| [1] |

He Wei, Lei Wenjie, Peng Dandi. Effects of stress-relief annealing on mechanical properties and microstructure of TB15 titanium alloy[J]. Hot Working Technology, 2021,50(24):146−151. (贺韡, 雷文杰, 彭丹迪. 去应力退火对TB15钛合金力学性能和组织的影响[J]. 热加工工艺, 2021,50(24):146−151.

|

| [2] |

Wang Yao, Li Yonggang, Li Wenhui, et al. Barrel finishing properties of TC4 titanium alloy with cryogenic treatment[J]. Chinese Journal of Rare Metals, 2020,45(11):1289−1298. (王瑶, 李永刚, 李文辉, 等. 深冷处理对TC4钛合金滚磨光整加工性能的影响[J]. 稀有金属, 2020,45(11):1289−1298. doi: 10.13373/j.cnki.cjrm.XY19080032

|

| [3] |

Zheng Yufeng, Xia Dandan, Shen Yunong, et al. Additively manufactured biodegradable metal implants[J]. Acta Metallurgica Sinica, 2021,57(11):1499−1520. (郑玉峰, 夏丹丹, 谌雨农, 等. 增材制造可降解金属医用植入物[J]. 金属学报, 2021,57(11):1499−1520. doi: 10.11900/0412.1961.2021.00294

|

| [4] |

Huang Jianguo, Xu Shubin. Research status and prospect of aluminum alloy manufactured by slective laser melting[J]. Materials Reports, 2021,35(23):142−152. (黄建国, 徐淑彬. 选区激光熔化成型铝合金的研究现状及展望[J]. 材料导报, 2021,35(23):142−152. doi: 10.11896/cldb.20060035

|

| [5] |

马琳, 宋雨健, 崔庆贺, 等. 搅拌摩擦加工工艺及水冷对A356合金晶粒细化作用及变形控制[J]. 材料导报, 2021, 24(35): 122-127.Ma Lin, Song Yujian, Cui Qinghe, et al. Effect of friction stir processing parameters and water cooling on grain refinement and deformation control of A356 casting aluminum alloy[J]. Materials Reports, 2021, 24(35): 122-127.

|

| [6] |

季玲玲. 钛-7A52铝合金轧制复合工艺研究[D]. 沈阳: 东北大学, 2012.Ji Lingling. Research on roll bonding process of titanium-7A52 aluminum alloy clad sheets[D]. Shenyang: Northeastern University, 2012.

|

| [7] |

Kim D W, Lee D H, Kim J, et al. Novel twin-roll-cast Ti/Al clad sheets with excellent tensile properties[J]. Scientific Reports. 2017, 7(1): 8110-8121.

|

| [8] |

Fronczek D M, Wojewoda-Budka J, Chulist R, et al. Structural properties of Ti/Al clads manufactured by explosive welding and annealing[J]. Materials & Design, 2016, 91: 80-89.

|

| [9] |

Guo Xunzhong, Fan Minyu, Liu Zhongli, et al. Explosive cladding and hot pressing of Ti/Al/Ti laminates[J]. Rare Metal Materials and Engineering, 2017,46(5):1192−1196. (郭训忠, 范敏郁, 刘忠利, 等. 钛/铝/钛层状复合材料的爆炸复合制备及后续热压处理研究[J]. 稀有金属材料与工程(英文), 2017,46(5):1192−1196. doi: 10.1016/S1875-5372(17)30135-2

|

| [10] |

Fan Minyu, Guo Xunzhong, Cui Shengqiang, et al. One-step explosive bonding preparation of titanium/aluminium/titanimu laminates with three layers[J]. Rare Metal Materials and Engineering, 2017,46(3):770−776. (范敏郁, 郭训忠, 崔圣强, 等. 钛/铝/钛三层板的一次爆炸复合[J]. 稀有金属材料与工程, 2017,46(3):770−776.

|

| [11] |

Li Yan, Chen Chuang, Li Yanbiao, et al. Interface characterization and metallurgical bonding mechanism of Ti/Al explosively welded composite plates[J]. Pressure Vessel Technology, 2021,38(7):9−16. (李岩, 陈闯, 李艳彪, 等. 钛/铝爆炸焊接复合板界面表征及冶金连接机制[J]. 压力容器, 2021,38(7):9−16. doi: 10.3969/j.issn.1001-4837.2021.07.002

|

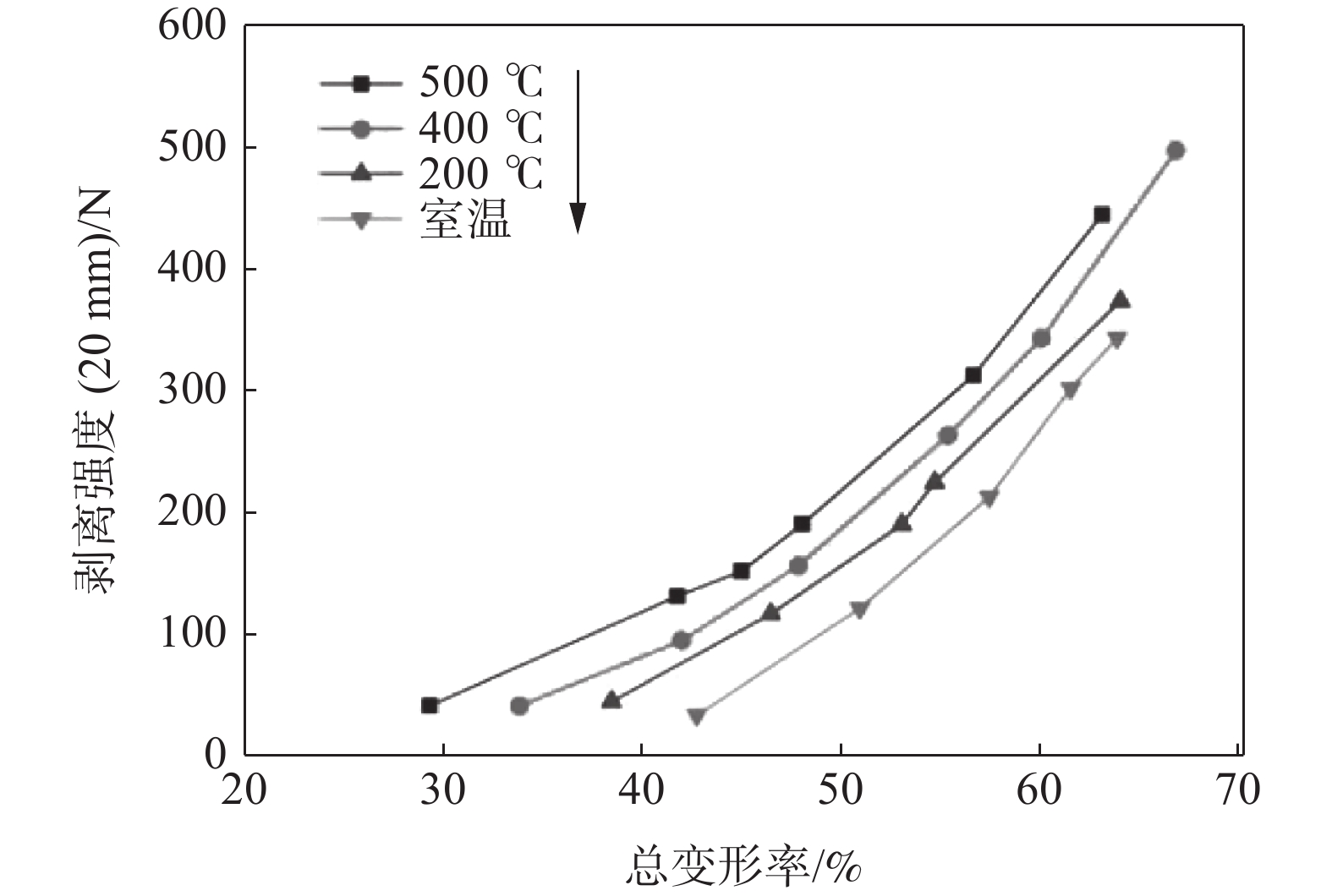

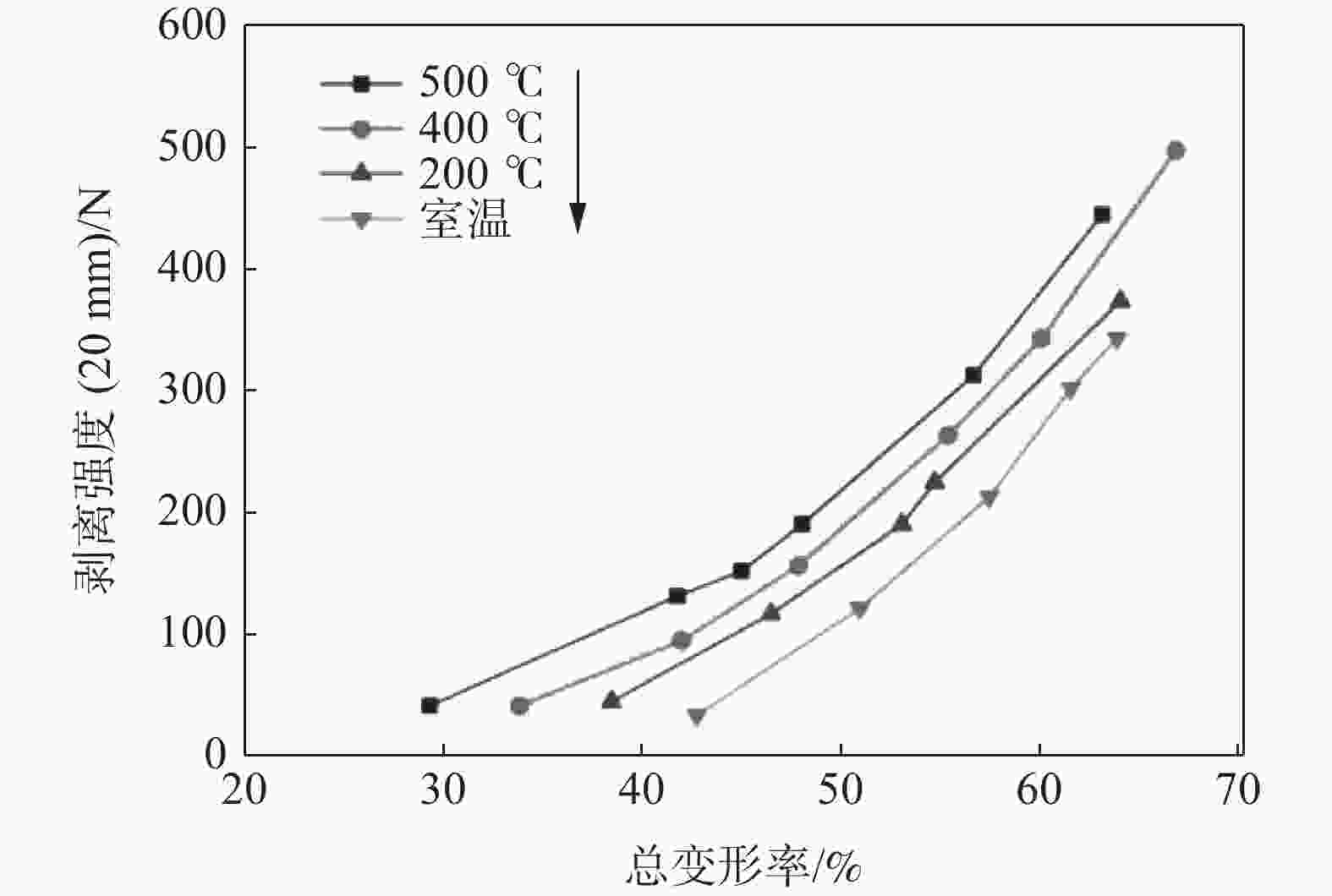

| [12] |

Liu Yingbin, Yin Chufan, An Wentong, et al. Study on explosive welding of titanium/aluminum multilayer composite bond[J]. Hot Working Technology, 2021,50(11):128−136. (刘迎彬, 尹楚藩, 安文同, 等. 钛/铝多层复合板爆炸焊接研究[J]. 热加工工艺, 2021,50(11):128−136. doi: 10.14158/j.cnki.1001-3814.20192728

|

| [13] |

宗恒达. 钛/铝复合板爆炸焊接数值模拟及试验分析[D] . 西安: 长安大学, 2021.Zong Hengda. Numerical simulation and experimental analysis of explosive welding of titanium/aluminum clad plate[D]. Xi’an: Chang’an University, 2021.

|

| [14] |

Yan Xuebai, Li Zhenghua, Li Xuanming, et al. Effect of rolling parameters on the bonding strength and morphology of the peeled surface of Ti/Al clad sheet[J]. Rare Metal Materials and Engineering, 1991,20(4):36−44. (颜学柏, 李正华, 李选明, 等. 轧制参数对钛/铝轧制复合板的结合强度和剥离面SEM形貌的影响[J]. 稀有金属材料与工程, 1991,20(4):36−44. doi: 10.3321/j.issn:1002-185X.1991.04.005

|

| [15] |

王明鑫. 钛铝轧制复合的工艺及数值模拟研究[D]. 沈阳: 东北大学, 2012.Wang Mingxin. Study of numerical simulation on roll bonding process of titanium-7A52 aluminum alloy[D]. Shenyang: Northeastern University, 2012.

|

| [16] |

Wang Wenji, Wang Yuhao, Wang Yifan, et al. Experimental study on interface property improvement of titanium-aluminum composite plate in vibrating cast-rolling forming[J]. Journal of Plasticity Engineering, 2021,28(12):44−50. (王文基, 王宇浩, 王一帆, 等. 钛铝复合板振动铸轧成形界面性能实验研究[J]. 塑性工程学报, 2021,28(12):44−50. doi: 10.3969/j.issn.1007-2012.2021.12.006

|

| [17] |

Han Yujie, Jiang Bo, Hou Hongliang, et al. Mechanical property analysis of Ti/Al laminated composites manufactured by ultrasonic consolidation process[J]. Chinese Journal of Rare Metals, 2020,44(6):597−602. (韩玉杰, 姜波, 侯红亮, 等. 超声固结Ti/Al叠层复合材料力学性能分析[J]. 稀有金属, 2020,44(6):597−602.

|

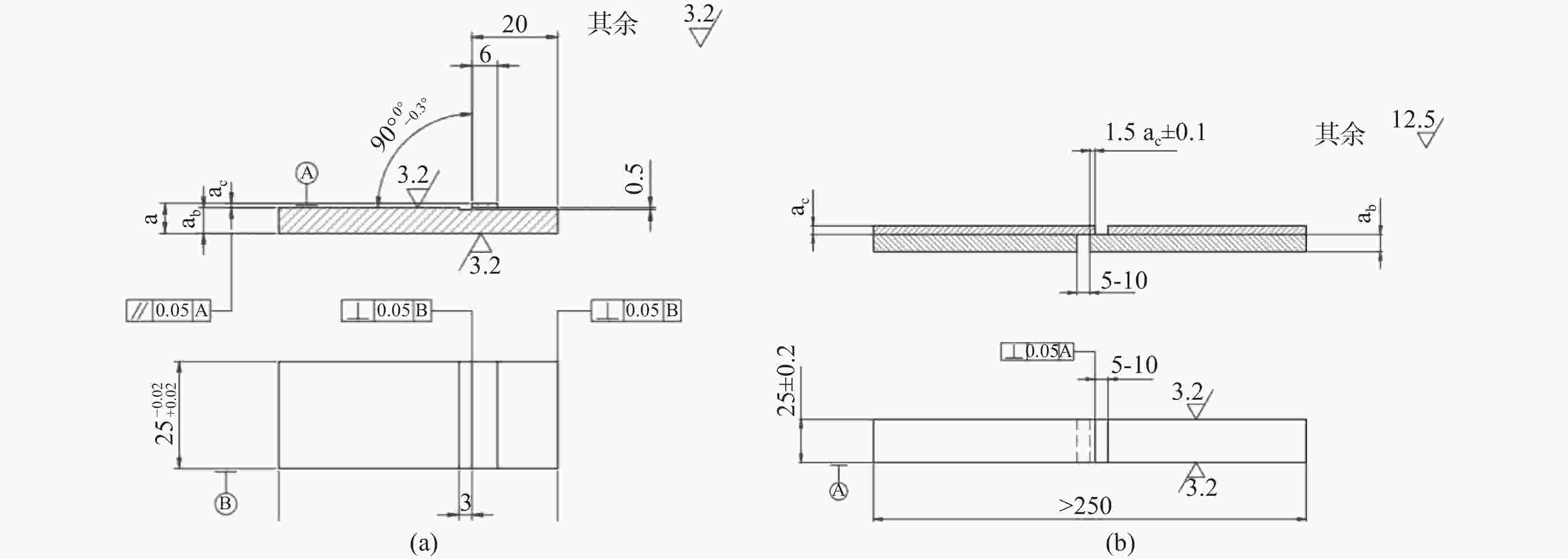

| [18] |

曹苗. Ti/Al层状复合材料的微观组织、力学性能和成形行为研究[D]. 太原: 太原理工大学, 2021: 20−21.Cao Miao. Study on microstructure, mechanical properties and formability of Ti/Al laminated composites [D]. Taiyuan: Taiyuan University of Technology, 2021: 20−21.

|

| [19] |

Wang Wenyan, Shi Shiqin, Shang Zhengping, et al. Interfacial microstructure and properties of Ti-Al rolling-casted composite plate[J]. Special-cast and Non-ferrous Alloys, 2016,36(10):1084−1088. (王文焱, 史士钦, 尚郑平, 等. 铸轧法制备钛铝复合板的界面组织与性能[J]. 特种铸造及有色合金, 2016,36(10):1084−1088. doi: 10.15980/j.tzzz.2016.10.022

|

| [20] |

Guo Leiming, Wang Wenyan, Huang Yabo, et al. Effect of annealing process on microstructure and properties of interface of cast and rolled Ti-Al compostie plate[J]. Heat Treatment of Metals, 2018,43(4):194−198. (郭雷明, 王文焱, 黄亚博, 等. 退火工艺对铸轧钛铝复合板界面组织与性能的影响[J]. 金属热处理, 2018,43(4):194−198. doi: 10.13251/j.issn.0254-6051.2018.04.039

|

| [21] |

崔鹏鹏. 双金属带材固液复合铸轧过程的研究[D]. 太原: 太原理工大学, 2016: 50−51.Cui Pengpeng. Research on bimetal strip solid-liquid composite rolling-cast process[D]. Taiyuan: Taiyuan University of Technology, 2016: 50−51.

|

| [22] |

Huang H G, Chen P, Ji C. Solid-liquid cast-rolling bonding (SLCRB) and annealing of Ti/Al[J]. Materials & Design, 2017,118(15):233−244.

|

| [23] |

Wolcott P J, Sridharan N, Babu S S, et al. Characterisation of Al-Ti dissimilar material joints fabricated using ultrasonic additive manufacturing[J]. Science and Technology of Welding and Joining, 2016,21(2):114−123. doi: 10.1179/1362171815Y.0000000072

|

| [24] |

Zhang J Y, Zhao X J, Wang Y H, et al. Interfacial microstructure evolution during solid-liquid reaction in cold-rolled Ti/Al laminated composites[J]. Rare Metal Materials and Engineering, 2021,50(7):2375−2384.

|

| [25] |

Bowden F P, Tabor D. The area of contact between stationary and between moving surfaces[J]. Mathematical and Physical Sciences, 1939,169:391−413.

|

| [26] |

Burton M S. Metallurgical principles of metal bonding[J]. Welding Journal, 1954,33(11):1051−1054.

|

| [27] |

Cave J A, Williams J D. The mechanisms of cold pressure welding by rolling[J]. Journal of the Institure of Metals, 1973,7(101):203−207.

|

| [28] |

Vaidyanath L R. Pressure welding by rolling[J]. British Welding Journal, 1959,6:13−18.

|

| [29] |

Parks J M. Recrystallization in welding[J]. Welding Journal, 1953,32(5):209.

|

| [30] |

Jong S H, Sun L H. Deformation and fracture of Ti/439 stainless steel clad composite at intermediate temperatures[J]. Materials Science and Engineering A, 2016,651:805−809. doi: 10.1016/j.msea.2015.11.041

|

| [31] |

Bay N. Characteristics, bonding mechanisms, bond strength[J]. Metal Construction, 1986,18(6):369−374.

|

| [32] |

Bay N. Influence of surface preparation on bond strength[J]. Metal Construction, 1986,18(10):625−629.

|

| [33] |

Qi Zichen, Yu Chao, Xiao Hong, et al. Deformation coordination compatibility and bondign properties of Ti/Al composite plates prepared by different temperature rolling[J]. The Chinese Journal of Nonferrous Metals, 2018,28:1121−1127. (祁梓宸, 余超, 肖宏, 等. 异温轧制制备钛/铝复合板的变形协调性与复合性能[J]. 中国有色金属学报, 2018,28:1121−1127. doi: 10.19476/j.ysxb.1004.0609.2018.06.05

|

| [34] |

Dong Xiaomeng, Ren Xueping, Wang Yaoqi, et al. Structure and mechanical properties of Ti/Al multilayered composite[J]. Chinese Journal of Rare Metals, 2017,41(11):1208−1213. (董晓萌, 任学平, 王耀奇, 等. 叠轧Ti/Al复合板结构与力学性能研究[J]. 稀有金属, 2017,41(11):1208−1213. doi: 10.13373/j.cnki.cjrm.xy16060018

|

| [35] |

祖国胤. 层状金属复合材料制备理论与技术[M]. 沈阳: 东北大学出版社, 2013: 125-126.Zu Guoyin. Theories and technologies of preparation layered metal composite[M]. Shenyang: Northeastern University Press, 2013: 125-126.

|

| [36] |

Sun Y, Zhao Y, Zhang D, et al. Multilayered Ti-Al intermetallic sheets fabricated by cold rolling and annealing of titanium and aluminum foils[J]. Transactions of Nonferrous Metals Society of China, 2011,21(8):1722−1727. doi: 10.1016/S1003-6326(11)60921-7

|

| [37] |

韩建超, 刘畅, 贾燚, 等. 钛/铝复合板研究进展[J], 中国有色金属学报, 2020, 30(6): 1270-1280.Han Jianchao, Liu Chang, Jia Yi, et al. Research progress on titanium/aluminum composite plate[J]. The Chinese Journal of Nonferrous Metals, 2020, 30(6): 1270-1280.

|

| [38] |

刘畅. 钛/铝复合板波-平冷轧工艺及组织性能研究[D]. 太原: 太原理工大学, 2020: 67-68.Liu Chang. Corrugated-flat cold rolling process and microstructure and properties of Ti/Al composite plate[D]. Taiyuan: Taiyuan University of Technology, 2020: 67-68.

|

| [39] |

Li L, Nagai K, Yin F. Progress in cold roll bonding of metals[J]. Science and Technology of Advanced Materials, 2008,9:1468−1478.

|

| [40] |

Li Sha, Jia Yi, Liu Xinyang, et al. Research progress on rolling process of laminated Mg/Al clad plate[J]. Journal of Netshape Forming Engineering, 2021,13(6):1−11. (李莎, 贾燚, 刘欣阳, 等. 层状镁/铝复合板轧制工艺研究进展[J]. 精密成型工程, 2021,13(6):1−11.

|

| [41] |

Chekhonin P, Beausir B, Scharnweber J, et al. Confined recrystallization of high-purity aluminium during accumulative roll bonding of aluminium laminates[J]. Acta Materialia, 2012,60(11):4661−4671. doi: 10.1016/j.actamat.2012.04.004

|

| [42] |

Camilo D C, Kliauga A M, Ferrante M, et al. Asymmetric cryorolling of AA6061 Al alloy strain: Strain distribution, texture and age hardening behavior[J]. Materials Science and Engineering A, 2018,736:53−60. doi: 10.1016/j.msea.2018.08.075

|

| [43] |

Yan Xuebai, Li Zhenghua, Gao Wenzhu, et al. The effect of heat treatment to interface bonding strength and microstructure of titanium / hard aluminum laminated plates[J]. Journal of Materials Engineering, 1992,(S1):233−235. (颜学柏, 李正华, 高文柱, 等. 热处理对钛/硬铝合金轧制复合板界面结合性能和显微结构的影响[J]. 材料工程, 1992,(S1):233−235.

|

| [44] |

Assari A H, Eghbali B. Interfacial layers evolution during annealing in Ti-Al multi-laminated composite processed using hot press and roll bonding[J]. Metals and Materials International, 2016,22:915−923. doi: 10.1007/s12540-016-5647-z

|

| [45] |

Kattner U R, Lin J C, Chang Y A. Thermodynamic assessment and calculation of the Ti-Al system[J]. Metallurgical Transaction A, 1992,23:2081−2090. doi: 10.1007/BF02646001

|

| [46] |

Han Yinna, Zhang Xiaojun, Li Long, et al. Microstructure and properties of warm rolled Ti/Al clad plate during annealing[J]. Heat Treatment of Metals, 2017,42(11):45−51. (韩银娜, 张小军, 李龙, 等. 温轧钛/铝复合板退火过程的组织与性能[J]. 金属热处理, 2017,42(11):45−51. doi: 10.13251/j.issn.0254-6051.2017.11.009

|

| [47] |

Peng L M, Li H, Wang J H. Processing and mechanical behavior of laminated titanium-titanium trialuminide composites[J]. Materials Science and Engineering A, 2005,406(1-2):309−318. doi: 10.1016/j.msea.2005.06.067

|

| [48] |

宋卓. 钛-铝层状复合板各向异性研究[D]. 洛阳: 河南科技大学, 2020: 78−79.Song Zhuo. Anisotropy of Ti/Al laminated composites[D]. Luoyang: Henan University of Science and Technology, 2020: 78−79.

|

| [49] |

Fan M, Domblesky J, Jin K, et al. Effect of original layer thicknesses on the interface bonding and mechanical properties of Ti/Al laminate composites[J]. Materials & Design, 2016,99:535−542.

|

| [50] |

张轩昌. 颗粒增强镁板的制备、纤维组织及性能[D]. 太原: 太原理工大学, 2020: 41−42.Zhang Xuanchang. Preparation, microstructure and properties of particle reinforced magnesium sheet[D]. Taiyuan: Taiyuan University of Science and Technology, 2020: 41−42.

|

| [51] |

GB/T 6369—2008. 复合钢板力学及工艺性能试验方法[S]. 北京: 中国国家标准化管理委员会, 2008.GB/T6369—2008. Clad steel plates-mechanical and technological test[S].Beijing: Standardization Administration of the Peoples's Republic of China, 2008.

|

下载:

下载: