Study on hydrogen embrittlement resistance of Ti-microalloying hot forming steel for automobile

-

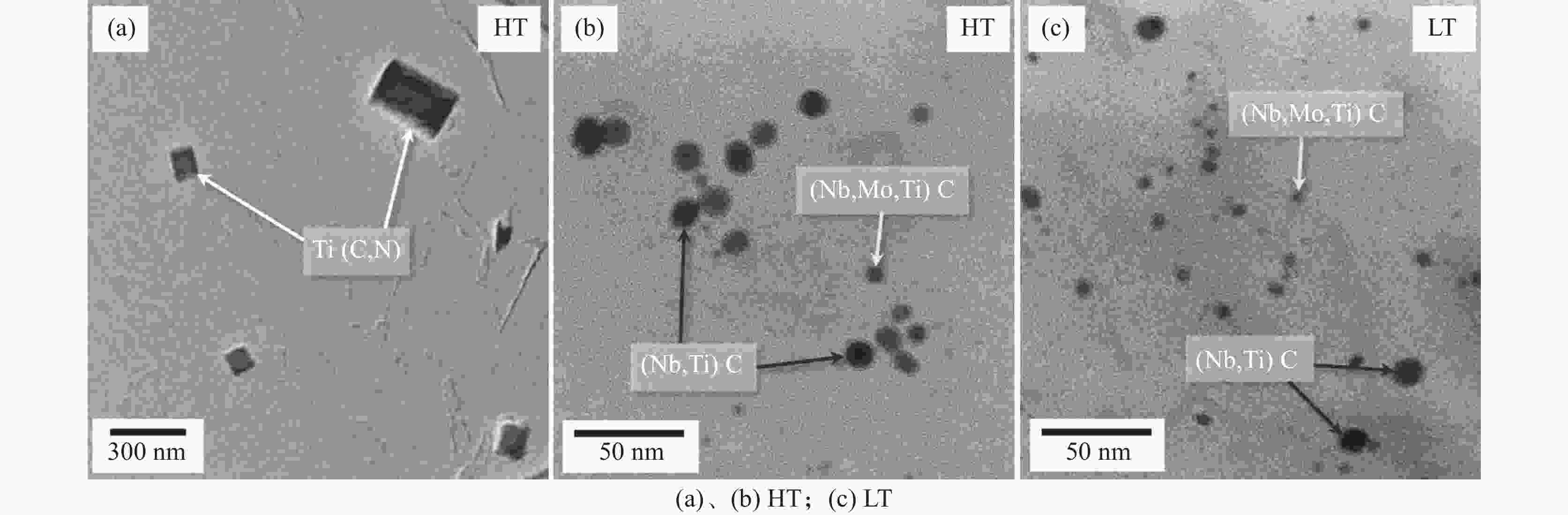

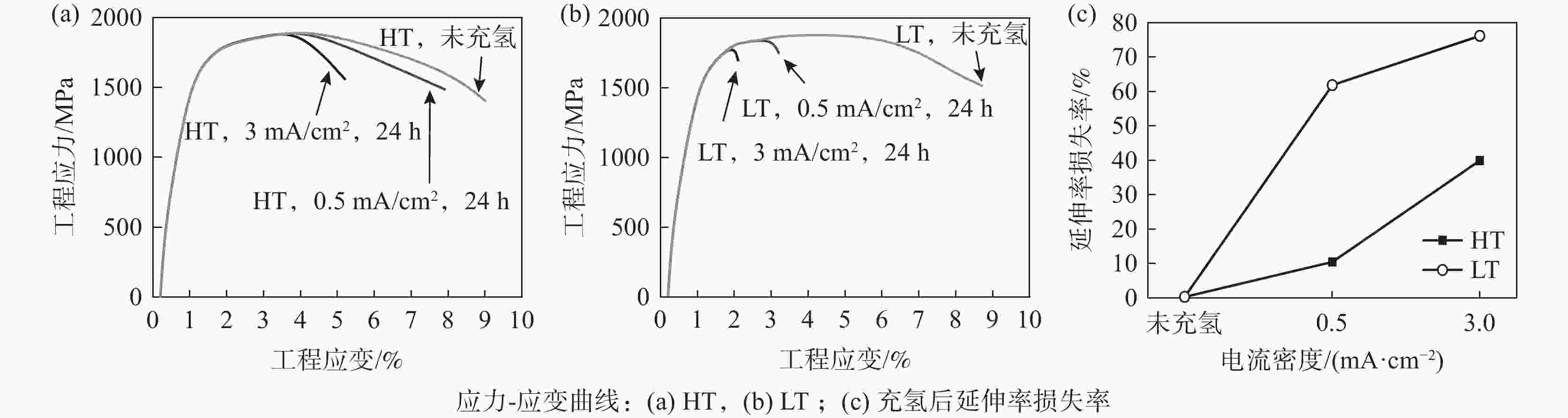

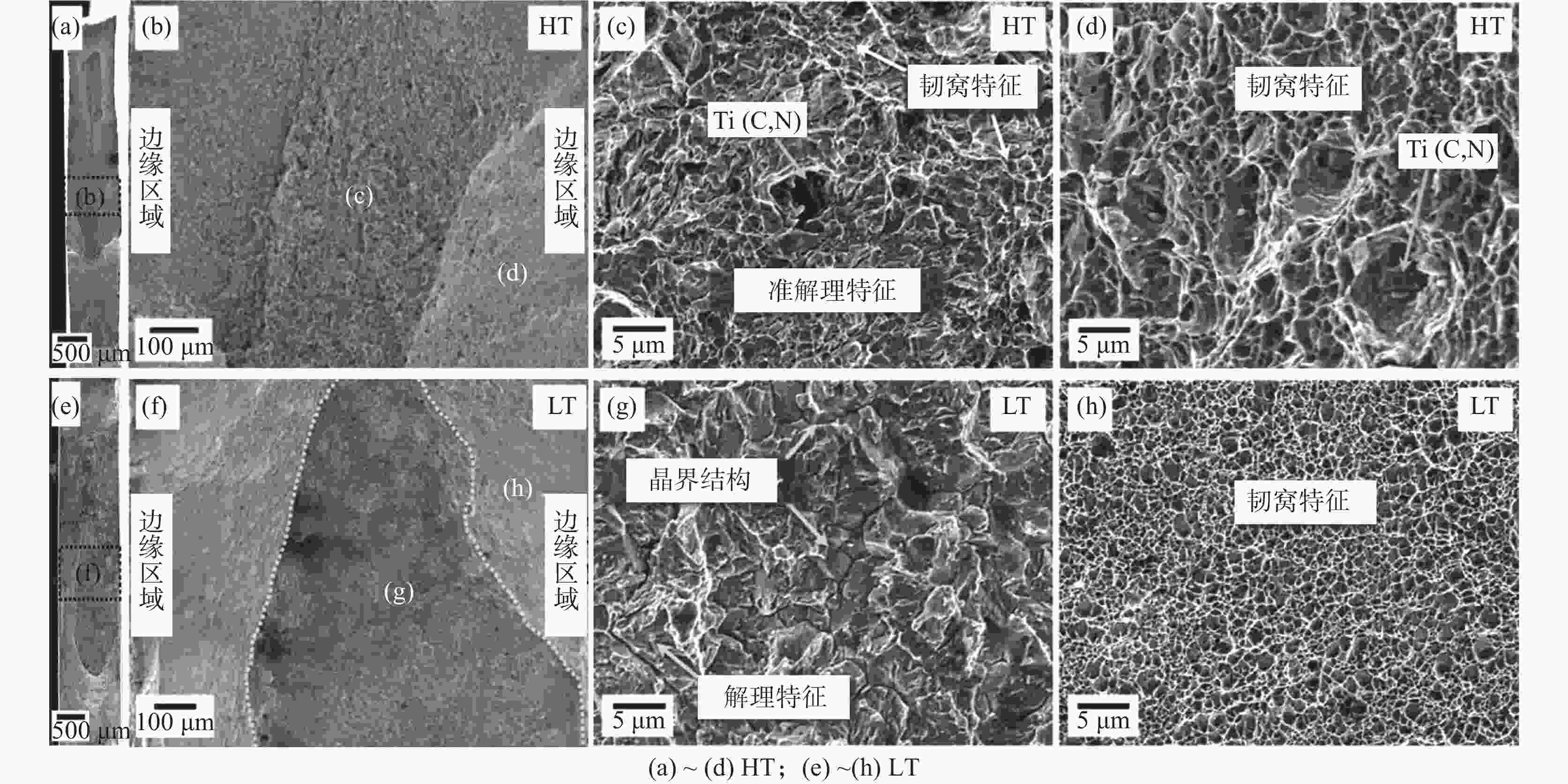

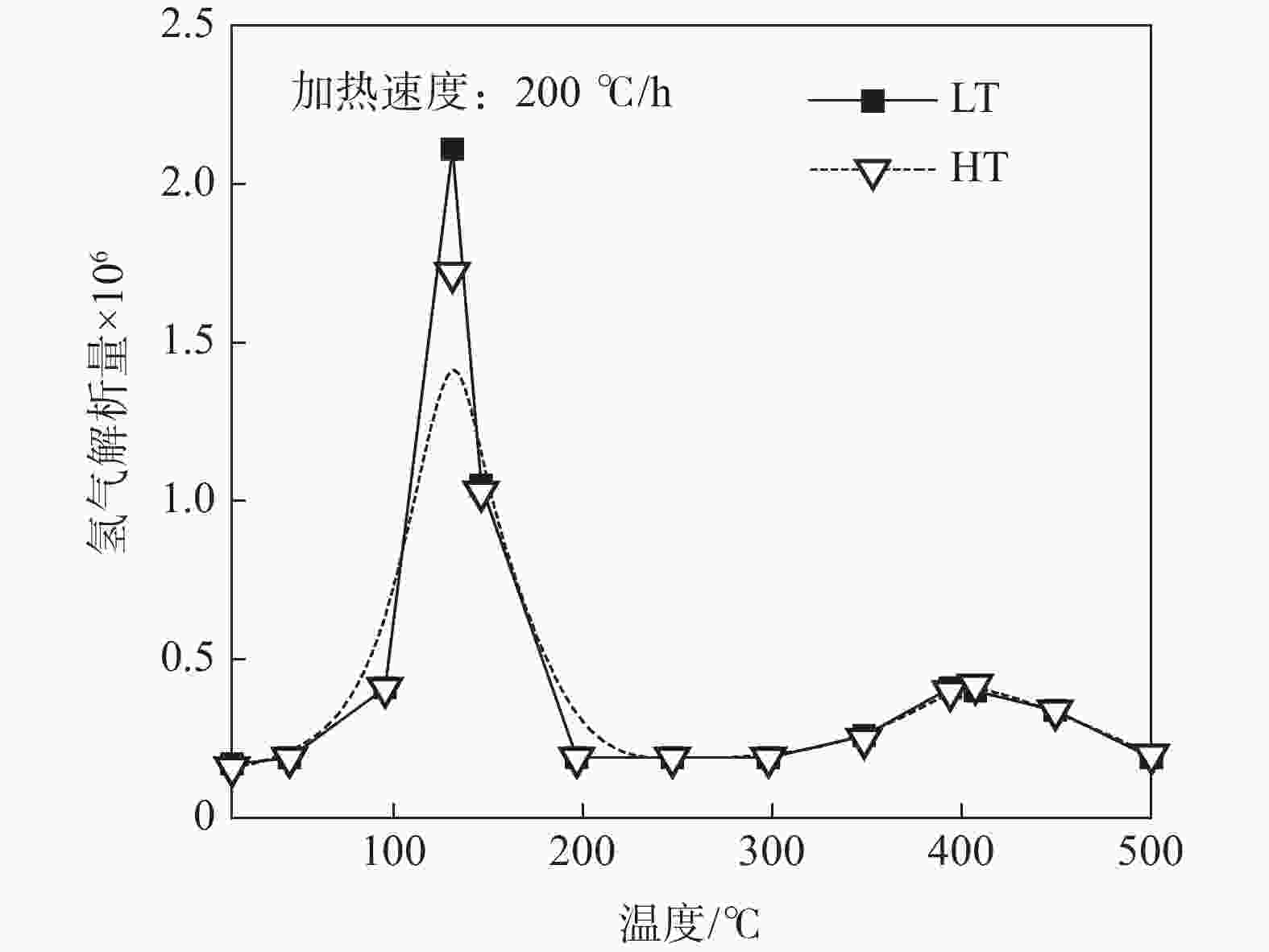

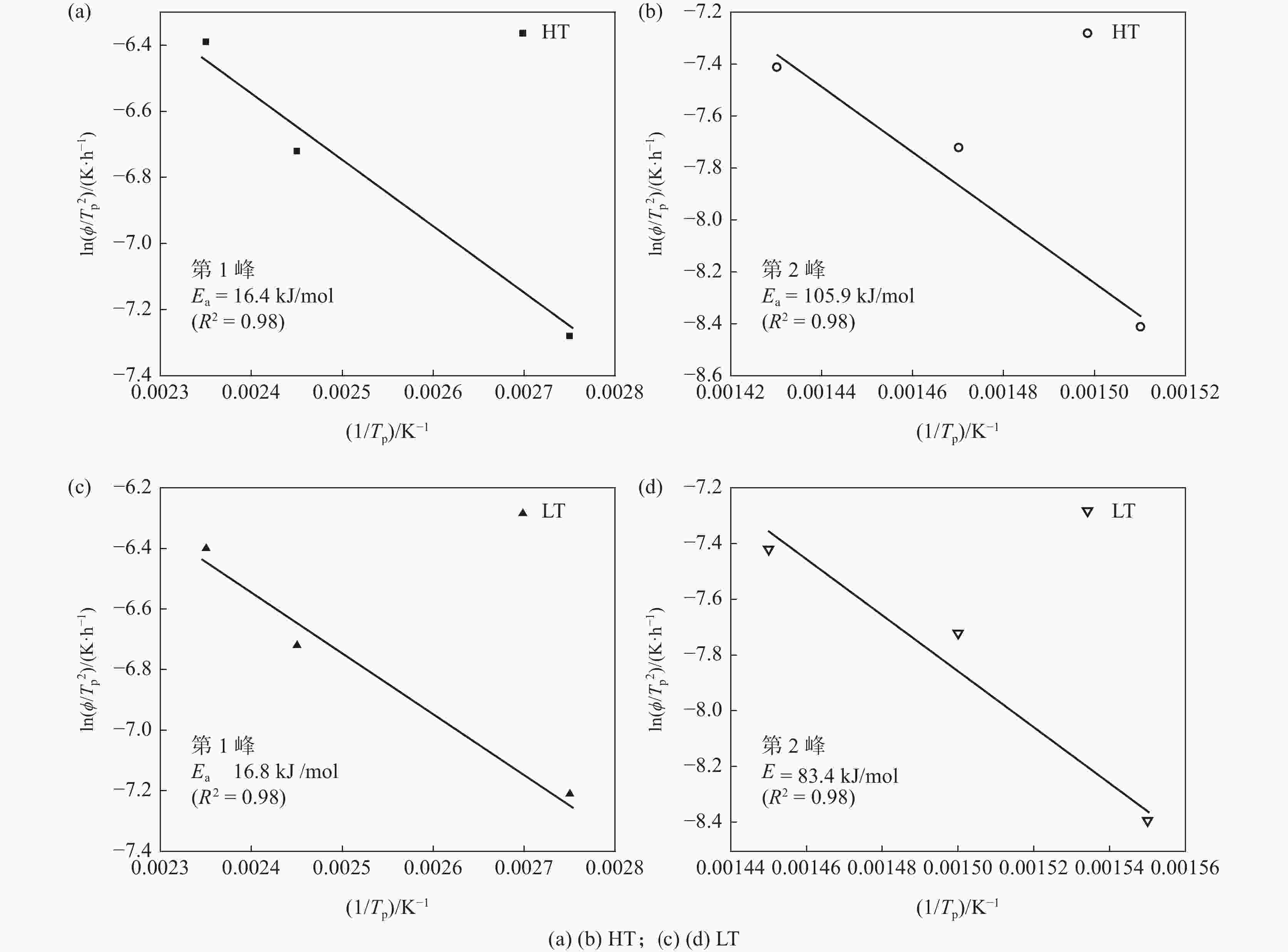

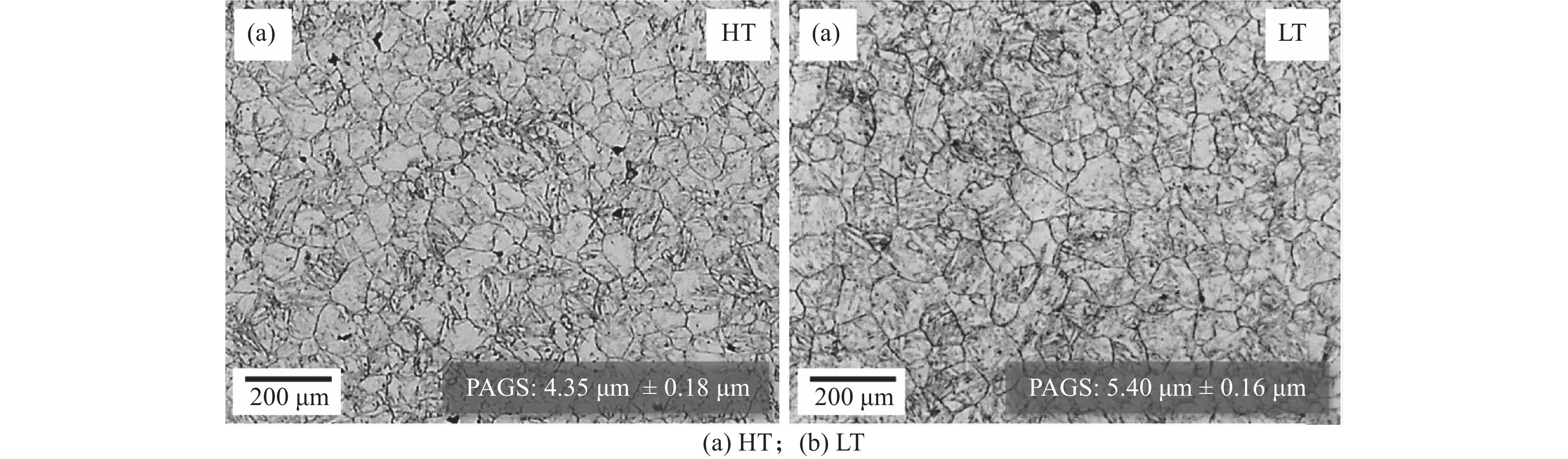

摘要: 利用充氢拉伸及氢解吸试验手段对比研究了两种钛含量汽车用含Nb-Mo热成型钢的抗氢脆敏感性。试验结果表明:随着Nb-Mo热成型钢中的钛含量由0.015%增加至0.03%,其原奥氏体晶粒尺寸由5.40 μm降低至4.35 μm,晶界数量增多;新析出粗大的TiC颗粒,且(Nb,Ti)C、(Nb,Mo,Ti)C颗粒尺寸明显增大。虽然钛含量的增加会导致Nb-Mo热成型钢中析出粗大的Ti(C,N),可促进氢脆断裂行为的发生,但是粗大碳化物颗粒导致材料的氢解吸高温峰对应的氢脱附激活能由83.4 kJ/mol增加至105.9 kJ/mol,对氢原子的不可逆捕获能增加,有效减少了钢中的可扩散氢原子,且奥氏体晶界数量的增加使氢原子分布更为均匀,最终可提升Nb-Mo热成型钢的抗氢脆敏感性。Abstract: The hydrogen embrittlement resistance of two kinds of Nb-Mo hot forming steels with different Ti contents for automobile was studied by slow strain rate tensile test along with hydrogen charging and hydrogen desorption test in this paper. The results show that with increasing titanium content from 0.015% to 0.03%, the original austenite grain size of Nb-Mo hot forming steel decreases from 5.40 μm to 4.35 μm. Besides, the number of grain boundaries increased, and newly precipitated TiC particles are coarse, the size of (Nb, Ti) C, (Nb, Mo, Ti) C particles increases remarkably. The increase of Ti content leads to the precipitation of coarse Ti(C, N) in Nb-Mo hot forming steel, which promotes the occurrence of hydrogen embrittlement fracture. However, the activation energy of hydrogen desorption corresponding to the high temperature peak of hydrogen desorption is increased from 83.4 kJ/mol to 105.9 kJ/mol due to the coarse carbide particles. The energy of capturing irreversible hydrogen atom is increased, which can effectively reduce the amount of diffusible hydrogen atom in the steel. The increasing number of austenite grain boundaries can enable the hydrogen atom distribution more uniform, and finally improves the hydrogen embrittlement resistance of Nb-Mo hot forming steel.

-

Key words:

- hot formed steel /

- hydrogen embrittlement /

- titanium content /

- hydrogen desorption

-

表 1 试验钢的主要化学成分

Table 1. Main chemical compositions of tested steels

% 编号 C Si Mn P S Al Ti Nb Mo HT 0.32 0.48 1.2 <0.10 <0.08 0.045 0.030 0.05 0.1 LT 0.32 0.46 1.2 <0.10 <0.08 0.046 0.015 0.05 0.1 -

[1] Gao Yunkai, Gao Dawei, Yu Haiyan, et al. Hot forming technology of high strength steel for automobile[J]. Automobile Technology, 2010,(8):56−60. (高云凯, 高大威, 余海燕, 等. 汽车用高强度钢热成型技术[J]. 汽车技术, 2010,(8):56−60. doi: 10.3969/j.issn.1000-3703.2010.08.014Gao Yunkai, Gao Dawei, Yu Haiyan, et al. Hot forming technology of high strength steel for automobile[J]. Automobile Technology, 2010 (8): 56-60 doi: 10.3969/j.issn.1000-3703.2010.08.014 [2] Cheng Yajie, Sun Bintang, Liao Qingliang, et al. Effect of starting rolling temperature on hydrogen induced delayed cracking of Nb microalloyed hot forming steel[J]. Journal of Beijing University of Science and Technology, 2016,38(10):1423−1428. (程亚杰, 孙斌堂, 廖庆亮, 等. 开轧温度对铌微合金化热成型钢氢致延迟开裂性能的影响[J]. 北京科技大学学报, 2016,38(10):1423−1428.Cheng Yajie, Sun Bintang, Liao Qingliang, et al. Effect of starting rolling temperature on hydrogen induced delayed cracking of Nb microalloyed hot forming steel[J]. Journal of Beijing University of Science and Technology, 2016, 38 (10): 1423-1428 [3] Chang Kaidi, Gu Jialin, Fang Hongsheng, et al. Hydrogen embrittlement sensitivity of new 1500 MPa high strength steel[J]. Metal Heat Treatment, 2002,27(3):8−11. (常开地, 顾家琳, 方鸿生, 等. 新型1500 MPa级高强钢的氢脆敏感性研究[J]. 金属热处理, 2002,27(3):8−11. doi: 10.3969/j.issn.0254-6051.2002.03.003Chang Kaidi, Gu Jialin, Fang Hongsheng, et al. Hydrogen embrittlement sensitivity of new 1500 MPa high strength steel[J]. Metal Heat Treatment, 2002, 27 (3): 8-11 doi: 10.3969/j.issn.0254-6051.2002.03.003 [4] Zhang S, Huang Y, Sun B, et al. Effect of Nb on hydrogen-induced delayed fracture in high strength hot stamping steels[J]. Mater. Sci. Eng., 2015,626:136−143. doi: 10.1016/j.msea.2014.12.051 [5] Mohrbacher H. Property optimization in as-quenched martensitic steel bymolybdenum and niobium alloying[J]. Metals, 2018,(8):234−255. [6] Takahashi J, Kawakami K, Tarui T. Direct observation of hydrogen trapping sites in vanadium carbide precipitation steel by atom probe tomography[J]. Scripta Mater., 2012,67:213−216. doi: 10.1016/j.scriptamat.2012.04.022 [7] Wei F G, Hara T, Tsuzaki K. Precise determination of the activation energy for desorption of hydrogen in two Ti-added steels by a single thermal-desorption spectrum[J]. Metall. Mater. Trans. B, 2004,35:587−597. doi: 10.1007/s11663-004-0057-x [8] Chen Kang, Xia Bin, Xu Le, et al. Hydrogen embrittlement sensitivity of 2000 MPa martensitic steel[J]. Journal of Material Heat Treatment, 2017,(8):76−82. (谌康, 夏彬, 徐乐, 等. 2000 MPa级马氏体钢的氢脆敏感性[J]. 材料热处理学报, 2017,(8):76−82.Chen Kang, Xia Bin, Xu Le, et al. Hydrogen embrittlement sensitivity of 2000 mPa martensitic steel[J]. Journal of Material Heat Treatment, 2017 (8): 76-82 [9] Wu Guangzong, Wang Maoqiu, Gan Guoyou, et al. Study on hydrogen diffusion in two kinds of martensitic steels by TDS method[J]. Journal of Iron and Steel Research, 2011,(9):42−45. (武光宗, 王毛球, 甘国友, 等. 利用TDS方法研究氢在两种马氏体钢中的扩散[J]. 钢铁研究学报, 2011,(9):42−45.Wu Guangzong, Wang Maoqiu, Gan Guoyou, et al. Study on hydrogen diffusion in two kinds of martensitic steels by TDS method[J]. Journal of Iron and Steel Research, 2011 (9): 42-45 [10] Pan Chuan, Li Zhengbang, Tian Zhiling, et al. Quantitative study on hydrogen embrittlement of stainless steel induced by hydrogen and hydrogen induced martensite[J]. Chinese Science E:Technical Science, 2002,3(3):57−63. (潘川, 李正邦, 田志凌, 等. 氢和氢致马氏体导致不锈钢氢脆的定量研究[J]. 中国科学E辑:技术科学, 2002,3(3):57−63.Pan Chuan, Li Zhengbang, Tian Zhiling, et al. Quantitative study on hydrogen embrittlement of stainless steel induced by hydrogen and hydrogen induced martensite[J]. Chinese Science E: Technical Science, 2002, 3 (3): 57-63 -

下载:

下载: