Composition design of CaO-Al2O3 series low reactivity continuous casting molding flux for high titanium steel

-

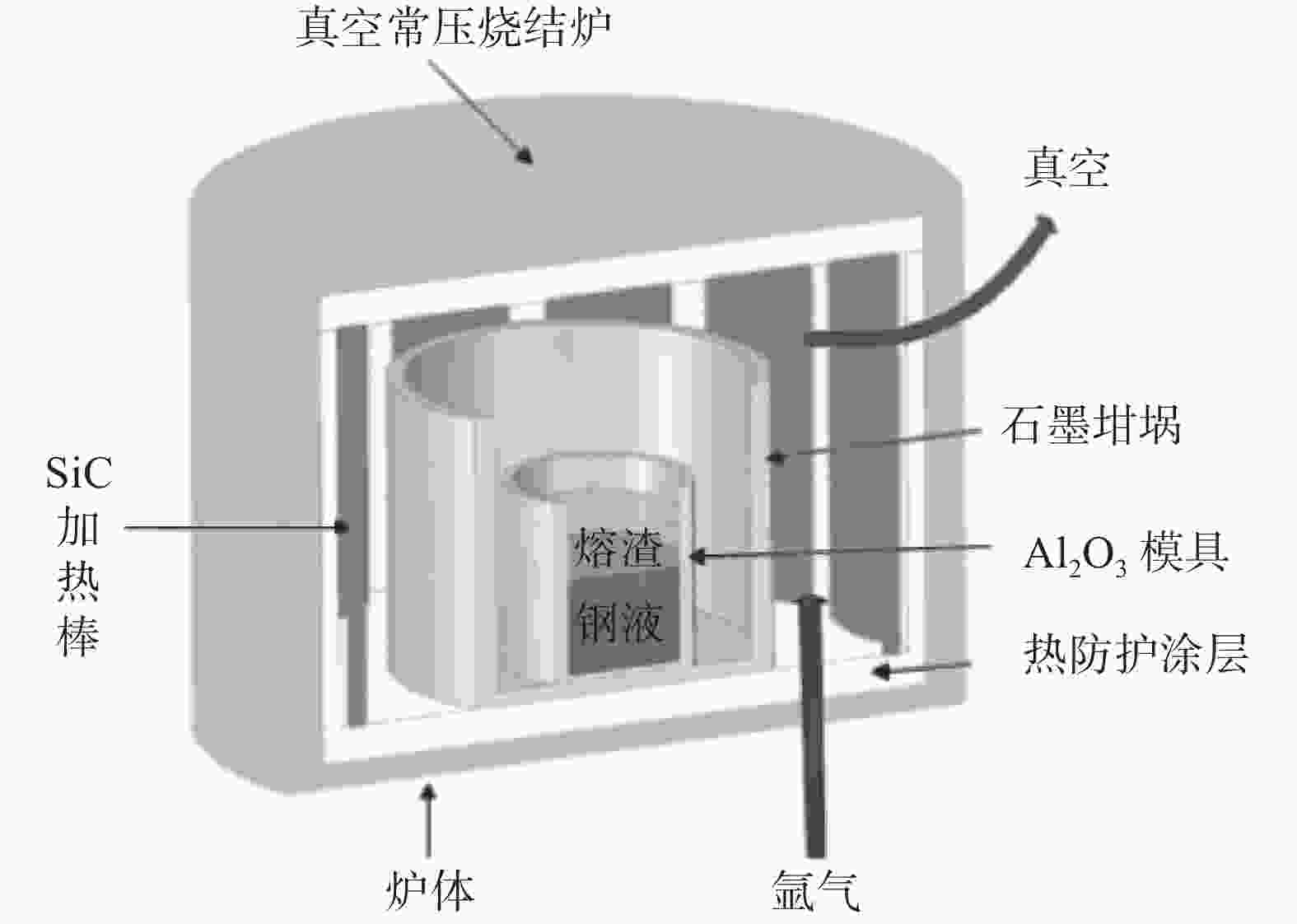

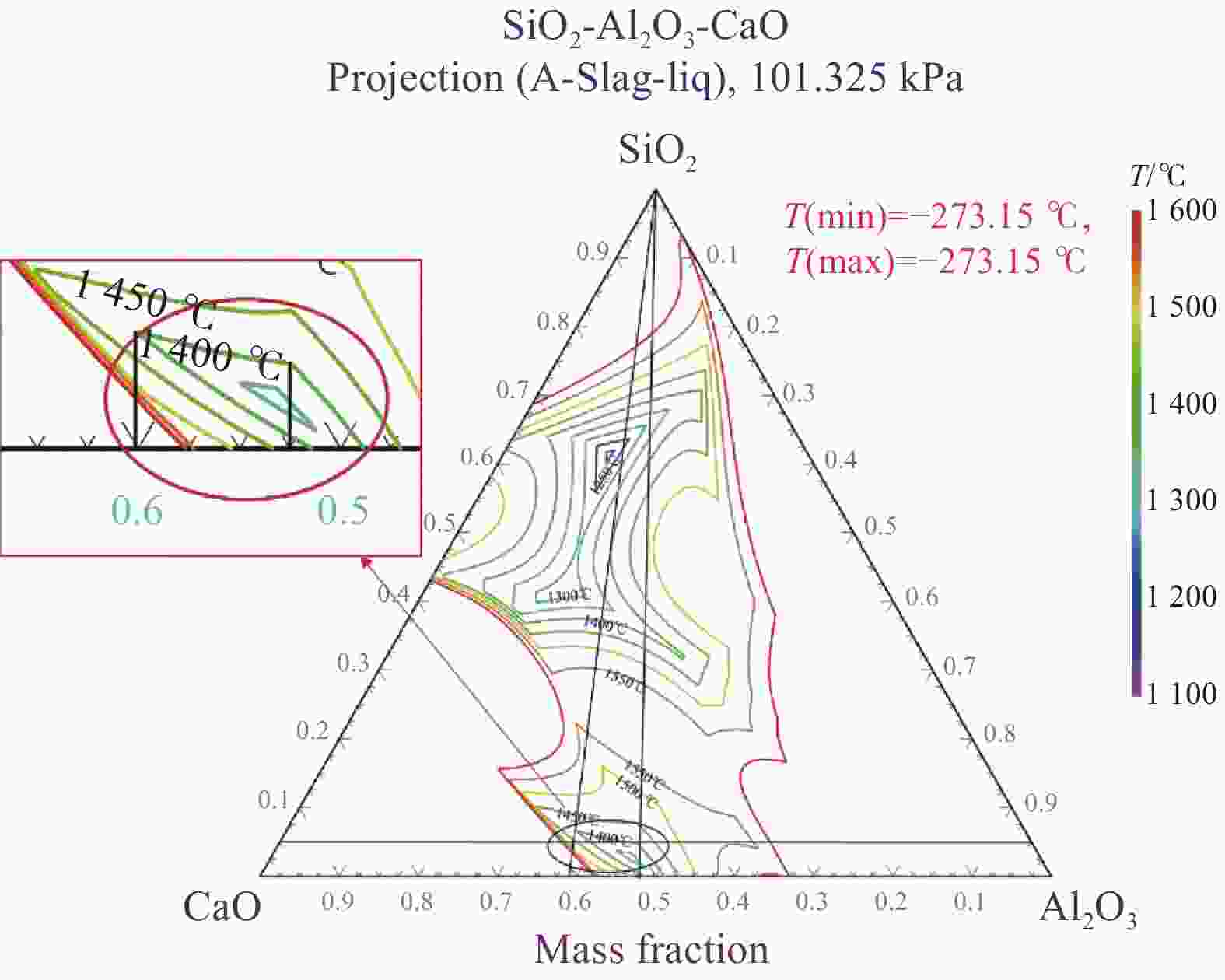

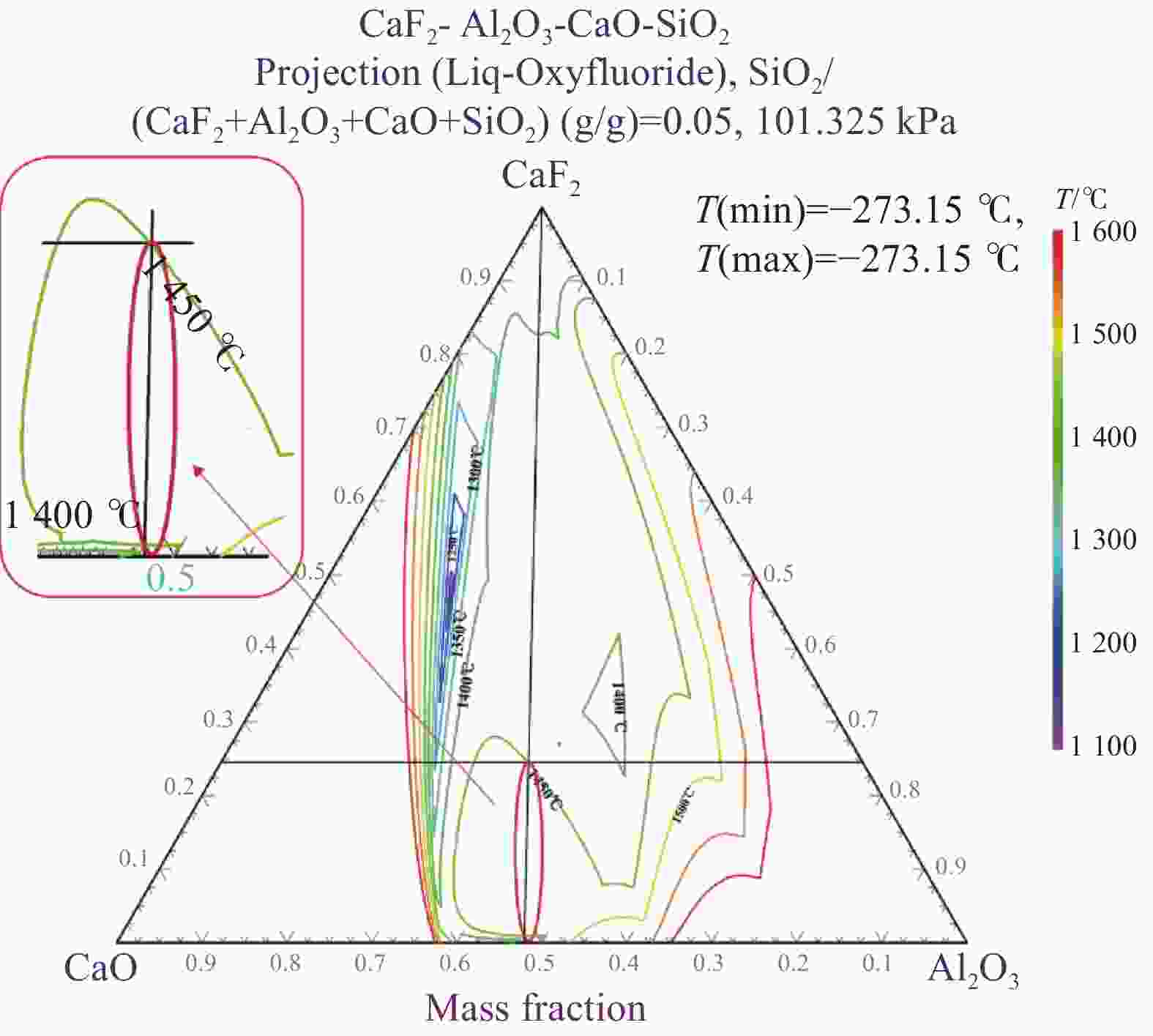

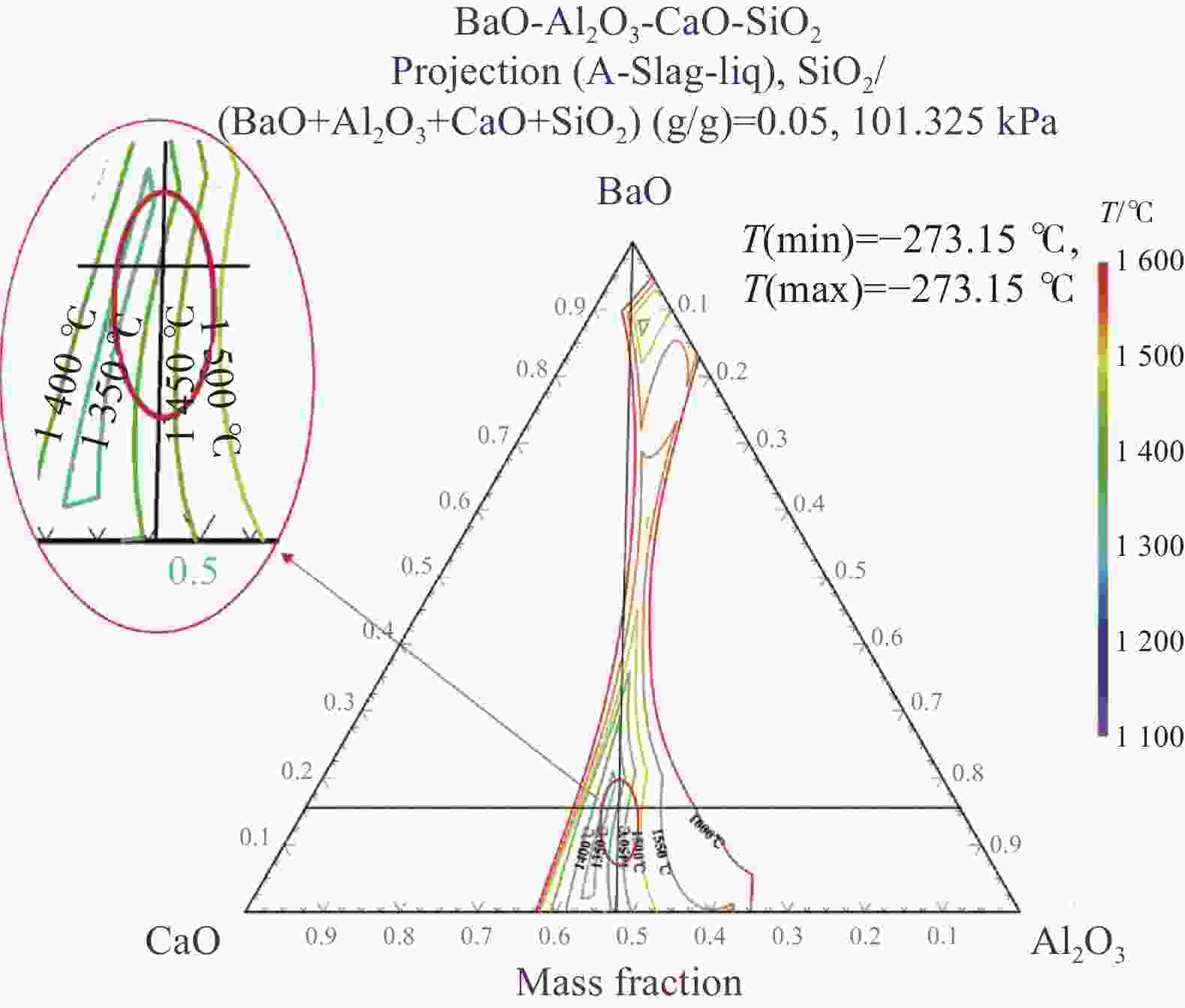

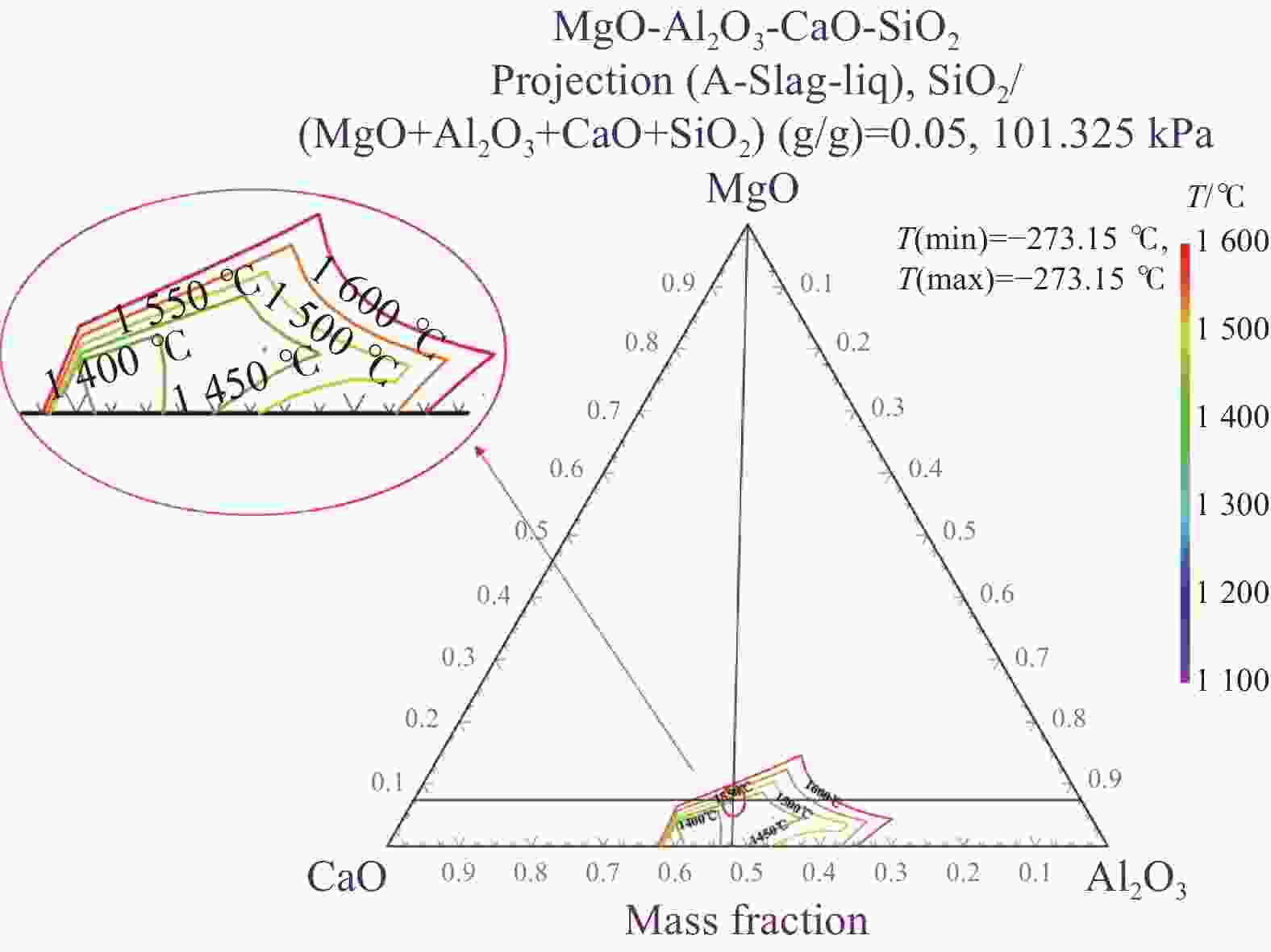

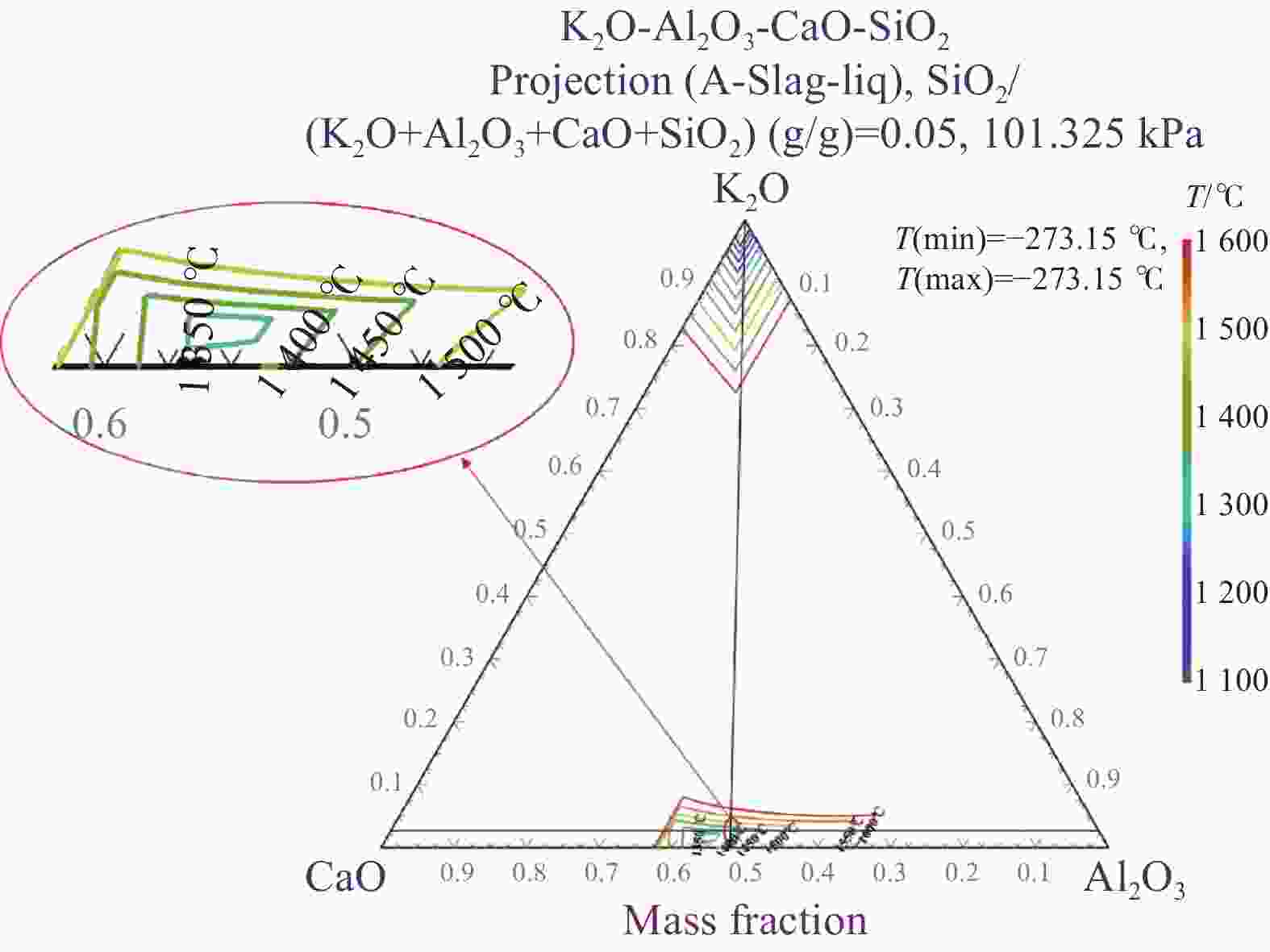

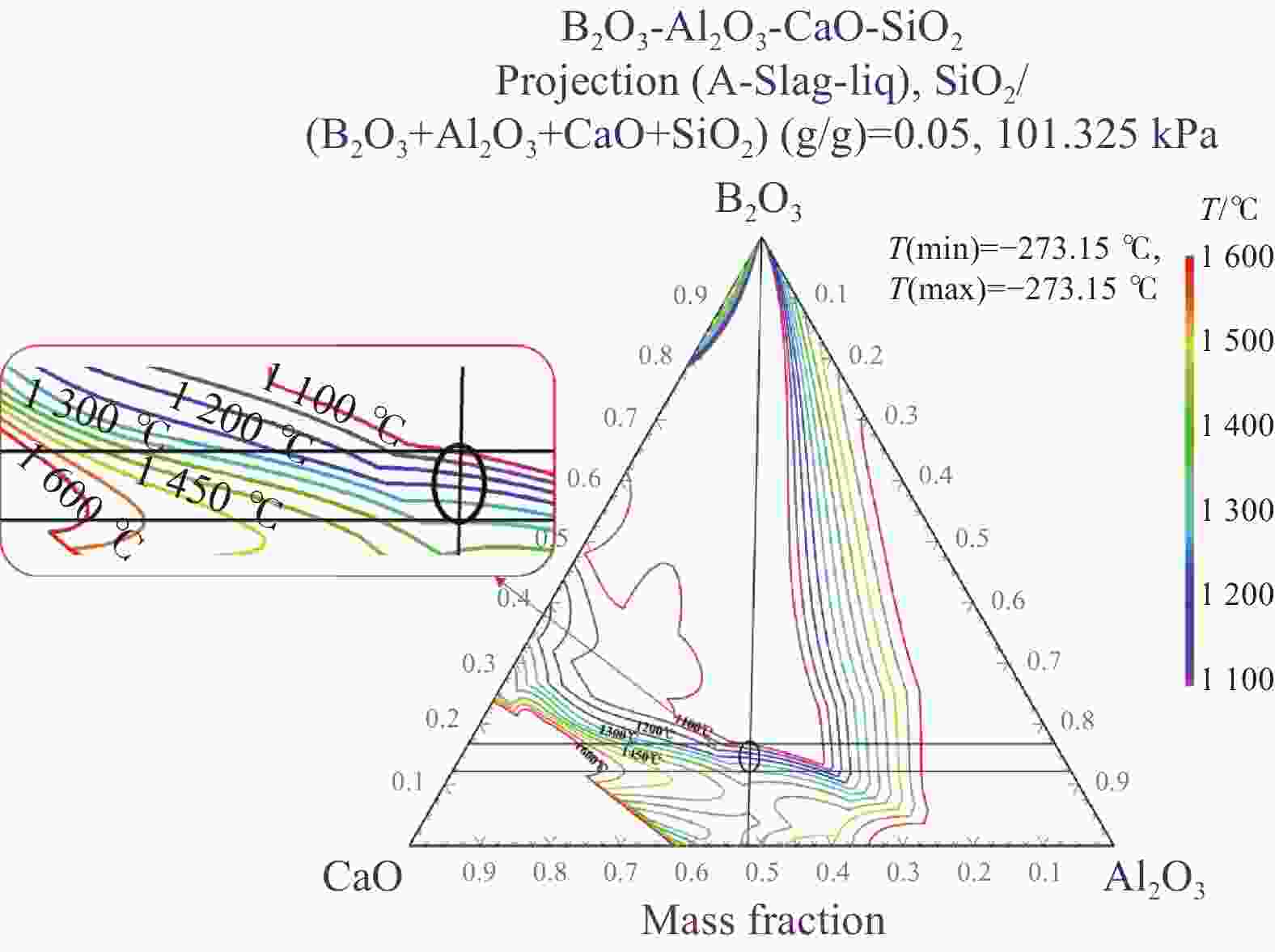

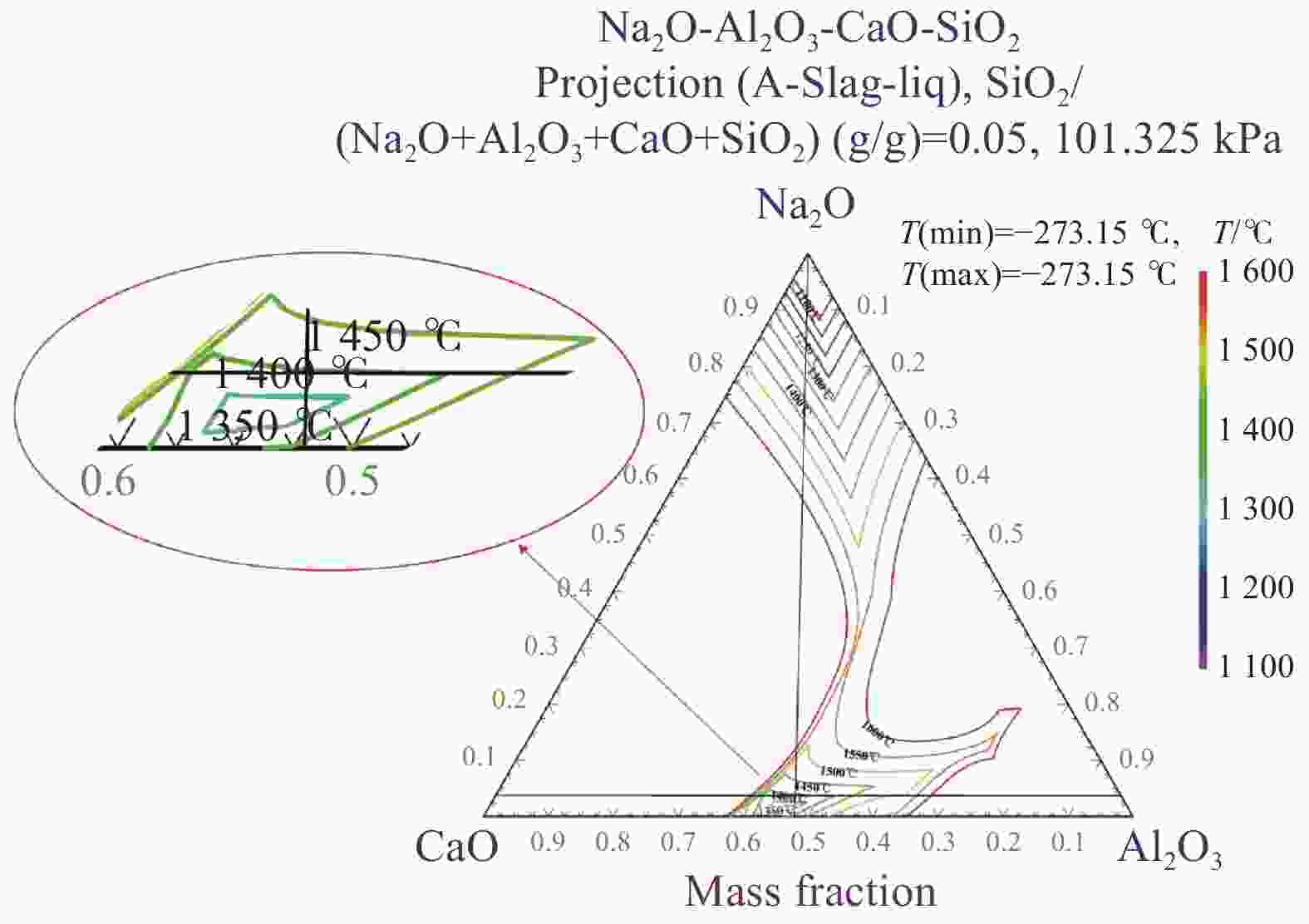

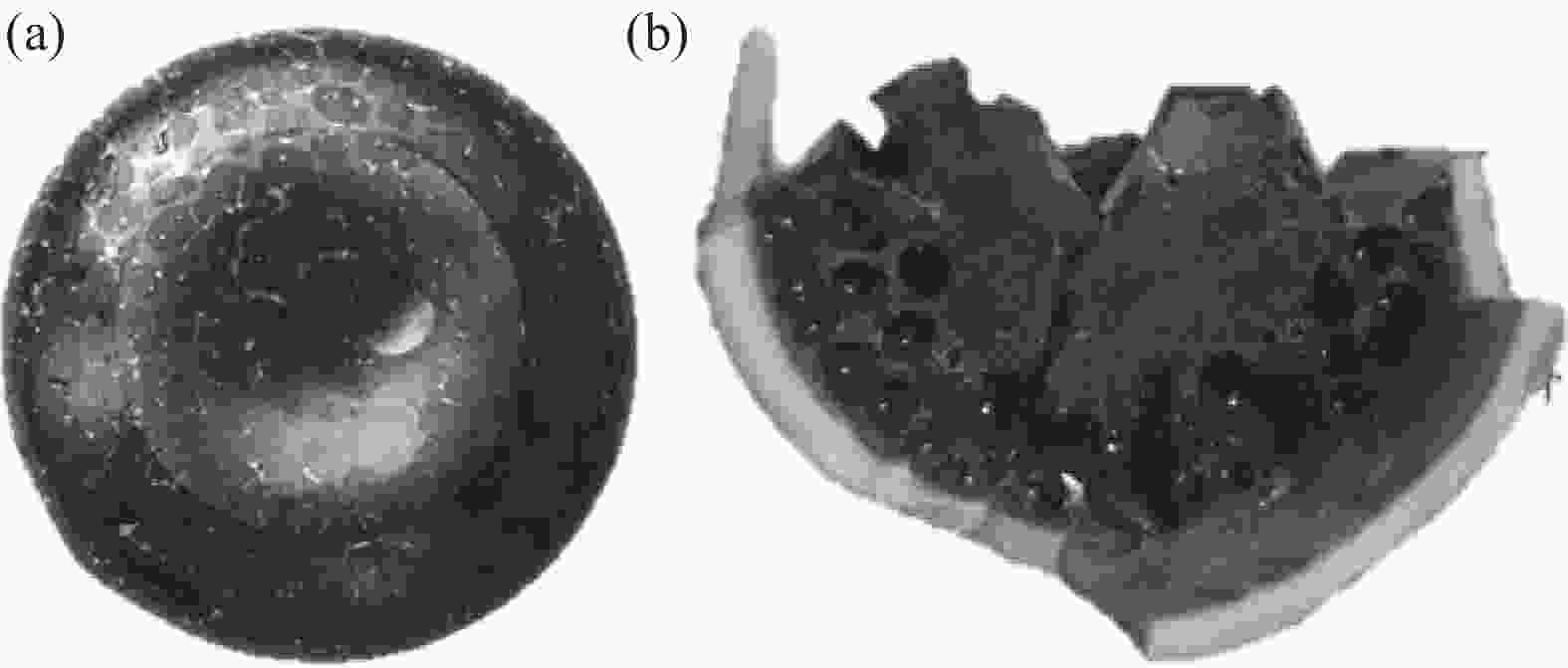

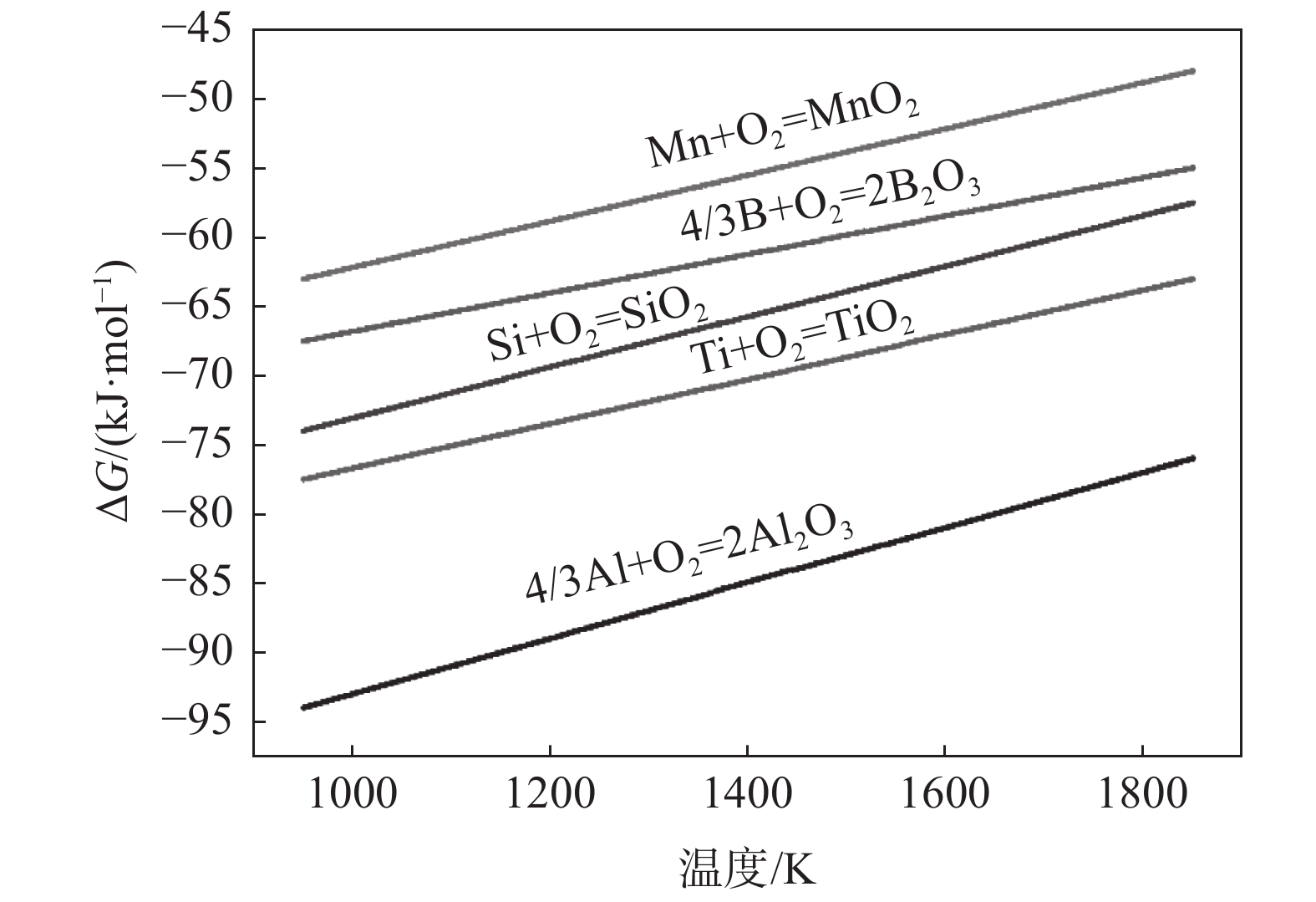

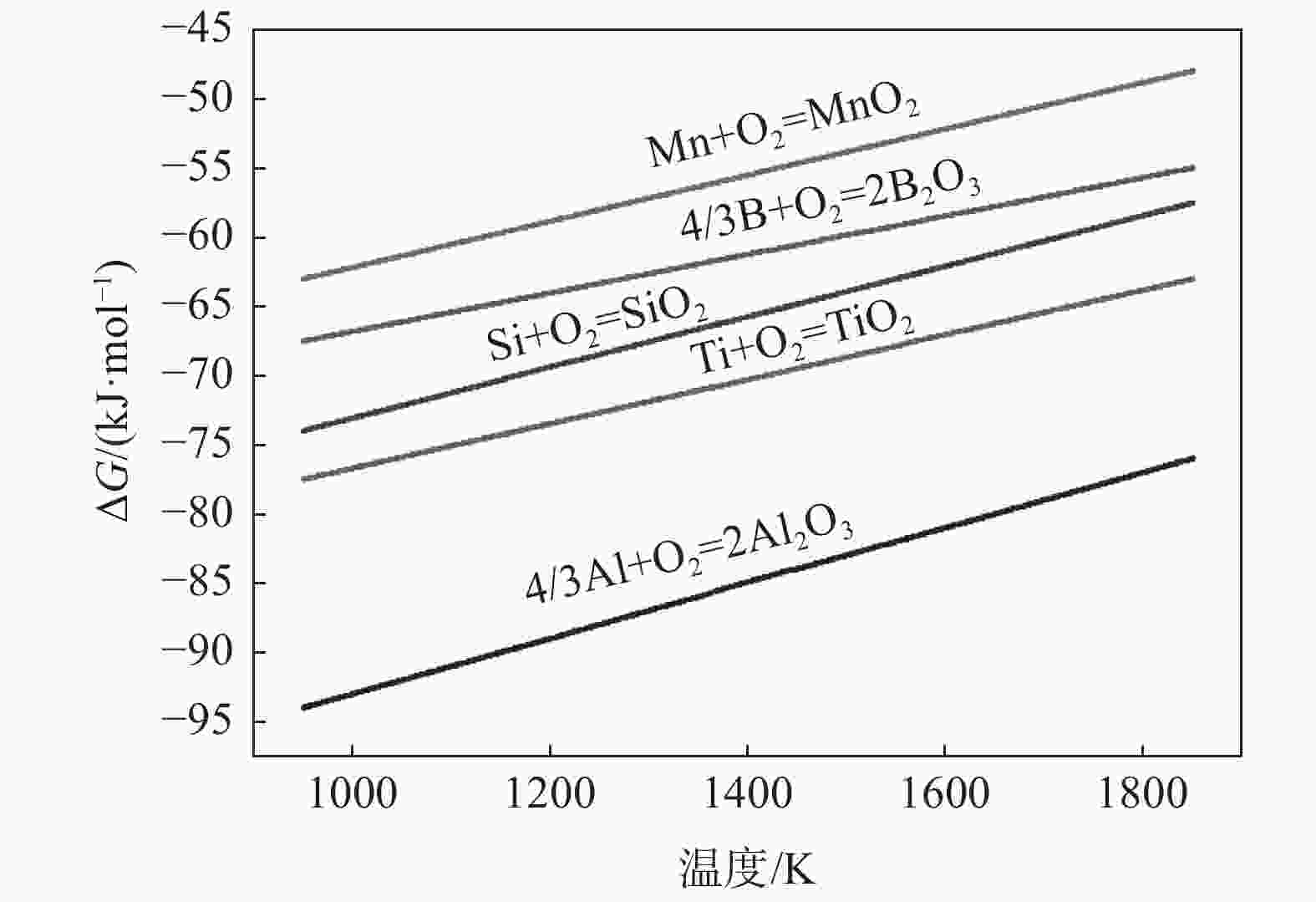

摘要: 高钛钢连铸过程采用传统的CaO-SiO2-Al2O3连铸保护渣会发生剧烈的钢渣界面反应,影响连铸顺行。为减弱钢渣界面反应,设计了高钛钢低反应性连铸保护渣,通过钢渣界面热力学计算,确定CaO-Al2O3基保护渣的可行性,使用Factsage热力学软件计算低反应性保护渣成分范围,对拟定的三组保护渣采用旋转黏度测试仪和全自动炉渣熔点熔速测定仪测量其黏度和熔点,并对新开发的适合连铸生产的保护渣采用VSgr-60-2000型真空气氛压力烧结炉进行钢渣界面反应试验。结果表明,开发的高钛钢专用CaO-Al2O3系低反应性保护渣渣中CaO/Al2O3为1.1,配加10%CaF2、7%MgO、5%Na2O、3%K2O、13%B2O3以及5%SiO2,黏度为0.413 Pa·s,熔点为1106 ℃,钢渣界面反应试验后,钢中Ti含量降低0.03个百分点,保护渣中TiO2含量增加0.002个百分点,界面反应微弱。新开发的保护渣极大程度抑制了钢渣界面反应的进行。Abstract: In the continuous casting process of high-titanium steel, the traditional CaO-SiO2-Al2O3 mold slag will produce a violent steel/slag interface reaction, which will affect the continuous casting process stability. In order to weaken the interface reaction of steel/slag, a low reactivity mold flux for casting high titanium steel had been designed and the feasibility of CaO-Al2O3 based mold flux had been determined through the thermodynamic calculation of the steel slag interface by using Factsage thermodynamic software to calculate the composition range of the low reactivity mold flux. The viscosity and melting point of the three groups of mold slag were measured by rotary viscosity tester and automatic slag melting point and melting rate tester, and the newly developed mold slag suitable for continuous casting production was tested by VSgr-60-2000 vacuum atmosphere pressure sintering furnace. The CaO/Al2O3 in newly developed mold flux at 1.1, with addition of 10%CaF2, 7%MgO, 5%Na2O, 3%K2O, 13%B2O3 and 5%SiO2, its viscosity measured by viscometer is 0.413 Pa·s, and the melting point is 1106 ℃. After the steel/slag interface reaction test, the Ti content in the steel decreases by 0.03%, and the TiO2 content in the mold slag increases by 0.002%, and the interface reaction is weak. The newly developed mold slag can extremely suppress the progress of the interfacial reaction of steel/slag.

-

表 1 高钛钢专用保护渣成分可选取范围

Table 1. The selectable composition range of special mold flux for high titanium steel

CaO/Al2O3 w/% SiO2 MgO Na2O CaF2 B2O3 K2O BaO 1.1 5 0~7 0~5 0~25 12~17 0~3 0~16 表 2 保护渣的拟定成分

Table 2. The composition designs of mold flux

% 编号 CaO Al2O3 SiO2 MgO Na2O CaF2 B2O3 K2O BaO N0 21 20 5 7 5 10 13 3 16 N1 31 28 5 7 2 5 13 1 8 N2 20 18 5 4 2 18 17 1 16 表 3 保护渣熔点、黏度测试结果

Table 3. Mold melting point and viscosity test results

编号 熔点/℃ 黏度/(Pa·s) 试验值 平均 试验值 平均 N0 1098, 1108, 1112 1106 0.415, 0.410, 0.413 0.413 N1 1207, 1201, 1212 1207 0.605, 0.610, 0.608 0.608 N2 1199, 1187, 1192 1193 0.796, 0.808, 0.803 0.802 表 4 界面反应前后钢种S4的成分分析

Table 4. Composition analysis of S4 steel after interfacial reaction

% C Mn Si Als Cr Ni Mo Ti 反应前 0.11 2.62 1.60 1.23 0.41 1.43 0.34 2.02 反应后 0.11 2.54 1.58 1.01 0.40 1.36 0.34 1.99 表 5 界面反应前后N0保护渣的成分分析

Table 5. Composition analysis of N0 mold flux after interface reaction

% 编号 CaO Al2O3 SiO2 MgO Na2O CaF2 B2O3 K2O TiO2 BaO N0 21 20 5 7 5 10 13 3 — 16 反应后 19.87 21.3 4.98 6.89 4.16 — 15.68 10.25 0.002 15.58 -

[1] Mudali U K, Dayal R K, Gnanamoorthy J B. Corrosion studies on materials of construction for spent nuclear fuel reprocessing plant equipment[J]. Journal of Nuclear Materials, 1993,203(1):73−82. doi: 10.1016/0022-3115(93)90432-X [2] Zha Yongjin, Hu Shijie, Zhuo Lubin, et al. Research on the application prospect of titanium alloy oil pipe[J]. Drilling and Production Technology, 2017,40(4):1−3. (查永进, 胡世杰, 卓鲁斌, 等. 钛合金石油管材应用前景研究[J]. 钻采工艺, 2017,40(4):1−3. doi: 10.3969/J.ISSN.1006-768X.2017.04.01Zha Yongjin, Hu Shijie, Zhuo Lubin, et al. Research on the application prospect of titanium alloy oil pipe[J]. Drilling and Production Technology, 2017, 40(4): 1-3. doi: 10.3969/J.ISSN.1006-768X.2017.04.01 [3] Pressouyre G M, Bernstein I M. An example of the effect of hydrogen trapping on hydrogen embrittlement[J]. Metallurgical Transactions A, 1981,12(5):835−844. doi: 10.1007/BF02648348 [4] Xie Hui, Zhang Yuqin, Meng Zengdong, et al. Characteristics of β-titanium alloy and its application status and research progress in the field of orthopedics[J]. Orthopaedic Biomechanics Materials and Clinical Study, 2013,10(6):29−32. (谢辉, 张玉勤, 孟增东, 等. β钛合金特性及其在骨科领域的应用现状和研究进展[J]. 生物骨科材料与临床研究, 2013,10(6):29−32. doi: 10.3969/j.issn.1672-5972.2013.06.009Xie Hui, Zhang Yuqin, Meng Zengdong, et al. Characteristics of β-titanium alloy and its application status and research progress in the field of orthopedics[J]. Orthopaedic Biomechanics Materials and Clinical Study, 2013, 10(6): 29-32. doi: 10.3969/j.issn.1672-5972.2013.06.009 [5] Zhu Jiang. Optimization of rolling process of wire rod containing Ti[J]. Bengang Technology, 2015,(2):4. (朱江. 含Ti焊丝盘条轧制工艺的优化[J]. 本钢技术, 2015,(2):4.Zhu Jiang. Optimization of rolling process of wire rod containing Ti[J]. Bengang Technology, 2015(2): 4. [6] Li X, Li F, Cui Y, et al. The effect of manganese content on mechanical properties of high titanium microalloyed steels[J]. Materials Science & Engineering A, 2016,677:340−348. [7] Hao Zhanquan, Chen Weiqing, Carsten L, et al. Effect of titanium oxide on properties of titanium-containing stainless steel continuous casting mold[J]. The Chinese Journal of Process Engineering, 2009,9(3):514−519. (郝占全, 陈伟庆, Carsten L, 等. 氧化钛对含钛不锈钢连铸保护渣性能的影响[J]. 过程工程学报, 2009,9(3):514−519. doi: 10.3321/j.issn:1009-606X.2009.03.017Hao Zhanquan, Chen Weiqing Carsten L, et al. Effect of titanium oxide on properties of titanium-containing stainless steel continuous casting mold[J]. The Chinese Journal of Process Engineering, 2009, 9(3): 514-519. doi: 10.3321/j.issn:1009-606X.2009.03.017 [8] Jin Hebin, Ji Junde, Wang Shisong, et al. Influence of steel slag reaction on physicochemical properties of high titanium steel mold slag[J]. Continuous Casting, 2021,(6):59−64. (靳贺斌, 吉俊德, 王时松, 等. 钢渣反应对高钛钢保护渣物化特性的影响[J]. 连铸, 2021,(6):59−64. doi: 10.13228/j.boyuan.issn1005-4006.20210112Jin Hebin, Ji Junde, Wang Shisong, et al. Influence of steel slag reaction on physicochemical properties of high titanium steel mold slag[J]. Continuous Casting, 2021(6): 59-64. doi: 10.13228/j.boyuan.issn1005-4006.20210112 [9] Kenneth B, Yin H B, Skoczylas G, et al. Development and evaluation of silicon-calcium and aluminum-calcium mold powder for high-alumina transformation-induced plasticity steel[J]. World Iron and Steel, 2013,13(3):8−17. (Kenneth B, Yin H B, Skoczylas G, 等. 高铝相变诱发塑性钢用硅钙和铝钙结晶器保护渣的开发评估[J]. 世界钢铁, 2013,13(3):8−17. doi: 10.3969/j.issn.1672-9587.2013.03.002Kenneth B, Yin H B, Skoczylas G, et al. Development and evaluation of silicon-calcium and aluminum-calcium mold powder for high-alumina transformation-induced plasticity steel[J]. World Iron and Steel, 2013, 13(3): 8-17. doi: 10.3969/j.issn.1672-9587.2013.03.002 [10] Chen Zhuo, Zheng Ruiqi, Wang Qian. Effect of titanium inclusions on performance of mold flux during continuous casting of Ti-bearing steel[J]. Continuous Casting, 2021,(2):33−37. (陈卓, 郑睿琦, 王谦. 含钛夹杂物对连铸保护渣性能的影响[J]. 连铸, 2021,(2):33−37. doi: 10.13228/j.boyuan.issn1005-4006.20200144Chen Zhuo, Zhen Ruiqi, Wang Qian. Effect of titanium inclusions on performance of mold flux during continuous casting of Ti-bearing steel[J]. Continuous Casting, 2021(2): 33-37. doi: 10.13228/j.boyuan.issn1005-4006.20200144 [11] Wang Wei, Qi Jie, Zhai Jun, et al. Effect of property evolution of mold slag on slab quality during continuous casting of titanium-containing ferritic stainless steel[J]. Steelmaking, 2021,37(5):76−79,84. (王伟, 亓捷, 翟俊, 等. 含钛铁素体不锈钢连铸过程保护渣性能演变对铸坯质量的影响[J]. 炼钢, 2021,37(5):76−79,84.Wang Wei, Qi Jie, Zhai Jun, et al. Effect of property evolution of mold slag on slab quality during continuous casting of titanium-containing ferritic stainless steel[J]. Steelmaking, 2021, 37(5): 76-79, 84. [12] 王珍, 束奇峰, 周国治. TiO2替代含钛不锈钢保护渣中SiO2对渣系结晶性能的影响[C]//2012年全国冶金物理化学学术会议专辑(下册). 昆明: 中国有色金属学会, 2012: 208-214.Wang Zhen, Su Qifeng, Zhou Guozhi. Effect of TiO2 substituting SiO2 in titanium-containing stainless steel molding slag on crystallization properties of slag[C]//2012 National Metallurgical Physical Chemistry Academic Conference Album (Volume 2). Kunming: The Nonferrous Metals Society of China, 2012: 208-214. [13] Liu Liang, Zhang Jiongming, Wang Wei. Analysis of factors affecting the change of titanium content in refining and continuous casting of titanium-containing stainless steel[J]. Foundry Technology, 2016,(10):2169−2172. (刘亮, 张炯明, 王伟. 含钛不锈钢精炼连铸中钛含量变化影响因素分析[J]. 铸造技术, 2016,(10):2169−2172. doi: 10.16410/j.issn1000-8365.2016.10.032Liu Liang, Zhang Jiongming, Wang Wei. Analysis of factors affecting the change of titanium content in refining and continuous casting of titanium-containing stainless steel[J]. Foundry Technology, 2016(10): 2169-2172. doi: 10.16410/j.issn1000-8365.2016.10.032 [14] 陈涛. 钛微合金化焊接用钢质量控制研究[D]. 北京: 北京科技大学, 2017.Chen Tao. Research on quality control of titanium microalloyed welding steel[D]. Beijing: University of Science and Technology Beijing, 2017. [15] Kim W Y, Jo J O, Lee C O, et al. Thermodynamic relation between aluminum and titanium in liquid iron[J]. ISIJ International, 2008,48(1):17−22. doi: 10.2355/isijinternational.48.17 [16] Chen Z, Xu K P, He S P, et al. Thermodynamic calculation on the reactivity between slag and Ti-stabilized stainless steel[C]//8th International Symposium on High-temperature Metallurgical Processing. United states: 2017: 169–176. [17] Pan Weijie, Li Min, Zhu Lilong, et al. Effect of Na2O on properties of ultra-basicity continuous casting molding powder[J]. Iron and Steel, 2022,57(1):93−101. (潘伟杰, 李民, 朱礼龙, 等. Na2O对超高碱度连铸保护渣性能的影响[J]. 钢铁, 2022,57(1):93−101.Pan Weijie, Li Min, Zhu Lilong, et al. Effect of Na2O on properties of ultra-basicity continuous casting molding powder[J]. Iron and Steel, 2022, 57(1): 93-101. [18] Zhu Liguang, Zhang Xiaoshi, Wang Xingjuan, et al. Analysis of melting characteristics of special mold flux based on CaO-Al2O3 for high titanium welding wire steel[J]. China Metallurgy, 2020,30(10):9−16. (朱立光, 张晓仕, 王杏娟, 等. 高钛焊丝钢CaO-Al2O3基专用保护渣熔化特性分析[J]. 中国冶金, 2020,30(10):9−16.Zhu Liguang, Zhang Xiaoshi, Wang Xingjuan, et al. Analysis of melting characteristics of special mold flux based on CaO-Al2O3 for high titanium welding wire steel[J]. China Metallurgy, 2020, 30(10): 9-16. [19] Liu Ke, Han Yihua, Yang Fan, et al. Effect of MgO on microstructure of CaO-Al2O3-based quaternary molding slag[J]. Iron and Steel, 2020,55(5):52−58. (刘克, 韩毅华, 杨帆, 等. MgO对CaO-Al2O3基四元系保护渣熔渣微结构的影响[J]. 钢铁, 2020,55(5):52−58.Liu Ke, Han Yihua, Yang Fan, et al. Effect of MgO on microstructure of CaO-Al2O3-based quaternary molding slag [J]. Iron and Steel, 2020, 55(5): 52-58. [20] Wang Xingjuan, Jin Hebin, Zhu Liguang, et al. Influence of B2O3 on properties and structure of CaO-Al2O3-SiO2-based continuous casting molding flux[J]. Materials Review, 2019,33(8):1395−1400. (王杏娟, 靳贺斌, 朱立光, 等. B2O3对CaO-Al2O3-SiO2基连铸保护渣性能及结构的影响[J]. 材料导报, 2019,33(8):1395−1400. doi: 10.11896/cldb.19010018Wang Xinjuan, Jin Hebin, Zhu Liguang, et al. Influence of B2O3 on properties and structure of CaO-Al2O3-SiO2-based continuous casting molding flux[J]. Materials Review, 2019, 33(8): 1395-1400. doi: 10.11896/cldb.19010018 [21] 西峡龙成冶金材料有限公司. 含钛板坯不锈钢专用连铸结晶器保护渣及其生产工艺: 中国, CN200710193114.2[P]. 2008-07-16.Xixia Longcheng Metallurgical Materials Co. , Ltd. . Continuous casting mold powder for stainless steel slab containing titanium and its production process: China, CN200710193114.2[P]. 2008-07-16. -

下载:

下载: