Effect of volumetric energy density on surface roughness and density of selective laser melted titanium alloy

-

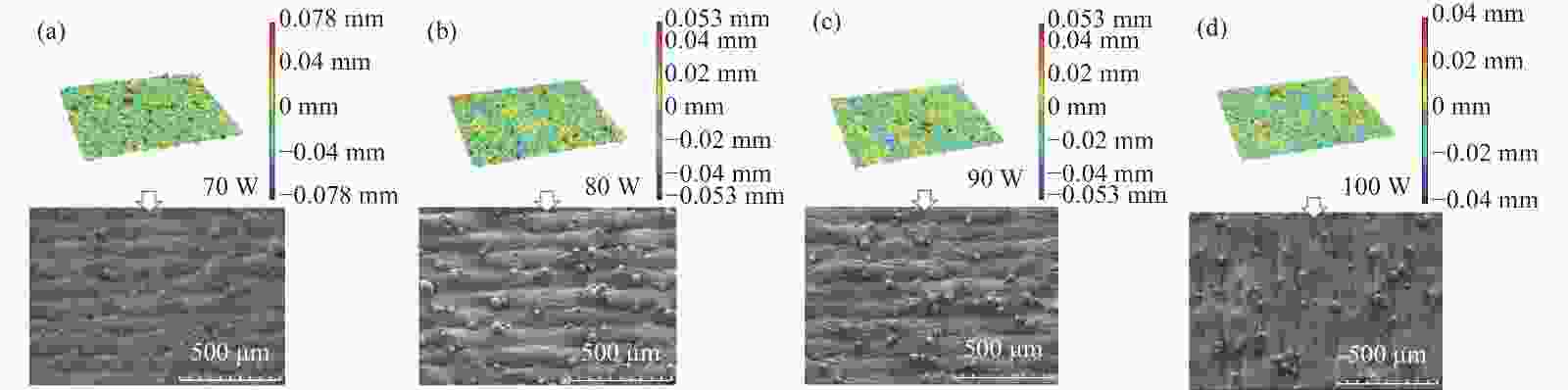

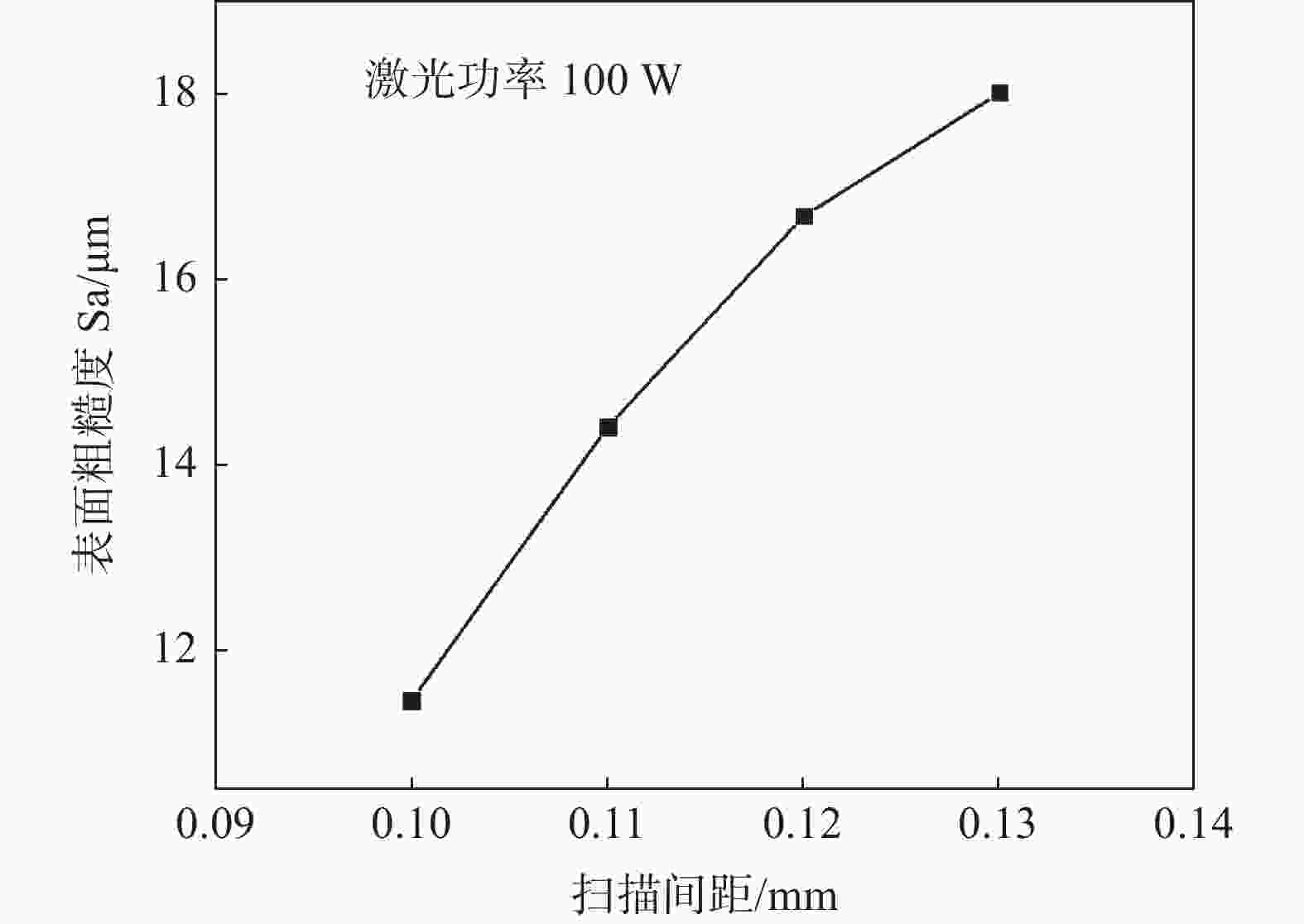

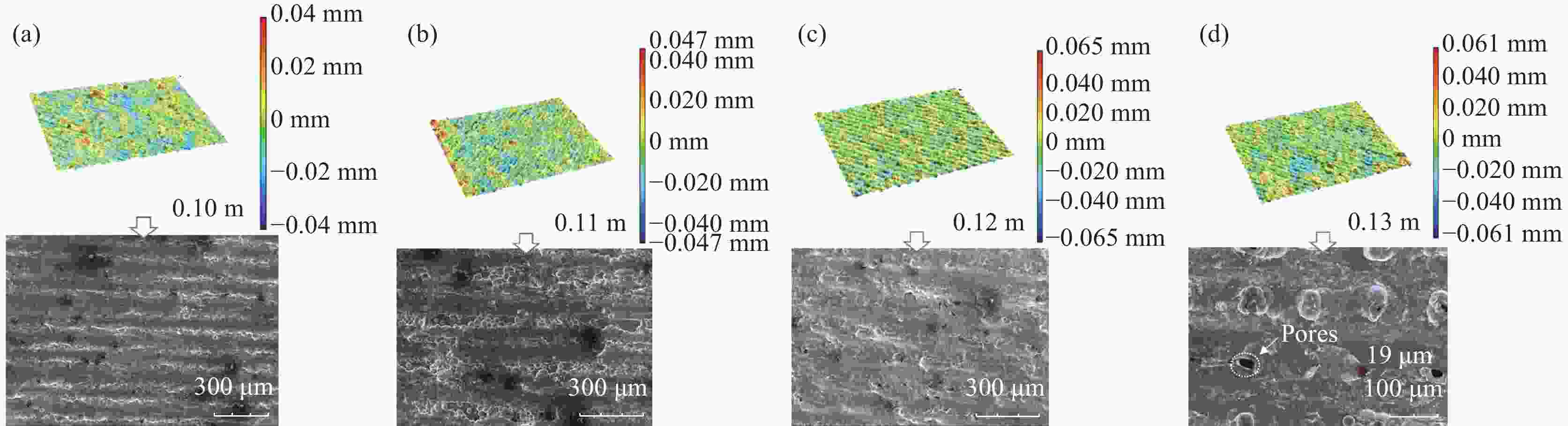

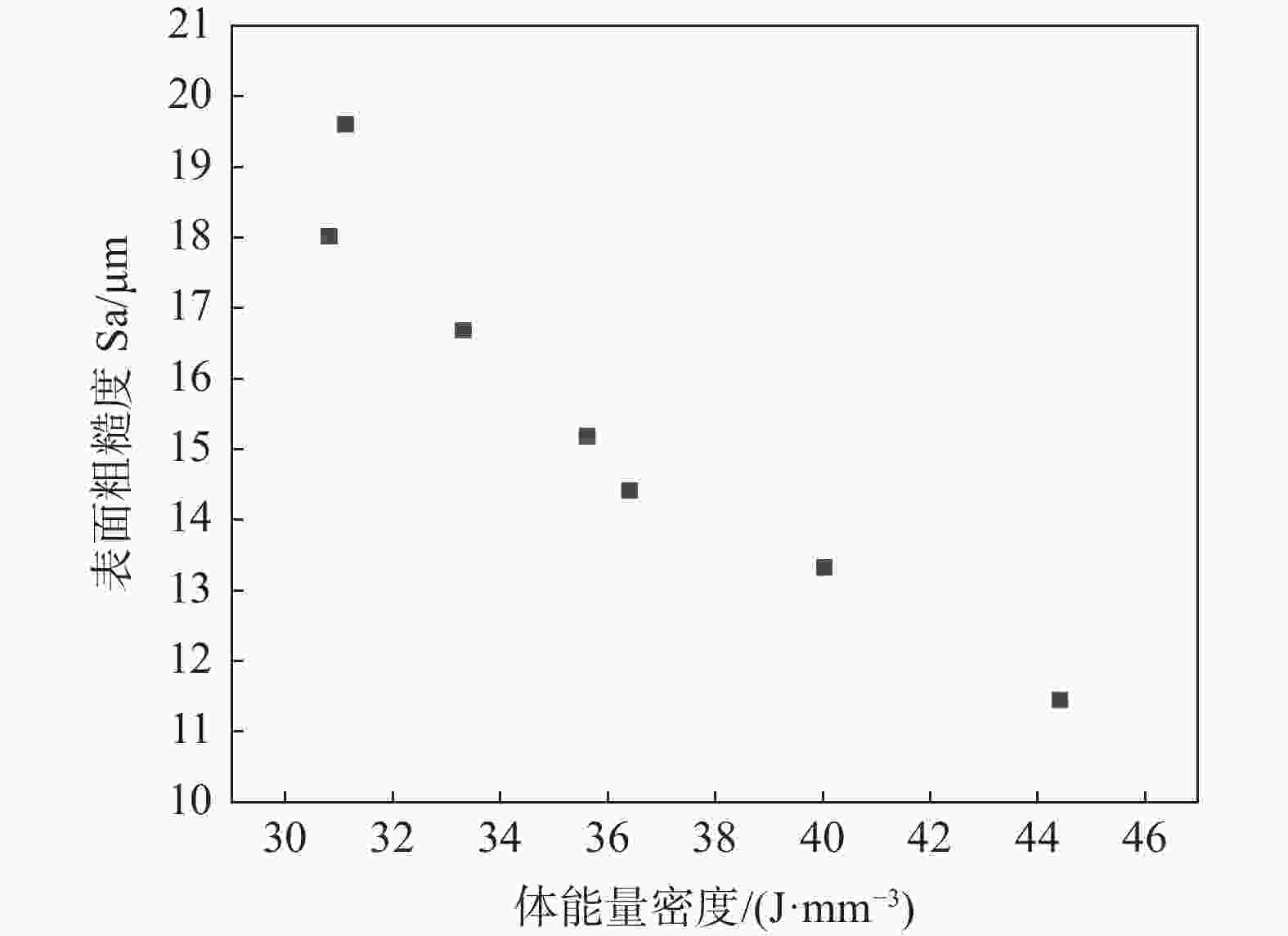

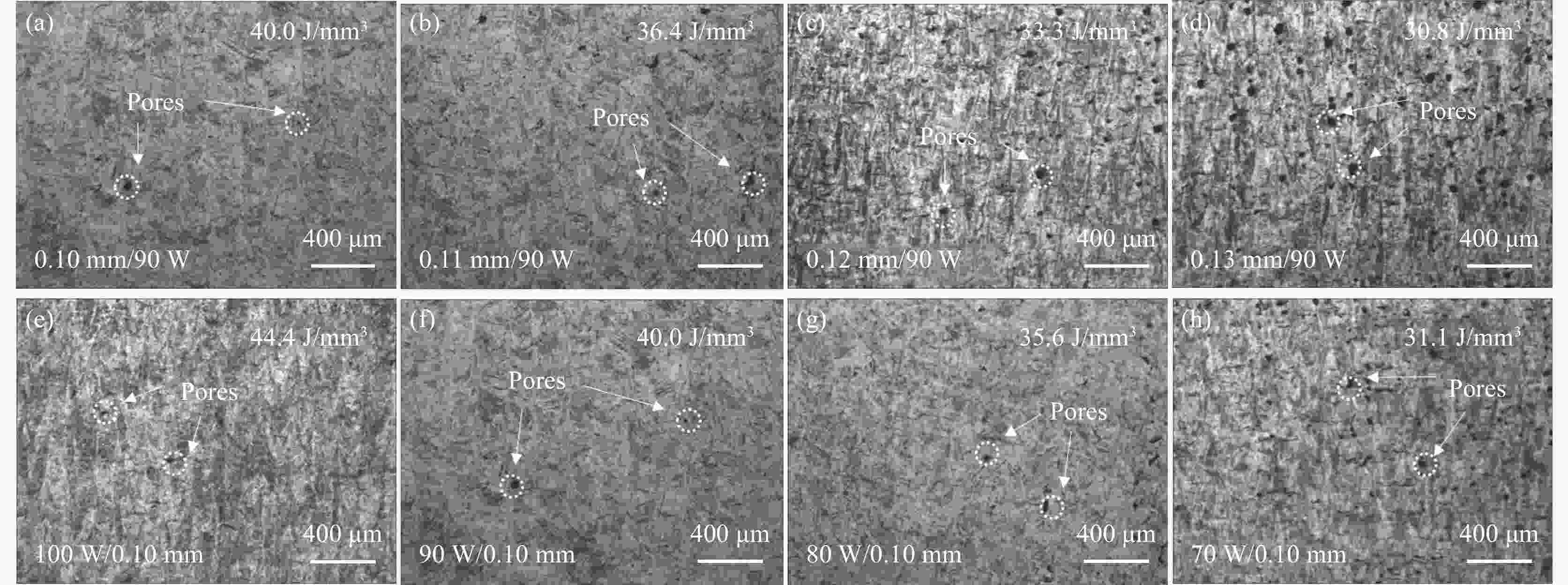

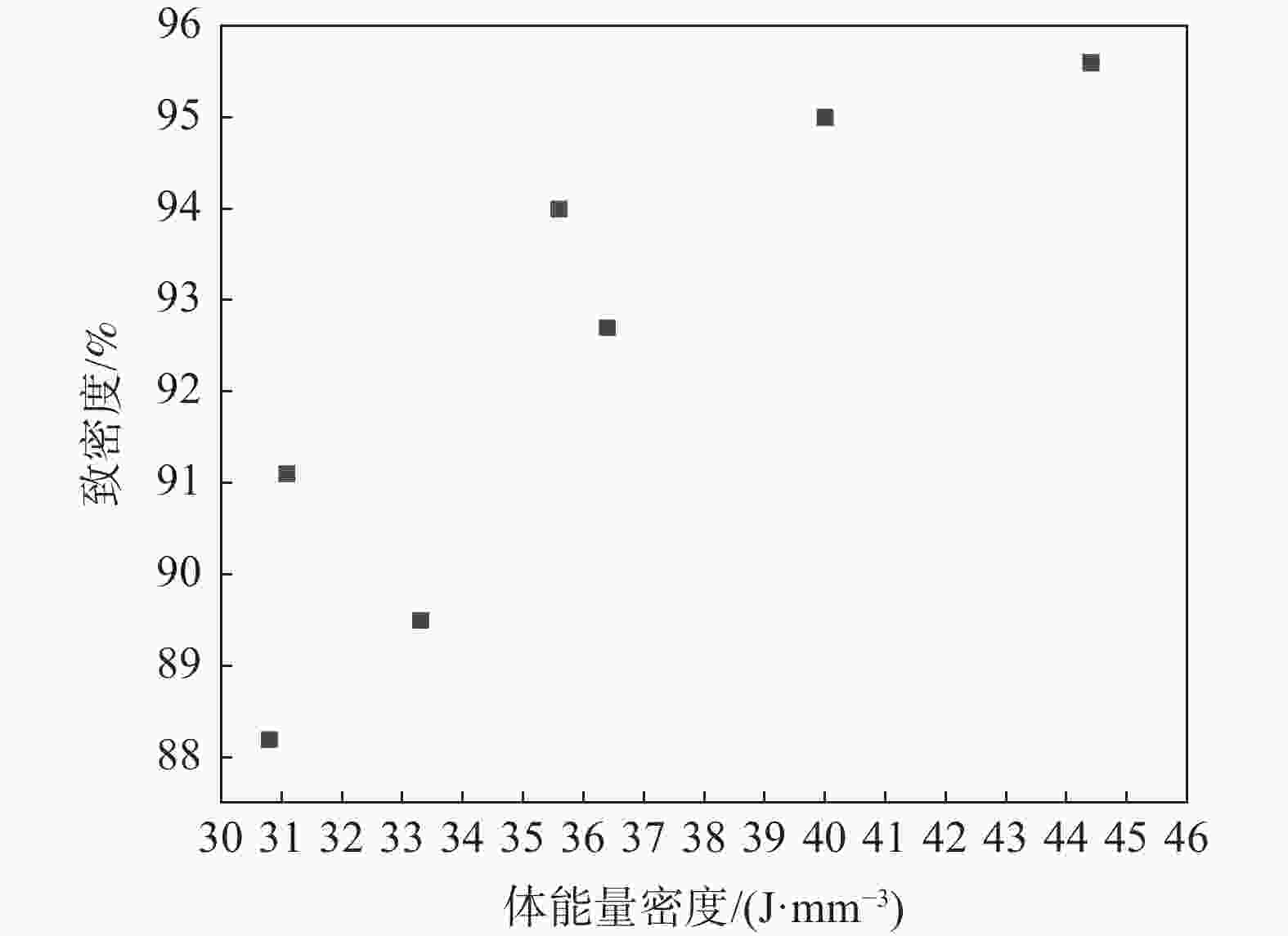

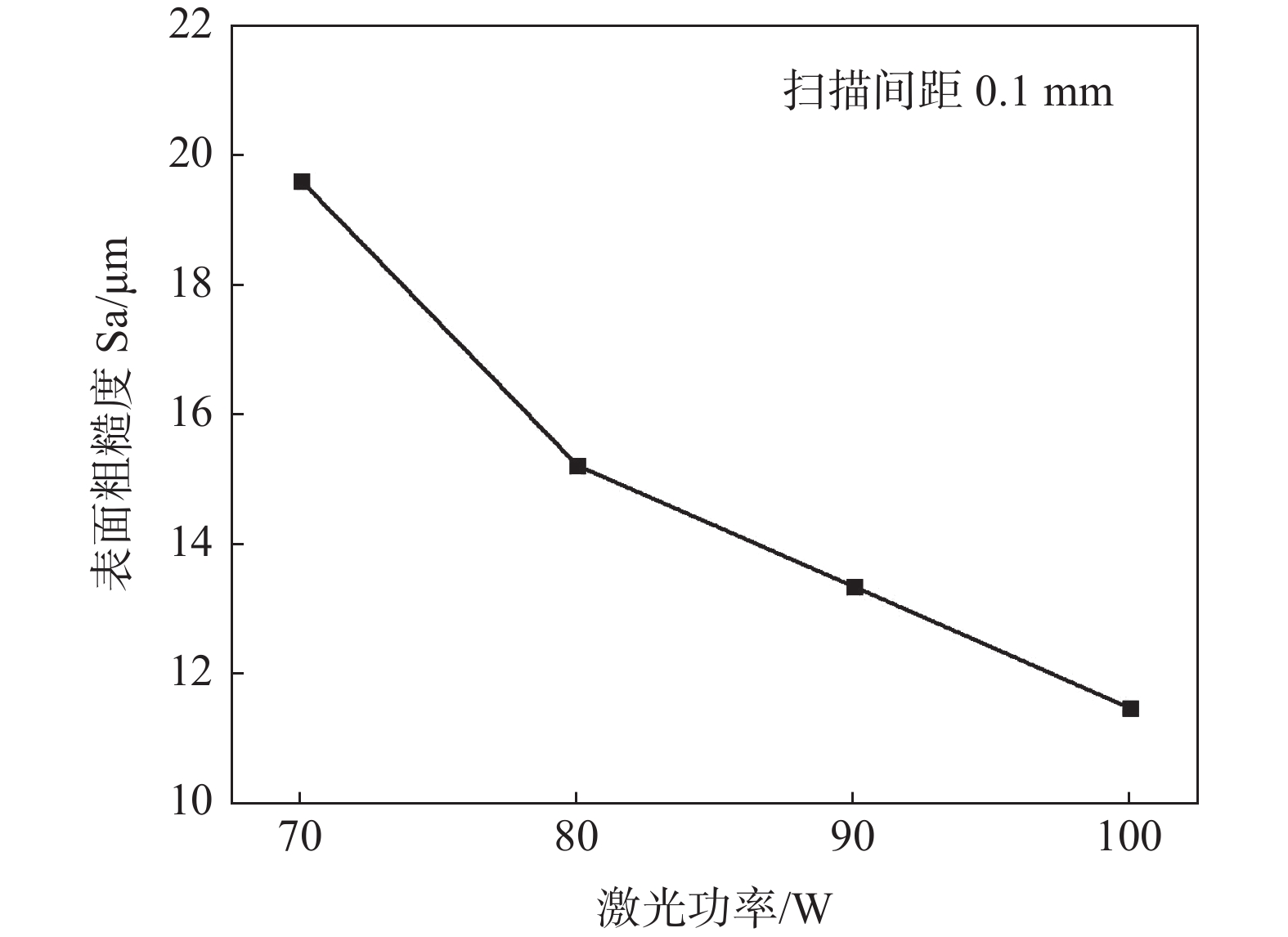

摘要: 分别对选区激光熔化的激光功率、扫描间距进行了研究,引入了激光体能量密度,综合分析了工艺参数对钛合金致密度及表面粗糙度的影响。试验结果表明:随着体能量密度的增大,所加工出的金属样的表面粗糙度呈减小趋势。而通过调节激光功率使体能量密度增大的方式更有利于加工出更高致密度的金属零件。Abstract: In this paper, the laser power and scanning distance of selective laser melting were studied respectively, and the influence of process parameter on density and surface roughness of titanium alloy was comprehensively analyzed by introducing volumetric laser energy density. The experimental results show that the surface roughness of machined metal samples decreases with the increase of volumetric energy density via tuning laser power.

-

Key words:

- titanium alloy /

- selective laser melting /

- energy density /

- surface roughness /

- density

-

表 1 工艺参数设计方案

Table 1. Selected technical parameters

编号 激光功率/W 扫描速度/(mm·s−1) 扫描间距/mm 铺粉厚度/mm 体能量密度VED/(J·mm−3) 1 70 900 0.1 0.025 31.1 2 80 900 0.1 0.025 35.6 3 90 900 0.1 0.025 40.0 4 100 900 0.1 0.025 44.4 5 90 900 0.11 0.025 36.4 6 90 900 0.12 0.025 33.3 7 90 900 0.13 0.025 30.8 -

[1] 杨永强, 王迪. 激光选区熔化3D打印技术[M].武汉: 华中科技大学出版社, 2019.Yang Yongqiang, Wang Di. Laser selective melting 3D printing technology [M]. Wuhan: Huazhong University of Science and Technology Press, 2019. [2] Han Guoliang, Shi Wentian, Han Yufan, et al. Research on surface forming quality of selective laser melting TC4 titanium alloy based on single channel test[J]. Journal of Laser, 2021,42(3):163−169. (韩国梁, 石文天, 韩玉凡, 等. 基于单熔道试验的选区激光熔化成形TC4钛合金表面成形质量研究[J]. 激光杂志, 2021,42(3):163−169. doi: 10.14016/j.cnki.jgzz.2021.03.163Han Guoliang, Shi Wentian, Han Yufan, et al. Research on Surface Forming Quality of Selective Laser Melting TC4 Titanium Alloy Based on Single Channel Test [J]. Journal of Laser, 2021, 42(03): 163-169 . doi: 10.14016/j.cnki.jgzz.2021.03.163 [3] An Chao, Zhang Yuanming, Zhang Jinsong. Influence of selected laser melting parameters on density and surface roughness of cobalt-chromium alloy materials[J]. Applied Laser, 2018,38(3):328−333. (安超, 张远明, 张金松. 选区激光熔化工艺参数对钴铬合金材料成型件致密度与表面粗糙度的影响规律研究[J]. 应用激光, 2018,38(3):328−333.An Chao, ZHANG Yuanming, ZHANG Jinsong. Influence of Selected Laser Melting Parameters on Density and Surface Roughness of Cobalt-Chromium Alloy Materials [J]. Applied laser, 2018, 38(03): 328-333 [4] Pan Lu, Liu Qihui, Wang Liang, et al. Effect of linear energy density on fabrication of 316L stainless steel by selective laser melting[J]. Journal of Applied Laser, 2019,39(1):21−27. (潘露, 刘麒慧, 王亮, 等. 线能量密度对选区激光熔化制备316L不锈钢缺陷的影响[J]. 应用激光, 2019,39(1):21−27.Pan Lu, Liu Qihui, Wang Liang, et al. Effect of linear energy density on fabrication of 316 L stainless steel by selective laser melting [J]. Journal of applied laser, 2019, 39(01): 21-27 [5] Lan Fang, Liang Yanjuan, Huang Binbin. Research on quality of selective laser melting forming[J]. Equipment Manufacturing Technology, 2018,281(5):162−164,172. (兰芳, 梁艳娟, 黄斌斌. 选区激光熔化成形质量研究[J]. 装备制造技术, 2018,281(5):162−164,172. doi: 10.3969/j.issn.1672-545X.2018.05.045LAN Fang, Liang Yanjuan, Huang Binbin. Research on quality of selective laser melting forming [J]. Equipment manufacturing technology, 2018, 281(05): 162-164+172 doi: 10.3969/j.issn.1672-545X.2018.05.045 [6] Liu Ruicheng, Yang Yongqiang, Wang Di. Study on surface roughness of selective laser melting forming metal parts[J]. Laser Technology, 2013,37(4):425−430. (刘睿诚, 杨永强, 王迪. 选区激光熔化成型金属零件上表面粗糙度的研究[J]. 激光技术, 2013,37(4):425−430.Liu Ruicheng, Yang Yongqiang, Wang Di. Study on Surface Roughness of Selective Laser Melting Forming Metal Parts [J]. Laser technology, 2013, 37(04): 425-430 [7] Lv Jinjian, Jia Changzhi, Yang Jianchun. Effect of laser energy density on quality of selective laser melting[J]. Hot Working Technology, 2018,47(20):156−159. (吕金建, 贾长治, 杨建春. 激光能量密度对选区激光熔化成型质量的影响[J]. 热加工工艺, 2018,47(20):156−159. doi: 10.14158/j.cnki.1001-3814.2018.20.039Lu Jinjian, Jia Changzhi, Yang Jianchun. Effect of laser energy density on quality of selective laser melting [J]. Hot working technology, 2018, 047(020): 156-159. doi: 10.14158/j.cnki.1001-3814.2018.20.039 -

下载:

下载: