Analysis on typical rail damage of high speed railway

-

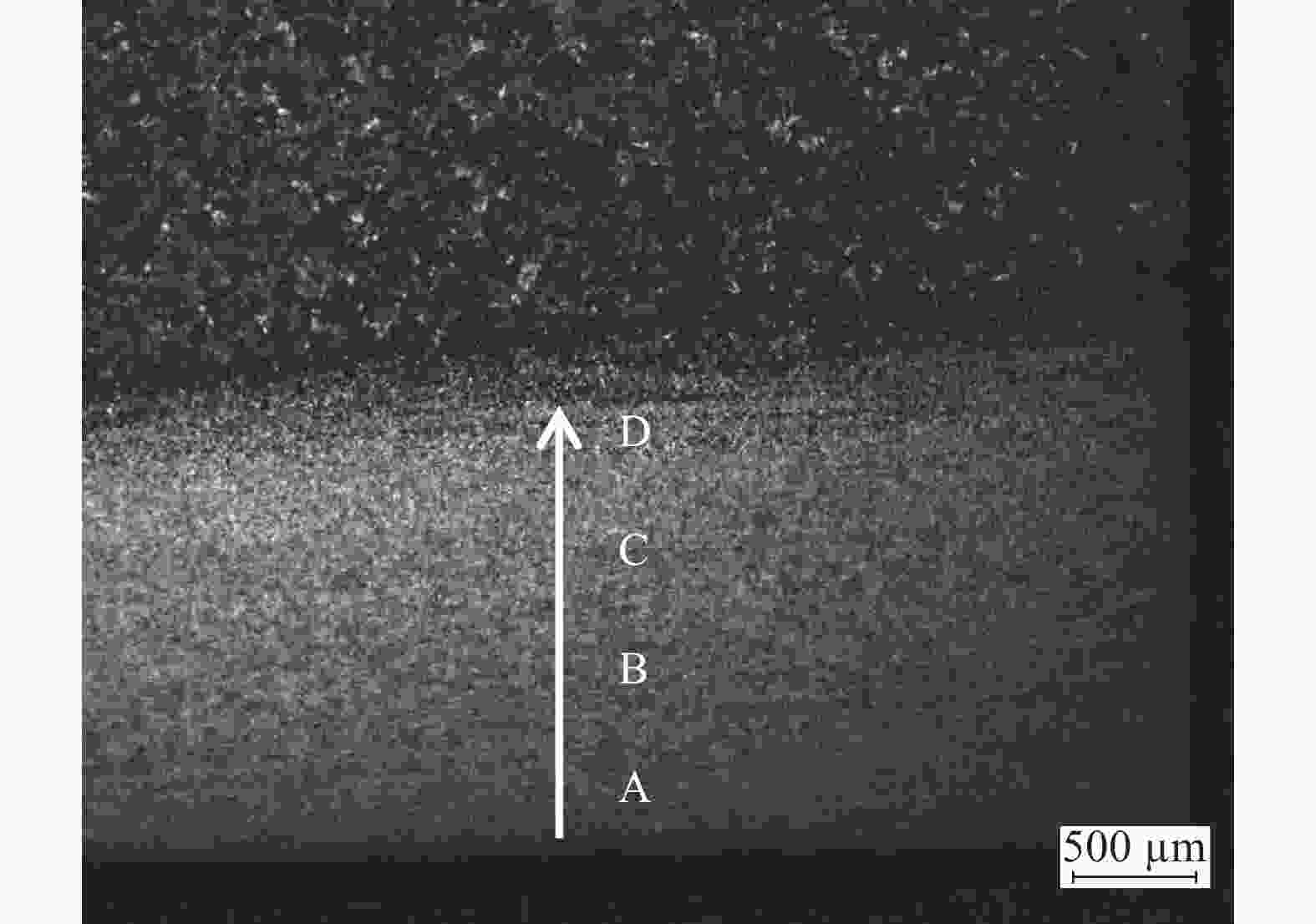

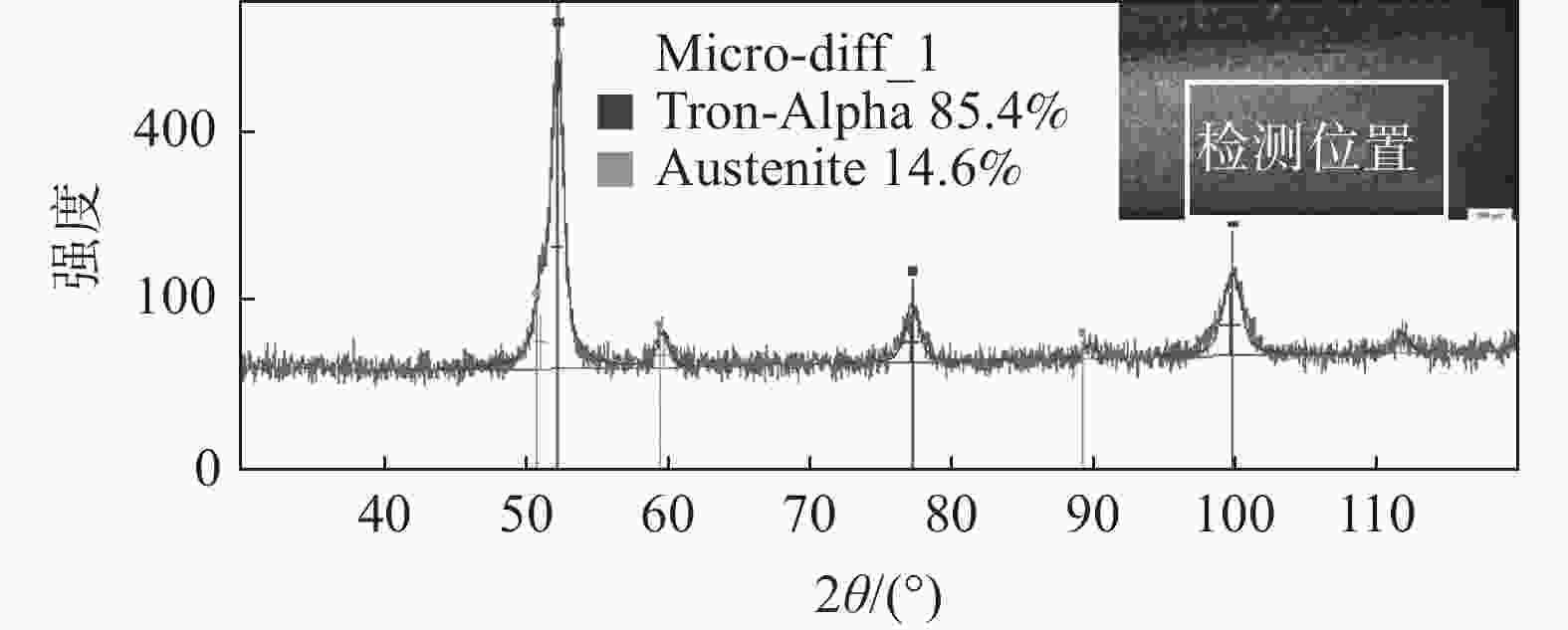

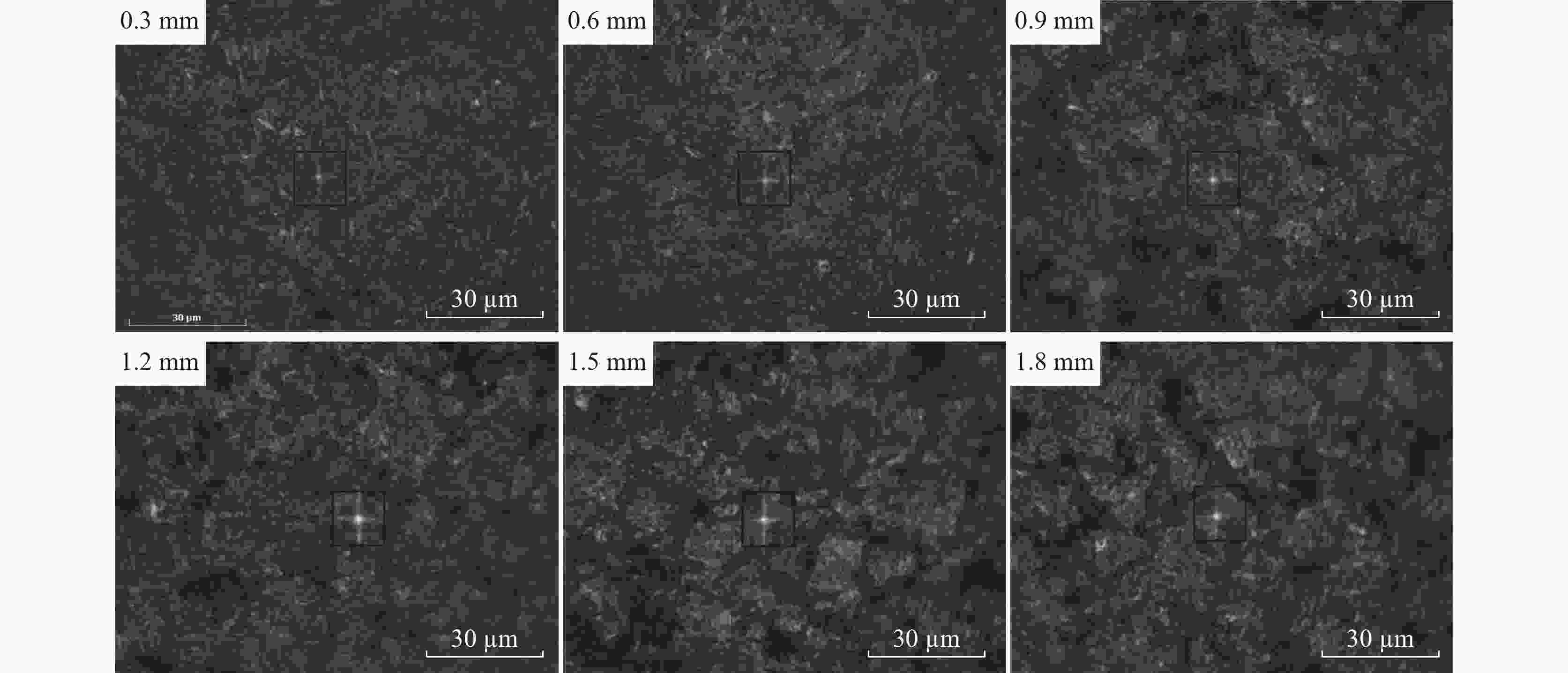

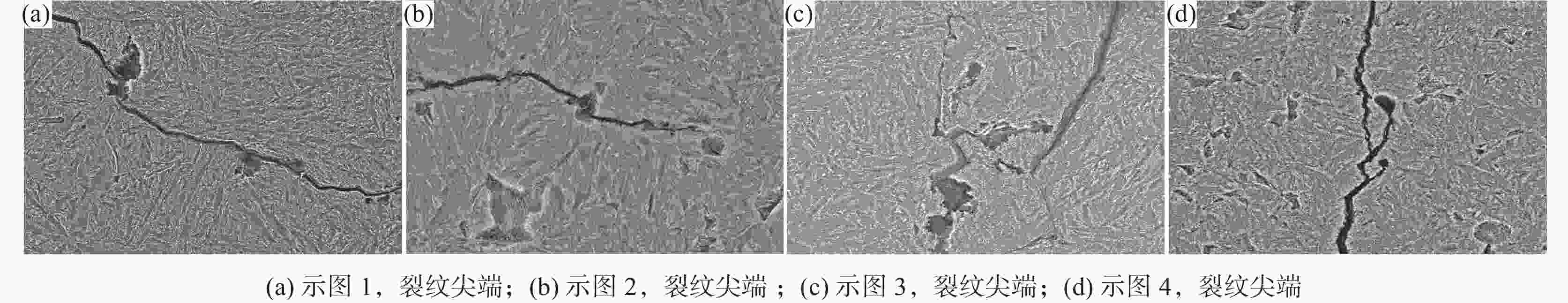

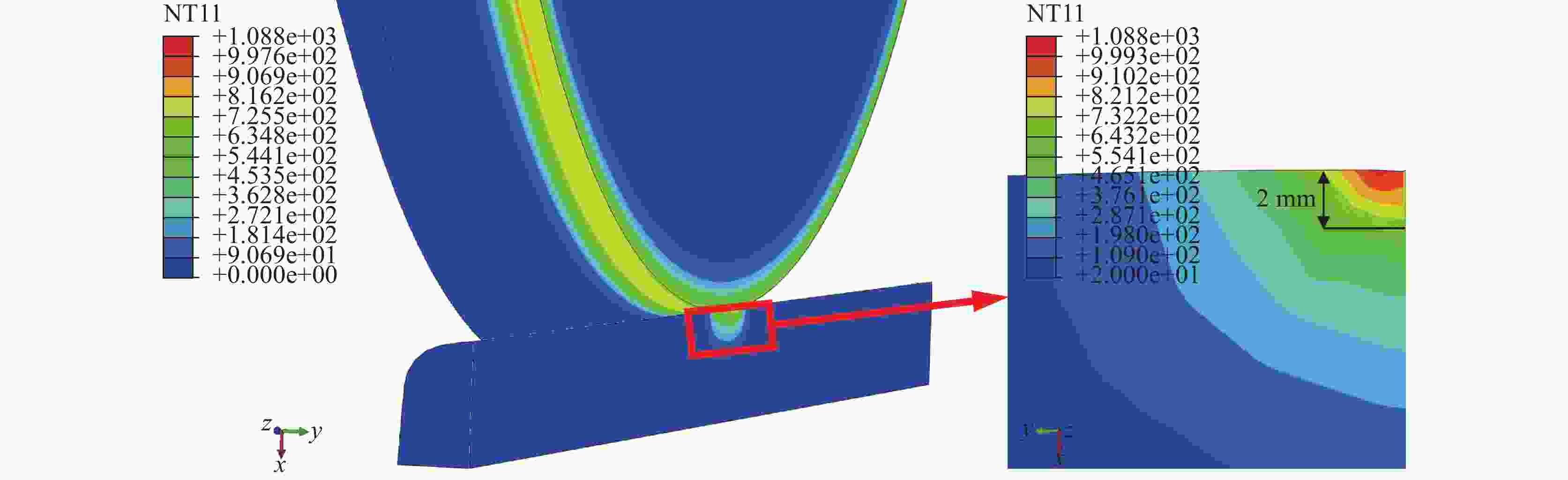

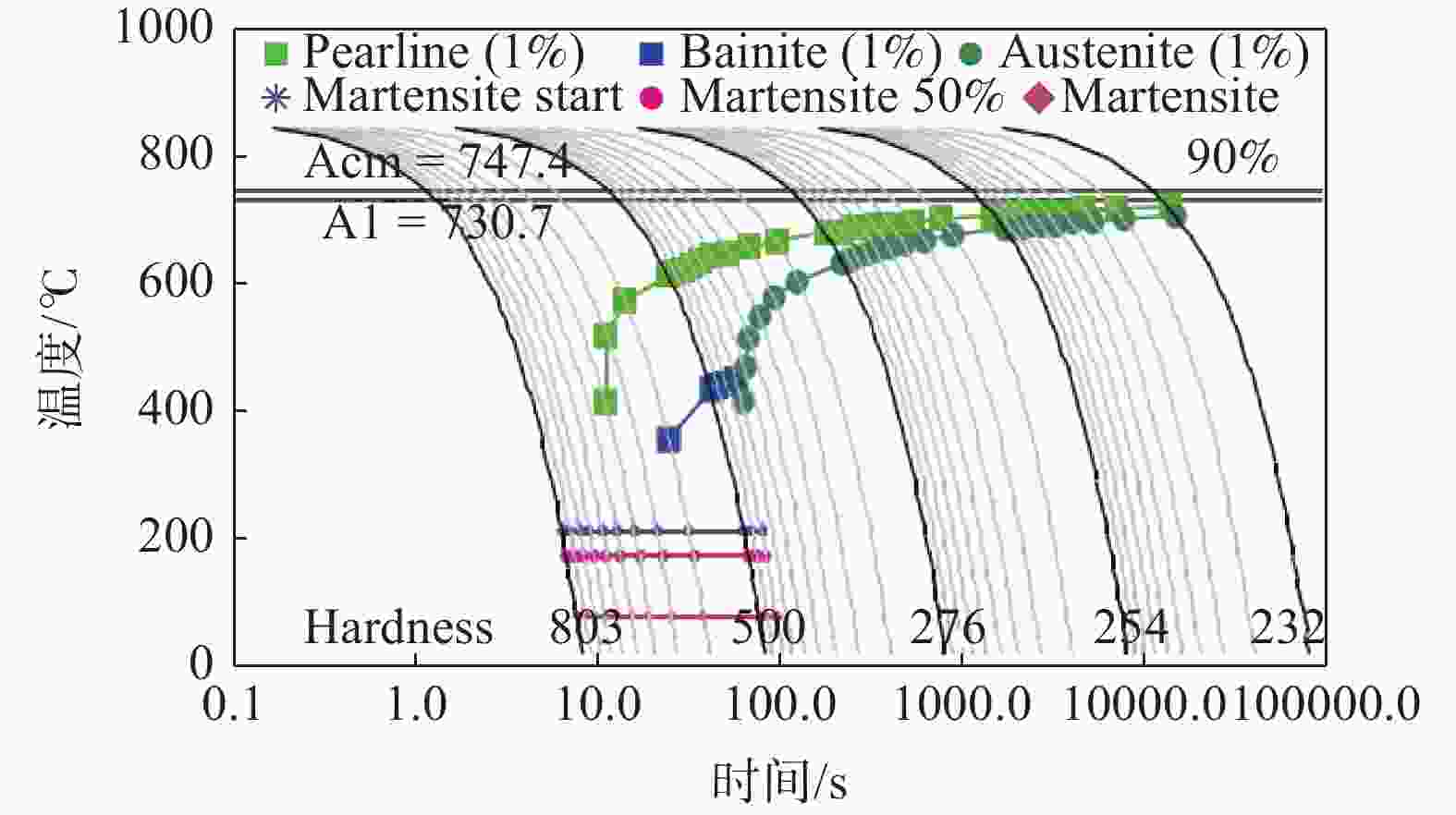

摘要: 钢轨伤损制约着轮轨接触稳定,影响行车安全。针对某铁路钢轨在线服役中产生的伤损,采用Axio Observer 5m金相显微镜、Empyrean型 X射线衍射仪、Sigma 500型扫描电镜、FALCON 500显微硬度计进行多方位检验,基于有限元仿真技术重现了车轮异常启动状况下的钢轨接触部位瞬时温度场分布。分析结果表明:该钢轨伤损属于典型擦伤,伤损深度超过2 mm,钢轨伤损部位随着踏面深度的增加,马氏体含量逐渐减少,残余奥氏体含量逐渐增多,导致其对应的显微硬度值逐渐降低。残余奥氏体被马氏体组织包围,增加微裂纹继续扩展的阻力,钝化裂纹尖端,在轮轨表层剪切应力共同作用下,为微裂纹扩展提供通道,诱导微裂纹横向扩展,最终导致钢轨擦伤区域剥离破坏。计算机仿真结果与实际伤损特征基本吻合。Abstract: Rail damage restricts the stable contact between wheel and rail and affects the driving safety. Regarding the damage of a railway rail in on-line service, the multi-directional inspections had been carried out by using Axio observer 5m metallographic microscope, Empyrean X-ray diffractometer, sigma 500 scanning electron microscope and Falcon 500 microhardness tester. Based on the finite element simulation technology, the instantaneous temperature field distribution of the rail contact part under the abnormal starting condition of the wheel was reproduced. The analysis results show that the rail damage is a typical scratch with a damage depth of more than 2 mm. With the increase of tread depth, the volume fraction of martensite gradually decreases and the volume fraction of retained austenite gradually increases, so that the corresponding microhardness value gradually decreases. The retained austenite is surrounded by martensite structure, which increases the resistance to the continuous propagation of microcracks and passivates the crack tip. Under the joint action of wheel rail surface shear stress, it provides a channel for microcrack propagation, induces microcrack transverse propagation, and finally leads to peeling failure in rail scratch area. The computer simulation results are agreement with the actual damage characteristics.

-

Key words:

- rail /

- debonding failure /

- martensite /

- microcrack /

- finite element simulation

-

表 1 化学成分和拉伸性能

Table 1. Chemical compositions and tensile properties of rail steel

项目 化学成分/% 屈服强度/MPa 抗拉强度/MPa 伸长率/% C Si Mn P S V Al 钢轨试样 0.71 0.46 0.99 0.011 0.008 0.020 0.002 540 935 15.5 标准要求 0.65~0.76 0.15~0.58 0.70~1.20 ≤0.025 ≤0.025 ≤0.030 ≤0.004 ≥880 ≥10 -

[1] Jin Xuesong, Zhang Jiye, Wen Zefeng, et al. Overview of phenomena of rolling contact fatigue of wheel/rail[J]. Journal of Mechanical Strength, 2002,24(2):250−257. (金学松, 张继业, 温泽峰, 等. 轮轨滚动接触疲劳现象分析[J]. 机械强度, 2002,24(2):250−257. doi: 10.3321/j.issn:1001-9669.2002.02.023Jin Xuesong, Zhang Jiye, Wen Zefeng, et al. Overview of phenomena of rolling contact fatigue of wheel/rail[J]. Journal of Mechanical Strength, 2002, 24(2): 250-257. doi: 10.3321/j.issn:1001-9669.2002.02.023 [2] Pal S, Valente C, Daniel W, et al. Metallurgical and physical understanding of rail squat initiation and propagation[J]. Wear, 2012,284:30−42. [3] Sarvesh Pal, William J T Daniel, Carlos H G Valente, et al. Surface damage on new AS60 rail caused by wheel slip[J]. Engineering Failure Analysis, 2012,(22):152−165. [4] Zhou Y, Peng J F, Luo Z P, et al. Phase and microstructural evolution in white etching layer of a pearlitic steel during rolling-sliding friction[J]. Wear, 2016,(362-363):8−17. [5] Deng Yong, Deng Jianhui. Reason analysis on defects in high-speed railway rail[J]. PTCA (Part A:Phys. Test), 2013,(11):766−769. (邓勇, 邓建辉. 某高速铁路钢轨伤损原因分析[J]. 理化检验(物理分册), 2013,(11):766−769.Deng Yong, Deng Jianhui. Reason analysis on defects in high-speed railway rail[J]. PTCA (Part A: Phys. Test), 2013(11): 766-769. [6] Wu Lei, Wen Zefeng, Jin Xuesong. Wheel/rail frictional temperature analysis under wheel rolling[J]. Engineering Mechanics, 2007,24(10):150−155. (吴磊, 温泽峰, 金学松. 车轮原地打滑时轮轨接触界面摩擦温升分析[J]. 工程力学, 2007,24(10):150−155. doi: 10.3969/j.issn.1000-4750.2007.10.026Wu Lei, Wen Zefeng, Jin Xuesong. Wheel/rail frictional temperature analysis under wheel rolling[J]. Engineering Mechanics, 2007, 24(10): 150-155. doi: 10.3969/j.issn.1000-4750.2007.10.026 [7] 苏航, 潘涛, 杨才福, 等. 车轮钢摩擦热致相变及损伤机理研究[C]// 中国铁道学会2004年度学术活动优秀论文评奖论文集. 北京: 中国铁道学会, 2005.Su Hang, Pan Tao, Yang Caifu, et al. The friction heat induced phase transformation and spalling mechanism of train wheel steel[C]// Collection of Excellent Papers in 2004 Academic Activities of China Railway Society. Beijing: China Railway Society, 2005. [8] Liu Haibo, Li Yanlei, Shi Qilong. Thermal stress simulation analysis of urban rail transit vehicles tread braking[J]. Mechanical Engineering & Automation, 2012,(1):49−51. (刘海波, 厉砚磊, 石启龙. 城市轨道交通车辆踏面制动热应力仿真分析[J]. 机械工程与自动化, 2012,(1):49−51. doi: 10.3969/j.issn.1672-6413.2012.01.019Liu Haibo, Li Yanlei, Shi Qilong. Thermal stress simulation analysis of urban rail transit vehicles tread braking[J]. Mechanical Engineering & Automation, 2012(1): 49-51. doi: 10.3969/j.issn.1672-6413.2012.01.019 [9] Wang Haixin, Wu Yaping, Liu Zheng. Influence analysis of coefficients of convective heat transfer on the characteristic of wheel/rail sliding contact[J]. Journal of Railway Science and Engineering, 2018,15(2):336−342. (王海新, 吴亚平, 刘振. 对流换热系数对轮轨滑动接触特性的影响分析[J]. 铁道科学与工程学报, 2018,15(2):336−342. doi: 10.3969/j.issn.1672-7029.2018.02.009Wang Haixin, Wu Yaping, Liu Zheng. Influence analysis of coefficients of convective heat transfer on the characteristic of wheel/rail sliding contact[J]. Journal of Railway Science and Engineering, 2018, 15(2): 336-342. doi: 10.3969/j.issn.1672-7029.2018.02.009 [10] 王伟. 基于ANSYS的轮轨摩擦生热分析[D]. 成都: 西南交通大学, 2011.Wang Wei. Analysis of the frictional heating of wheel-rail based on ANSYS[D]. Chengdu: Southwest Jiaotong University, 2011. -

下载:

下载: