Experimental study on durability of high-titanium heavy slag concrete under salt freezing

-

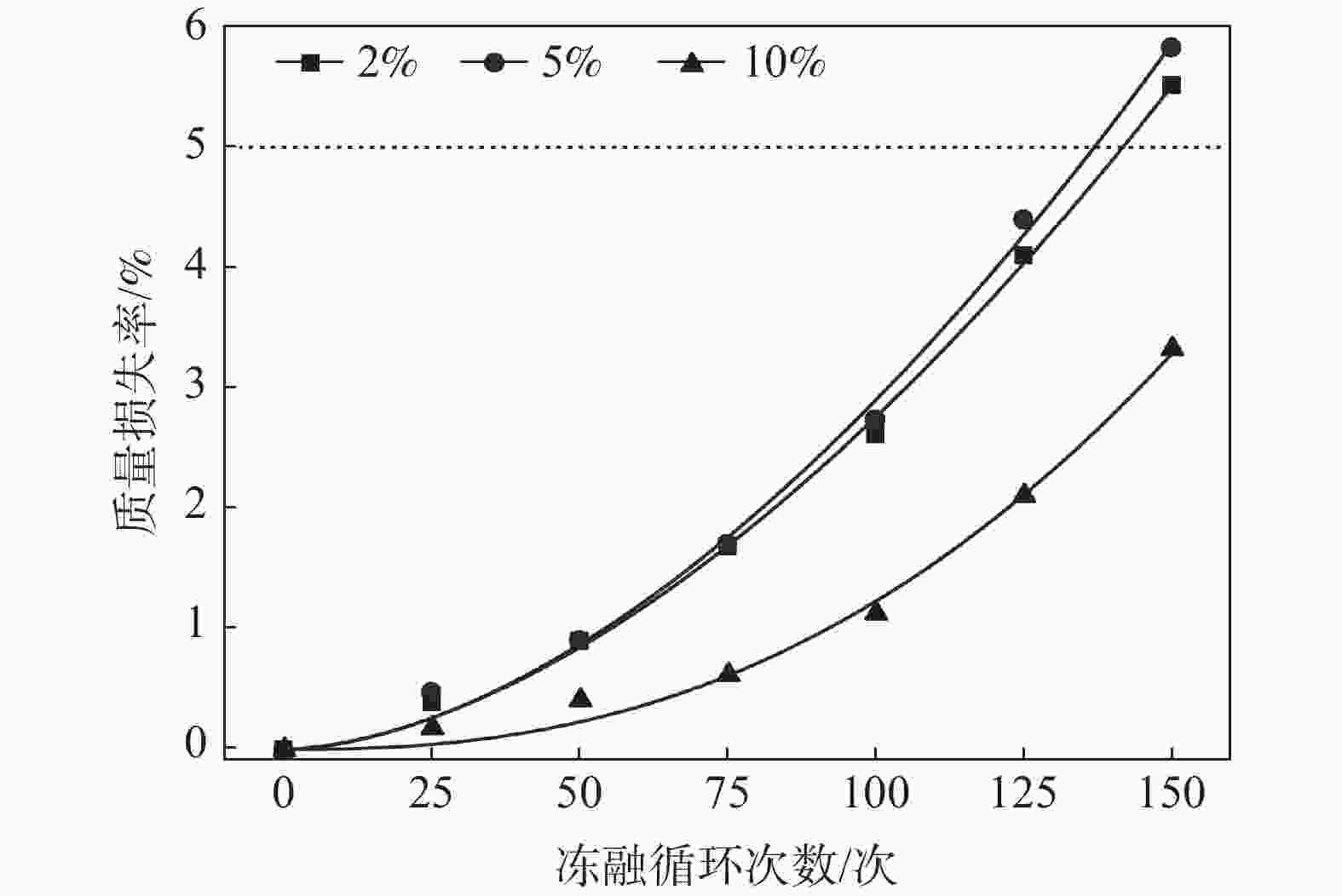

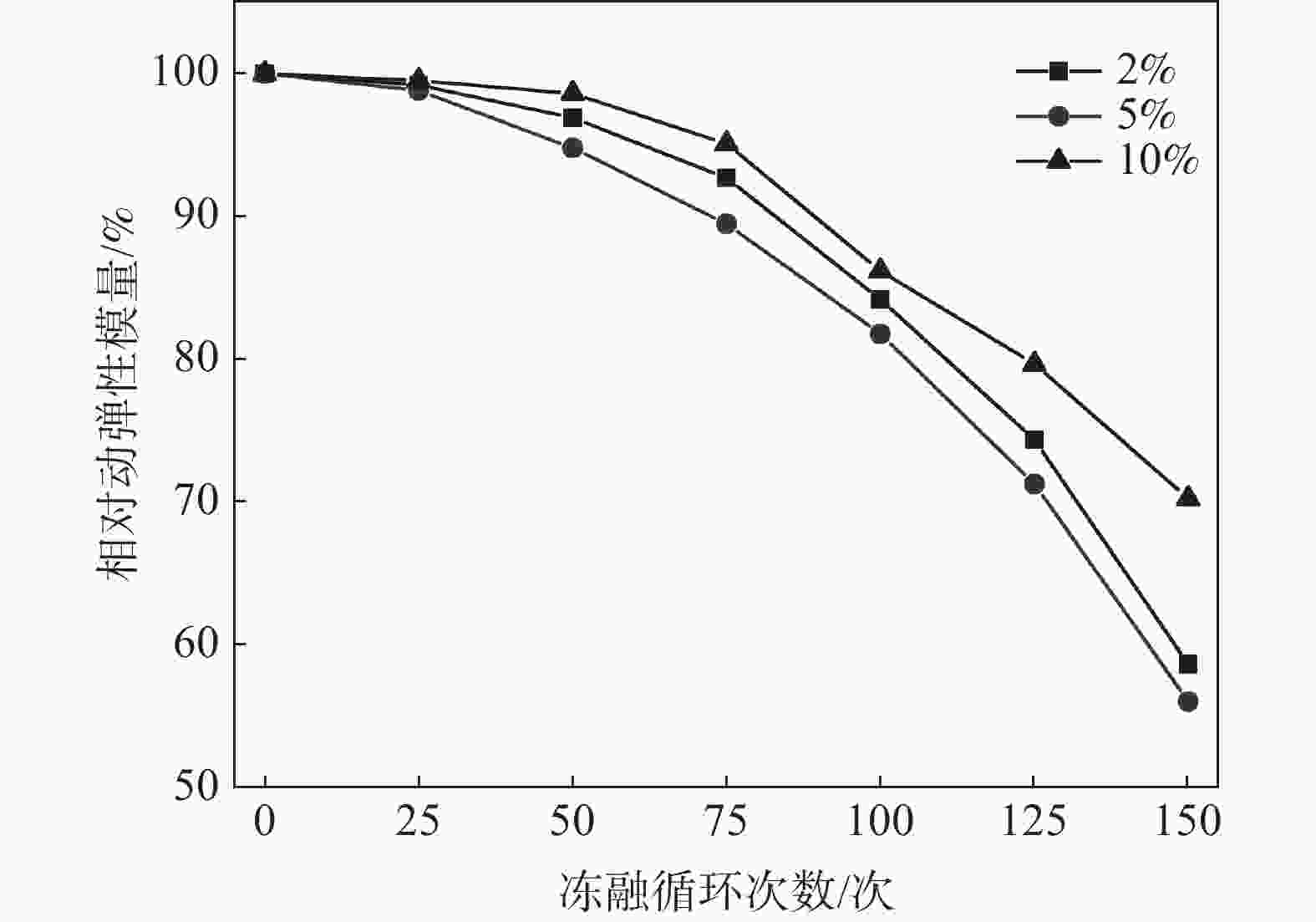

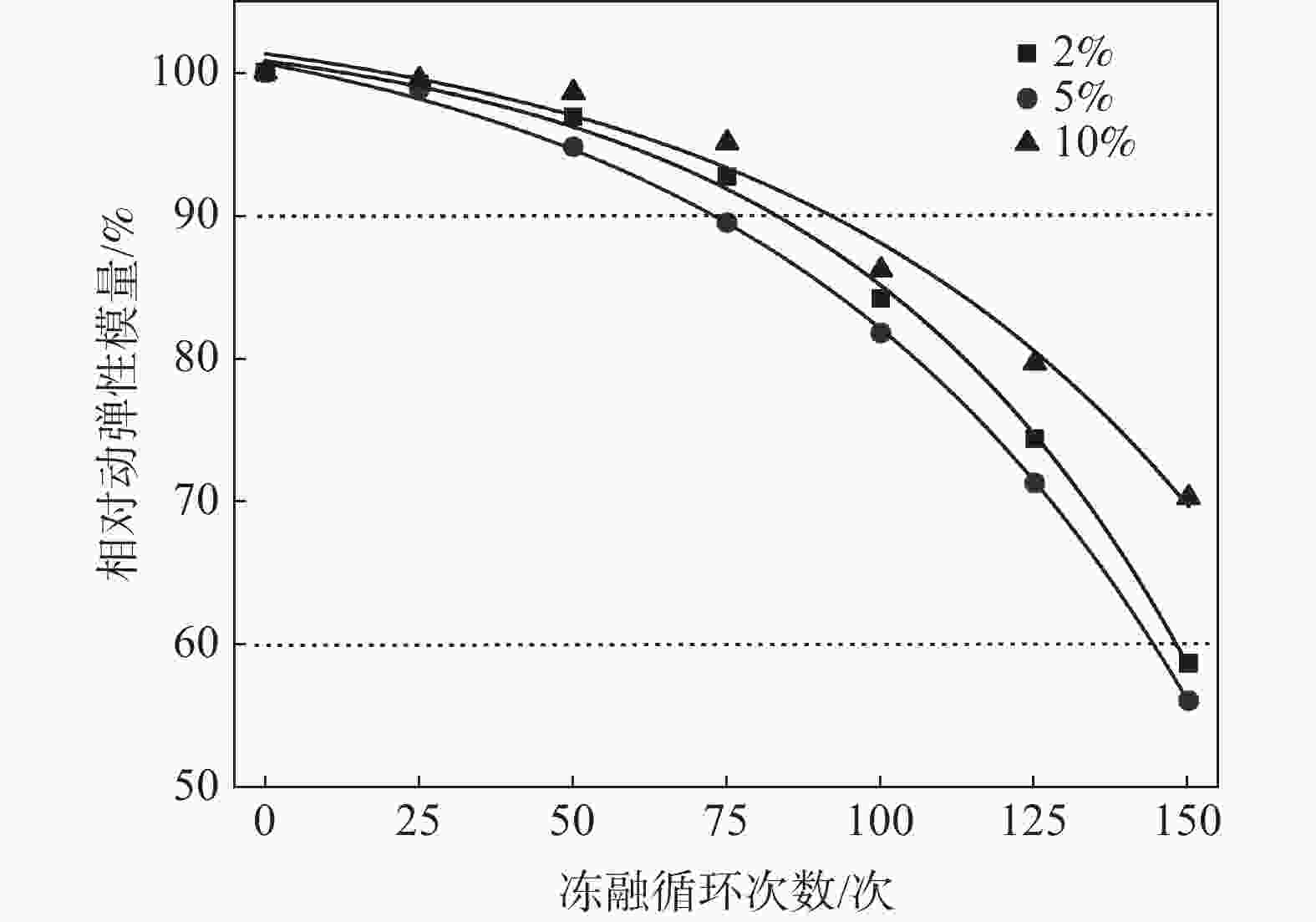

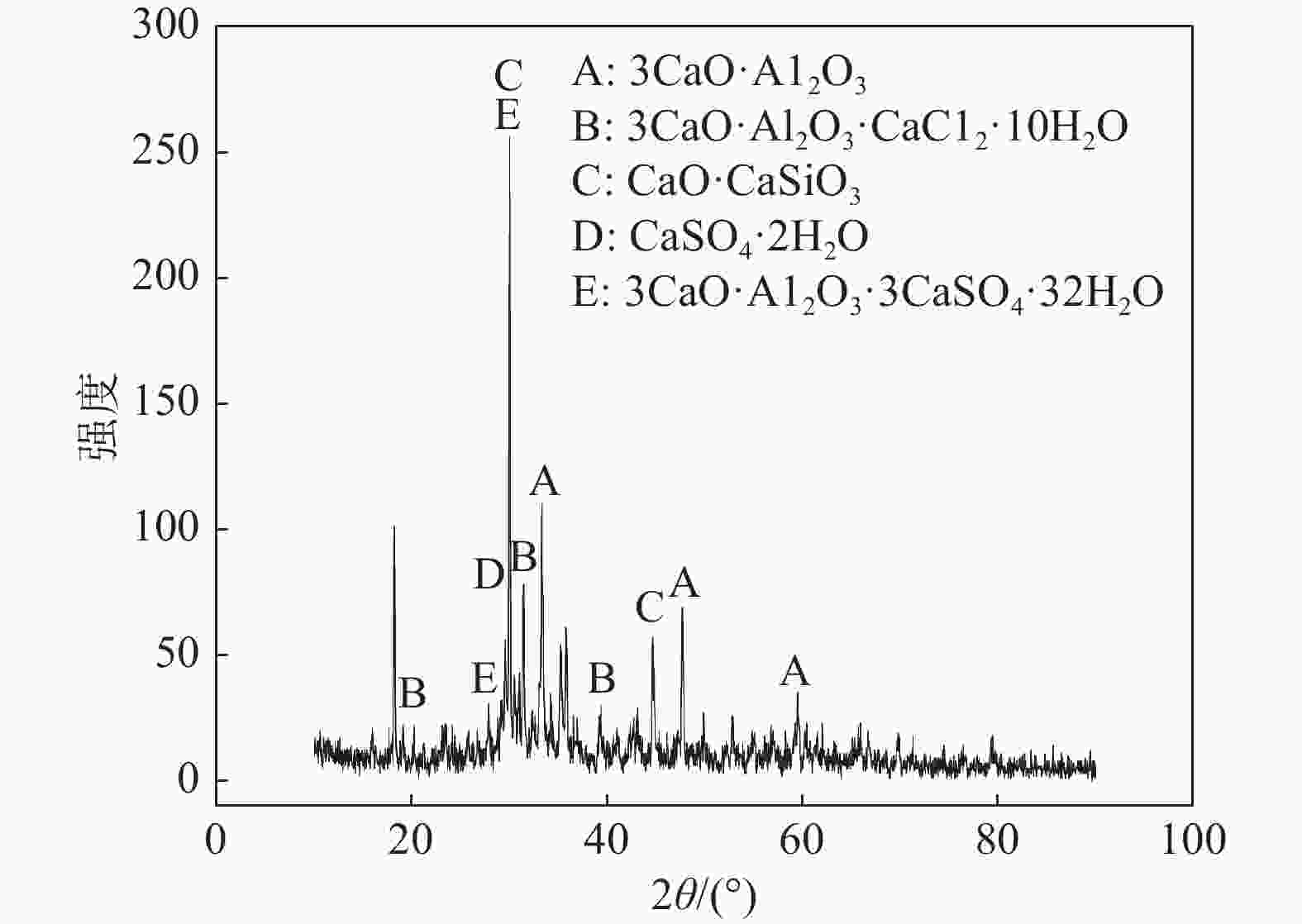

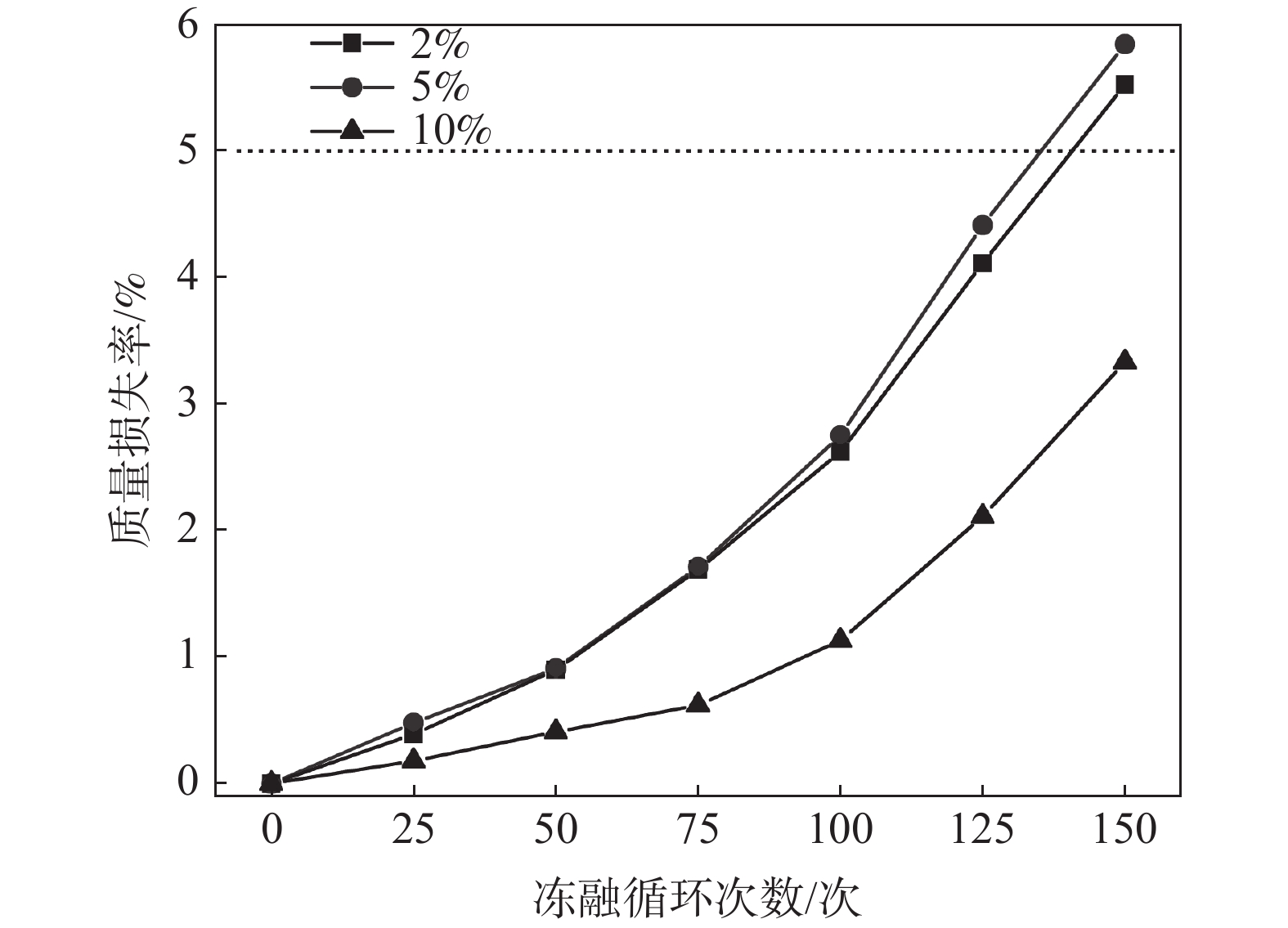

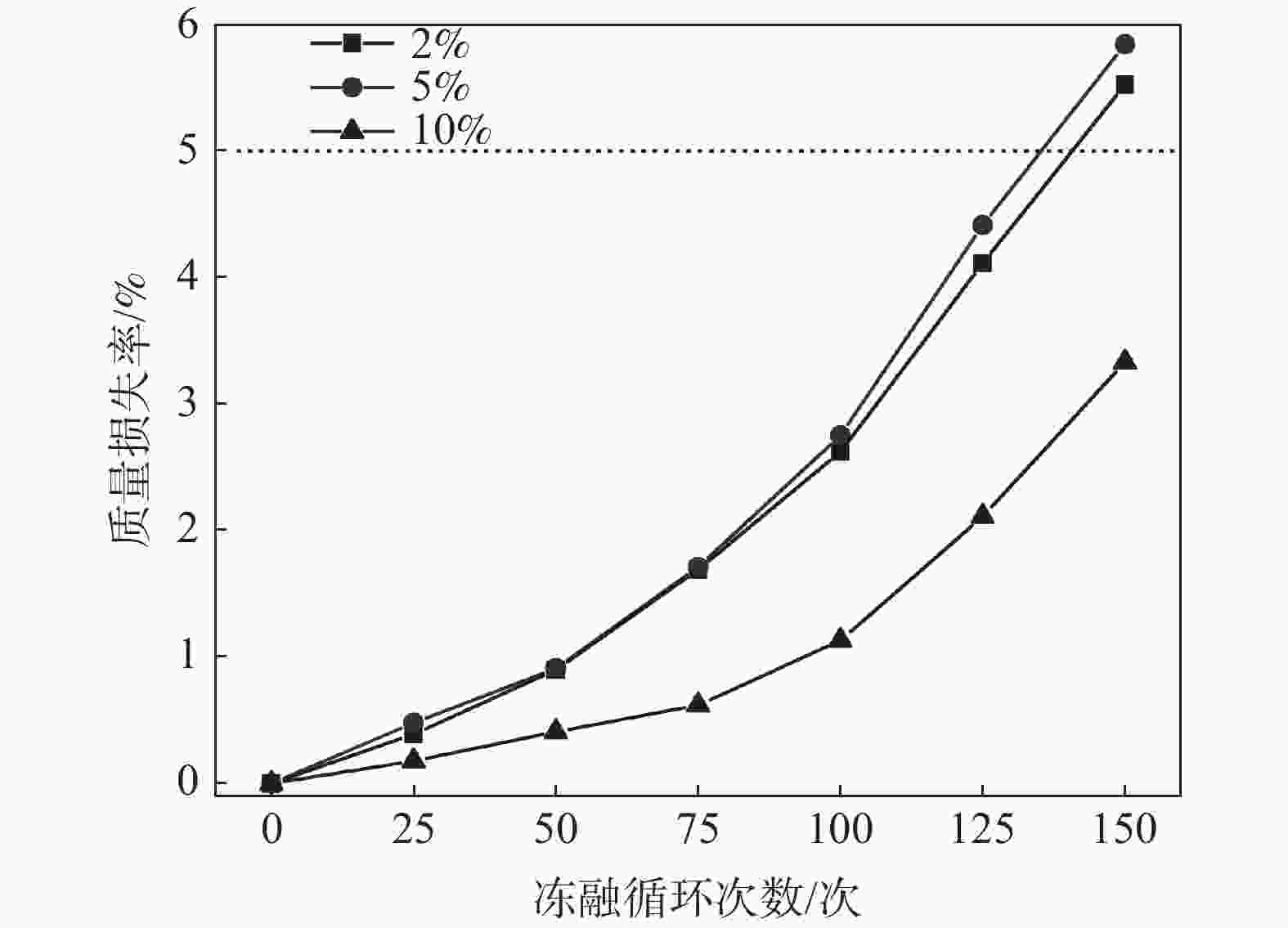

摘要: 考虑水胶比、粉煤灰掺量、复合盐溶液浓度三个因素,采用正交试验,研究不同因素对高钛重矿渣混凝土耐久性影响。试验结果表明:复合盐溶液浓度对高钛重矿渣混凝土的质量损失率和动弹性模量影响最大。在水胶比和粉煤灰掺量一定的情况下,随着冻融循环的次数增加,高钛重矿渣混凝土试块质量损失率逐渐增大,呈现指数函数变化趋势。随着冻融循环的次数增加,高钛重矿渣混凝土试块的动弹性模量快速减小,呈现负指数函数变化趋势。复合盐冻融循环下的高钛重矿渣混凝土试块的质量损失与动弹性模量的衰减的主要原因有两方面,一是NaCl和Na2SO4物理结晶产生的结晶拉力破坏;二是Cl−与高钛重矿渣混凝土水化产物发生化学反应产生氯铝酸钙,SO42−与水化铝酸钙发生化学反应,产生钙矾石,导致高钛重矿渣混凝土试块内部结构劣化。Abstract: Considering the three factors of water-binder ratio, fly ash content, and composite salt solution concentration, orthogonal experiments are used to study the influence of different factors on the durability of high-titanium heavy slag concrete. The experimental results show that the concentration of the composite salt solution has the greatest influence on the mass loss rate and dynamic elastic modulus of the high-titanium heavy slag concrete. For a certain water-binder ratio and fly ash content, when the number of freeze-thaw cycles increases, the mass loss rate of high-titanium heavy slag concrete specimens gradually increases, showing an exponential function change trend. With the increase in the number of freeze-thaw cycles, the dynamic elastic modulus of the high-titanium heavy slag concrete test block decreases rapidly, showing a negative exponential function change trend. There are two main reasons for the mass loss and the attenuation of dynamic elastic modulus of the high-titanium heavy slag concrete test block under the composite salt freeze-thaw cycle. The first is the destruction of crystal tension caused by the physical crystallization of NaCl and Na2SO4; the second is the chemical reaction between Cl− and the high-titanium heavy slag concrete hydrate to produce calcium chloroaluminate, and the chemical reaction of SO42− with calcium aluminate hydrate to produce ettringite, resulting in the deterioration of the internal structure of the high-titanium heavy slag concrete test block.

-

表 1 高钛重矿渣化学组成

Table 1. Chemical composition of high-titanium heavy slag

% SiO2 CaO TiO2 Al2O3 MgO Fe2O3 MnO SO3 TFe 23.26 25.59 21.32 12.66 8.12 1.91 0.54 1.39 5.21 表 2 高钛重矿渣物理性能指标

Table 2. Physical performance index of high-titanium heavy slag

样品 堆积密度/(kg·m−3) 表观密度/(kg·m−3) 压碎指标值/% 吸水率/% 高钛重矿渣 1350 2840 8 6.2 表 3 水泥各项品质指标

Table 3. Various quality indexes of cement

抗压强度/MPa 抗折强度/MPa 凝结时间/min 烧失量

/%SO3

/%MgO

/%Cl−

/%3 d 28 d 3 d 28 d 初凝 终凝 28.5 45.4 5.3 7.5 180 280 1.91 2.36 1.94 0.02 表 4 因素-水平

Table 4. Factor-level table

A:水胶比 B:粉煤灰掺量/% C: 复合盐溶液浓度/% 1 0.50(A1) 0(B1) 2(C1) 2 0.55(A2) 10(B2) 5(C2) 3 0.60(A3) 20(B3) 10(C3) 表 5 正交试验

Table 5. Orthogonal test table

组号 A(水胶比) B(粉煤灰掺量) C(复合盐溶液浓度) F1 A1 B1 C1 F2 A1 B2 C2 F3 A1 B3 C3 F4 A2 B1 C2 F5 A2 B2 C3 F6 A2 B3 C1 F7 A3 B1 C3 F8 A3 B2 C1 F9 A3 B3 C2 表 6 复合盐-冻融(150次)作用下质量损失率极差分析

Table 6. Range analysis of the mass loss rate under composite salt freeze-thaw (150 times)

组号 A(水胶比) B(粉煤灰掺量) C(复合盐溶液浓度) 质量损失率/% F1 A1 B1 C1 5.21 F2 A1 B2 C2 5.84 F3 A1 B3 C3 2.79 F4 A2 B1 C2 5.77 F5 A2 B2 C3 3.01 F6 A2 B3 C1 5.31 F7 A3 B1 C3 2.73 F8 A3 B2 C1 5.54 F9 A3 B3 C2 6.12 极差R 0.19 0.23 3.07 表 7 复合盐-冻融(150次)作用下相对动弹性模量极差分析

Table 7. Range analysis of relative dynamic elastic modulus under composite salt freeze-thaw (150 times)

组号 A(水胶比) B(粉煤灰

掺量)C(复合盐溶液

浓度)相对动弹性

模量/%F1 A1 B1 C1 59.68 F2 A1 B2 C2 56.11 F3 A1 B3 C3 72.32 F4 A2 B1 C2 57.03 F5 A2 B2 C3 72.94 F6 A2 B3 C1 57.36 F7 A3 B1 C3 74.32 F8 A3 B2 C1 57.21 F9 A3 B3 C2 50.21 极差R 2.12 3.72 18.74 -

[1] Li Xiaowei, Chen Wei, Li Xuewei. Experimental study on seismic performance of high strength concrete columns with high titanium heavy slag as coarse and fine aggregates[J]. Building Structure, 2013,43(9):96−100. (李小伟, 陈伟, 李学伟. 高钛重渣骨料高强混凝土柱抗震性能试验研究[J]. 建筑结构, 2013,43(9):96−100.Li Xiaowei, Chen Wei, Li Xuewei. Experimental study on seismic performance of high strength concrete columns with high titanium heavy slag as coarse and fine aggregates [J]. Building Structure, 2013, 43(9): 96-100. [2] Yang He, Liang Hezhi, Chen Wei, et al. Analysis on the abrupt change mechanism of high titanium heavy slag powder composite cementitious materials[J]. Non-Metallic Mines, 2020,43(4):99−102. (杨贺, 梁贺之, 陈伟, 等. 高钛重矿渣粉复合胶凝材料强度突变机理分析[J]. 非金属矿, 2020,43(4):99−102.Yang He, Liang Hezhi, Chen Wei, et al. Analysis on the abrupt change mechanism of high titanium heavy slag powder composite cementitious materials[J] Non-Metallic Mines, 2020, 43(04): 99-102. [3] Qian Bo, Hu Jianchun, Qi Mingqiang, et al. Experimental research on performance of C30 concrete with aggregate of high titanium heavy slag in Xichang city[J]. Bulletin of the Chinese Ceramic Society, 2018,37(6):2062−2066. (钱波, 胡建春, 戚明强, 等. C30西昌全高钛重矿渣骨料混凝土性能试验研究[J]. 硅酸盐通报, 2018,37(6):2062−2066.Qian Bo, Hu Jianchun, Qi Mingqiang, et al. Experimental Research on Performance of C30 Concrete with Aggregate of High Titanium Heavy Slag in Xichang City [J]. Bulletin of the Chinese Ceramic Society, 2018, 37(06): 2062-2066 [4] Chen Wei, Huang Shuanghua, Sun Jinkun, et al. Experiment reseach on flexural performance of RC beamby high titanium blast furnance slag[J]. Sichuan Building Science, 2009,35(4):51−53. (陈伟, 黄双华, 孙金坤, 等. 高钛高炉渣钢筋混凝土梁正截面强度试验研究[J]. 四川建筑科学研究, 2009,35(4):51−53. doi: 10.3969/j.issn.1008-1933.2009.04.014Chen Wei, Huang Shuanghua, Sun Jinkun, et al. Experiment reseach on flexural performance of RC beamby high titanium blast furnance slag [J]. Sichuan Building Science , 2009, 35(4): 51-53. doi: 10.3969/j.issn.1008-1933.2009.04.014 [5] Mou Tingmin, Kong Dedong, Cao Panpan, et al. Preparation and application of C50 high-titanium heavy slag sand high-performance pumping concrete[J]. Concrete, 2014,(6):101−104. (牟廷敏, 孔德栋, 曹攀攀, 等. C50高钛重矿渣砂高性能泵送混凝土的制备与应用[J]. 混凝土, 2014,(6):101−104. doi: 10.3969/j.issn.1002-3550.2014.06.029Mou Tingmin, Kong Dedong, Cao Panpan, et al. Preparation and application of C50 high-titanium heavy slag sand high-performance pumping concrete[J]. Concrete, 2014(06): 101-104. doi: 10.3969/j.issn.1002-3550.2014.06.029 [6] Yang He, Liang Hezhi, Die Jian, et al. Mechanical properties of high titanium heavy slag fiber-reinforced concrete[J]. Iron Steel Vanadium Titanium, 2020,41(2):69−74. (杨贺, 梁贺之, 迭健, 等. 高钛重矿渣纤维混凝土力学性能试验研究[J]. 钢铁钒钛, 2020,41(2):69−74.Yang He, Liang Hezhi, Die Jian, et al. Mechanical properties of high titanium heavy slag fiber-reinforced concrete[J]. Iron Steel Vanadium Titanium, 2020, 41(02): 69-74. [7] Wang Wei. Experimental study on durability of high titanium heavy slag recycled concrete[J]. Iron Steel Vanadium Titanium, 2020,41(3):79−83. (王伟. 高钛重矿渣再生混凝土耐久性试验研究[J]. 钢铁钒钛, 2020,41(3):79−83.Wang Wei. Experimental study on durability of high titanium heavy slag recycled concrete [J]. Iron Steel Vanadium Titanium, 2020, 41(03): 79-83. ) [8] Su Xiaoping, Wang Qing. Corrosion damage of concrete under multi - salt soaking, freezing - thawing and dry - wet cycles[J]. Journal of Jilin University ( Engineering and Technology Edition), 2015,45(1):112−120. (宿晓萍, 王清. 复合盐浸-冻融-干湿多因素作用下的混凝土腐蚀破坏[J]. 吉林大学学报(工学版), 2015,45(1):112−120.Su Xiaoping, Wang Qing. Corrosion damage of concrete under multi - salt soaking, freezing - thawing and dry - wet cycles [J]. Journal of Jilin University ( Engineering and Technology Edition) , 2015, 45(01): 112-120. [9] Chen Xiaobin, Tang Mengxiong, Ma Kunlin. Underground concrete structure exposure tosulfate and chloride invading environment[J]. Journal of Central South University (Science and Technology), 2012,43(7):2803−2812. (陈晓斌, 唐孟雄, 马昆林. 地下混凝土结构硫酸盐及氯盐侵蚀的耐久性实验[J]. 中南大学学报(自然科学版), 2012,43(7):2803−2812.Chen Xiaobin, Tang Mengxiong, Ma Kunlin. Underground concrete structure exposure tosulfate and chloride invading environment [J]. Journal of Central South University (Science and Technology), 2012, 43(07): 2803-2812. [10] 苑立冬. 硫酸盐侵蚀与冻融循环共同作用下混凝土耐久性试验研究[D]. 西安: 西安建筑科技大学, 2013.Yuan Lidong. Experimental study on the durability of concrete under the combined action of sulfate erosion and freeze-thaw cycle[D]. Xi'an: Xi'an University of Architecture and Technology, 2013. [11] 梁贺之. 多因素耦合作用下高钛重矿渣混凝土的耐腐蚀性能研究[D].成都: 西华大学, 2021.Liang Hezhi. Study on corrosion resistance of high titanium heavy slag concrete under multi-factor coupling[D].Chengdu: Xihua University, 2021. [12] 吴泽媚. 氯盐和冻融对混凝土破坏特征及机理研究[D]. 南京: 南京航空航天大学, 2012.Wu Zemei. Failure characteristics and mechanism of chlorine deicers and freeze-thaw on concrete[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2012. -

下载:

下载: