Phase transformation kinetics of high Nb-TiAl alloy during isothermal treatments

-

摘要: 采用原位热膨胀法较为系统地研究了高Nb-TiAl合金的等温相变动力学。结果表明:高Nb-TiAl合金α2→α等温相变过程中,其“鼻尖”温度为1170 ℃,此温度下α相的转变速度最快,且该相的形成呈“S”曲线。基于热膨胀曲线,获取了等温过程中相应的JMA等温相变动力学方程,基于JMA方程,通过对数拟合相转变分数-时间曲线,获取高Nb-TiAl合金等温相变动力学Avrami指数n和温度常数K,建立了高Nb-TiAl合金温度-时间-相转变的定量关系TTT曲线(Time-Temprature-Transformation);并揭示了合金扩散控制的相变动力学机制。

-

关键词:

- 高Nb-TiAl合金 /

- 原位热膨胀法 /

- 等温相变 /

- 动力学

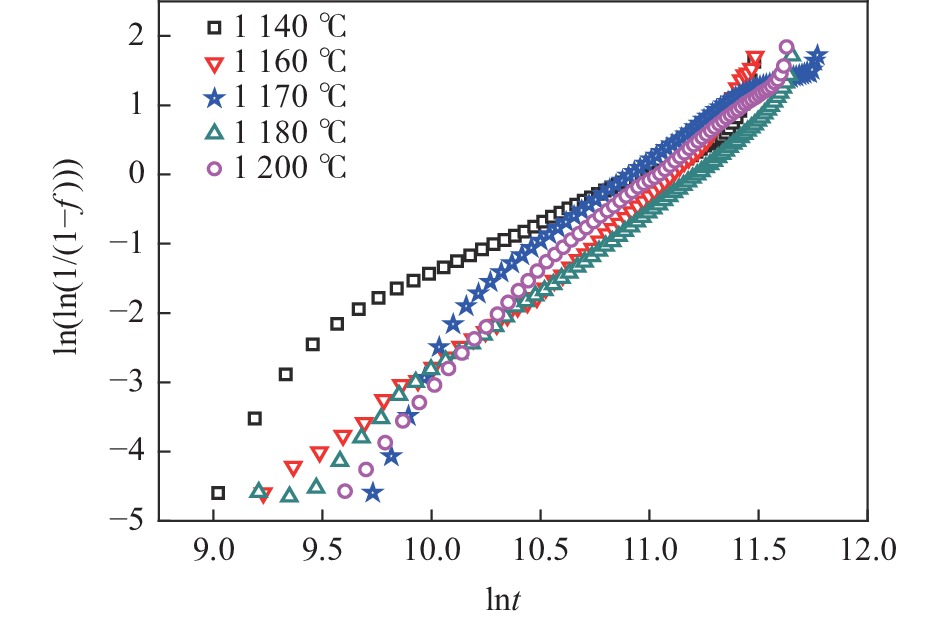

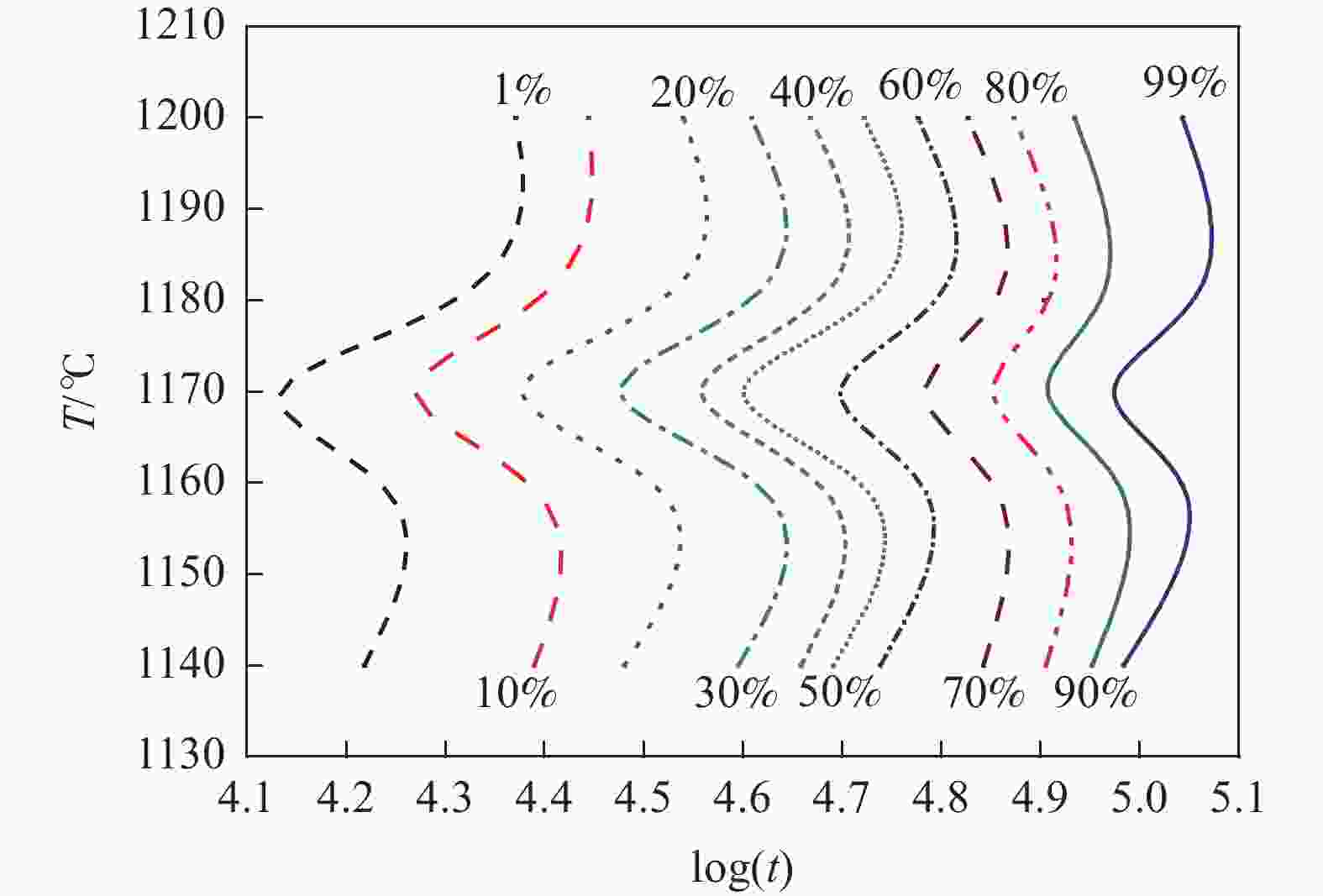

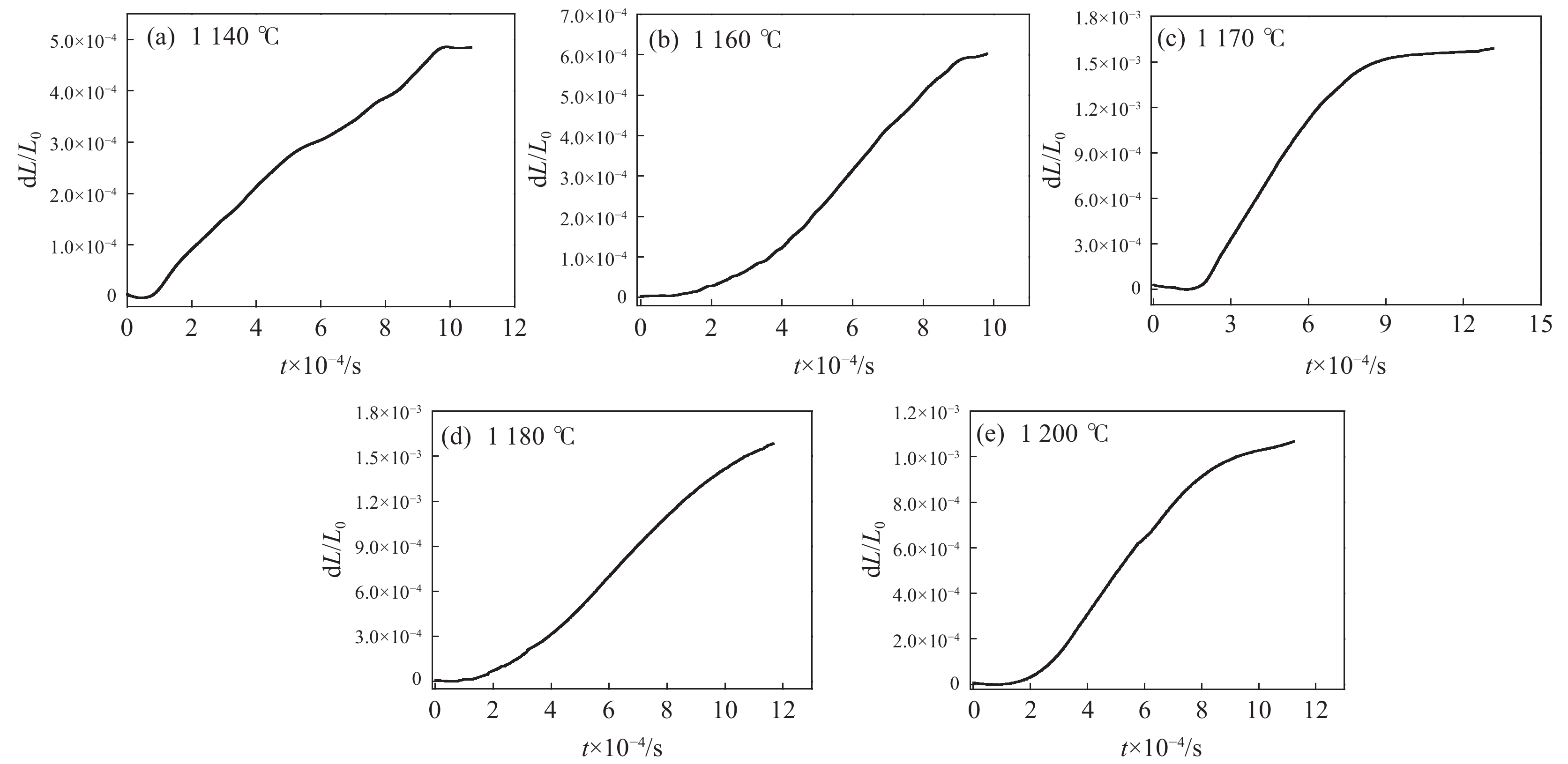

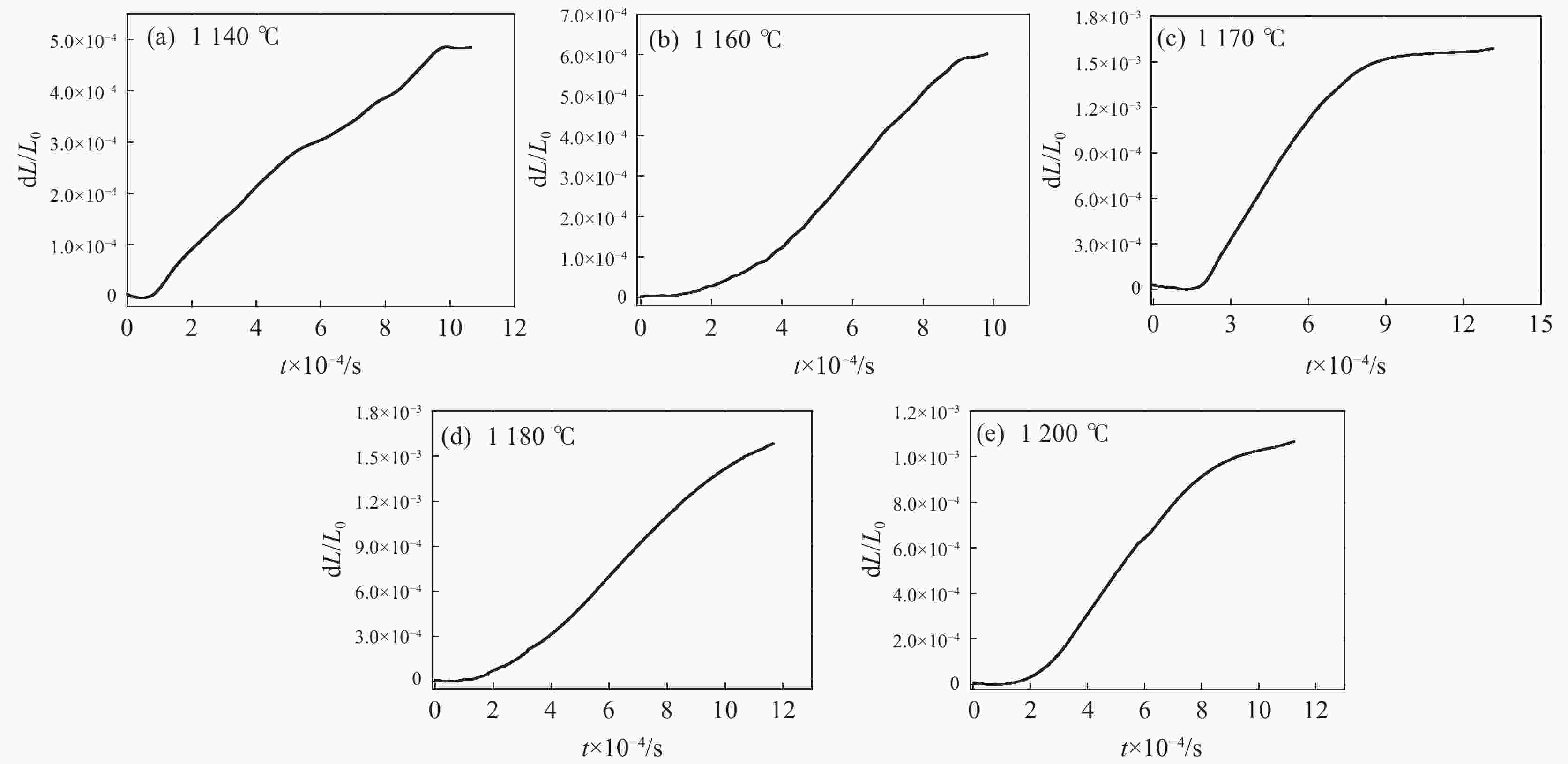

Abstract: The isothermal phase transformation kinetics of α2→α at the temperature 1140−1200 ℃ in high Nb-TiAl alloy were systematically studied by in-situ thermal expansion method. The results show that during the α2→α isothermal phase transformation of high Nb-TiAl alloy, the “nose tip” temperature of α2→α phase transformation is 1170 ℃, and the formation of α phase presents an “S” curve. Based on the thermal expansion curve, the corresponding JMA isothermal phase transformation kinetics equation during the isothermal process was obtained. On the basis of the JMA equation, the Avrami exponent n and temperature constant K of isothermal phase transformation of high Nb-TiAl alloy were obtained by logarithmic fitting the fractional time curve of phase transformation. Based on the results of thermal expansion measurement, the time-temperature-transformation diagram (TTT diagram) was plotted for high Nb-TiAl alloy. The phase transformation kinetics mechanism of high Nb-TiAl alloy controlled by diffusion was revealed. -

表 1 高Nb-TiAl合金等温相变JMA方程中的Avrami方程中指数n值与k值

Table 1. The Avrami exponen n and k value of JMA parameters for high Nb-TiAl alloys during aging treatment

T/℃ n k 1140 1.52 5.53×10−8 1160 2.70 9.94×10−14 1170 2.45 2.08×10−12 1180 2.51 6.45×10−13 1200 2.82 3.05×10−14 -

[1] Chen Yuyong, Wu Jingxi. Research and advances in processing, working, microstructure, properties and industrial application of β-solidifying TiAl alloy[J]. Iron Steel Vanadium Titanium, 2021,42(6):1−16. (陈玉勇, 吴敬玺. β相凝固TiAl合金的制备、加工、组织、性能及工业应用研究进展[J]. 钢铁钒钛, 2021,42(6):1−16. doi: 10.7513/j.issn.1004-7638.2021.06.001 [2] Chen G L, Wang J G, Ni X D, et al. A new intermetallic compound in TiAl+Nb composition areaof the Ti-Al-Nb ternary system[J]. Intermetallics, 2005,13(3-4):329−336. doi: 10.1016/j.intermet.2004.07.006 [3] Liu Z C, Lin J P, Li S J, et al. Effects of Nb and Al on the microstructuresand mechanical properties of high Nb containing TiAl base alloys[J]. Intermetallics, 2002,10:653−659. doi: 10.1016/S0966-9795(02)00037-7 [4] Li M G, Xiao S L, Xu L J, et al. Mechanical properties, deformation behavior and microstructure evolution of Ti-43Al-6Nb-1Mo-1Cr alloys[J]. Materials Characterization, 2018,136:69−83. doi: 10.1016/j.matchar.2017.11.050 [5] Qiao Jingqian, Feng Wei. Isothermal phase transformation behavior analysis and kinetic model establishment for 20CrMnTi steel[J]. Heat Treatment of Metals, 2020,45(11):115−121. (乔靖乾, 冯玮. 20CrMnTi钢的等温相变行为分析及动力学建模[J]. 金属热处理, 2020,45(11):115−121. [6] Zhou Li, Xue Renjie, Cao Xiaoen, et al. Study on microstructure and properties of high aluminum dual phase steel with high formability 980DH[J]. Iron Steel Vanadium Titanium, 2022,43(2):186−191. (周莉, 薛仁杰, 曹晓恩, 等. 高铝增强成形性双相钢980DH组织性能研究[J]. 钢铁钒钛, 2022,43(2):186−191. doi: 10.7513/j.issn.1004-7638.2022.02.028 [7] Wu Nan, Cui Xuefei, Wei Yanguang, et al. Effect of Cr content on isothermal transformation kinetics and TTT diagram of Ti5Mo5V3Al-Cr alloys[J]. Journal of Materials Engineering, 2018,46(9):115−121. (吴 楠, 崔雪飞, 魏衍广, 等. Cr含量对Ti5Mo5V3Al-Cr系合金等温相变动力学和TTT图的影响[J]. 材料工程, 2018,46(9):115−121. doi: 10.11868/j.issn.1001-4381.2016.001270 [8] Chen F, Xu G, Zhang X, et al. Isothermal kinetics of β ↔α transformation in Ti-55531 alloy influenced by phase composition and microstructure[J]. Materials & Design, 2017,130:302−316. [9] Esin V A, Mallick R, Dadé M, et al. Combined synchrotron X-ray diffraction, dilatometry and electrical resistivity in situ study of phase transformations in a Ti2AlNb alloy[J]. Materials Characterization, 2020,169(4):110654. [10] Hu D, Botten R R. Phase transformations in some TiAl-based alloys[J]. Intermetallics, 2002,10(7):701−715. doi: 10.1016/S0966-9795(02)00047-X [11] Li Ying, Zhou Lian, Lin Junping, et al. Microstructure evolutions of high Nb-Ti Al during continuous heating process[J]. Journal of Nanjing University of Technology(Natural Science Edition), 2016,38(4):1−6. (李莹, 周廉, 林均品, 等. 高Nb-TiAl合金连续升温过程的组织演变[J]. 南京工业大学学报(自然科学版), 2016,38(4):1−6. [12] Charpentier M, Hazotte A, Daloz D. Lamellar transformation in near-γTiAl alloys—Quantitative analysis of kinetics and microstructure[J]. Materials Science and Engineering A, 2008,491(1-2):321−330. doi: 10.1016/j.msea.2008.02.009 -

下载:

下载: