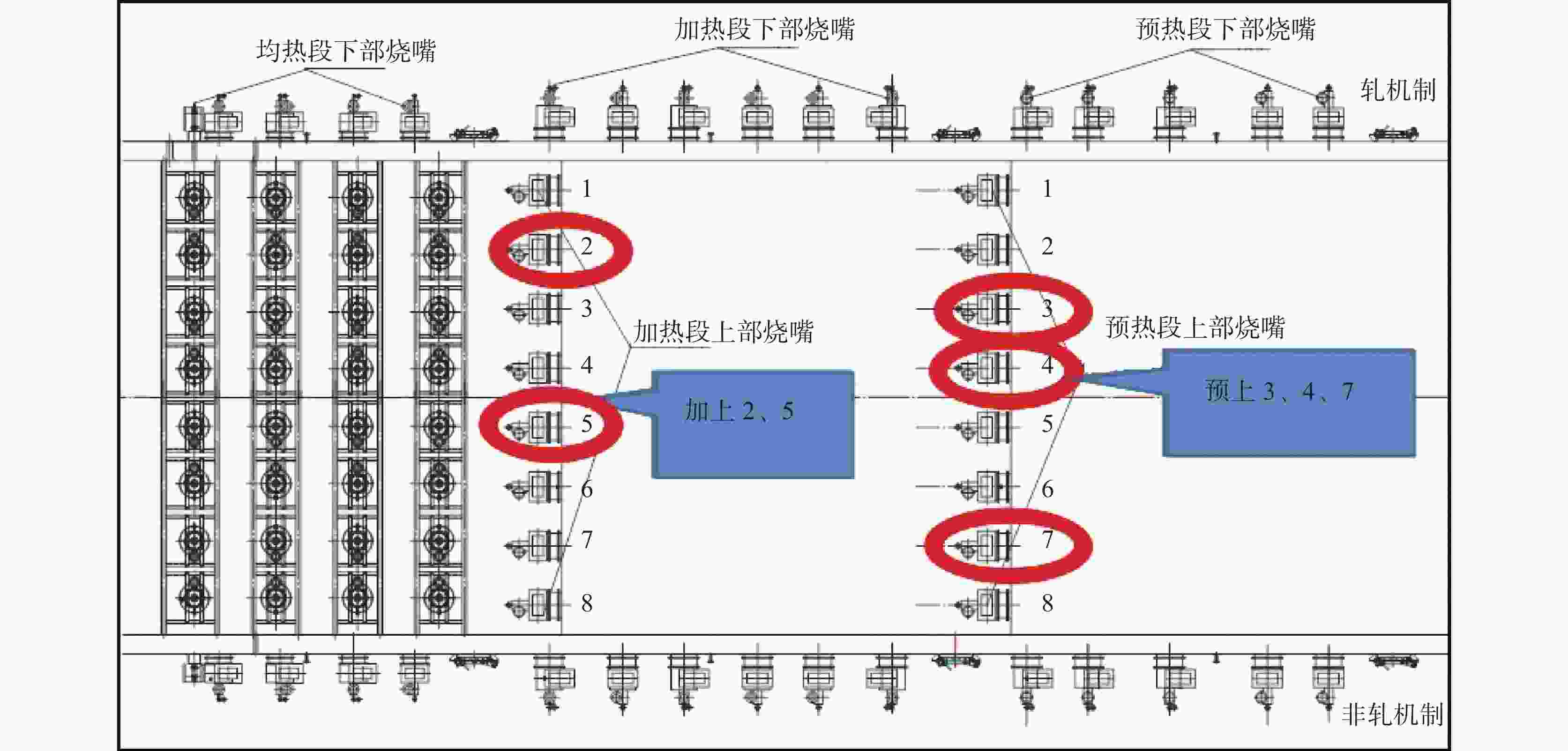

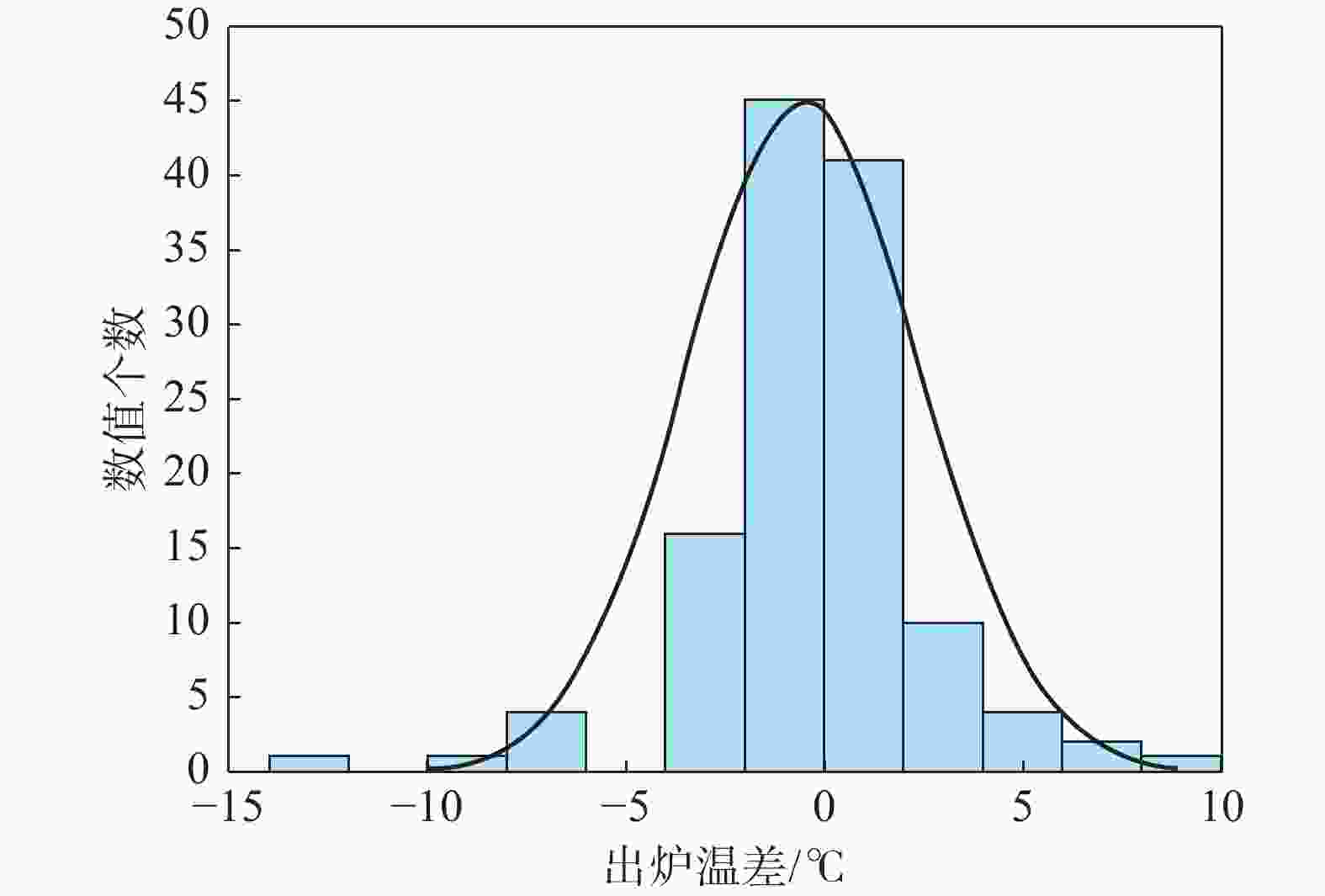

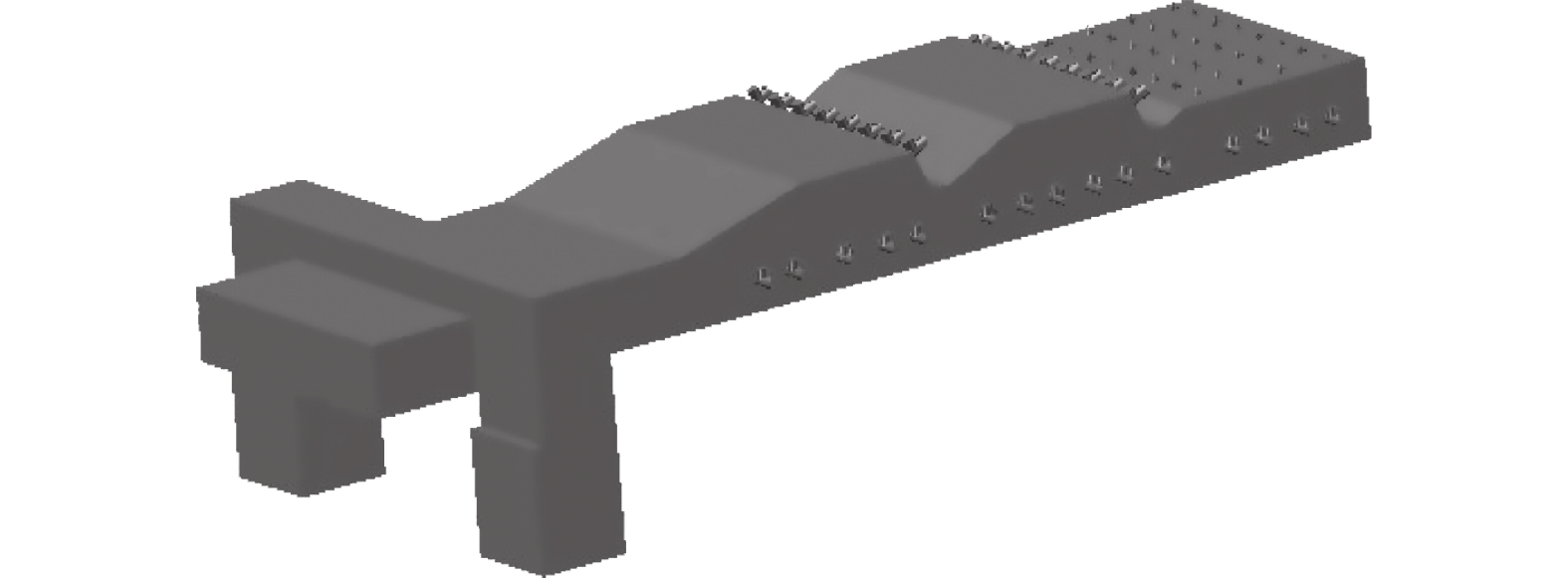

摘要: 钛由于其具有各种优异的性能,被广泛应用于国防及民用领域。高效、低成本地连续生产大卷重钛带卷,利用常规热连轧生产线进行钛、钛合金-钢共线生产是大卷重钛带卷生产的发展趋势。对于钢-钛共线轧制热轧钛带卷,加热是关键环节。在某1 450 mm热带钢连轧线基础上,针对钛带卷生产效率低、加热能耗大等问题,通过ANSYS有限元建立钢坯加热炉实体模型,Fluent仿真得到加热炉内温度场和流场,分析了钛板坯在加热炉中不同阶段的温度分布,成功突破了大型钢坯加热炉多炉况同步加热钛坯技术,实现了钛带卷的高效高质量生产。Abstract: Titanium is widely used in national defense and civil fields due to its various excellent properties. In order to continuously produce large coils of heavy titanium strip with high efficiency and low cost, conventional hot tandem rolling production lines for co-linear production of titanium, titanium alloys and steel are the development trend. For steel-titanium co-linear rolling of hot-rolled titanium coil, reheating is the key step. Based on the 1 450 mm hot strip rolling line, in order to solve the problems of low efficiency and high energy consumption of titanium coils, a solid model of the billet heating furnace through ANSYS finite element had been developed to analyze the fluid conditions in the furnace through Fluent simulation calculation. The temperature distribution of titanium slab at different stages in the reheating furnace under optimal air-fuel ratio had been studied. The technology of synchronously reheating titanium billets in large billet reheating furnaces had been well established from this research and successfully been used to achieve efficient and high-quality production of titanium coils.

-

Key words:

- titanium coil /

- steel-titanium collinear rolling /

- finite element /

- air-fuel ratio

-

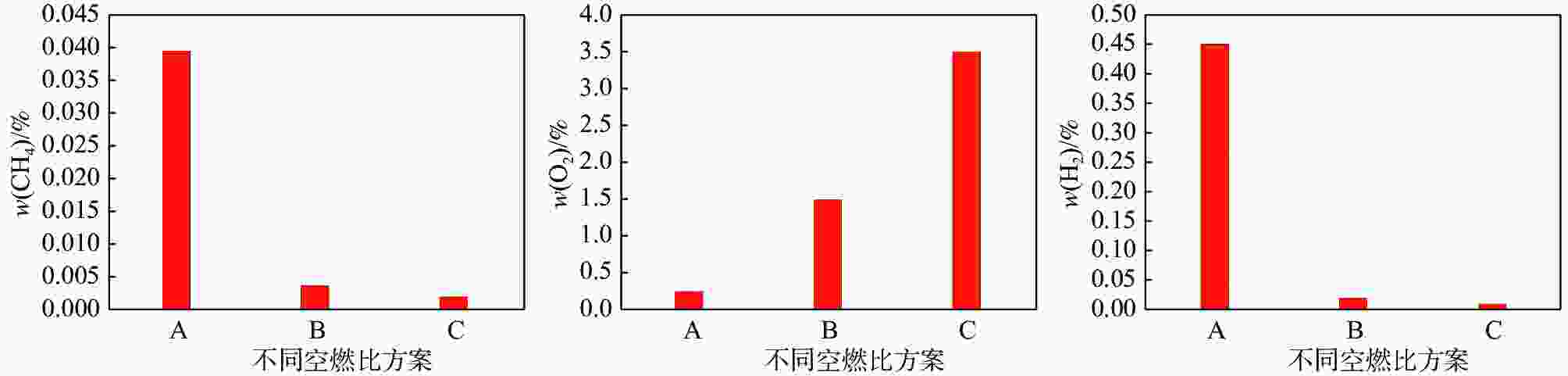

表 1 混合煤气的成分组成

Table 1. Chemical composition of mixed gas

% CO2 CmHn O2 CO H2 9.4 0.8 0.2 17.8 26.1 表 2 加热炉不同情况的空燃比

Table 2. Air fuel ratio of reheating furnace under different conditions

不同部位 加热段一

炉顶加热段一

两侧加热段二

炉顶加热段二

两侧均热段

炉顶均热段

两侧方案1(A) 3.50 4.70 3.50 4.70 5.10 2.80 方案2(B) 4.60 5.87 4.67 5.87 7.65 4.20 方案3(C) 8.00 10.0 8.00 9.0 10 6 表 3 金属钛材热连轧轧制效率及能耗对比

Table 3. Comparison of efficiency and energy consumption in metallic titanium hot continuous rolling

钛带轧制量/t 能耗/(GJ·t−1) 轧制时间/min 小时轧制量/t 加热方式 194.73 20.45 115.52 101.14 双炉 162.14 20.88 89.67 108.49 双炉 161.7 20.53 96.38 100.66 双炉 208.84 20.39 110.37 113.53 双炉 182.93 21.04 108.61 101.06 双炉 161.18 21.70 91.03 106.24 双炉 186.44 19.95 114.96 97.31 双炉 128.93 20.48 80.41 96.20 双炉 129.01 22.41 76.47 101.22 双炉 205.58 20.17 109.79 112.35 双炉 220.59 21.27 127.85 103.52 双炉 167.46 39.21 174.27 57.66 单炉 -

[1] Wang Xuezheng. Panxi has become the key development zone of metal resources in China[J]. Shanghai Nonferrous Metals, 1995,6:352. (王学正. 攀西已成为我国金属资源重点开发区[J]. 上海有色金属, 1995,6:352.Wang xuezheng. Panxi has become the key development zone of metal resources in China [J]. Shanghai Nonferrous Metals, 1995, 06: 352-352. [2] Wu Quanxing. Progress of titanium industry technology in China[J]. Rare Metals Letters, 2004,23(9):1−4. (吴全兴. 我国钛工业技术的进展[J]. 稀有金属快报, 2004,23(9):1−4.Wu Quanxing. Progress of Titanium industry technology in China[J]. Rare Metals Letters, 2004, 023(009): 1-4. [3] Kazuo Muraoka. Cooling production technology of industrial pure iron[J]. Nonferrous Metals Processing, 1996,(6):30−37. (村冈一雄. 工业纯铁的冷化生产技术[J]. 有色金属加工, 1996,(6):30−37.Kazuo Muraoka. Cooling Production technology of Industrial pure Iron [J]. Nonferrous Metals Processing, 1996, (6): 30-37. [4] 严国平. 华菱链钢热乳机组成功试化出我国第一盘铁带卷[N]. 世界金属导报, 2007-08-07(15).Yan Guoping. Valin chain steel hot milk unit successfully tested the first iron strip coil in China[N]. World Metal Review, 2007-08-07(15). [5] 徐欣磊. 宝钢1880 mm热轧钛板轧制技术研究与实现[D]. 沈阳: 东北大学, 2014.Xu Xinlei. Research and implementation of Baosteel 1880 mm hot rolled titanium plate rolling technology [D]. Shenyang: Northeastern University, 2014. [6] Xin Jianqing, Zhang Huaifu. Development of technology for producing large coil weight and wide titanium strip in 1549 mm hot strip mill[J]. Shanxi Metallurgy, 2015,38(2):10-11. (辛建卿, 张怀富. 1549 mm热连轧机生产大卷重宽幅钛带技术开发[J]. 山西冶金, 2015,38(2):10-11.Xin Jianqing, ZHANG Huaifu. Development of technology for producing large coil weight and wide titanium strip in 1549 mm Hot Strip Mill [J]. Shanxi Metallurgy, 2015, 38(2): 2. [7] Xiang Guojin, Luo Xu, Geng Naitao, et al. Study on temperature field of titanium slab heating process based on walking-beam-type furnace[J]. Iron Steel Vanadium Titanium, 2021,42(6):191−198. (向国进, 罗许, 耿乃涛, 等. 基于步进式加热炉的钛坯加热过程温度场研究[J]. 钢铁钒钛, 2021,42(6):191−198.Xiang Guojin, Luo Xu, gengnaitao et al. Study on Temperature Field of Titanium Slab Heating Process Based on Walking-Beam-Type Furnace[J]. Steel Vanadium and Titanium, 2021, 42(06): 191-198. [8] Gu Mingyan , Chen Guang . Numerical simulation of slab heating process in a regenerative walking beam reheating furnace[J]. International Journal of Heat and Mass Transfer, 2014,76:405−410. [9] Harish J, Dutta P. Heat transfer analysis of pusher type reheat furnace[J]. Ironmak. Steelmak, 2005,32(2):151−158. -

下载:

下载: