Study of high-calcium vanadium slag with blank roasting carbonation leaching process

-

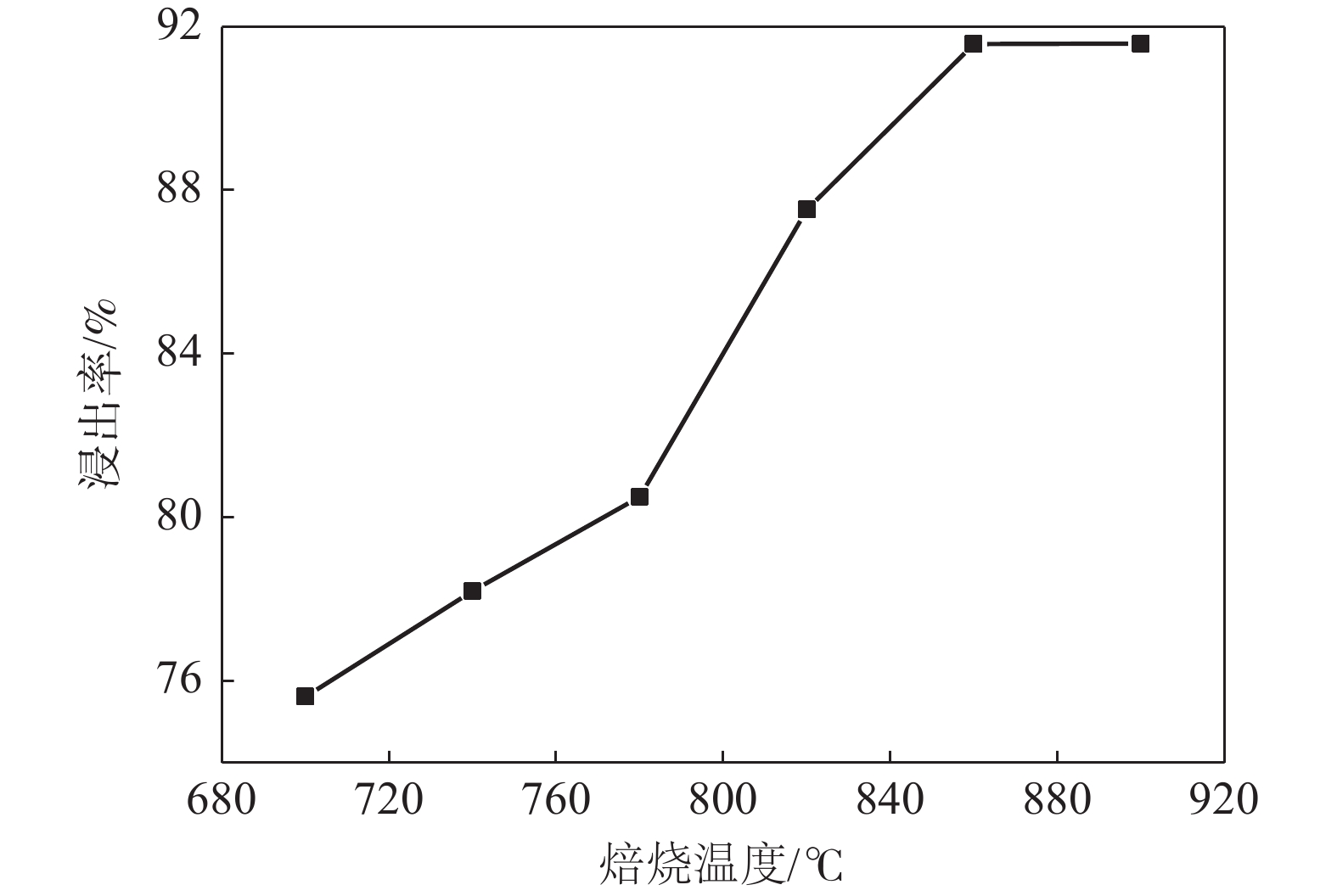

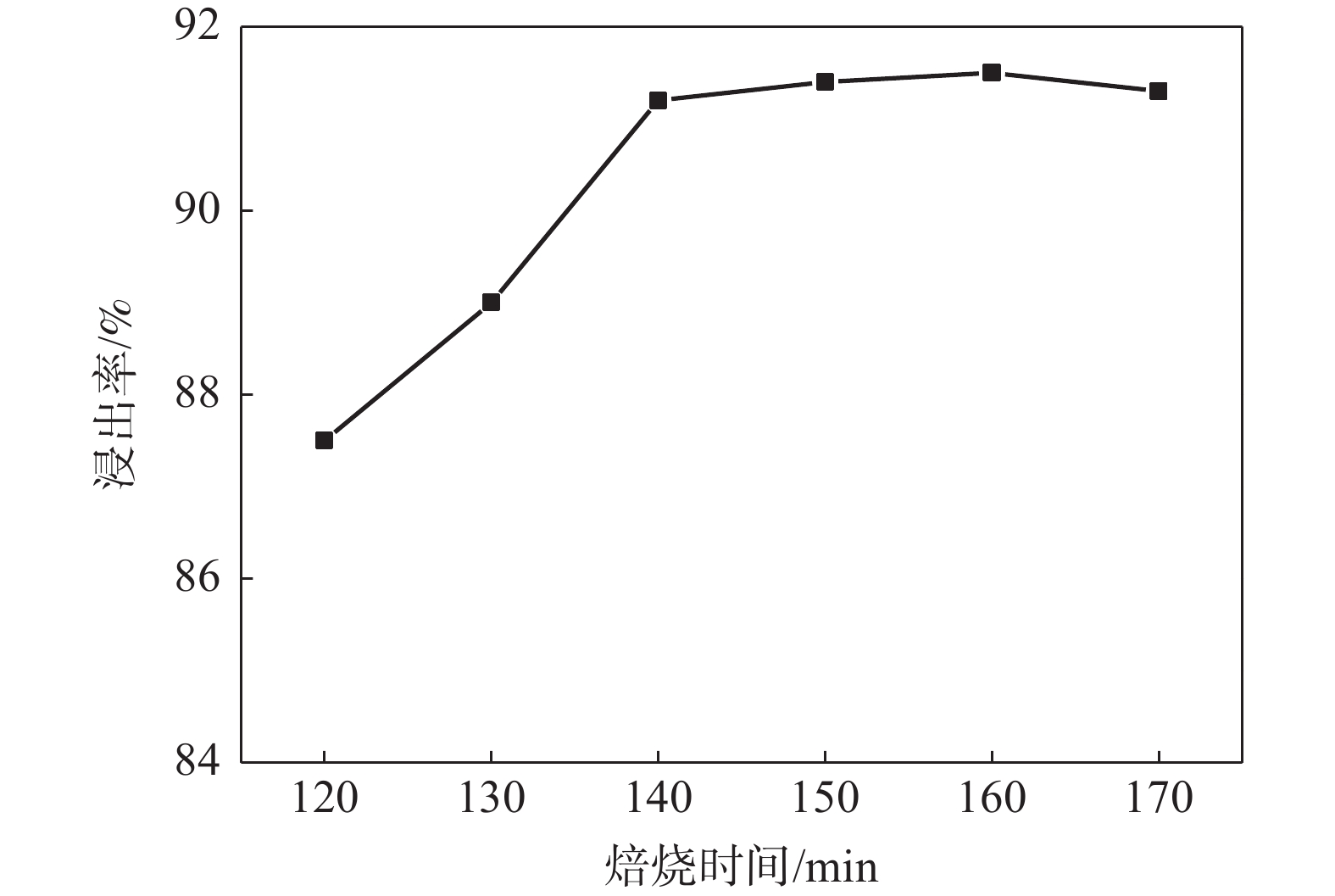

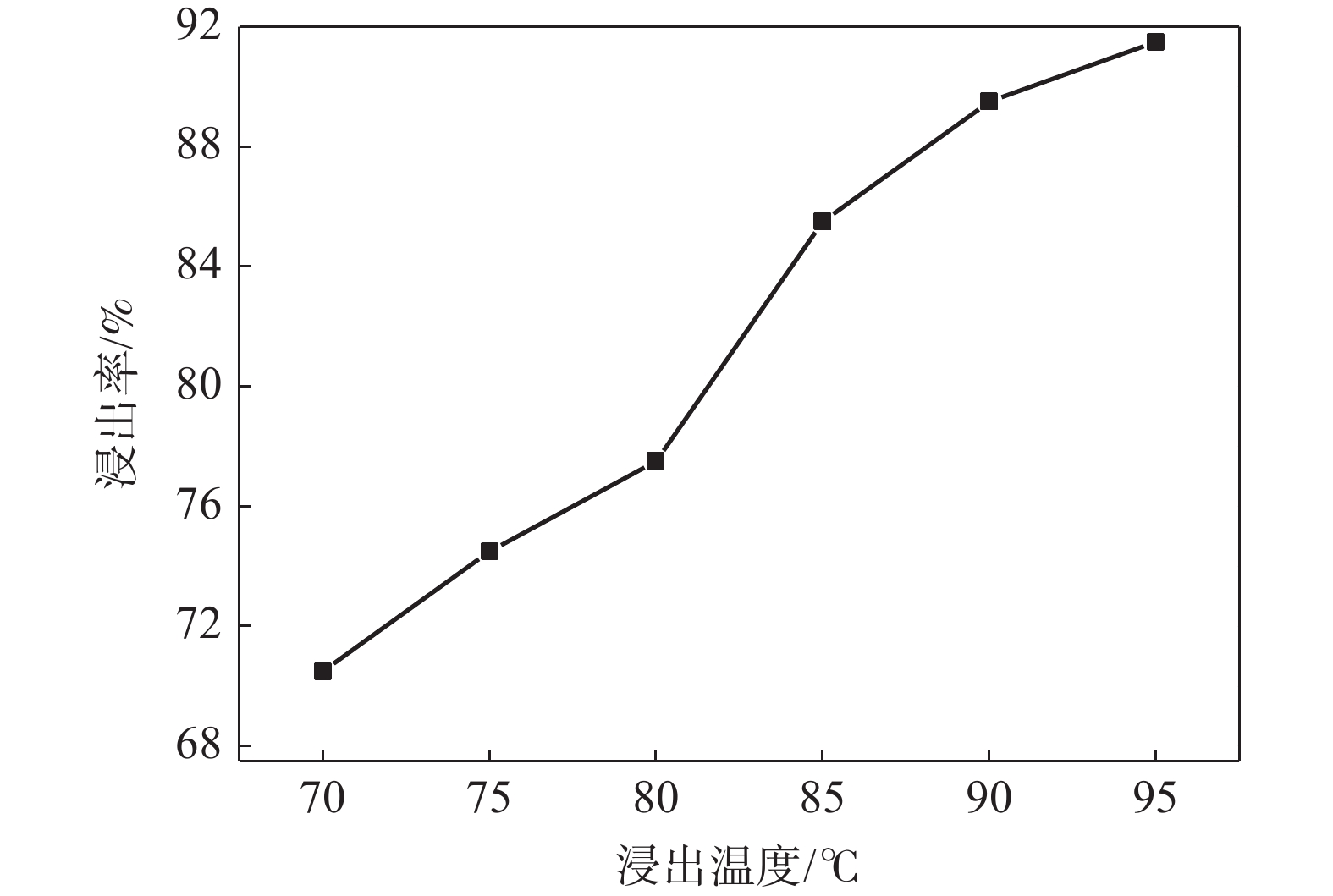

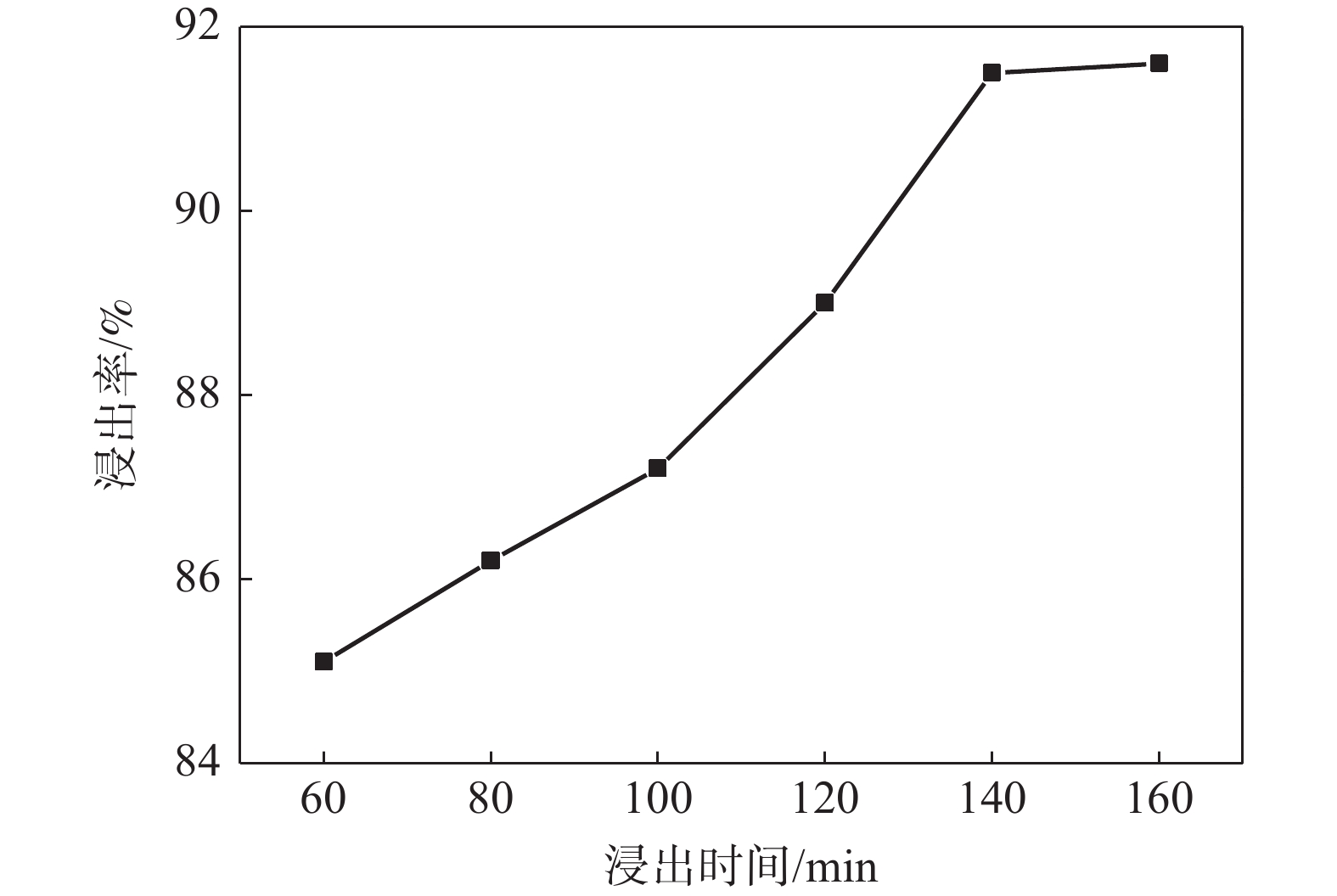

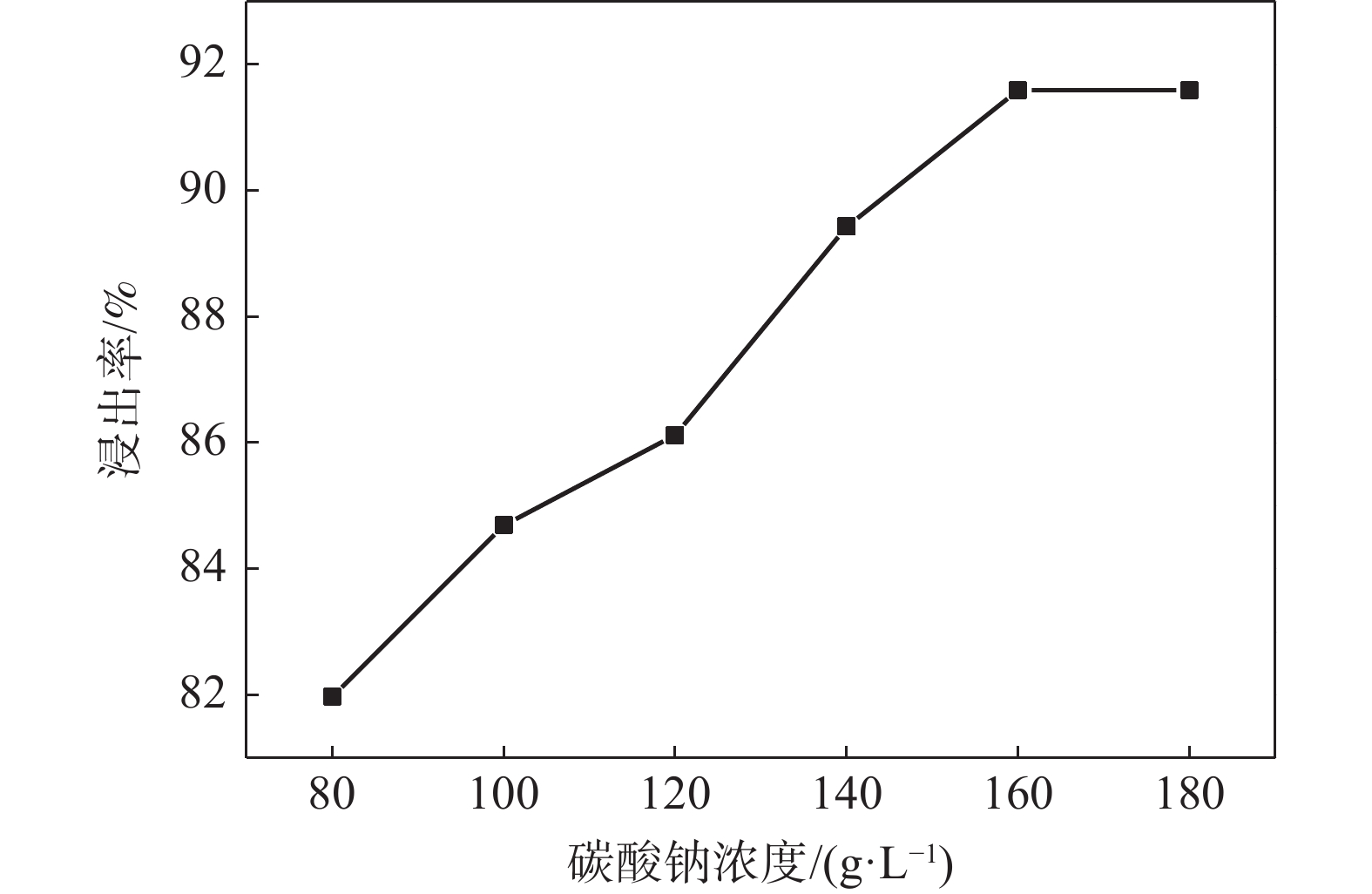

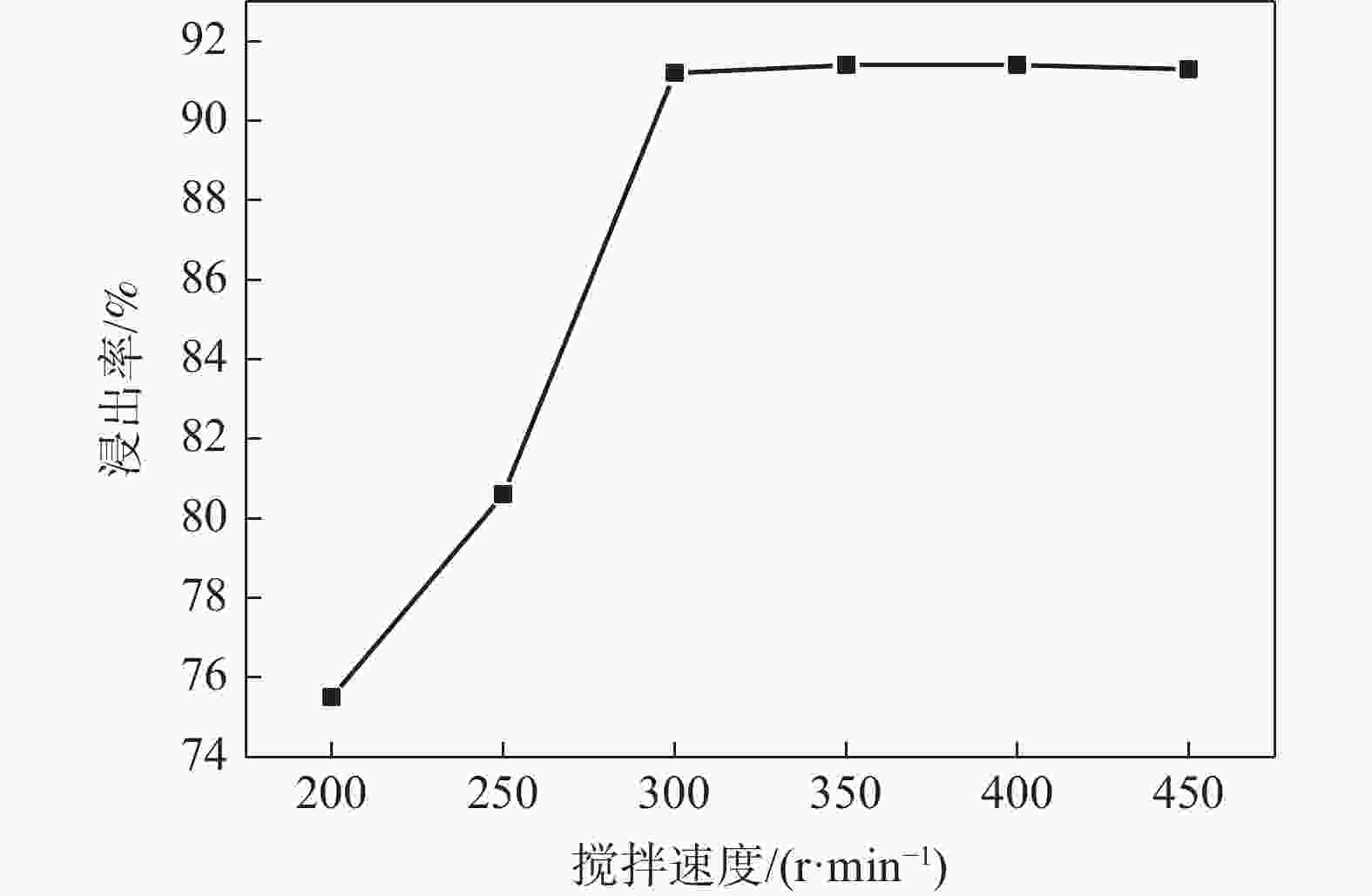

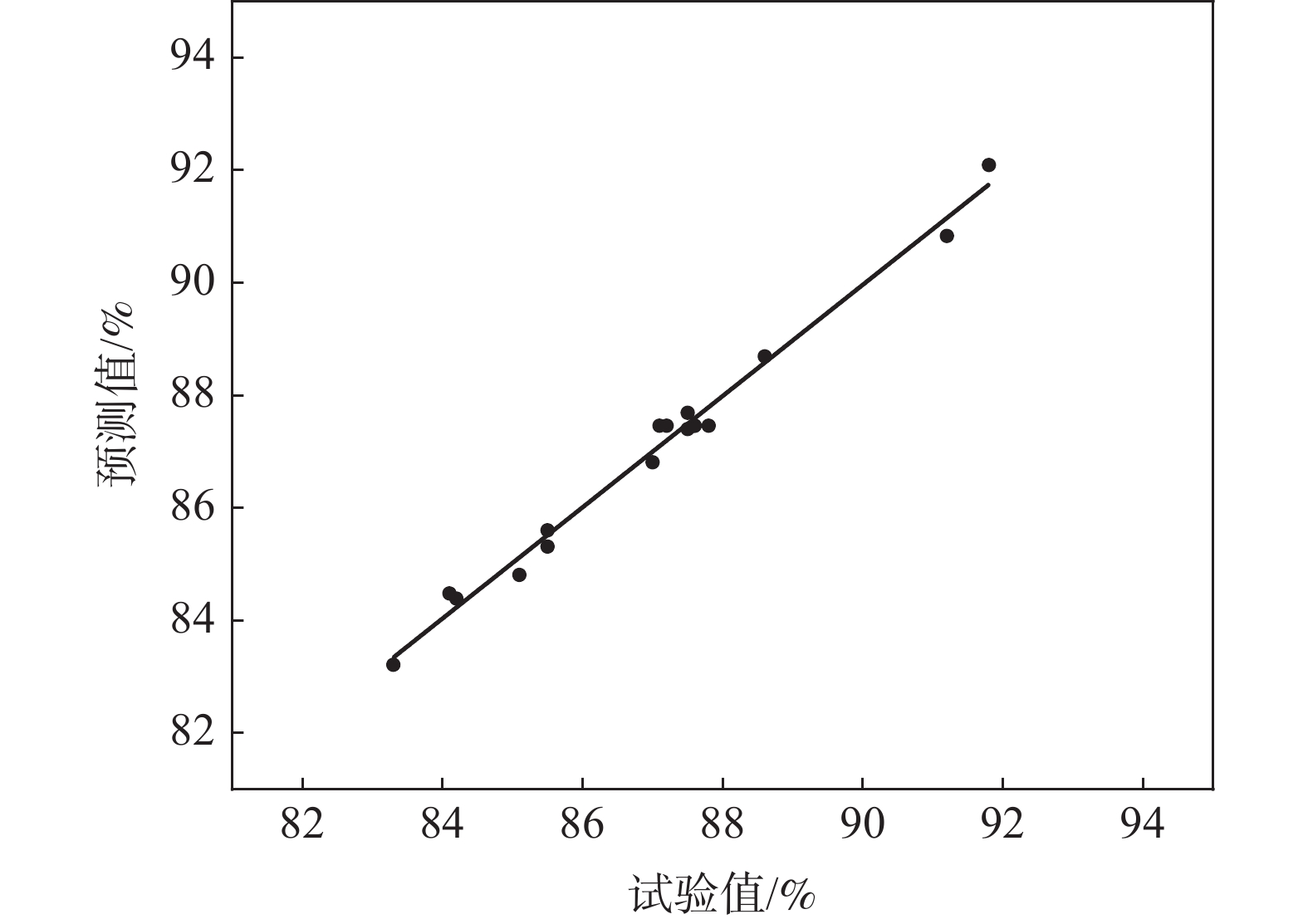

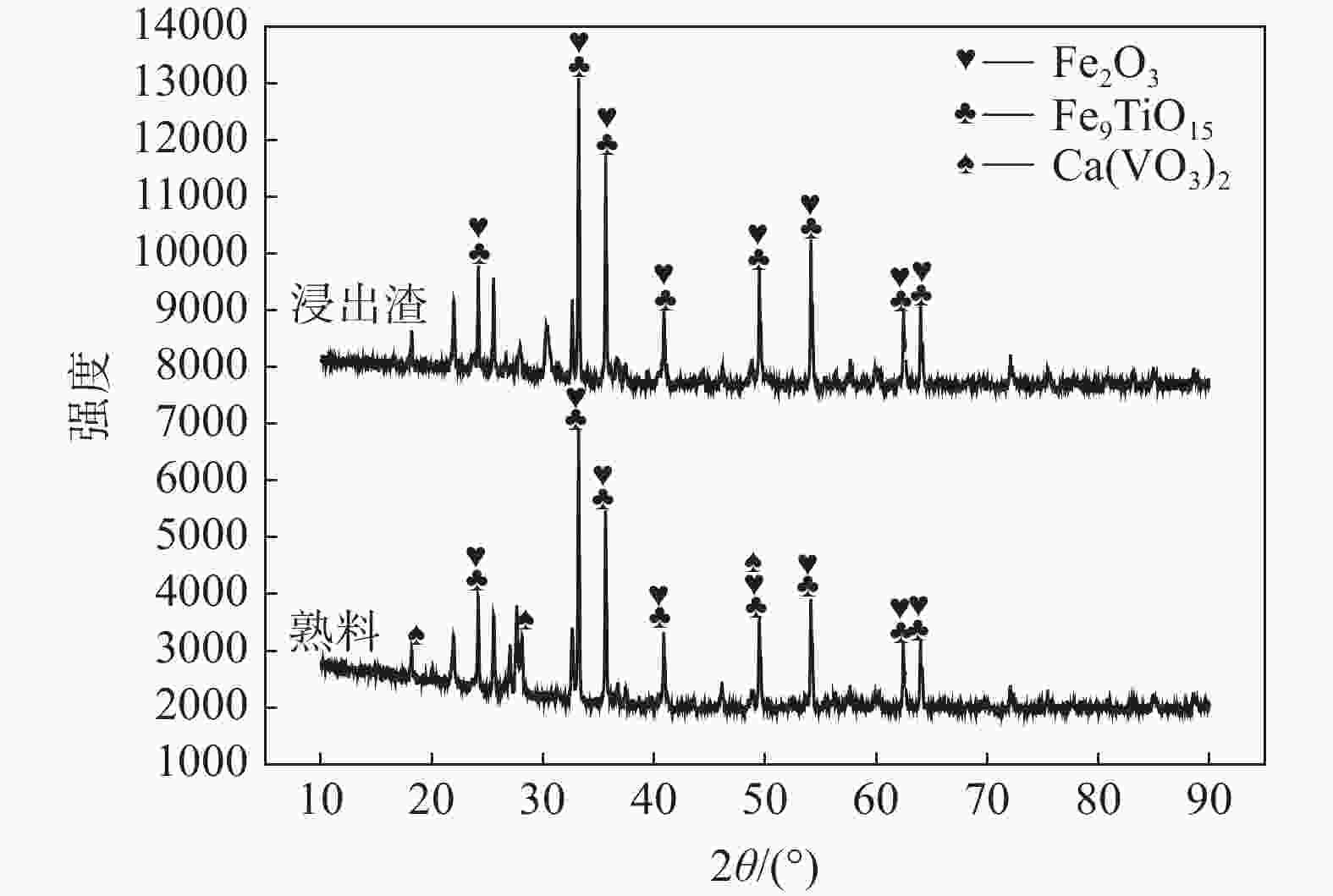

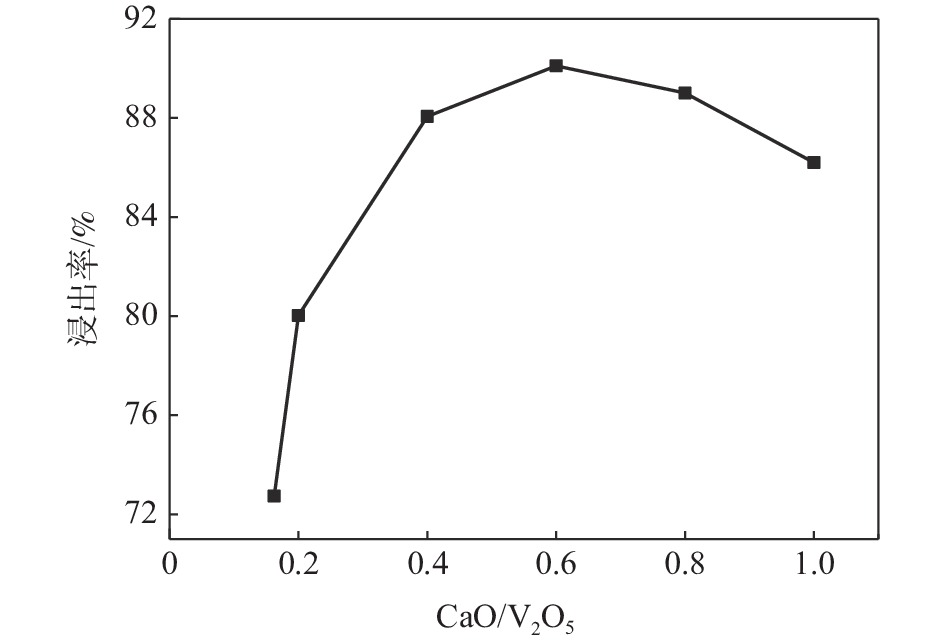

摘要: 针对高钙高磷钒渣钙含量高,现有提钒工艺难以有效提钒的现状,采用空白焙烧-碳酸化浸出工艺进行了试验研究,并采用响应曲面法进行了优化。考察了高钙钒渣中CaO/V2O5(质量比)、焙烧温度、焙烧时间、浸出搅拌速度、浸出温度、浸出时间和碳酸钠溶液浓度等条件对高钙钒渣中钒浸出率的影响。结果表明:钒渣中的CaO/V2O5(质量比)=0.6、899 ℃钙化焙烧160 min,熟料在浸出温度95 ℃、浸出时间140 min、碳酸钠浓度168 g/L、搅拌速度为300 r/min等条件下浸出,钒浸出率平均为92.22%。相比于传统的提钒工艺,空白焙烧碳酸化浸出工艺对于高钙钒渣具有钒浸出率高的优势。Abstract: In view of the high-calcium content of high calcium and high-phosphorus vanadium slag and the existing vanadium extraction process difficult to effectively extract vanadium, blank roasting-carbonation leaching process is investigated, and the response surface method is used for optimization. The effects of CaO/V2O5 mass ratio, roasting temperature, roasting time, leaching stirring speed, leaching temperature, leaching time and sodium carbonate solution concentration on the leaching rate of vanadium from high-calcium vanadium slag were investigated. The results show that the average vanadium leaching rate is 92.22% when the mass ratio of CaO/V2O5 in vanadium slag is 0.6, calcination at 899 ℃ for 160 min, clinker leaching temperature at 95℃, leaching time of 140 min, sodium carbonate concentration of 168 g/L and stirring speed of 300 r/min. Compared with the traditional vanadium extraction process, the blank roasting-carbonation leaching process has the advantage of high vanadium leaching rate for high-calcium vanadium slag.

-

表 1 钒渣精粉主要化学成分

Table 1. Main chemical constituents of vanadium slag fine powder

% V2O5 CaO P MgO MnO TFe Na2O SiO2 TiO2 Al2O3 14.16 2.30 0.051 2.92 7.35 35 0.45 14.96 9.98 4.35 表 2 试验因素水平编码

Table 2. Test factor level codes

水平 因素 A:焙烧温度/°C B:浸出温度/°C C:浸出剂浓度/(g·L−1) +1 900 95 180 0 860 90 160 −1 820 85 140 表 3 响应曲面试验设计及实际试验结果

Table 3. Response surface test design and actual test results

编号 因素 浸出率 /% A B C 1 −1.000 −1.000 0.000 84.1 2 1.000 −1.000 0.000 85.5 3 −1.000 1.000 0.000 87.5 4 1.000 1.000 0.000 91.2 5 −1.000 0.000 −1.000 83.3 6 1.000 0.000 −1.000 84.2 7 −1.000 0.000 1.000 85.5 8 1.000 0.000 1.000 88.6 9 0.000 −1.000 −1.000 85.1 10 0.000 1.000 −1.000 87.5 11 0.000 −1.000 1.000 87 12 0.000 1.000 1.000 91.8 13 0.000 0.000 0.000 87.2 14 0.000 0.000 0.000 87.6 15 0.000 0.000 0.000 87.6 16 0.000 0.000 0.000 87.8 17 0.000 0.000 0.000 87.1 表 4 方差分析

Table 4. Variance analysis

来源 平方和 自由度 均方 F值 P值 显著性 Model 82.22 9 9.14 65.62 < 0.0001 显著 A-T 10.35 1 10.35 74.35 < 0.0001 B-t 33.21 1 33.21 238.56 < 0.0001 C-C 20.48 1 20.48 147.11 < 0.0001 AB 1.32 1 1.32 9.50 0.0191 AC 1.21 1 1.21 8.69 0.0226 BC 1.44 1 1.44 10.34 0.0149 A² 8.46 1 8.46 60.77 0.0001 B² 4.49 1 4.49 32.24 0.0008 C² 1.74 1 1.74 12.49 0.0096 残差 0.9745 7 0.1392 失拟项 0.6225 3 0.2075 2.36 0.2128 不显著 纯误差 0.3520 4 0.0880 综合 83.19 16 -

[1] Li Haoran, Feng Yali, Liang Jianglong, et al. Vanadium recovery from clay vanadium mineral using an acid leaching method[J]. Rare Metals, 2008,27(2):116. doi: 10.1016/S1001-0521(08)60098-4 [2] Zhao Jie, Zhang Yimin, Huang Jing, et al. Process of blank roasting-sulphuric acid leaching of vanadium with leaching agent from stone coal[J]. Chinese Journal of Rare Metals, 2013,37(3):447. (赵杰, 张一敏, 黄晶, 等. 石煤空白焙烧-加助浸剂酸浸提钒工艺研究[J]. 稀有金属, 2013,37(3):447. doi: 10.3969/j.issn.0258-7076.2013.03.018Zhao Jie, Zhang Yimin, Huang Jing, et al. Process of blank roasting-sulphuric acid leaching of vanadium with leaching agent from stone coal[J]. Chinese Journal of Rare Metals, 2013, 37(3): 447. doi: 10.3969/j.issn.0258-7076.2013.03.018 [3] Zhang Guoquan, Zhang Ting, an, Lü Zhiguo, et al. Extraction of vanadium from vanadium slag by high pressure oxidative acid leaching[J]. International Journal of Minerals, Metallurgy and Materials, 2015,22(1):21. doi: 10.1007/s12613-015-1038-6 [4] Dong Yuming, Zhu Guangjin, Pei Lili, et al. Removal of phosphorus from leaching solution of sodium roasted vanadium slag clinker[J]. Inorganic Chemicals Industry, 2019, 51(12): 75-79, 93.

Dong Yuming, Zhu Guangjin, Pei Lili, et al. Removal of phosphorus from leaching solution of sodium roasted vanadium slag clinker[J]. Inorganic Chemicals Industry, 2019,51(12):75−79,93. (董玉明, 朱光锦, 裴丽丽, 等. 钒渣钠化焙烧熟料浸出液除磷工艺研究[J]. 无机盐工业, 2019,51(12):75−79,93.Dong Yuming, Zhu Guangjin, Pei Lili, et al. Removal of phosphorus from leaching solution of sodium roasted vanadium slag clinker[J]. Inorganic Chemicals Industry, 2019, 51(12): 75-79, 93.[5] Fu Zibi, Jiang Lin, Li Ming, et al. Simultaneous extraction of vanadium and chromium from vanadium-chromium slag by sodium roasting[J]. Iron Steel Vanadium Titanium, 2020,41(4):1−6. (付自碧, 蒋霖, 李明, 等. 钒铬渣钠化焙烧同步提取钒和铬[J]. 钢铁钒钛, 2020,41(4):1−6.Fu Zibi, Jiang Lin, Li Ming, et al. Simultaneous extraction of vanadium and chromium from vanadium-chromium slag by sodium roasting[J]. Iron Steel Vanadium Titanium, 2020, 41(4): 1-6. [6] 王康. 钒渣钠化焙烧过程中钒原子环境演变规律及碳酸铵浸出提钒研究[D]. 重庆: 重庆大学, 2017.Wang Kang. Study on the atom atmosphere evolution law of vanadium during sodium roasting of vanadium slag and the ammonium carbonate leaching for vanadium extraction[D]. Chongqing : Chongqing University, 2017. [7] Lv Changxiao, Zhang Ting'an, Zhang Ying, et al. Comprehensive recovery of vanadium from calcification roasting-acid leaching tailings[J]. Chinese Journal of Rare Metals, 2020,44(11):1208−1214. (吕昌晓, 张廷安, 张莹, 等. 从钙化焙烧-酸浸尾渣中综合回收钒的研究[J]. 稀有金属, 2020,44(11):1208−1214. doi: 10.13373/j.cnki.cjrm.xy19020016Lü Changxiao, Zhang Ting'an, Zhang Ying, et al. Comprehensive recovery of vanadium from calcification roasting-acid leaching tailings[J]. Chinese Journal of Rare Metals, 2020, 44(11): 1208-1214. doi: 10.13373/j.cnki.cjrm.xy19020016 [8] Wang Xindong, Li Lanjie, Du Hao, et al. Industrialized application of high efficient extraction of vanadium and chromium by sub-molten salt method[J]. The Chinese Journal of Process Engineering, 2020,20(6):667−677. (王新东, 李兰杰, 杜浩, 等. 亚熔盐高效提钒铬清洁生产技术产业化应用[J]. 过程工程学报, 2020,20(6):667−677. doi: 10.12034/j.issn.1009-606X.219274Wang Xindong, Li Lanjie, Du Hao, et al. Industrialized application of high efficient extraction of vanadium and chromium by sub-molten salt method[J]. The Chinese Journal of Process Engineering, 2020, 20(6): 667-677. doi: 10.12034/j.issn.1009-606X.219274 [9] Wang Shaona, Lv Yeqing, Liu Biao, et al. Assessment for cleaner production of vanadium and chromium co-extraction from vanadium slag by sub-molten salt method[J]. The Chinese Journal of Nonferrous Metals, 2021,31(3):736−747. (王少娜, 吕页清, 刘彪, 等. 钒渣亚熔盐法钒铬共提工艺清洁生产评价[J]. 中国有色金属学报, 2021,31(3):736−747. doi: 10.11817/j.ysxb.1004.0609.2021-37747Wang Shaona, LÜ Yeqing, Liu Biao, et al. Assessment for cleaner production of vanadium and chromium co-extraction from vanadium slag by sub-molten salt method[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(3): 736-747. doi: 10.11817/j.ysxb.1004.0609.2021-37747 [10] Fan Helin, Chen Dengfu, Xu Song, et al. Research on leaching conditions of sodium roasted vanadium slag with high Ca/V ratio[J]. The Chinese Journal of Process Engineering, 2013,13(6):958−963. (范鹤林, 陈登福, 徐松, 等. 高钙钒比钒渣钠化焙烧熟料浸出条件研究[J]. 过程工程学报, 2013,13(6):958−963.Fan Helin, Chen Dengfu, Xu Song, et al. Research on leaching conditions of sodium roasted vanadium slag with high Ca/V ratio[J]. The Chinese Journal of Process Engineering, 2013, 13(6): 958-963 [11] 恩·阿·瓦托林. 钒渣的氧化[M]. 北京: 冶金工业出版社, 1982: 121.Vatolin B A. The oxidation of vanadium slag[M]. Beijing: Metallurgical Industry Press, 1982: 121. [12] 黄道鑫. 提钒炼钢[M]. 北京: 冶金工业出版社, 2000: 17-51, 57-58, 67.Huang Daoxin. Vanadium recovery and steelmaking[M]. Beijing: Metallurgical Industry Press, 2000: 17-51, 57-58, 67. [13] Chen Housheng. Study on extract vanadium pentoxide from roasted vanadium slag with lime[J]. Iron Steel Vanadium Titanium, 1992,13(6):1−9. (陈厚生. 钒渣石灰焙烧提取V2O5工艺研究[J]. 钢铁钒钛, 1992,13(6):1−9. doi: 10.7513/j.issn.1004-7638.1992.06.001Chen Housheng. Study on extract vanadium pentoxide from roasted vanadium slag with lime[J]. Iron Steel Vanadium Titanium, 1992, 13(6): 1-9. doi: 10.7513/j.issn.1004-7638.1992.06.001 [14] Fu Zibi. Experimental research on vanadium extraction by calcified roasting and acid leaching[J]. Iron Steel Vanadium Titanium, 2014,35(1):1−6. (付自碧. 钒渣钙化焙烧-酸浸提钒试验研究[J]. 钢铁钒钛, 2014,35(1):1−6. doi: 10.7513/j.issn.1004-7638.2014.01.001Fu Zibi. Experimental research on vanadium extraction by calcified roasting and acid leaching[J]. Iron Steel Vanadium Titanium, 2014, 35(1): 1-6. doi: 10.7513/j.issn.1004-7638.2014.01.001 [15] Fu Nianxin, Zhang Lin, Liu Wuhan, et al. Mechanism analysis of phase transformation process in calcified roasting of vanadium slags[J]. The Chinese Journal of Nonferrous Metals, 2018,28(2):377−386. (付念新, 张林, 刘武汉, 等. 钒渣钙化焙烧相变过程的机理分析[J]. 中国有色金属学报, 2018,28(2):377−386.Fu Nianxin, Zhang Lin, Liu Wuhan, et al. Mechanism analysis of phase transformation process in calcified roasting of vanadium slags[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(2): 377-386. [16] Fu Zibi. Technology research on clean vanadium-extracting from vanadium slag by blank roasting[J]. Iron Steel Vanadium Titanium, 2019,40(4):17−23. (付自碧. 钒渣空白焙烧清洁提钒工艺探讨[J]. 钢铁钒钛, 2019,40(4):17−23. doi: 10.7513/j.issn.1004-7638.2019.04.004Fu Zibi. Technology research on clean vanadium-extracting from vanadium slag by blank roasting[J]. Iron Steel Vanadium Titanium, 2019, 40(4): 17-23. doi: 10.7513/j.issn.1004-7638.2019.04.004 [17] Shi Zhixin, Liu Jinyan, Wang Chunmei, et al. Effect of roasting time on the phase of vanadium slag[J]. Iron Steel Vanadium Titanium, 2015,36(4):7−12,18. (史志新, 刘锦燕, 王春梅, 等. 焙烧时间对钒渣焙烧过程中物相影响的机理分析[J]. 钢铁钒钛, 2015,36(4):7−12,18. doi: 10.7513/j.issn.1004-7638.2015.04.002Shi Zhixin, Liu Jinyan, Wang Chunmei, et al. Effect of roasting time on the phase of vanadium slag[J]. Iron Steel Vanadium Titanium, 2015, 36(4): 7-12, 18. doi: 10.7513/j.issn.1004-7638.2015.04.002 [18] 付自碧. 高钙高磷钒渣制备氧化钒工艺研究[D]. 北京: 中国科学院大学(中国科学院过程工程研究所), 2017.Fu Zibi. Technological research preparation of them vanadium oxidefrom high calcium and high phosphorus vanadium slag[D]. Beijing: University of Chinese Academy of Sciences(Institute of Process Engineering, Chinese Academy of Sciences), 2017. [19] 刘钶. 离子液体催化纤维素制备5-HMF的分子设计及实验研究[D]. 天津: 河北工业大学, 2019.Liu Ke. Molecular design and experimental study on preparation of 5-HMF from cellulose catalyzed by ionic liquids[D]. Tianjin: Hebei University of Technology, 2019. [20] 杨其文. 钒铬渣中钒和铬的浸出行为研究[D]. 重庆: 重庆大学, 2017.Yang Qiwen. Study on the leaching behavior of vanadium and chromium from vanadium-chromium slag[D]. Chongqing: Chongqing University, 2017. [21] Ashvin J, Makadia J, Nanavati I. Optimisation of machining parameters for turning operations based on response surface methodology[J]. Measurement, 2013,46(4):1521−1529. doi: 10.1016/j.measurement.2012.11.026 [22] Liu Bingguo, Peng Jinhui, Wan Rundong, et al. Optimization of preparing V2O5 by calcination from ammonium metavanadate using response surface methodology[J]. Transactions of Nonferrous Metals Society of China, 2011,21(3):673−678. doi: 10.1016/S1003-6326(11)60764-4 [23] Nie Wenlin, Luo Bin, He Yanbing. Experiment study on optimization of sulfuric acid leaching of titanium from titanium-bearing electric furnace slag by response surface methodology[J]. Mining & Metallurgy, 2021,30(2):83−87. (聂文林, 罗斌, 何雁冰. 响应曲面法优化硫酸浸出钒钛磁铁矿高炉渣试验研究[J]. 矿冶, 2021,30(2):83−87. doi: 10.3969/j.issn.1005-7854.2021.02.013Nie Wenlin, Luobin, He Yanbing. Experiment study on optimization of sulfuric acid leaching of titanium from titanium-bearing electric furnace slag by response surface methodology[J]. Mining &Metallurgy, 2021, 30(2): 83-87. doi: 10.3969/j.issn.1005-7854.2021.02.013 [24] Zheng Zhaoqiang, Xia Hongying, Peng Jinhui, et al. Process optimization for the preparation of activate carbon from abandoned dregs of gallumt using response surface methodology[J]. Environmental Pollution & Control, 2013,35(3):5−9. (郑照强, 夏洪应, 彭金辉, 等. 响应曲面法优化废弃五倍子药渣制取活性炭的研究[J]. 环境污染与防治, 2013,35(3):5−9. doi: 10.3969/j.issn.1001-3865.2013.03.002Zheng Zhaoqiang, Xia Hongying, Peng Jinhui, et al. Process optimization for the preparation of activate carbon from abandoned dregs of gallumt using response surface methodology[J]. Environmental Pollution & Control, 2013, 35(3): 5-9. doi: 10.3969/j.issn.1001-3865.2013.03.002 -

下载:

下载: