| [1] |

王兰. 过渡金属基水分解电催化剂的同步辐射研究[D]. 合肥: 中国科学技术大学, 2021.Wang Lan. Synchrotron radiation study on the transition metal bsed electrocatalyst for water decomposition[D]. Hefei: University of Science and Technology of China, 2021.

|

| [2] |

Zong Yuhao, Huang Li, Chang Zhengfeng, et al. Effect of Zn on the performance of industrial V-Mo/Ti denitration catalyst[J]. Iron Vanadium Titanium Steel, 2020,41(6):30−34. (纵宇浩, 黄力, 常峥峰, 等. Zn对工业V-Mo/Ti脱硝催化剂性能的影响[J]. 钢铁钒钛, 2020,41(6):30−34. doi: 10.7513/j.issn.1004-7638.2020.06.007Zong Yuhao, Huang Li, Chang Zhengfeng, et al. Effect of Zn on the performance of industrial V-Mo/Ti denitration catalyst[J]. Iron Vanadium Titanium Steel, 2020, 41(6): 30-34. doi: 10.7513/j.issn.1004-7638.2020.06.007

|

| [3] |

Li Rong, Jia Yuefa, Zhen Qiang, et al. Preparation and photocatalytic properties of photocatalytic Fe2O3/TiO2 ceramics[J]. Iron Steel Vanadium Titanium, 2015,36(1):26−31. (李榕, 贾悦发, 甄强, 等. 光催化功能Fe2O3/TiO2陶瓷的制备及其光降解特性[J]. 钢铁钒钛, 2015,36(1):26−31.Li Rong, Jia Yuefa, Zhen Qiang, et al. Preparation and photocatalytic properties of photocatalytic Fe2O3/TiO2 ceramics[J]. Iron Steel Vanadium Titanium, 2015, 36(1): 26-31.

|

| [4] |

Xia Geyao, Chen Nan, Hu Weiwu, et al. Magnetic Fe3O4/Ag3PO4 composite photocatalyst catalytic degradation of malachite green in dye wastewater[J]. Environmental Engineering Journal, 2015,9(8):3821−3827. (夏阁遥, 陈男, 胡伟武, 等. 磁性Fe3O4/Ag3PO4复合光催化剂催化降解染料废水中的孔雀石绿[J]. 环境工程学报, 2015,9(8):3821−3827. doi: 10.12030/j.cjee.20150838Xia Geyao, Chen Nan, Hu Weiwu, et al. Magnetic Fe3O4/Ag3PO4 composite photocatalyst catalytic degradation of malachite green in dye wastewater[J]. Environmental Engineering Journal, 2015, 9(8): 3821-3827. doi: 10.12030/j.cjee.20150838

|

| [5] |

Li Yi, Wan Yuan, Li Yanping, et al. Low-temperature selective catalytic reduction of NO with NH3 over Mn2O3-doped Fe2O3 hexagonal microsheets[J]. ACS Applied Materials & Interfaces, 2016,8(8):5224−5233.

|

| [6] |

Wang Peng, Sun Hong, Quan Xie, et al. Enhanced catalytic activity over MIL-100(Fe) loaded ceria catalysts for the selective catalytic reduction of NOx with NH3 at low temperature[J]. Journal of Hazardous Materials, 2016,301(15):512−521.

|

| [7] |

Yang Ying. Preparation of graphene-iron doped TiO2 composite and its photocatalytic performance[J]. Iron Steel Vanadium Titanium, 2019,40(6):12−17. (杨颖. 石墨烯—铁掺杂二氧化钛复合物制备及其光催化性能[J]. 钢铁钒钛, 2019,40(6):12−17.Yang Ying. Preparation of graphene-iron doped TiO2 composite and its photocatalytic performance[J]. Iron Steel Vanadium Titanium, 2019, 40(6): 12-17.

|

| [8] |

Hou Ruijun, Qiu Rui, Sun Kening. Advances in catalysts for methanol synthesis from Cu-based CO2[J]. Chemical Progress, 2020,39(7):2639−2647. (侯瑞君, 邱瑞, 孙克宁. Cu基CO2合成甲醇催化剂载体的研究进展[J]. 化工进展, 2020,39(7):2639−2647.Hou Ruijun, Qiu Rui, Sun Kening. Advances in catalysts for methanol synthesis from Cu-based CO2[J]. Chemical Progress, 2020, 39(7): 2639-2647.

|

| [9] |

Bi Xuegong, Liao Jiyong, Xiong Wei, et al. Experimental study on SO2 and NOx removal during sintering[J]. Journal of Wuhan University of Science and Technology ( Natural Science Edition ), 2008,31(5):449−452. (毕学工, 廖继勇, 熊玮, 等. 烧结过程中脱除SO2和NOx的试验研究[J]. 武汉科技大学学报(自然科学版), 2008,31(5):449−452.Bi Xuegong, Liao Jiyong, Xiong Wei, et al. Experimental study on SO2 and NOx removal during sintering [J]. Journal of Wuhan University of Science and Technology ( Natural Science Edition ), 2008, 31(5): 449-452.

|

| [10] |

Liu Shihu, Zhou Maojun. Overview of flue gas circulation sintering process and its application in baosteel[J]. Baosteel Technology, 2018,(6):37−44. (刘仕虎, 周茂军. 烟气循环烧结工艺综述及其在宝钢应用的探讨[J]. 宝钢技术, 2018,(6):37−44. doi: 10.3969/j.issn.1008-0716.2018.06.008Liu Shihu, Zhou Maojun. Overview of flue gas circulation sintering process and its application in baosteel[J]. Baosteel Technology, 2018(6): 37-44. doi: 10.3969/j.issn.1008-0716.2018.06.008

|

| [11] |

Wan Junying, Chen Tiejun, Zhou Xianlin, et al. Experimental study on catalytic reduction of NO by sinter[J]. Journal of Iron and Steel Research, 2019,31(4):354−360. (万军营, 陈铁军, 周仙霖, 等. 烧结矿催化还原NO的实验研究[J]. 钢铁研究学报, 2019,31(4):354−360. doi: 10.13228/j.boyuan.issn1001-0963.20180202Wan Junying, Chen Tiejun, Zhou Xianlin, et al. Experimental study on catalytic reduction of NO by sinter[J]. Journal of Iron and Steel Research, 2019, 31(4): 354-360. doi: 10.13228/j.boyuan.issn1001-0963.20180202

|

| [12] |

Hans Bodo Luengen, Michael Peters, Peter Schmoele. Iron making in western europe[C]//Proceedings of 3rd CSM-VDEh Metallurgical Seminar. Beijing: The Chinese Society for Metals Steel Institute VDEh, 2011: 18.

|

| [13] |

Zou Ming, Guan Kejing, Wang Cejun. The significance of limiting the volatile content of sintering fuel for pollution reduction[J]. Zhejiang Metallurgy, 2015,(3):6−8. (邹明, 关克静, 王策军. 论限定烧结燃料挥发分含量对污染减排的重要意义[J]. 浙江冶金, 2015,(3):6−8.Zou Ming, Guan Kejing, Wang Cejun. The significance of limiting the volatile content of sintering fuel for pollution reduction[J]. Zhejiang Metallurgy , 2015(3): 6-8.

|

| [14] |

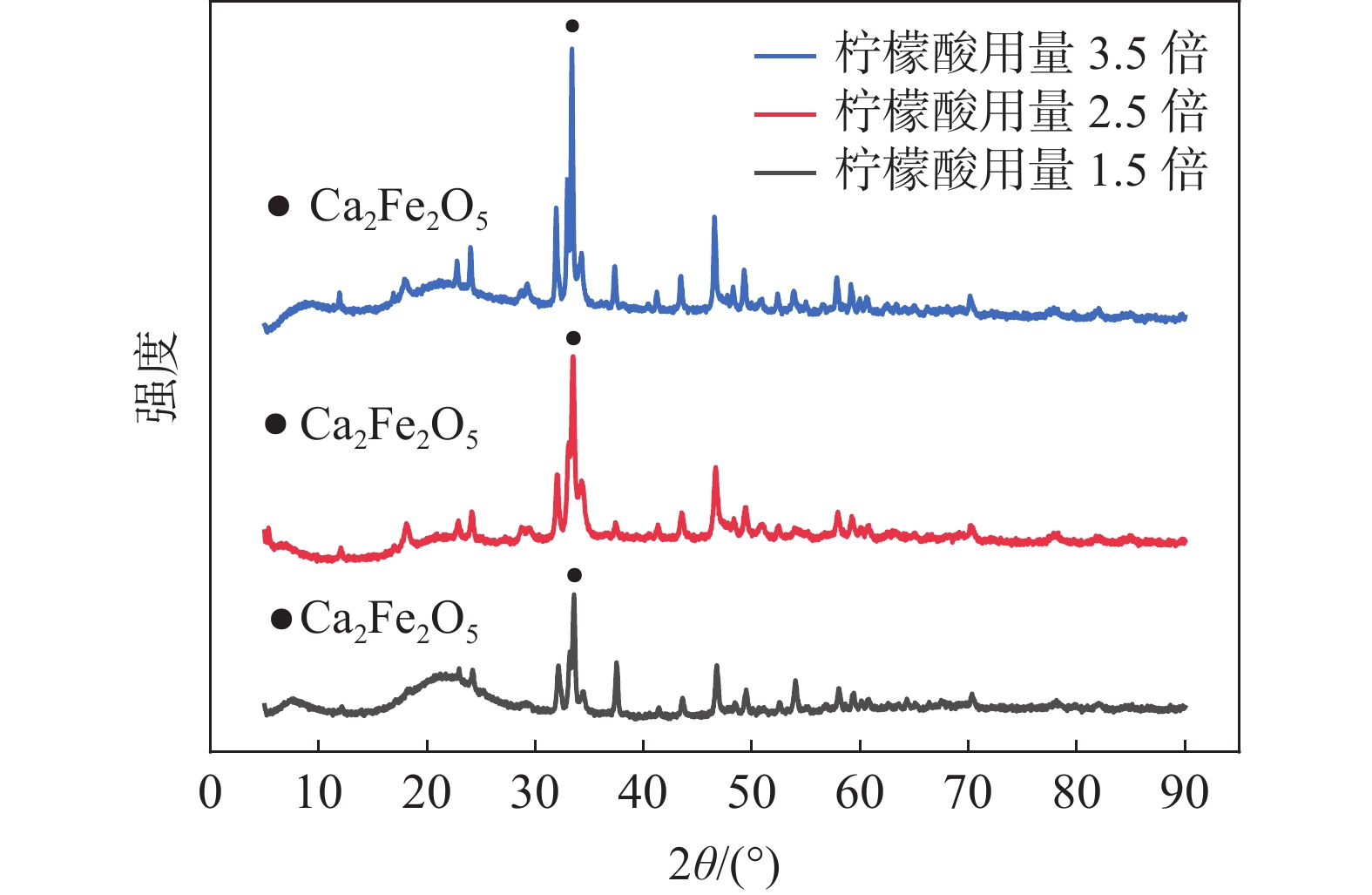

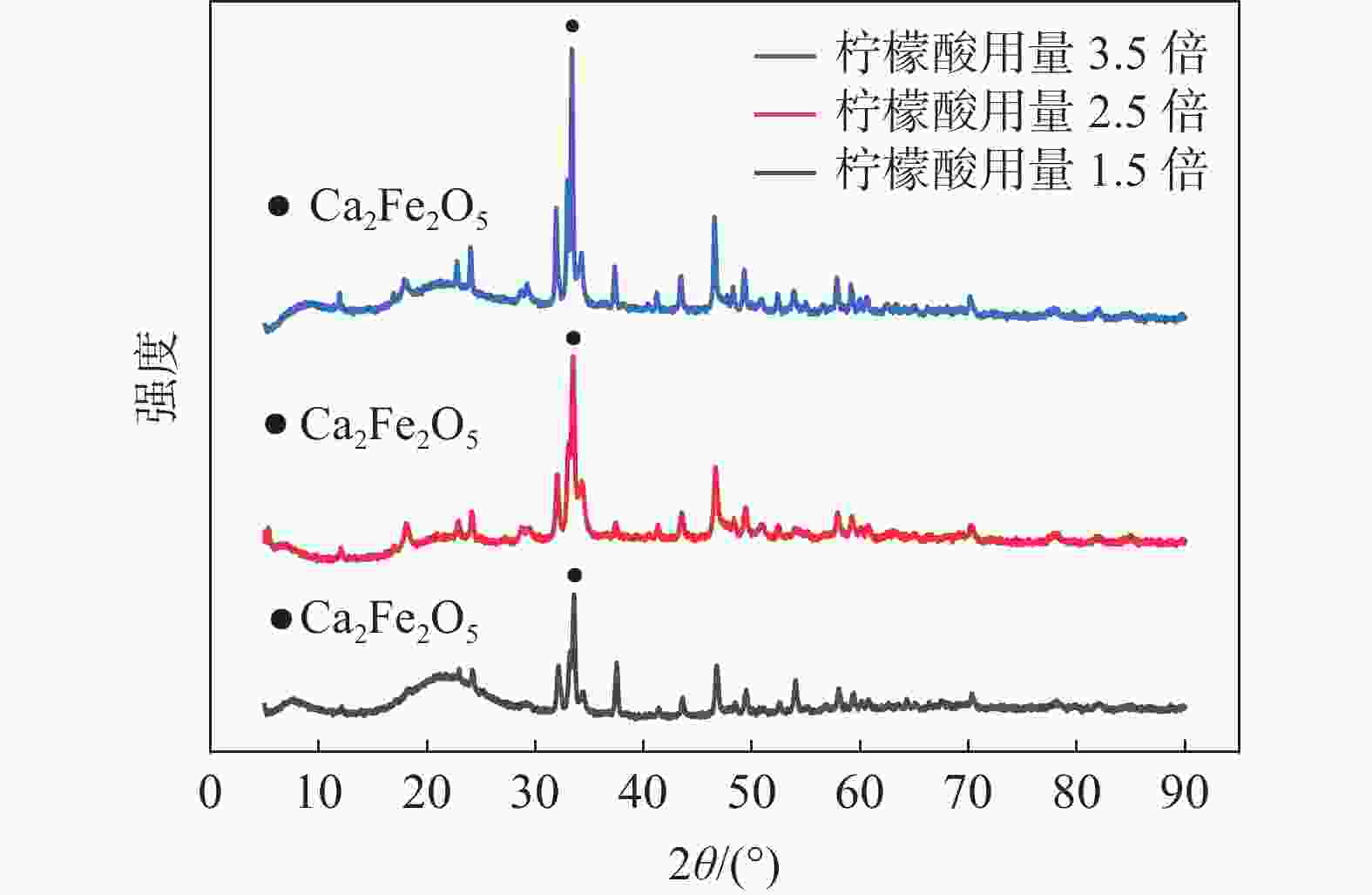

刘桂才. 生物质化学链气化特性及Ca2Fe2O5载氧体改性优化研究[D]. 广州: 华南理工大学, 2019.Liu Guicai. The chemical chain gasification characteristics of biomass and the modification and optimization of Ca2Fe2O5 oxygen carrier[D]. Guangzhou: South China University of Technology, 2019.

|

| [15] |

丁凯峰. LiMVO4(M=Mg, Zn)材料的制备[D]. 大连: 大连理工大学, 2018.Ding Kaifeng. Preparation of LiMVO4(M=Mg, Zn) materials[D]. Liaoning: Dalian University of Technology, 2018.

|

| [16] |

Cai Heshan, Liu Guoguang, Li Xiaoxia. Study on preparation and characterization of perovskite oxide photocatalyst[J]. Journal of Henan Normal University ( Natural Science Edition ), 2011,39(4):80−83,90. (蔡河山, 刘国光, 黎晓霞. 钙钛矿型氧化物光催化剂的制备及表征方法研究[J]. 河南师范大学学报(自然科学版), 2011,39(4):80−83,90.Cai Heshan, Liu Guoguang, Li Xiaoxia. Study on preparation and characterization of perovskite oxide photocatalyst[J]. Journal of Henan Normal University ( Natural Science Edition ), 2011,39(04): 80-83+9

|

下载:

下载: