Research and practice on optimization of grinding and classification process of low-grade vanadium titanomagnetite

-

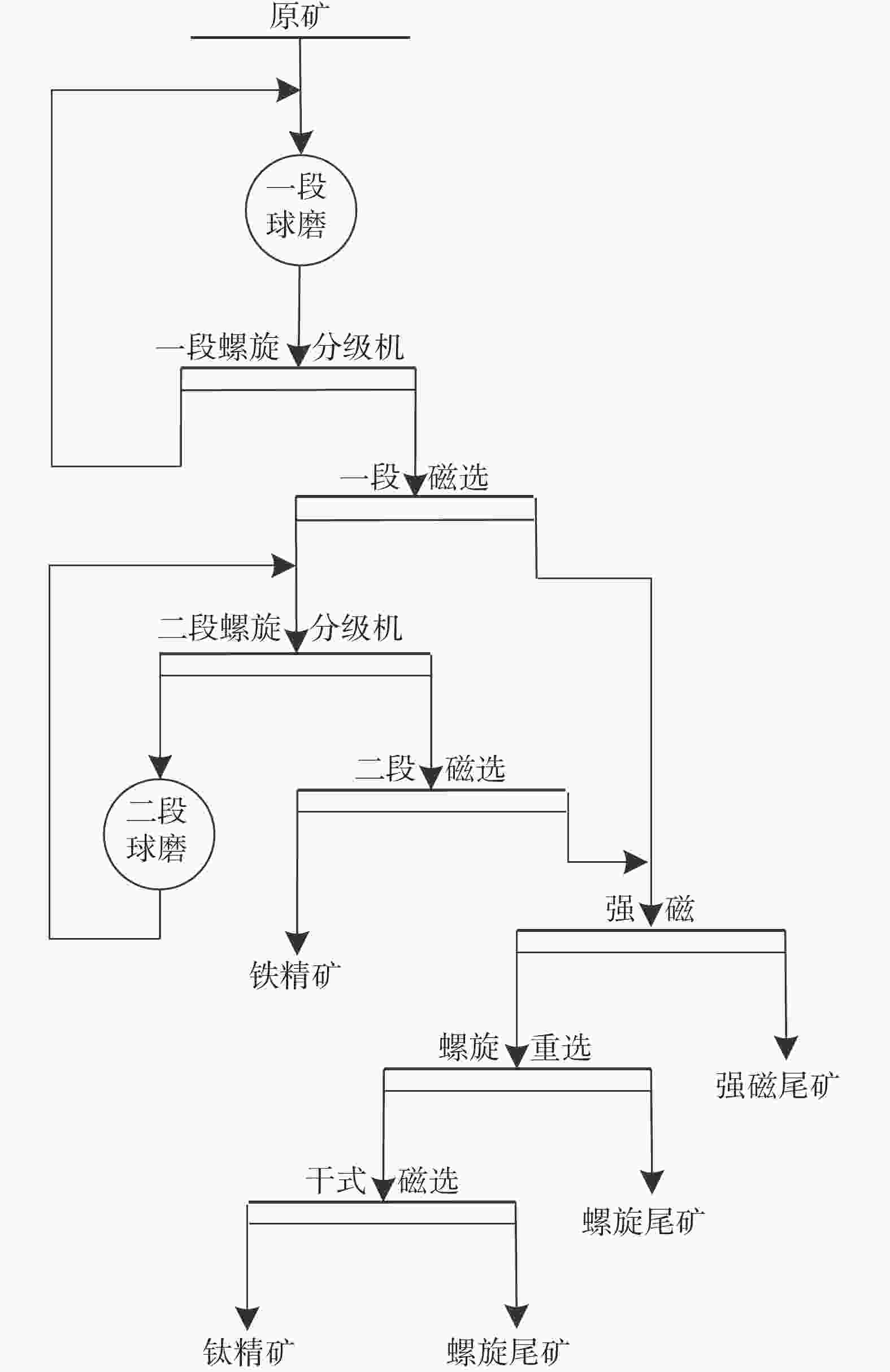

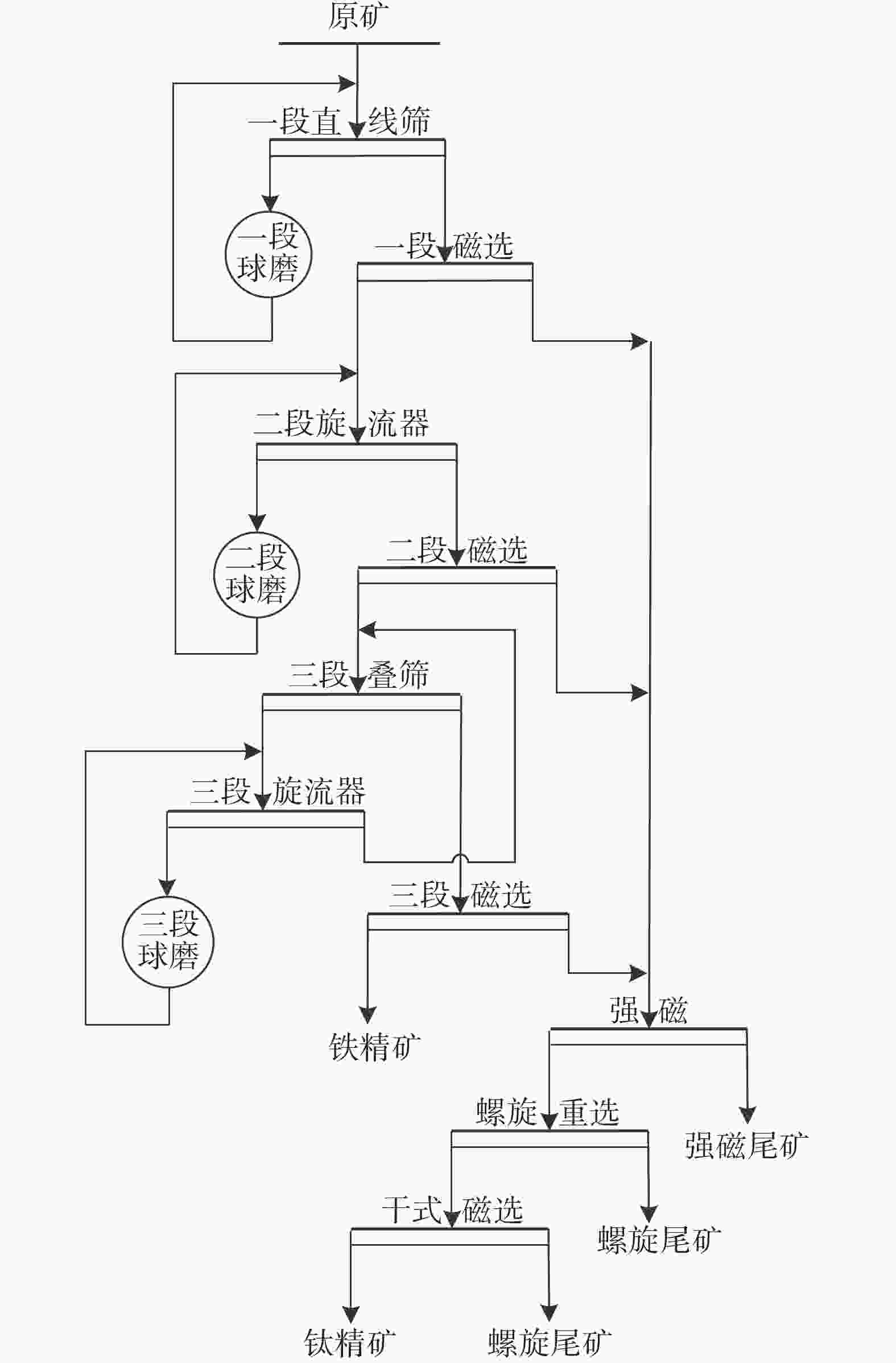

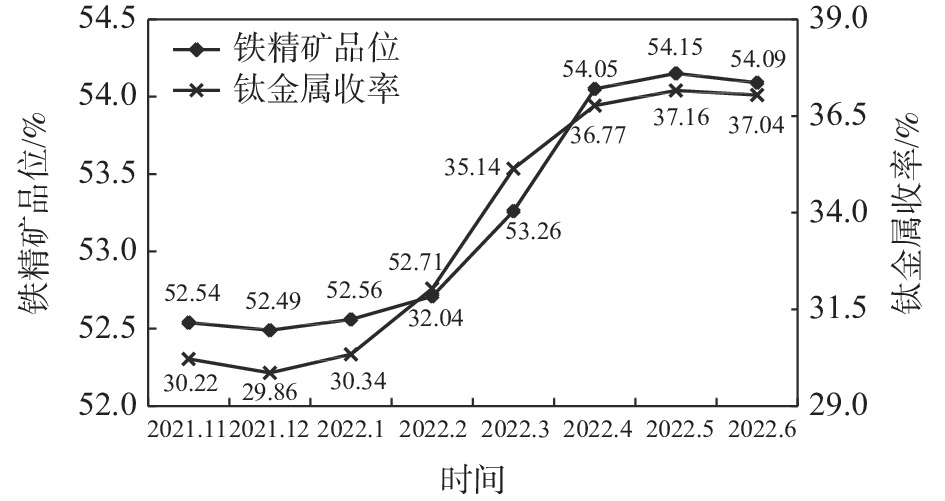

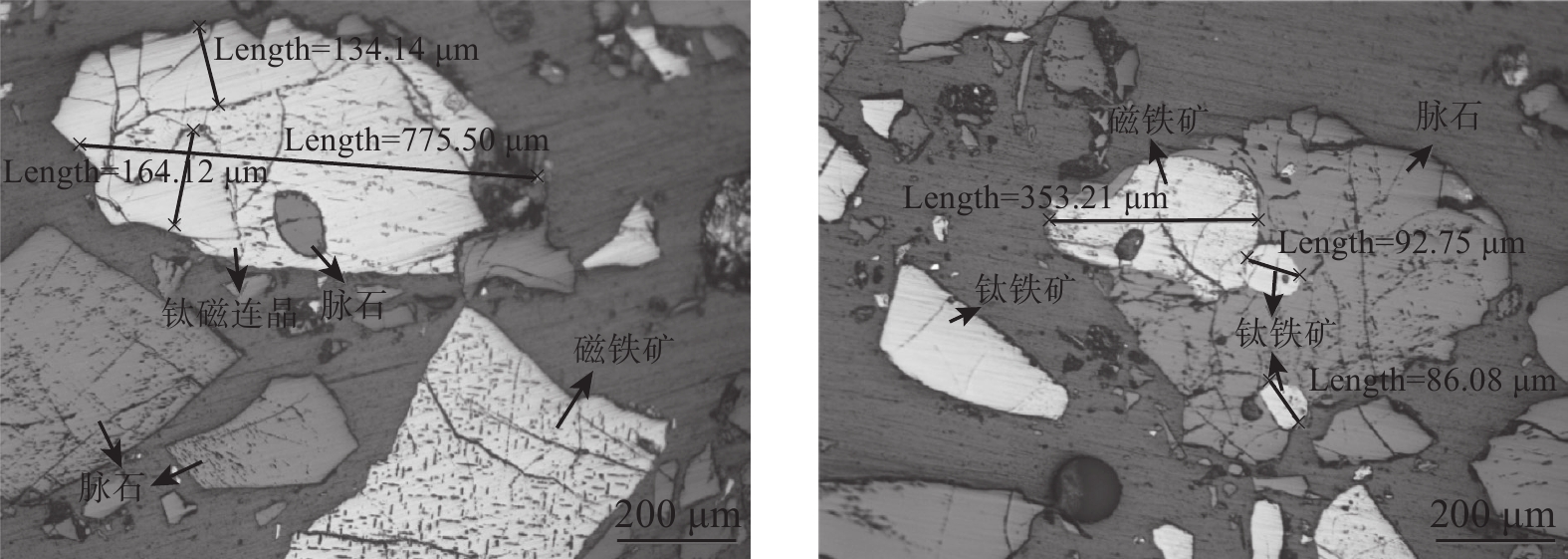

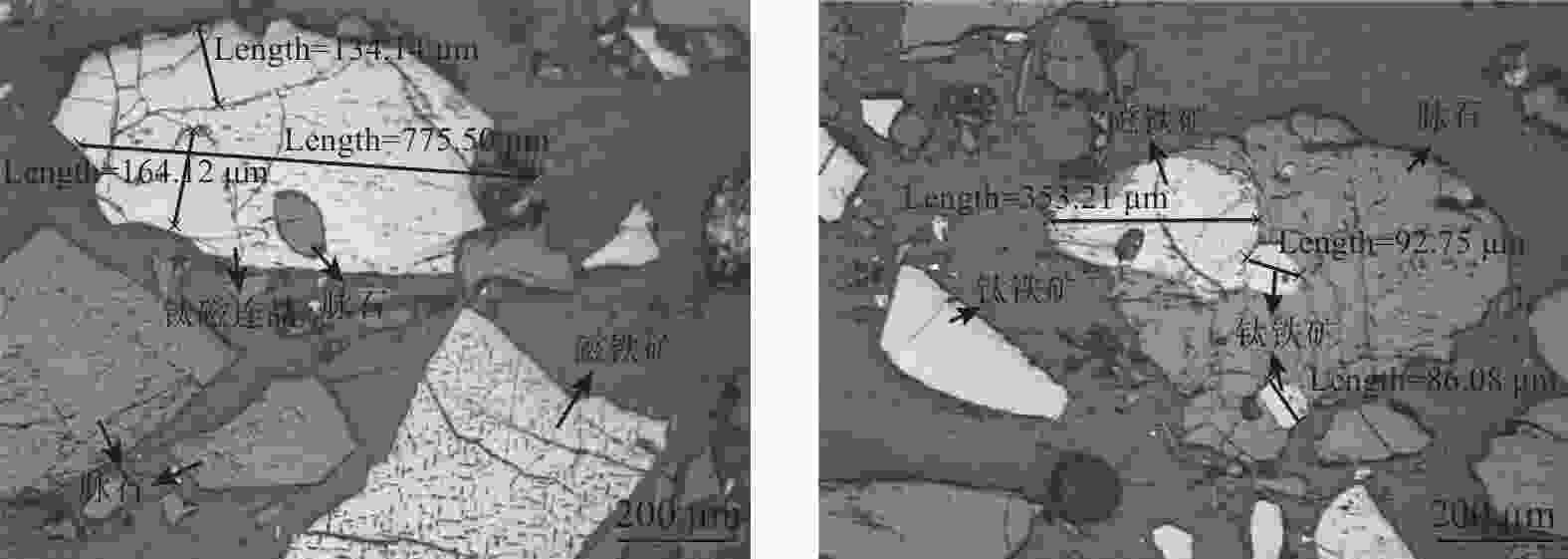

摘要: 针对攀枝花丰源矿业有限公司使用攀枝花矿区低品位钒钛磁铁矿选矿生产现状,提出了磨矿分级工艺优化的方案,在提升铁精矿细度条件下,减少了钛铁矿过磨,更适合后续钛铁矿重选工艺,提高了钛铁矿的回收率。生产实践表明,通过优化磨矿分级工艺,“两段磨矿”改为“三段磨矿”,原矿“先磨矿后分级”改为“先分级后磨矿”以及淘汰螺旋分级机。最终铁精矿细度(−0.074 mm)提升12.34个百分点,使铁精矿品位提升1.57个百分点,磁选尾矿中−0.0385 mm粒级的产率降低20.31个百分点,大幅改善了钛铁矿选别粒度,钛铁矿回收率提高6.85个百分点。Abstract: According to the production status of Panzhihua Fengyuan Mining Co., Ltd. using the low-grade vanadium titanomagnetite for beneficiation from Panzhihua mining area, this paper put forward an optimization scheme of grinding and classification process. Under the condition of improving the fineness of iron concentrate, the overgrinding of ilmenite was reduced, which was more suitable for the subsequent ilmenite gravity separation process, and the recovery rate of ilmenite was also improved. The production practice shows that by optimizing the grinding and classification process, "two-stage grinding" was changed to "three-stage grinding", the raw ore "grinding before classification" was changed to "classification before grinding" and the spiral classifier was eliminated. Finally, the fineness of iron concentrate (−0.074 mm) was increased by 12.34 percentage points, the grade of iron concentrate was increased by 1.57 percentage points, the yield of −0.0385 mm particle size in magnetic separation tailings was reduced by 20.31 percentage points, the separation particle size of ilmenite was greatly improved, and the recovery rate of ilmenite was increased by 6.85 percentage points.

-

Key words:

- low-grade vanadium titanomagnetite /

- mineral separation /

- grinding /

- iron concentrate /

- ilmenite /

- grade /

- recovery rate

-

表 1 原矿样品矿物组成及含量分析结果

Table 1. Mineral composition and content analysis results of raw ore sample

% 磁铁矿 钛铁矿 钛磁连晶 磁脉连晶 钛脉连晶 钛磁脉连晶 磁黄连晶 黄铁矿 黄铜矿 脉石 15.50 11.75 5.00 2.00 1.50 3.00 少量 2.00 少量 59.25 表 2 球磨粉矿粒级分布

Table 2. Raw ore particle size data

粒径/mm 产率/% +10 2.37 −10~+8 5.48 −8~+5 10.18 −5~+3 5.24 −3~+1 21.51 −1 55.22 表 3 一段磁选粒级对比数据

Table 3. Particle size comparison data of primary magnetic separation

样品名称 各粒级产率/% +1 mm −1~+0.3 mm −0.3~+0.15 mm −0.15~+0.074 mm −0.074~+0.045 mm −0.045~+0.0385 mm −0.0385 mm 优化前 进料 5.87 14.13 20.21 13.70 7.76 2.06 36.27 精矿 14.98 31.85 24.13 10.46 4.86 1.18 12.54 尾矿 4.49 12.27 19.35 11.19 12.20 2.58 37.92 优化后 进料 7.01 25.89 32.85 15.35 10.42 2.18 6.30 精矿 8.45 22.41 34.72 12.77 15.47 2.22 3.96 尾矿 4.85 28.63 25.22 18.80 8.21 1.75 12.54 表 4 二段不同分级设备对比数据

Table 4. Comparison data of different classification equipment in Section II

设备

名称样品名称 各粒级产率/% 分级

效率/%+0.3 mm −0.3~+0.15 mm −0.15~+0.074 mm −0.074~+0.045 mm −0.045~+0.0385 mm −0.0385 mm 螺旋分级机 进料 6.51 22.21 15.33 15.56 3.45 36.94 64.23 返砂 22.14 28.08 17.77 16.87 2.97 12.17 溢流 0.33 3.78 12.91 6.58 76.40 分级旋流器 进料 20.81 19.49 27.20 9.35 2.85 20.30 81.14 返砂 32.10 25.95 26.65 6.50 1.36 7.44 溢流 1.75 9.00 45.25 14.20 5.11 24.69 表 5 二段磁选粒级对比数据

Table 5. Particle size comparison data of secondary magnetic separation

样品名称 各粒级产率/% +0.3 mm −0.3~+0.15 mm −0.15~+0.074 mm −0.074~+0.045 mm −0.045~+0.0385 mm −0.0385 mm 优化前 进料 0.03 1.11 10.93 18.94 4.96 64.03 精矿 0.03 5.05 26.05 23.79 3.28 41.80 尾矿 6.16 14.32 12.06 3.19 64.27 优化后 进料 5.70 11.40 22.60 17.70 3.50 39.10 精矿 4.21 11.24 23.88 17.05 3.02 40.60 尾矿 6.50 4.70 13.30 29.40 4.10 42.00 表 6 铁精矿粒级产率对比数据

Table 6. Yield comparison of particle size of iron concentrate

各粒级产率/% +0.15 mm −0.15~+0.074 mm −0.074~+0.045 mm −0.045~+0.0385 mm −0.0385 mm 优化前 5.08 26.05 23.79 3.28 41.80 优化后 8.01 10.78 27.84 3.66 49.71 表 7 总磁尾粒级产率对比数据

Table 7. Yield comparison data of total magnetic tail particle size

各粒级产率/% +0.15 mm −0.15 mm −0.074 mm −0.045 mm −0.0385 mm 优化前 17.12 19.8 12.94 3.55 46.59 优化后 34.98 23.86 11.00 3.88 26.28 -

[1] Li Guoping, Shang Hongliang, Wang Zhiwei, et al. Application of new pre grinding dry pre concentration in a vanadium titanium magnetite mine in Panxi[J]. Nonferrous Metals, 2018,(2):1−3. (李国平, 尚红亮, 王芝伟, 等. 新型磨前干式预选在攀西某钒钛磁铁矿的应用[J]. 有色金属, 2018,(2):1−3. [2] 王洪彬, 张国华. 浅谈攀枝花密地, 白马, 潘家田钒钛铁精矿品位[C]//鲁冀晋琼粤川辽七省金属(冶金)学会第二十一届矿业学术交流会. 太原: 山西省金属学会, 2014.Wang Hongbin, Zhang Guohua. Brief discussion on the grade of vanadium titanium iron concentrate in Midi, Baima and Panjiatian of Panzhihua [C]// The 21st Mining Academic Exchange of the Metal (Metallurgy) Society of Seven Provinces of Shandong, Hebei, Shanxi, Hainan, Guangdong, Sichuan and Liaoning . Taiyuan: Shanxi Metal Society, 2014. [3] 王雪峰. 我国钒钛磁铁矿典型矿区资源综合利用潜力评价研究[D]. 北京: 中国地质大学(北京), 2015.Wang Xuefeng. Evaluation of comprehensive utilization potential of resources in typical vanadium titanomagnetite mining areas in China [D] . Beijing: China University of Geosciences (Beijing), 2015. [4] Chen Fulin, Yang Xiaojun, Cai Xianyan, et al. Experimental study on iron separation of Baima gabbro type ultra-low grade vanadium titanium magnetite in Panxi area[J]. Comprehensive Utilization of Minerals, 2020,(6):5. (陈福林, 杨晓军, 蔡先炎, 等. 攀西地区白马辉长岩型超低品位钒钛磁铁矿选铁试验研究[J]. 矿产综合利用, 2020,(6):5. doi: 10.3969/j.issn.1000-6532.2020.06.005 [5] Lian Qiang, Fang Fuyue. Promotion and application of step grinding and step separation process in Midi concentrator[J]. Modern Mining, 2007,23(9):53−54. (练强, 方福跃. 阶磨阶选工艺在密地选矿厂的推广应用[J]. 现代矿业, 2007,23(9):53−54. [6] Li Qianjin, Lu Zhiming, Zhang Liangliang, et al. Research on the application of hydrocyclone instead of spiral classifier in primary grinding and classification[J]. World Nonferrous Metals, 2018,(14):3−5. (李前进, 卢致明, 张亮亮, 等. 一段磨矿分级采用水力旋流器替代螺旋分级机的应用研究[J]. 世界有色金属, 2018,(14):3−5. doi: 10.3969/j.issn.1002-5065.2018.14.002 [7] 王耀, 崔振立. 一段磨矿分级使用直线振动筛的实践[C]// 2011年中国矿业科技大会.西安: 中国科技部, 2011.Wang Yao, Cui Zhenli . Practice of using linear vibrating screen for primary grinding and classification [C]// 2011 China Mining Science and Technology Conference . Xi'an: Ministry of Science and Technology of China , 2011. -

下载:

下载: