| [1] |

Gong Hongjun, Liang Xinteng, Zhou Zunchuan, et al. Application of rotary injection desulfurization technology in hot metal pretreatment[J]. Iron Steel Vanadium Titaniumm, 2020,41(1):173−178. (龚洪君, 梁新腾, 周遵传, 等. 旋转喷吹脱硫技术在铁水预处理上的应用研究[J]. 钢铁钒钛, 2020,41(1):173−178. doi: 10.7513/j.issn.1004-7638.2020.01.030

|

| [2] |

Zhang Maolin, Xu Anjun. Comparison of application of KR method with that of injection method in hot metal desulphurization[J]. Steelmaking, 2009,25(5):73−77. (张茂林, 徐安军. KR法与喷吹法在铁水脱硫中应用的比较[J]. 炼钢, 2009,25(5):73−77.

|

| [3] |

Yao Na, Xing Chao, Li Xiangsheng. Effect of hot metal desulfurization factors in KR method[J]. Journal of Materials and Metallurgy, 2010,9(3):164−167. (姚娜, 兴超, 李祥胜. KR法铁水脱硫效果的影响因素分析[J]. 材料与冶金学报, 2010,9(3):164−167. doi: 10.3969/j.issn.1671-6620.2010.03.002

|

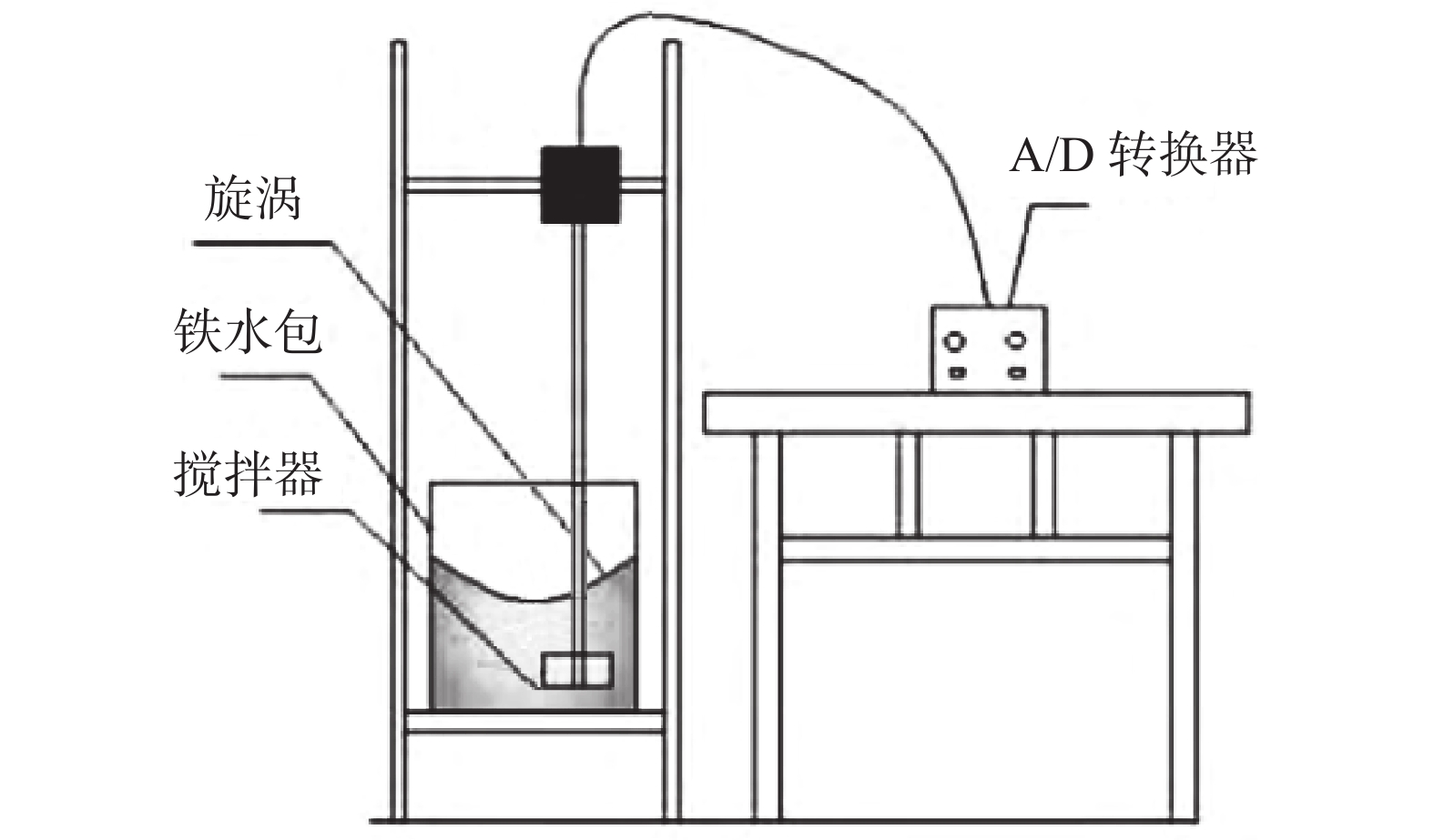

| [4] |

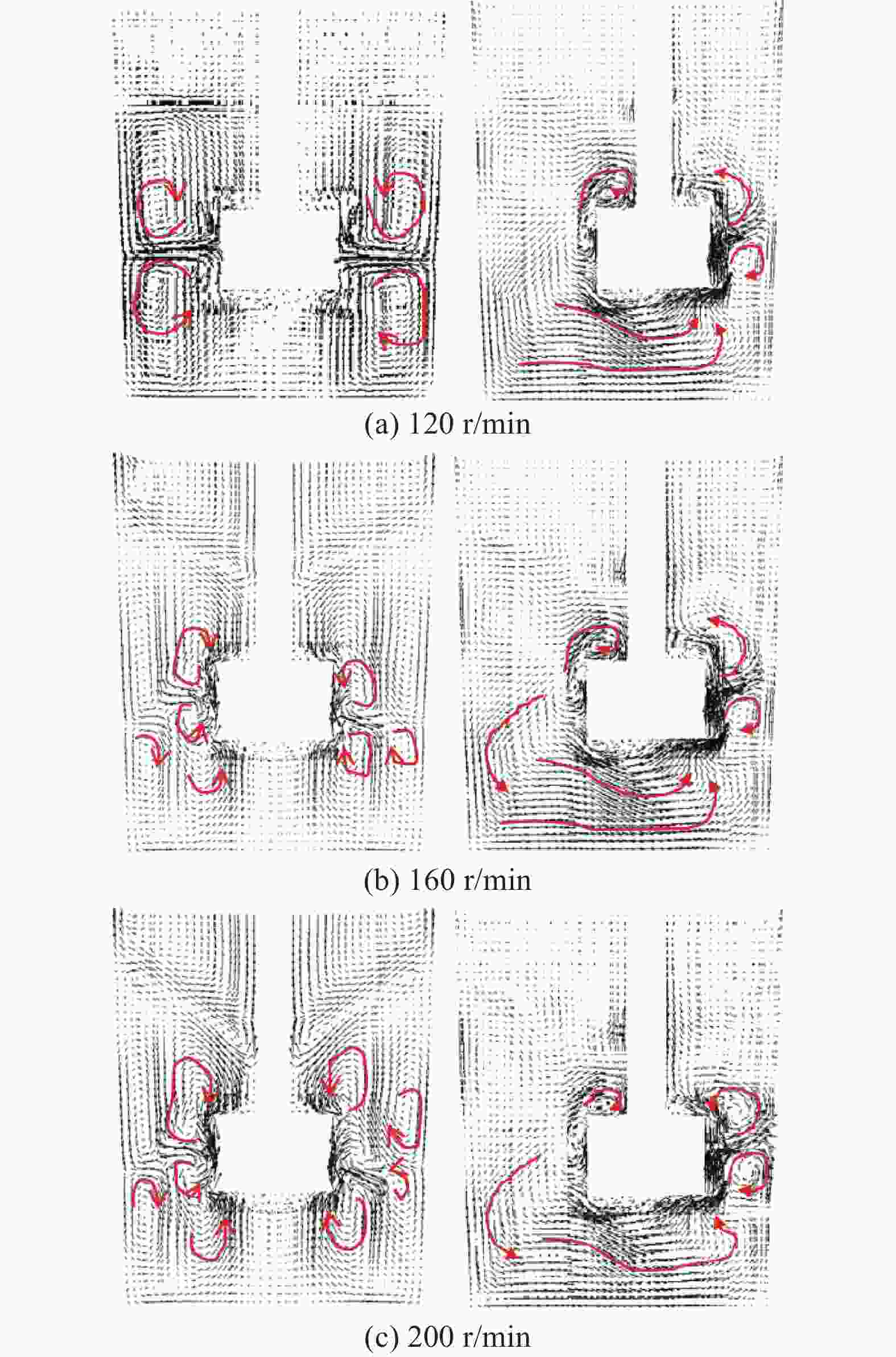

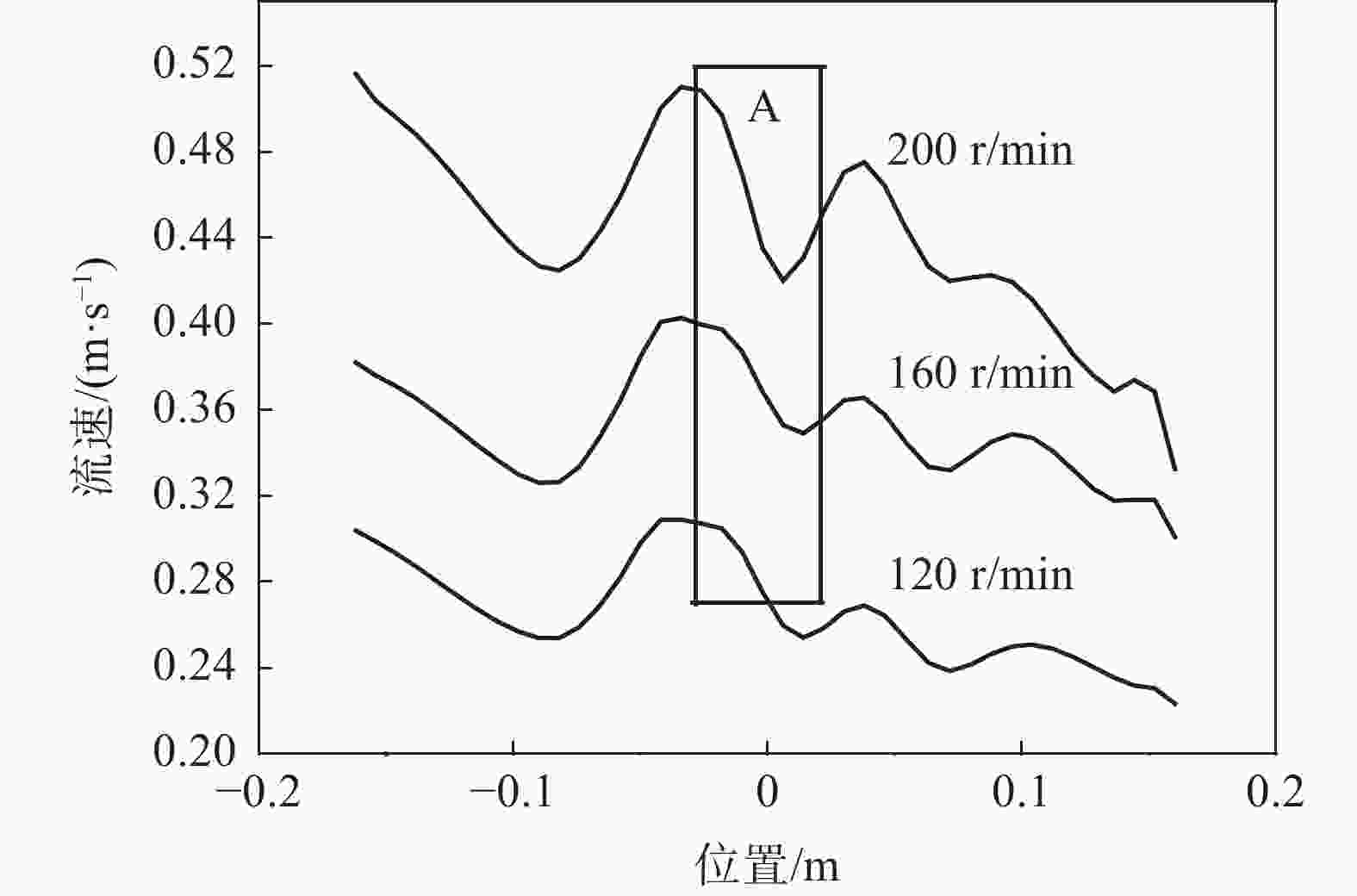

Dong Jiapeng, Zhang Lifeng, Zhao Yanyu, et al. Mixing phenomena of hot metal in KR desulfurization process using water modeling[J]. Journal of Iron and Steel Research, 2021,33(2):103−109. (董佳鹏, 张立峰, 赵艳宇, 等. KR法铁水脱硫过程铁水混合现象的水模型[J]. 钢铁研究学报, 2021,33(2):103−109.

|

| [5] |

Yan Fengyi, Song Mantang, Zhang Guiyu, et al. Optimization of desulphurization with based reagent.[J]. Iron and Steel, 2003,38(2):13−15. (阎凤义, 宋满堂, 张贵玉, 等. 镁基粉剂脱硫工艺优化与实践[J]. 钢铁, 2003,38(2):13−15. doi: 10.3321/j.issn:0449-749X.2003.02.004

|

| [6] |

He M L, Wang N, Chen M, et al. Distribution and motion behavior of desulfurizer particles in hot metal with mechanical stirring[J]. Powder Technology, 2020,361(1):455−461.

|

| [7] |

Ji J H, Liang R Q, He J C. Simulation on mixing behavior of desulfurizer and high-sulfur hot metal based on variable-velocity stirring[J]. ISIJ International, 2016,56(5):794−802. doi: 10.2355/isijinternational.ISIJINT-2015-549

|

| [8] |

闵昌飞. KR法铁水脱硫的流体流动特性研究[D]. 武汉: 武汉科技大学, 2021.Min Changfei. Study on fluid flow characteristics of KR hot metal desulfurization[D]. Wuhan: Wuhan University of Science and Technology, 2021.

|

| [9] |

田广亚, 徐强, 闵通宏, 等. KR法铁水脱硫水模型试验研究 [C]. 第四届冶金工程科学论坛论文集. 2005: 102-106.Tian Guangya, Xu Qiang, Min Tonghong, et al. Research on water modeling in KR desulfurization of hot metal [C]//Proceedings of the 4th Metallurgical Engineering Science Forum. 2005: 102-106.

|

| [10] |

Li Meiting, Li Wei, Li Xiaoguang, et al. Laminar flow field characteristics in the stirred vessel equipped with an eccentric-shaft impeller[J]. Journal of Shandong University (Engineering Science), 2019,49(4):93−98,107. (李美婷, 李威, 李晓光, 等. 偏心轴搅拌槽内的层流流场特性[J]. 山东大学学报(工学版), 2019,49(4):93−98,107.

|

| [11] |

Bi Huafei, Zhou Kun, Huang Xiongbin. Flow, suspension and mixing characteristics of eccentric stirring[J]. The Chinese Journal of Process Engineering, 2017,17(1):52−57. (毕华飞, 周坤, 黄雄斌. 偏心搅拌的流动、悬浮和混合特性[J]. 过程工程学报, 2017,17(1):52−57. doi: 10.12034/j.issn.1009-606X.216244

|

| [12] |

Liu Y, Zhang T A, Sano M, et al. Mechanical stirring for highly efficient gas injection refining[J]. Transaction Nonferrous Metals Society of China, 2011,21:1896−1904. doi: 10.1016/S1003-6326(11)60947-3

|

| [13] |

Liu Yan, Zhang Ting, an, Du Jingyao, et al. Numerical simulation of gas bubble disintegration and dispersion process in liquid[J]. The Chinese Journal of Process Engineering, 2009,9(S1):400−404. (刘燕, 张廷安, 杜靖尧, 等. 流体中气泡微细化与分散过程的数值模拟[J]. 过程工程学报, 2009,9(S1):400−404. doi: 10.3321/j.issn:1009-606X.2009.z1.088

|

| [14] |

Yang Fengling, Zhou Shenjie, Zhang Cuixun, et al. Study on the solid-liquid suspension in eccentrically stirred tanks[J]. J. Huazhong University of Science & Technology (Natural Science Edition), 2012,40(11):22−26. (杨锋苓, 周慎杰, 张翠勋, 等. 偏心搅拌槽内固-液悬浮特性研究[J]. 华中科技大学学报(自然科学版), 2012,40(11):22−26.

|

| [15] |

Zeng Tong. Water modeling experiment of KR mechanical stirring desulfurization tank[J]. Metallurgical Information Review, 2007,(3):27−29. (曾彤. 铁水罐KR机械搅拌式脱硫水模试验研究及应用[J]. 冶金信息导刊, 2007,(3):27−29. doi: 10.3969/j.issn.1008-3618.2007.03.008

|

| [16] |

Wang Weilong, Liu Xing, Sun Tongyun. Research of laminar stirred tank[J]. Petrochemical Industry Technology, 2017,24(12):91−94. (王伟龙, 刘欣, 孙桐运. 层流搅拌槽研究方法及研究现状[J]. 石化技术, 2017,24(12):91−94. doi: 10.3969/j.issn.1006-0235.2017.12.069

|

| [17] |

Chen S Y, Zhang T, Lv L, et al. Intensification of the liquid side mass transfer in double-side falling film microchannels by micro-mixing structures[J]. Chemical Engineering Science, 2019,193:264−275. doi: 10.1016/j.ces.2018.09.016

|

| [18] |

韩占忠. Fluent: 流体工程仿真计算实例与分析[M]. 北京: 北京理工大学出版社, 2009.Han Zhanzhong. Example and analysis of fluid engineering simulation[M]. Beijing: Beijing University of Technology Press, 2009.

|

| [19] |

Syrjanen J K, Manninen M T. Detailed CFD prediction of flow around a 45° pitched blad turbine[C]// Proceedings of 10th European Conference on Mixing. Delft. 2000: 265-272.

|

| [20] |

Zhu Huateng, Chen Guanghui, Wang Weiwen. Numerical simulation and analysis of secondary vortex in different cyclone separators[J]. Journal of Chemical Engineering of Chinese Universities, 2017,31(5):1062−1071. (祝华腾, 陈光辉, 王伟文, 等. 不同结构的旋风分离器二次涡的数值模拟和分析[J]. 高校化学工程学报, 2017,31(5):1062−1071. doi: 10.3969/j.issn.1003-9015.2017.05.007

|

| [21] |

Ma Qingshan, Feng Lianfang, Gu Xueping, et al. Power consumption for powder in horizonal agitated reactor[J]. Journal of Chemical Engineering of Chinese Universities, 1999,13(1):31−37. (马青山, 冯连芳, 顾雪萍, 等. 卧式单轴粉体搅拌反应器的搅拌功率[J]. 高校化学工程学报, 1999,13(1):31−37. doi: 10.3321/j.issn:1003-9015.1999.01.006

|

| [22] |

Chen Xinde, Sun Jianglong, Zhou Jiajian, et al. Numerical simulation analysis of the flow during hot metal desulfurization by KR method[J]. Journal of Wuhan University of Science and Technology, 2015,38(5):330−335. (程新德, 孙江龙, 周家健, 等. KR法铁水脱硫的流动数值模拟分析[J]. 武汉科技大学学报, 2015,38(5):330−335.

|

下载:

下载: