Research and application of improving the compressive strength of full V-Ti pellets

-

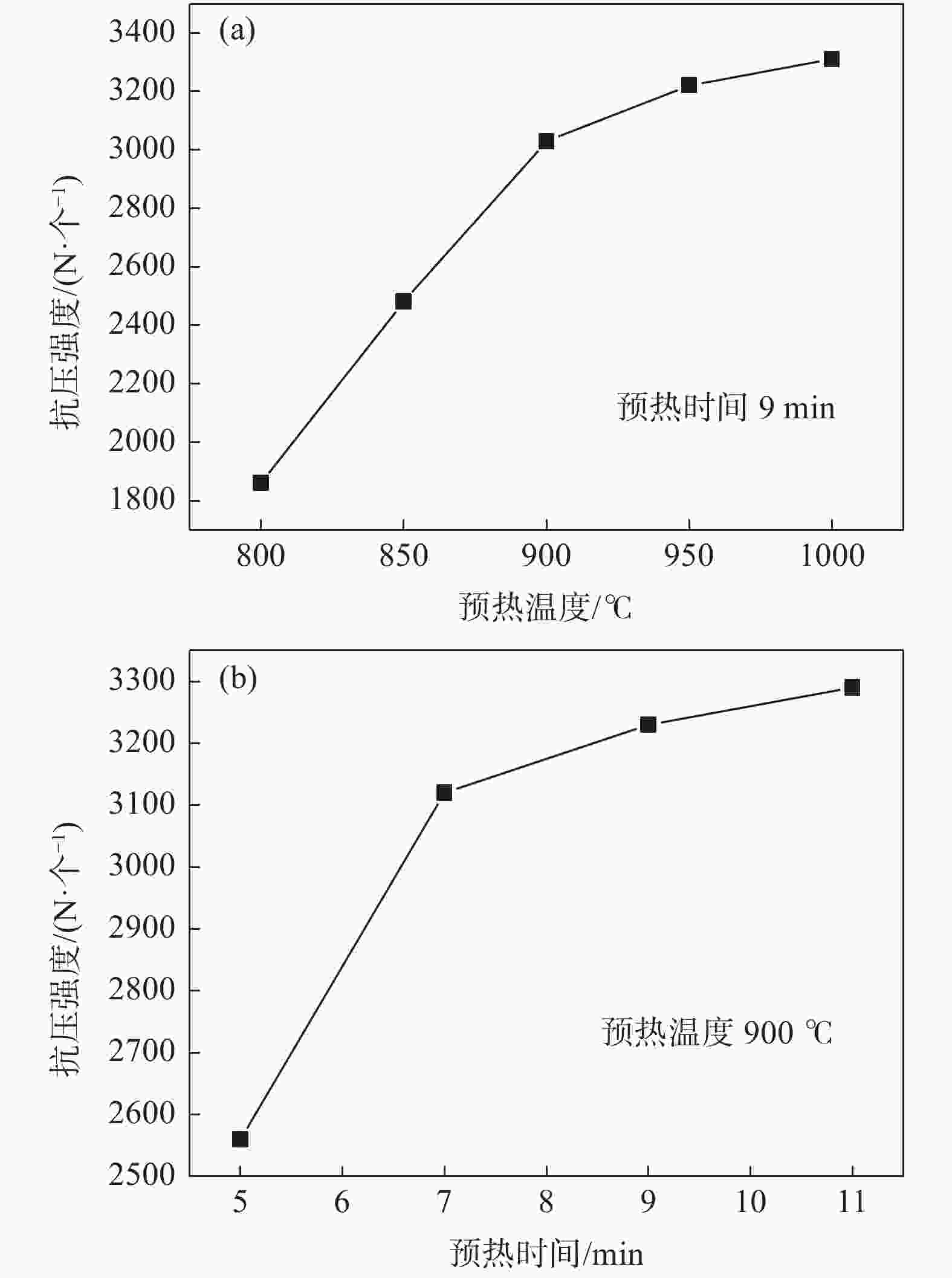

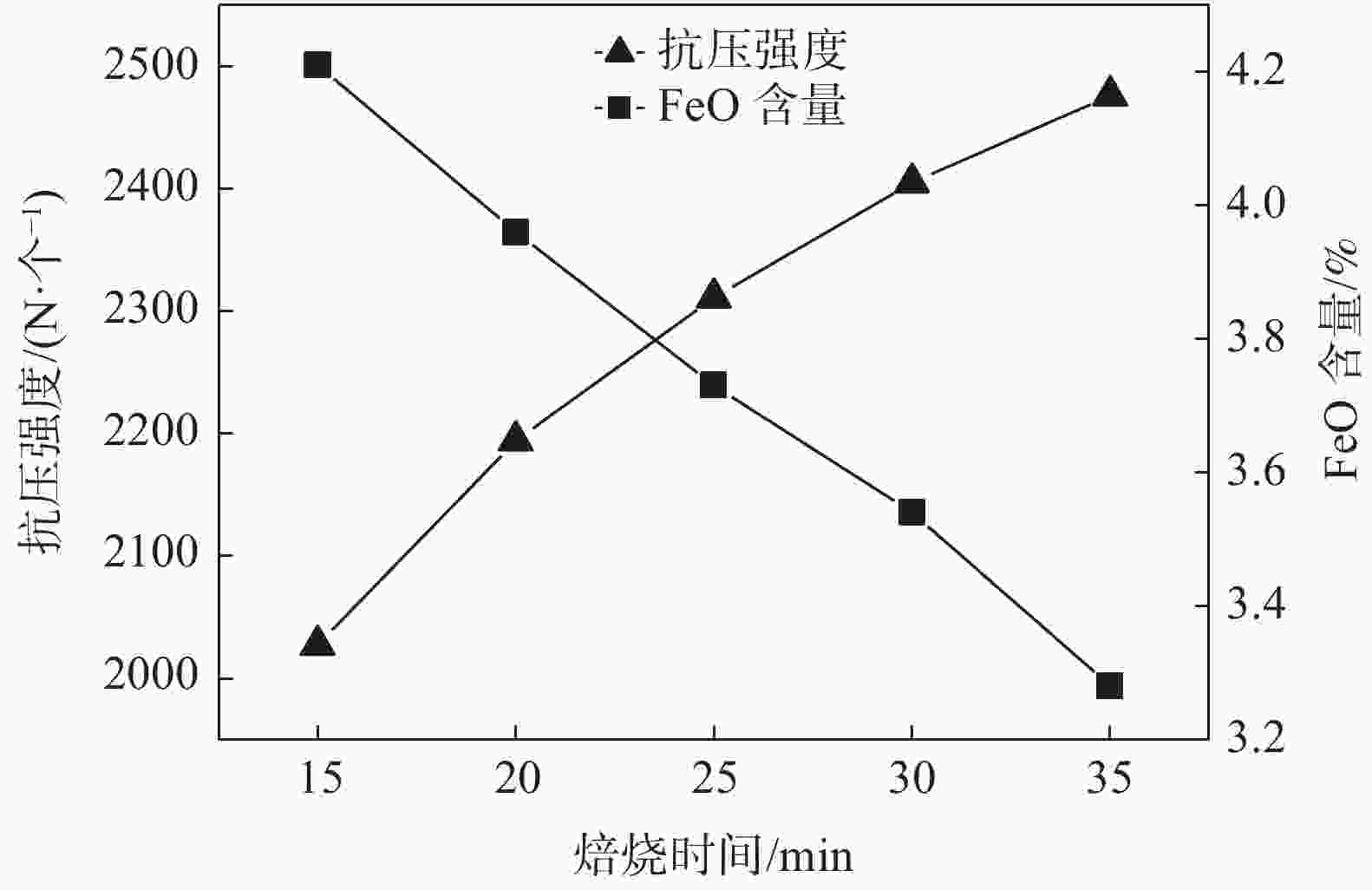

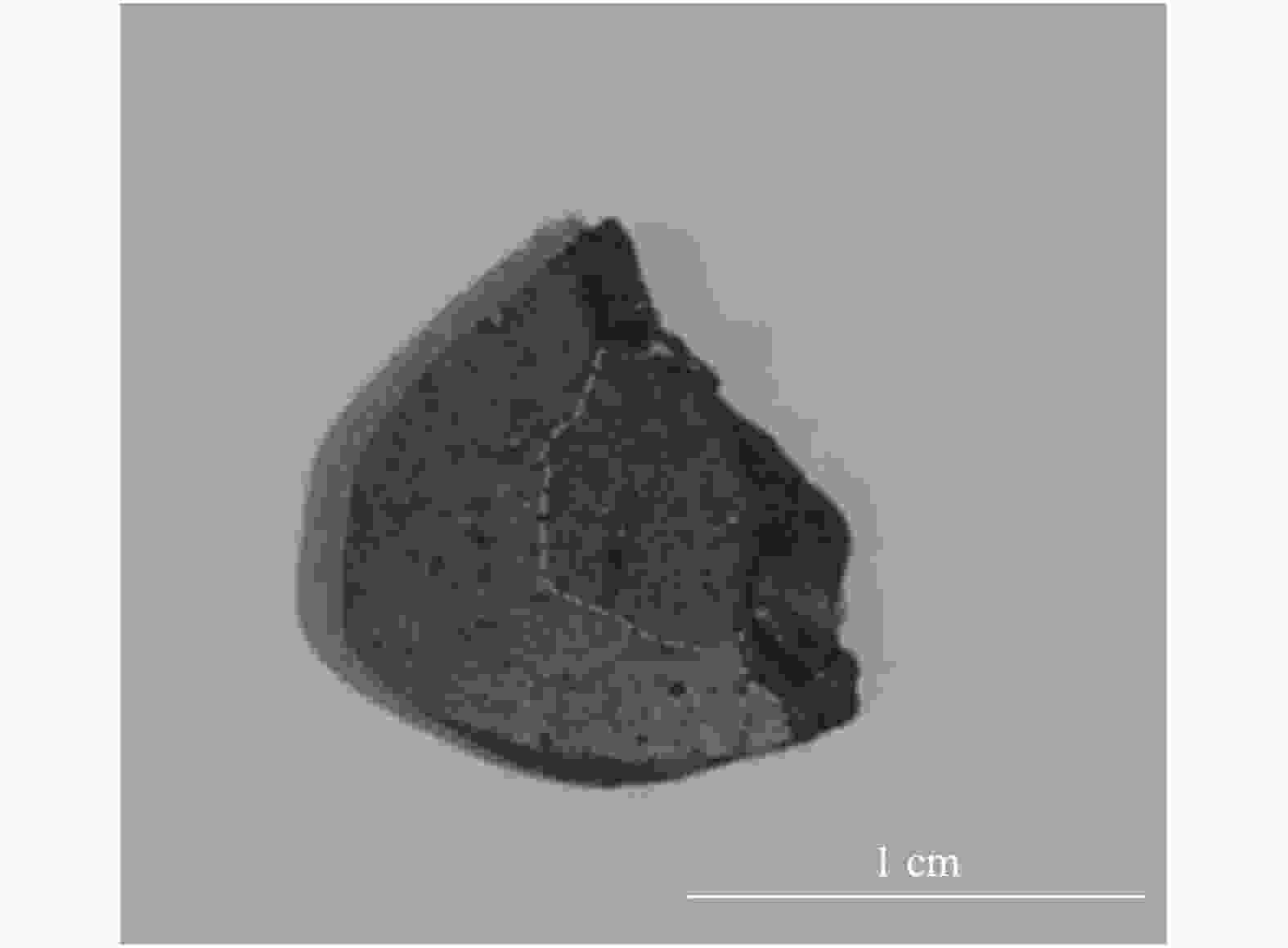

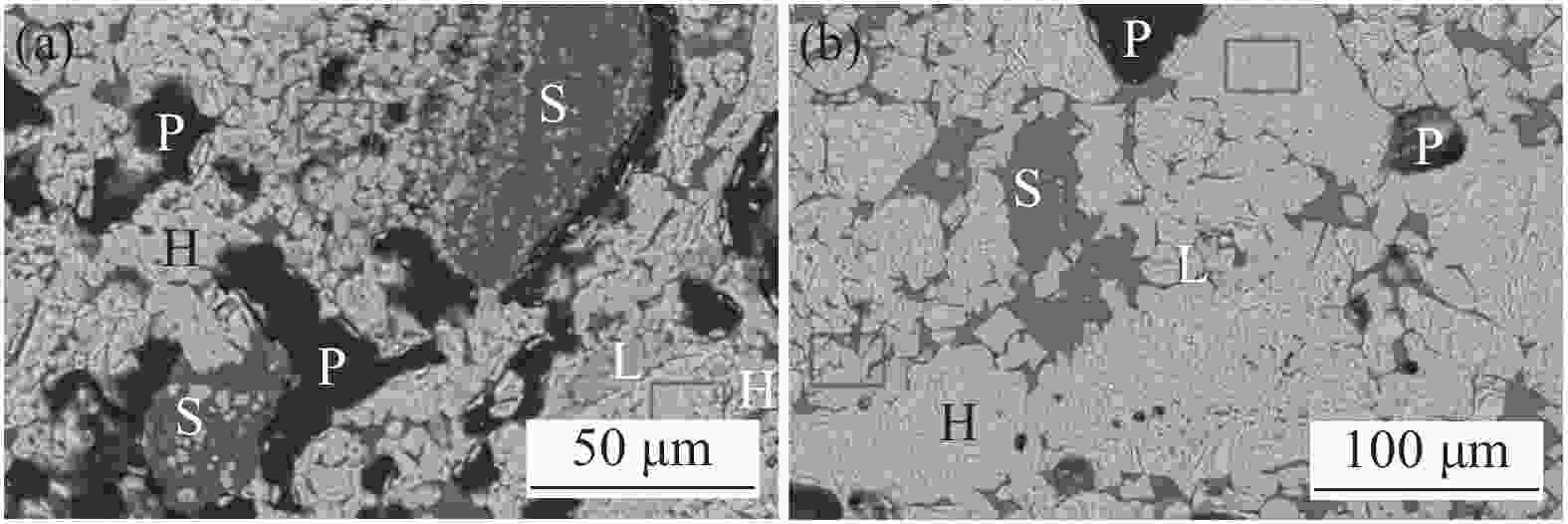

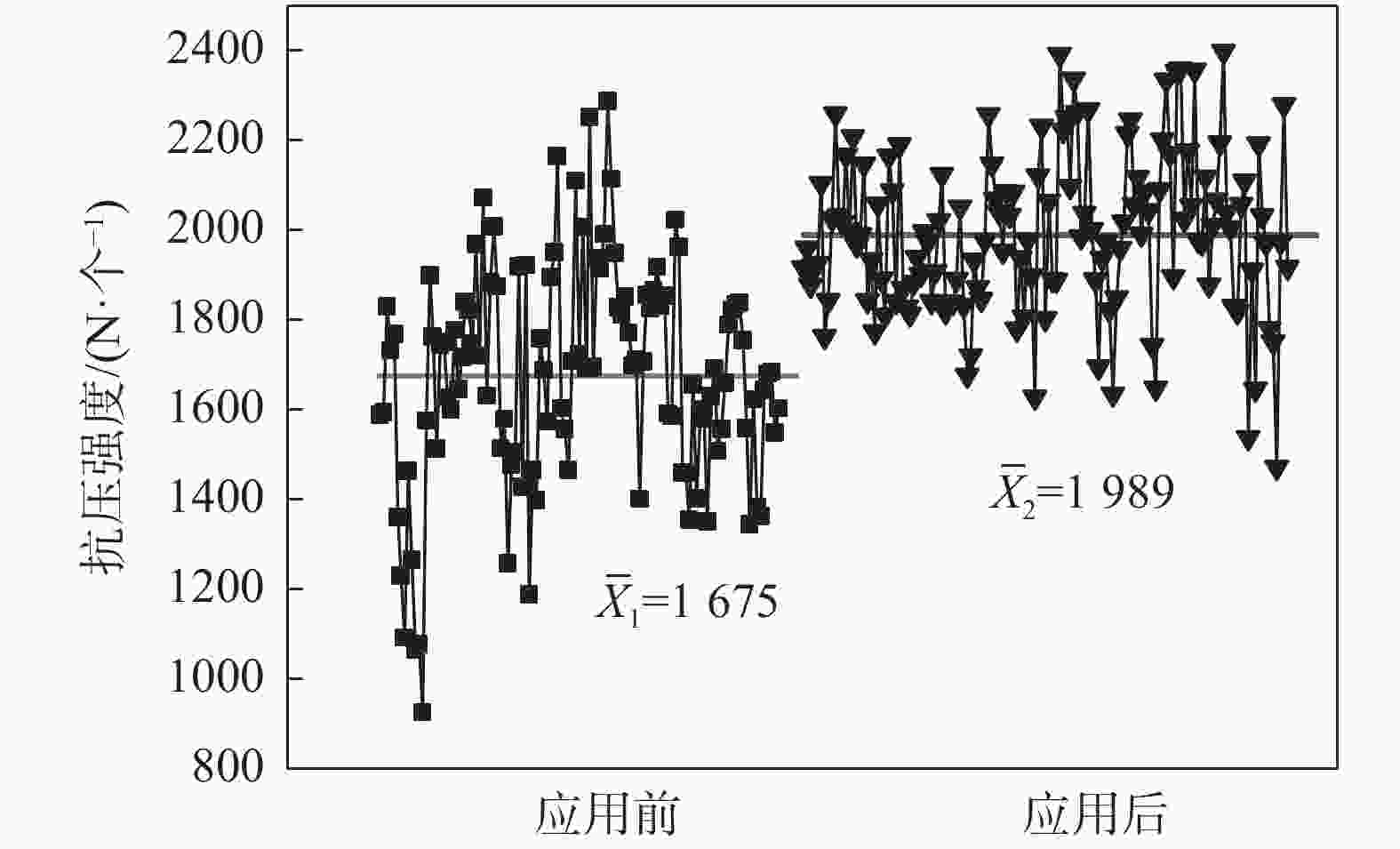

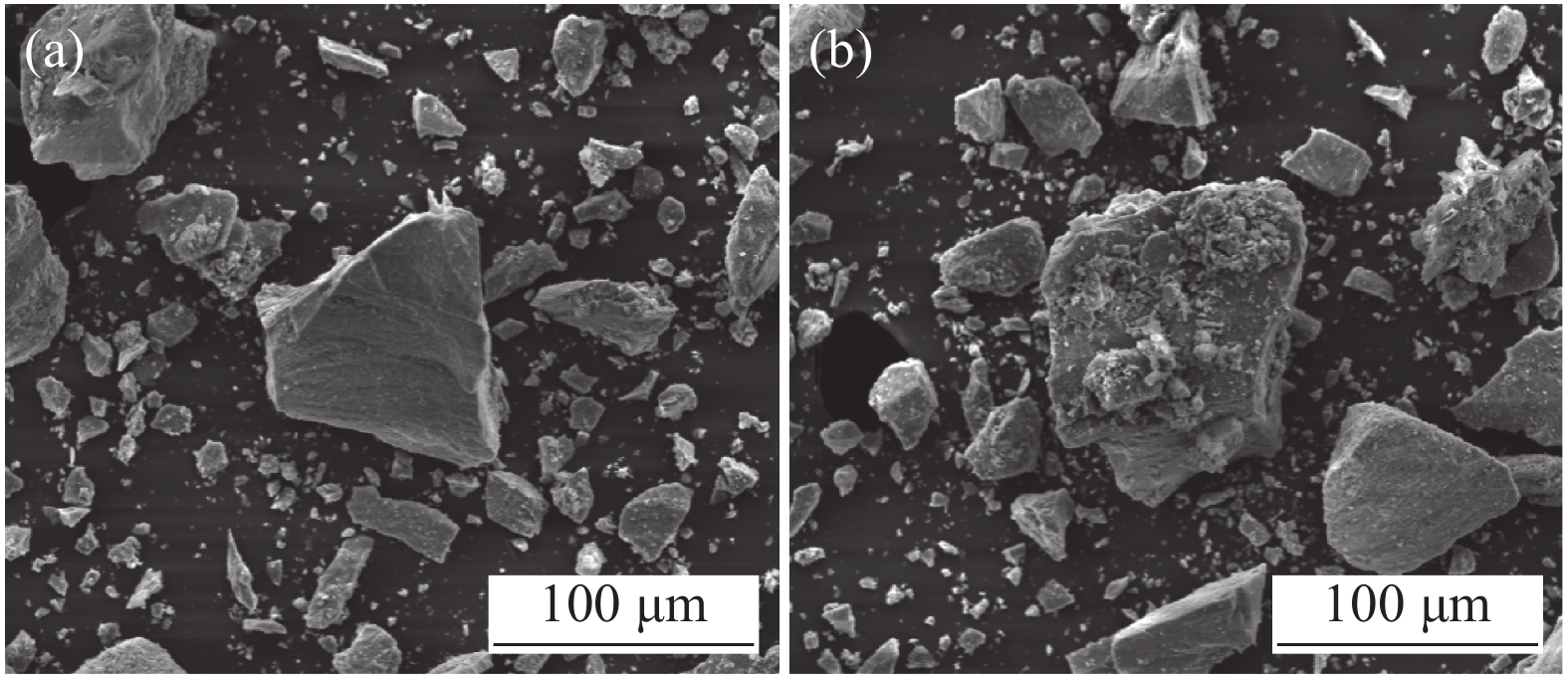

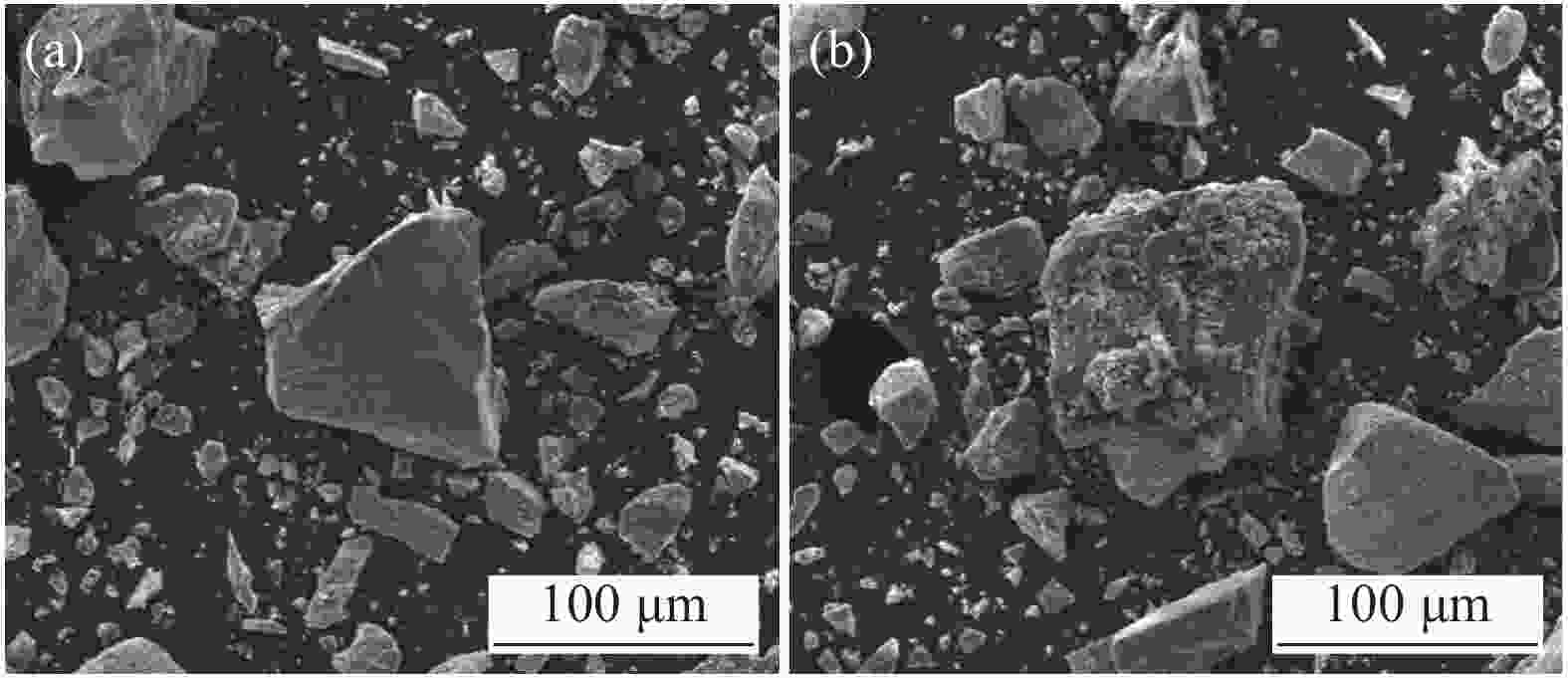

摘要: 针对全钒钛球团矿抗压强度低(平均1 600 N/个左右)、波动大(最低仅926 N/个,最高2 287 N/个),进入高炉冶炼后极大的影响了高炉稳定顺行,特开展了提高全钒钛球团矿抗压强度技术研究与应用。结果表明:通过增设润磨设备后,造球混合料粒度小于0.074 mm粒级由66.64%提高至71.69%,矿物颗粒表面变粗糙,粘结性增加,活性增强;且将预热二段温度提高到900 ℃左右、降低链篦机机速、延长预热时间,将焙烧温度从1150 ℃提高至1200 ℃以上,降低回转窑转速,延长焙烧时间后,球团矿内部带直径降低至3 mm以下,抗压强度提高至1 989 N/个,波动明显减小,为高炉稳定顺行提供了原料基础。Abstract: The low compressive strength (average 1 600 N/P) and large strength fluctuation (926 N/P min, 2287 N/P max) of V-Ti pellets greatly affect the stability and smooth operation of blast furnace after being smelted in blast furnace. The technical research and application of improving the compressive strength of full V-Ti pellets have been carried out. After utilizing wet grinding equipment, the proportion of pelletizing mixture less than 0.074 mm is increased from 66.64% to 71.69%. And the surface of mineral particles becomes rough. Besides, the cohesiveness and activity increases as result of installing wet grinding equipment. By increasing the temperature of second preheating stage to about 900 ℃ and reducing the grate speed to prolong the preheating time, at the same time increasing the roasting temperature from 1 150 ℃ to more than 1 200 ℃ and reducing the rotary kiln speed to prolong the roasting time, the diameter of inner zone of pellet can be reduced to less than 3 mm, and the compressive strength is increased to 1 989 N/P and its fluctuation become narrow.

-

Key words:

- V-Ti pellet /

- compressive strength /

- roasting temperature /

- microstructure

-

表 1 钒钛磁铁矿样品的主要化学成分及烧损

Table 1. Main chemical composition and Ig of sample V-Ti magnetite

% TFe FeO SiO2 CaO V2O5 TiO2 MgO Al2O3 Ig 55.22 29.46 4.15 0.80 0.707 9.99 3.80 3.85 −1.40 注:Ig为烧损量。 表 2 钒钛磁铁矿样品的粒度组成

Table 2. Size distribution of sample V-Ti magnetite

% >0.15 mm 0.15~0.074 mm 0.074~0.045 mm <0.045 mm <0.074 mm 7.03 28.26 21.06 43.65 64.71 表 3 膨润土的主要化学成分

Table 3. Main chemical composition of bentonite

% Fe2O3 SiO2 CaO Al2O3 MgO K2O Na2O Ig 3.22 55.00 4.82 14.03 3.42 0.98 1.52 14.69 表 4 膨润土的物理性能

Table 4. Physical properties of bentonite

胶质价/

%膨胀容/

(mL·g−1)吸兰量(100 g计)/

gpH值 粒度<0.074 mm的

矿物含量/%62.00 42.02 35.70 10.44 97.79 表 5 润磨时间对混合料粒度组成的影响

Table 5. Effect of wet grinding time on size distribution of mixture

润磨时间/min 粒度组成/% >0.15 mm 0.15~0.075 mm 0.074~0.045 mm <0.045 mm <0.074 mm 0 7.03 28.26 21.06 43.65 64.71 3 5.72 23.36 22.16 48.76 70.92 4 4.96 22.83 21.78 50.43 72.21 5 4.50 22.21 20.96 52.33 73.29 6 4.12 21.72 19.99 54.17 74.16 表 6 不同焙烧温度的内部带直径

Table 6. Inner band diameter of pellet after roasting at different temperatures

焙烧温度/℃ 内部带直径/mm 1150 5~8 1180 4~5 1200 3~4 1250 1~2 1280 0~1 表 7 链篦机-回转窑热工制度优化情况

Table 7. Optimization of grate kiln thermal system

项目 链篦机机速

/(m·min−1)预热一段

/℃预热二段

/℃回转窑转速

/(r·min−1)窑头温度

/℃窑中温度

/℃窑尾温度

/℃优化前 2.3 550~580 820~850 1.0 950~980 1150~1180 730~760 优化后 1.95 600~630 890~920 0.91 1070~1100 1220~1250 770~800 -

[1] Xu Manxing. Metallurgical properties and quality analysis of several pellets at home and abroad[J]. Ball Technology, 2005,(3):2. (许满兴. 国内外几种球团矿的冶金性能及质量分析[J]. 球团技术, 2005,(3):2.Xu manxing. Metallurgical properties and quality analysis of several pellets at home and abroad[J]. Ball speed, 2005(3): 2. [2] Ye Kuangwu. Review of BF burden composition development in EU and the progress of pellet production in China[J]. China Metallurgy, 2005,15(10):1. (叶匡吾. 欧盟高炉炉料结构评述和中国球团生产的进展[J]. 中国冶金, 2005,15(10):1.Ye Kuangwu. Review of BF burden composition development in EU and the progress of pellet production in China[J]. China Metallurgy, 2005, 15(10): 1. [3] 叶匡吾, 冯根生. 我国球团矿的发展与应用-高炉炼铁节能、减排最重要的技术措施[C]//2010年全国炼铁生产技术会议暨炼铁学术年会. 北京: 中国金属学会, 2009: 36.Ye Kuangwu, Feng gengsheng. Development and application of pellet in China-the most important technical measures of energy saving and emission reduction in BF ironmaking//2010 National Iron Making Technology Conference-Annual Meeting of Ironmaking. Beijing: China Metal Society, 2009: 36. [4] Ren yunfu, Yang Lixiang. Study on perovskite in sinter of Pangang[J]. Sintering and Pelletizing, 1987,12(1):35−37. (任允芙, 杨李香. 有关攀钢烧结矿中钙钛矿的研究[J]. 烧结球团, 1987,12(1):35−37.Ren yunfu, Yang Lixiang. Study on perovskite in sinter of Pangang[J]. Sintering and Pelletizing, 1987, 12(1): 35-37. [5] Jiang Dajun. Sintering characteristics and strengthening measures of V-Ti magnetite concentrate[J]. Sintering and Pelletizing, 1997,22(1):4−10. (蒋大均. 钒钛磁铁精矿的烧结特性及强化措施[J]. 烧结球团, 1997,22(1):4−10.Jiang dajun. Sintering characteristics and strengthening measures of V-Ti magnetite concentrate[J]. Sintering and Pelletizing, 1997, 22(1): 4-10. [6] Yang Yongbin, Huang Guixiang, Jiang Tao, et al. Application of organic binder as substitutes for bentonite in pellet preparation[J]. J. Cent. South University, 2007,38(5):850−855. (杨永斌, 黄桂香, 姜涛, 等. 有机粘结剂替代膨润土制备氧化球团[J]. 中南大学学报, 2007,38(5):850−855.Yang yongbin, Huang guixiang, Jiangtao et al. Application of organic binder as substitutes for bentonite in pellet preparation[J]. J. Cent. South University, 2007, 38(5): 850-855. [7] Wang Shutong, Yang Lixiang. Preliminary observation and analysis of ore phase of pellets during roasting in shaft furnace of Hangzhou Iron and Steel Co[J]. Sintering and Pelletizing, 1982,3(7):37−39. (王树同, 杨李香. 杭钢竖炉焙烧过程中球团矿矿相的初步观察分析[J]. 烧结球团, 1982,3(7):37−39.Wang shutong, Yang lixiang. Preliminary observation and analysis of ore phase of pellets during roasting in shaft furnace of Hangzhou Iron and Steel Co[J]. Sintering and Pelletizing, 1982, 3(7): 37-39. [8] Liu Kai, Chen Shujun, Lv Qing. Effects of preheating roasting on compressive strength of pellets[J]. Foundry Technology, 2017,38(3):636−639. (刘凯, 陈树军, 吕庆. 预热焙烧对球团矿抗压强度影响[J]. 铸造技术, 2017,38(3):636−639.Liukai, Chen Shujun, Lvqing. Effects of preheating roasting on compressive strength of pellets[J]. Foundry Technology, 2017, 38(3): 636-639 [9] Lv Qing, Kang Liming, Liu Shuguang, et al. Study on roasting mechanism of Jidong magnetite concentrate pellets[J]. Iron and Steel Research, 2008,36(1):9−12. (吕庆, 亢立明, 刘曙光,等. 冀东磁铁精矿球团焙烧机理的研究[J]. 钢铁研究, 2008,36(1):9−12.Lvqing, Kang Liming, Liu Shuguang et al. Study on roasting mechanism of Jidong magnetite concentrate pellets[J]. Iron and Steel Research, 2008, 36(1): 9-12. [10] Du Jun, Ma Wen, Wang Zhihong. Practice of improving pellet strength[J]. Sintering and Pelletizing, 2010,35(5):48−50. (杜君, 马文, 王志洪. 提高球团矿强度的实践[J]. 烧结球团, 2010,35(5):48−50.Dujun, Mawen, Wang Zhihong. Practice of improving pellet strength[J]. Sintering and Pelletizing, 2010, 35(5): 48-50. -

下载:

下载: