Preparation of graphene-reinforced titanium matrix composites by vacuum hot pressing

-

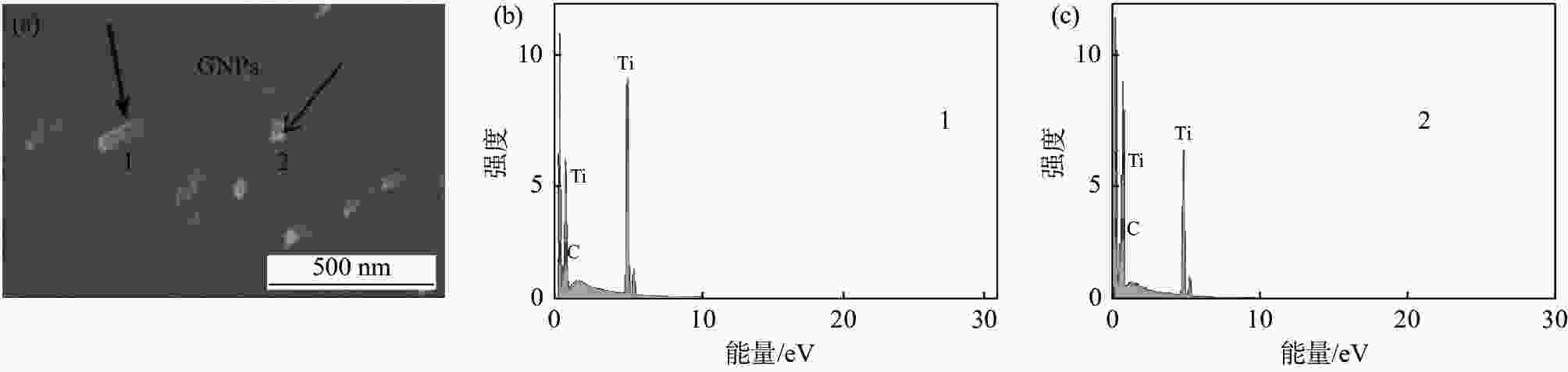

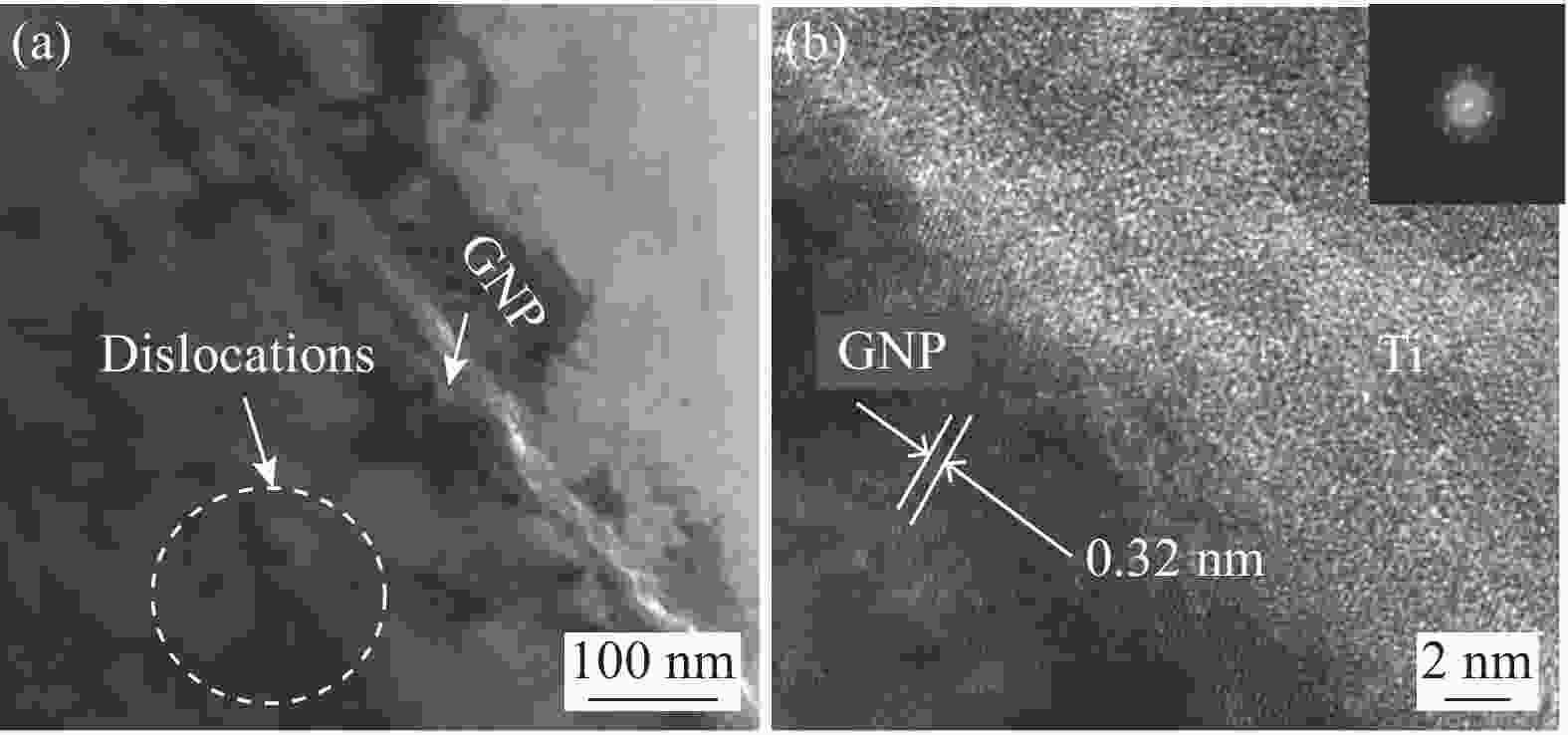

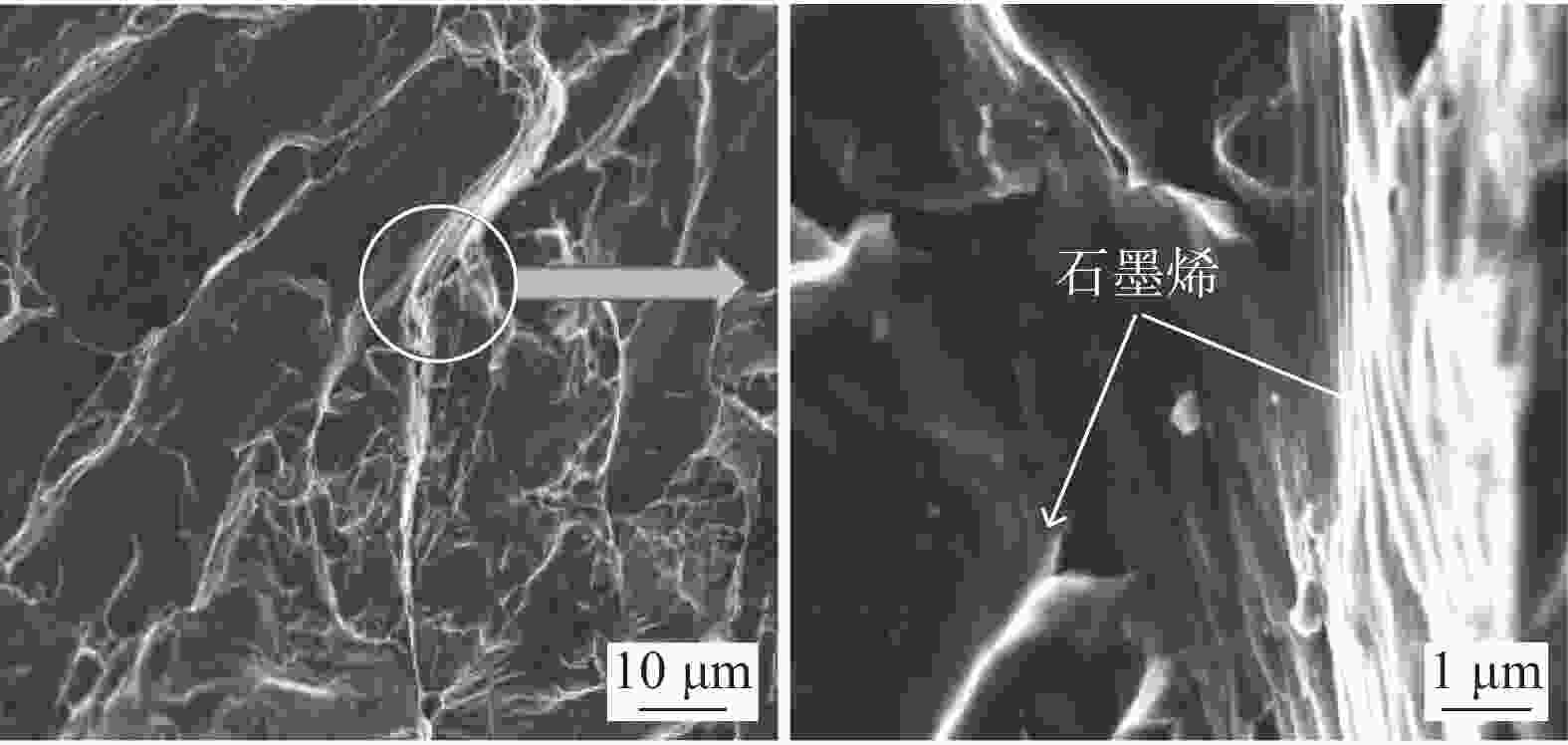

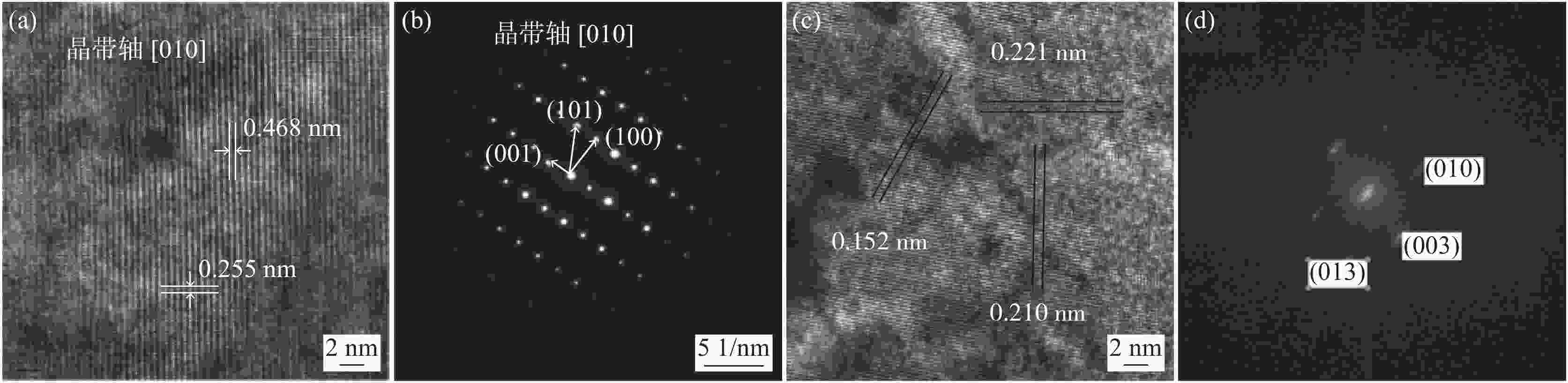

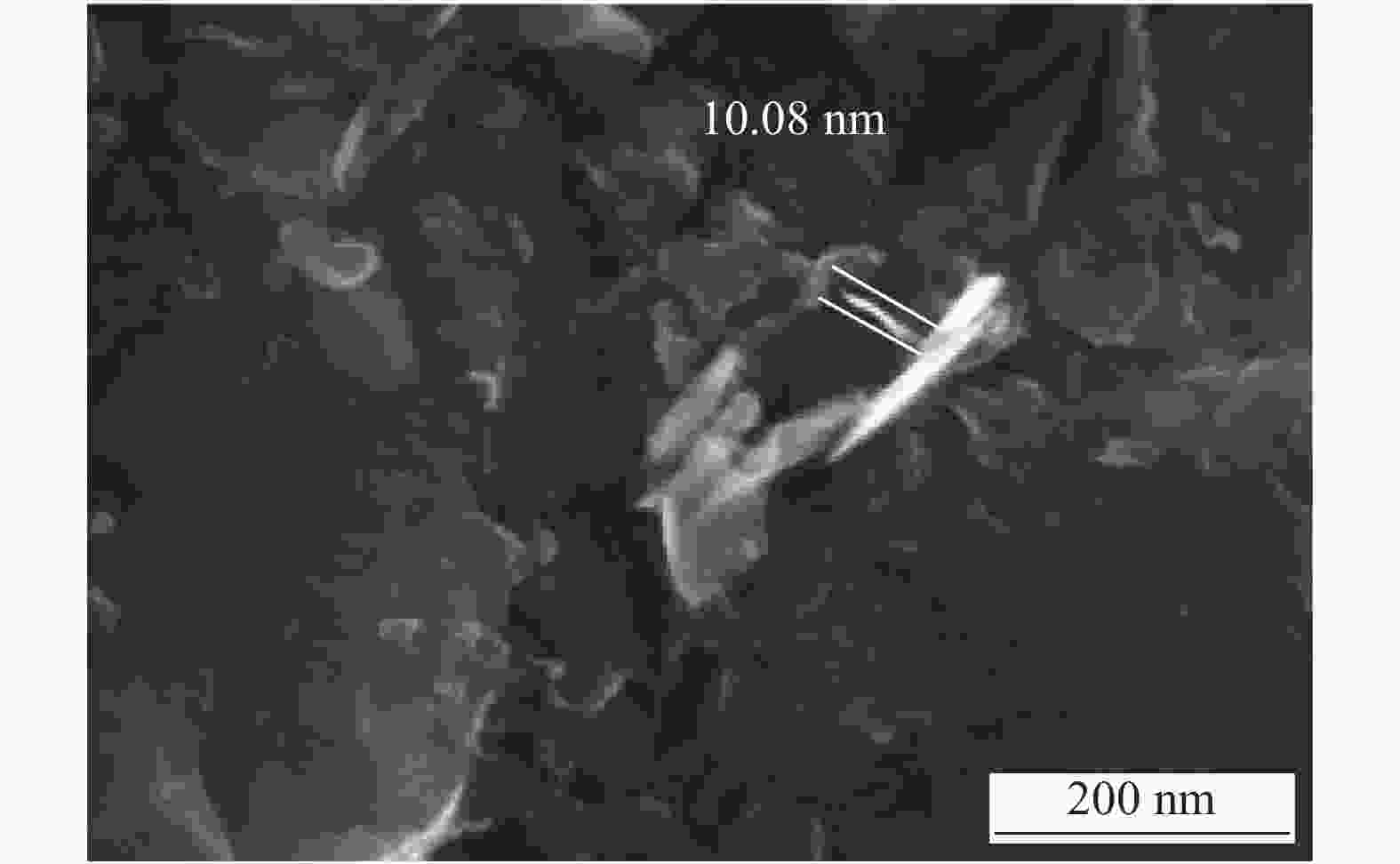

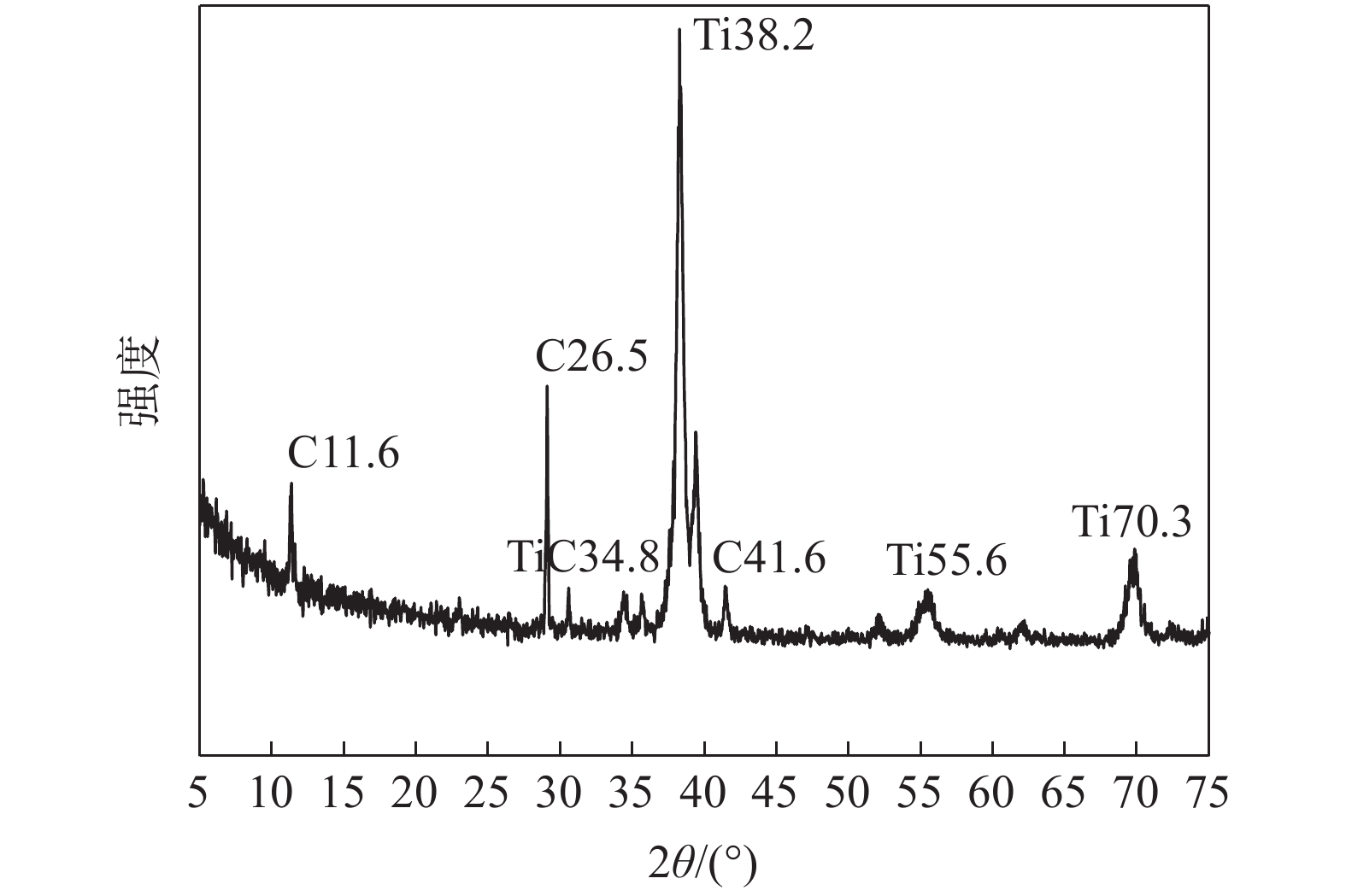

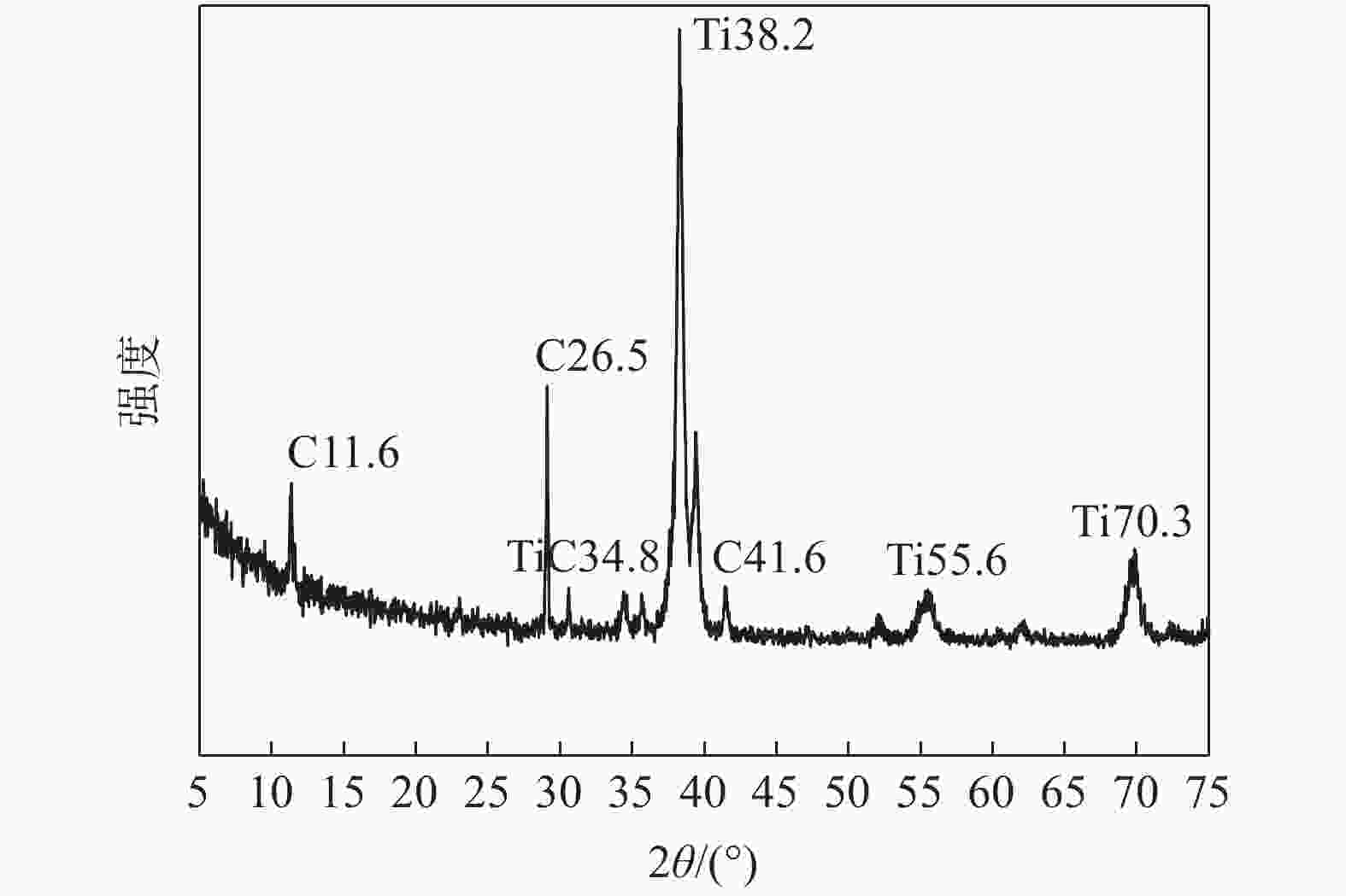

摘要: 采用葡萄糖和钛粉真空热压烧结原位合成了钛基体-石墨烯复合材料。复合材料界面结构稳定,界面处产生的石墨烯片层结构清晰,条纹间距约为 0.32 nm,与石墨层片理论间距 0.337 nm 相近。特别值得一提的是:在1300℃烧结条件下,复合材料屈服强度和延伸率跟相同条件制备的纯钛样品相比都在增加。其原因可能是原位合成的石墨烯和纳米颗粒TiC在钛基体内协调变形,为缓和复合材料的强塑性矛盾提供很好的解决思路。Abstract: In this paper, titanium matrix-graphene composites were successfully in-situ synthesized using glucose as carbon source. Graphene-reinforced pure titanium matrix composites were prepared in situ by vacuum hot-pressing sintering method using glucose solution and pure titanium powder as raw materials. The interfacial structure of the composite prepared by in-situ synthesis is stable, the structure of graphene lamellae at the interface is clear, and the spacing of striations is about 0.32 nm, which is close to the theoretical spacing of graphite lamellae of 0.337 nm. It can be concluded that the component is multilayer graphene. At 1 300 ℃, compared with pure titanium sintered under the same condition, the yield strength and elongation of the in situ synthesized composites increase, it provides a good way to solve the contradiction of strength and plasticity of composite materials.

-

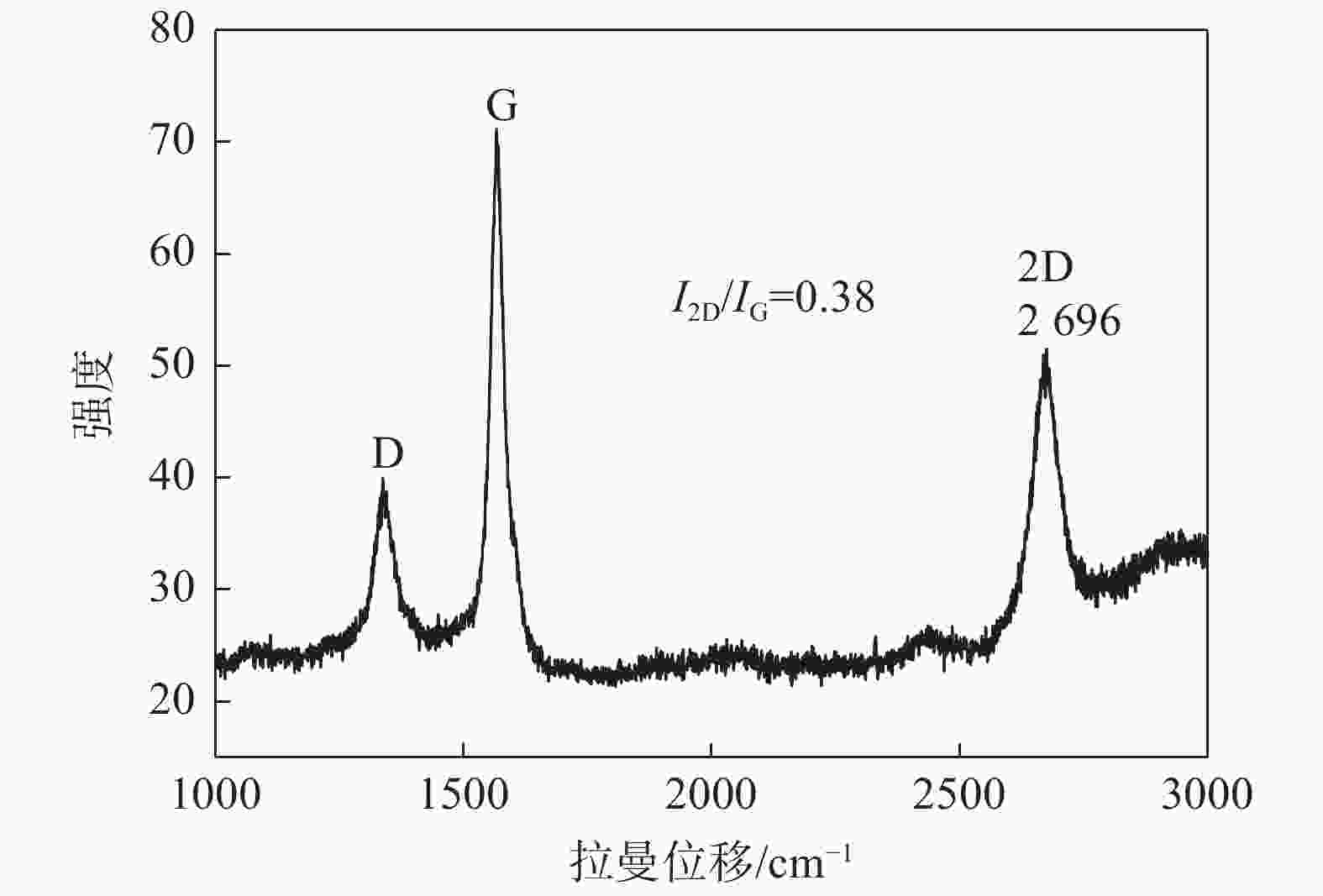

表 1 复合材料在不同烧结温度下的拉曼数据

Table 1. Raman data of composites at different sintering temperatures

烧结温度/℃ G峰值/cm−1 2D峰值/cm−1 ID/IG I2D/IG 1100 1584 2696 0.45 0.38 1200 1586 2719 0.51 0.78 1300 1589 2748 0.61 1.13 表 2 不同烧结温度复合材料的室温拉伸性能

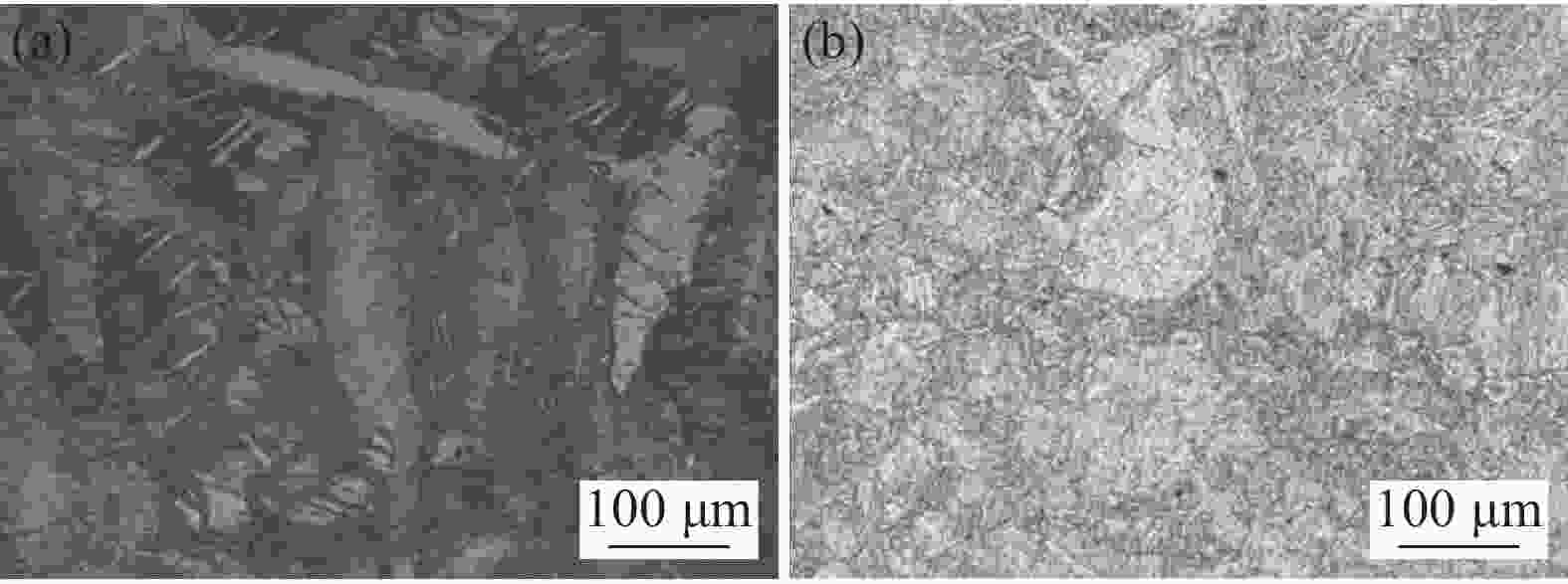

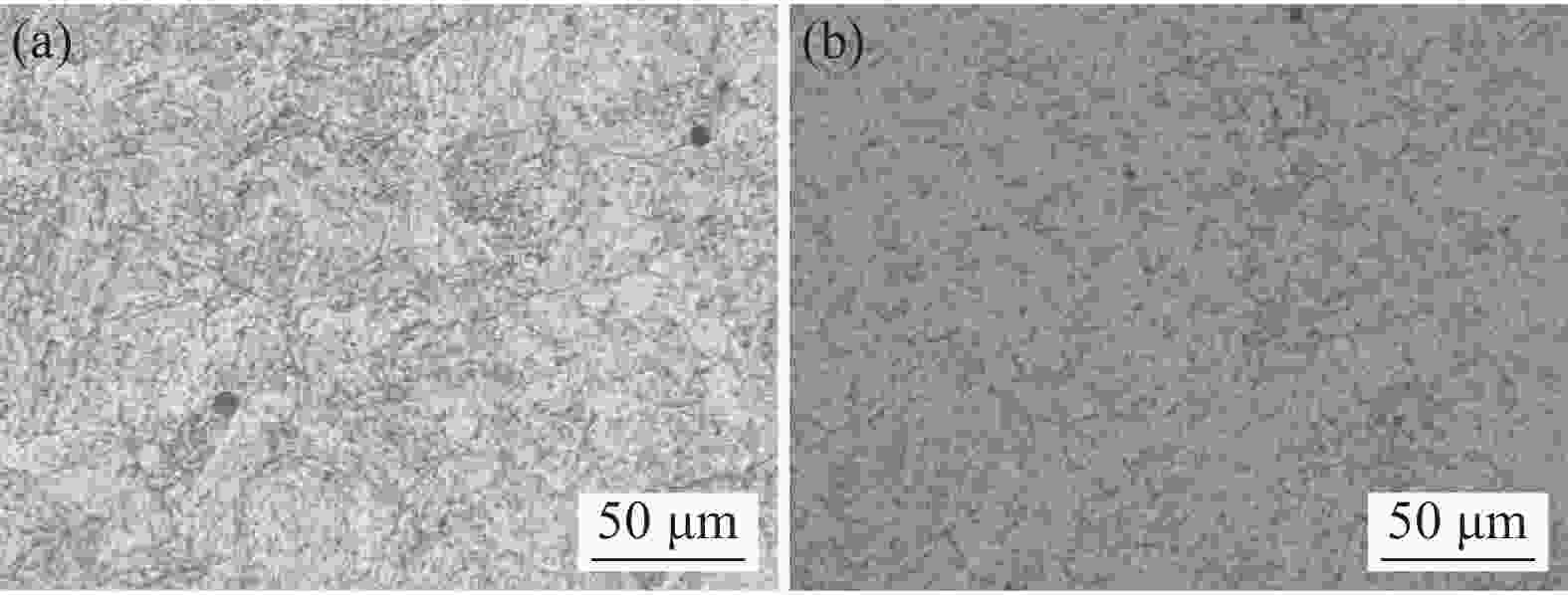

Table 2. Room-temperature tensile properties of composites with different sintering temperatures

烧结温度/°C 屈服强度/MPa 延伸率/% 纯钛 复合材料 纯钛 复合材料 1100 556.4 785.5 35.6 35.2 1200 547.5 688.3 38.2 36.8 1300 478.5 587.3 35.2 36.6 表 3 复合材料石墨烯边缘厚度统计

Table 3. Statistics of graphene edge thickness in composite material

尺寸/nm 片数/片 占比/% 2~4 12 30 5~9 20 50 15~18 8 20 -

[1] Fan X G, Zheng H J, Zhang Y, et al. Acceleration of globularization during interrupted compression of a two-phase titanium alloy[J]. Materials Science & Engineering A, 2018,720:214−224. [2] Narayana P L, Kim Seong-Woong, Hong Jae-Keun, et al. Tensile properties of a newly developed high-temperature titanium alloy at room temperature and 650 °C[J]. Materials Science & Engineering A, 2018,718:287−291. [3] Sun Y, Luo G, Zhang J, et al. Phase transition, microstructure and mechanical properties of TC4 titanium alloy prepared by plasma activated sintering[J]. Journal of Alloys and Compounds, 2018,741:918−926. doi: 10.1016/j.jallcom.2018.01.197 [4] Kim Young-Jig, Yadav Poonam, Hahn Junhee, et al. Oxidation of titanium matrix composites reinforced with (TiB+TiC) particulates[J]. Metals and Materials International, 2019,29(3):627−632. [5] 周鹏. 粉末冶金多元增强钛基复合材料的制备、微观结构及力学性能[D]. 上海: 上海交通大学: 2009.Zhou Peng. Preparation, microstructure and mechanical properties of powder metallurgy multicomponent reinforced titanium matrix composites[D]. Shanghai: Shanghai Jiaotong University: 2009. [6] Yu Lanlan, Mao Xiaonan, Zhao Yongqing, et al. New progress in research on particle-reinforced titanium matrix composites[J]. Progress in Chinese Materials, 2006,25(4):1−4. (于兰兰, 毛小南, 赵永庆, 等. 颗粒增强钛基复合材料研究新进展[J]. 中国材料进展, 2006,25(4):1−4. doi: 10.3969/j.issn.1674-3962.2006.04.001Yu Lanlan, Mao Xiaonan, Zhao Yongqing, et al. New progress in research on particle-reinforced titanium matrix composites[J]. Progress in Chinese Materials, 2006, 25(4): 1-4 doi: 10.3969/j.issn.1674-3962.2006.04.001 [7] Morsi K. Review: titanium–titanium boride composites[J]. Journal of Materials Science(A), 2019,54(9):6753−6771. doi: 10.1007/s10853-018-03283-w [8] Jian L, Mingxia W, Yi Y, et al. Preparation and mechanical performance of graphene platelet reinforced titanium nanocomposites for high temperature applications[J]. Journal of Alloys and Compounds, 2018,765(10):1111−1118. [9] Li S, Sun B, Imai H, et al. Powder metallurgy titanium metal matrix composites reinforced with carbon nanotubes and graphite[J]. Composites Part A:Applied Science & Manufacturing, 2013,48(1):57−66. [10] 雷红. 钛基体上碳纳米管的原位合成及其复合材料的制备与性能研究[D]. 天津: 天津大学, 2014.Lei Hong. In situ synthesis of carbon nanotubes on titanium substrates and the preparation and properties of their composites[D]. Tianjin: Tianjin University, 2014. [11] 巩文斌. 碳/金属复合纳米结构性质调控及其能量转化的理论研究[D]. 北京: 中国科学院大学, 2014.Gong Wenbin. Theoretical study on the property regulation and energy conversion of carbon/metal composite nanostructures[D]. Beijing: University of Chinese Academy of Sciences, 2014. [12] Kerker G P. Non-singular atomic pseudopotentials for solid-state applications[J]. Journal of Physics C, 1980,(13):189−194. [13] Yu Hailing, Zhu Jiaqi, Cao Wenxin, et al. Research progress in the preparation of graphene by metal catalysis[J]. Acta Physica Sinica, 2013,62(2):10−19. (于海玲, 朱嘉琦, 曹文鑫, 等. 金属催化制备石墨烯的研究进展[J]. 物理学报, 2013,62(2):10−19.Yu Hailing, Zhu Jiaqi, Cao Wenxin, et al. Research progress in the preparation of graphene by metal catalysis[J]. Acta Physica Sinica, 2013, 62(2): 10-19 [14] Shelton M C, Cotterill I C, Novak S T A, et al. 2-Keto-3-deoxy-6-phosphogluconate aldolases as catalysts for stereocontrolled carbon-carbon bond formation[J]. Journal of the American Chemical Society, 1996,118(9):2117−2125. doi: 10.1021/ja952596+ [15] 戚正风. 固态金属中的扩散与相变[M]. 北京: 机械工业出版社, 1998.Qi Zhengfeng. Diffusion and phase transition in solid metals[M]. Beijing: Machinery Industry Press, 1998. [16] 颜莹. 固体材料界面基础[M]. 沈阳: 东北大学出版社, 2008.Yan Ying. The interface basis of solid materials[M]. Shengyang: Northeastern University Press, 2008. [17] Giovannetti G, Khomyakov P A, Brocks G, et al. Substrate-induced bandgap in graphene on hexagonal boron nitride[J]. Physical Review B, 2007,76(7):3009−3014. -

下载:

下载: