Effects of strain aging on the microstructure and properties of X90 high-strength pipeline steel

-

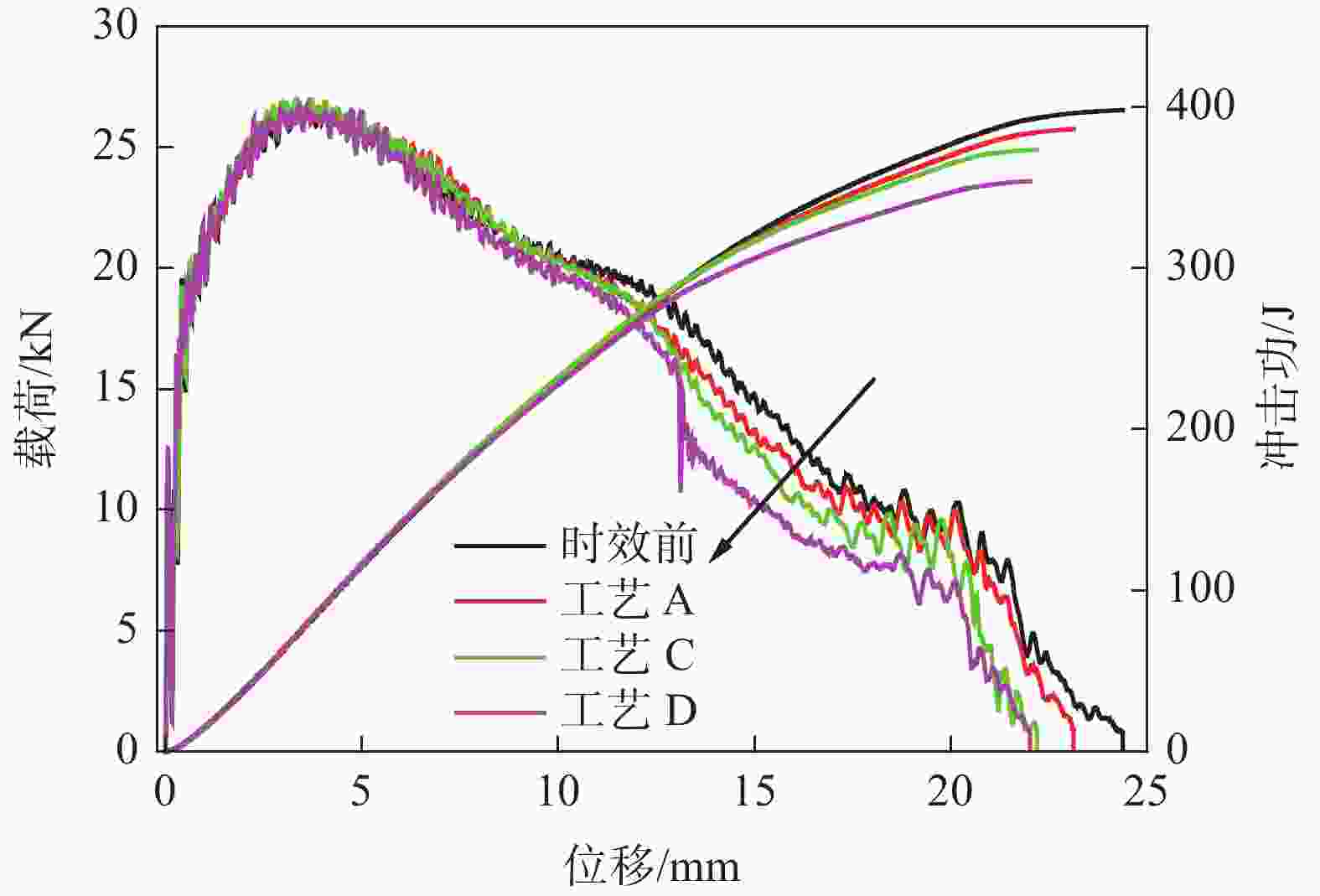

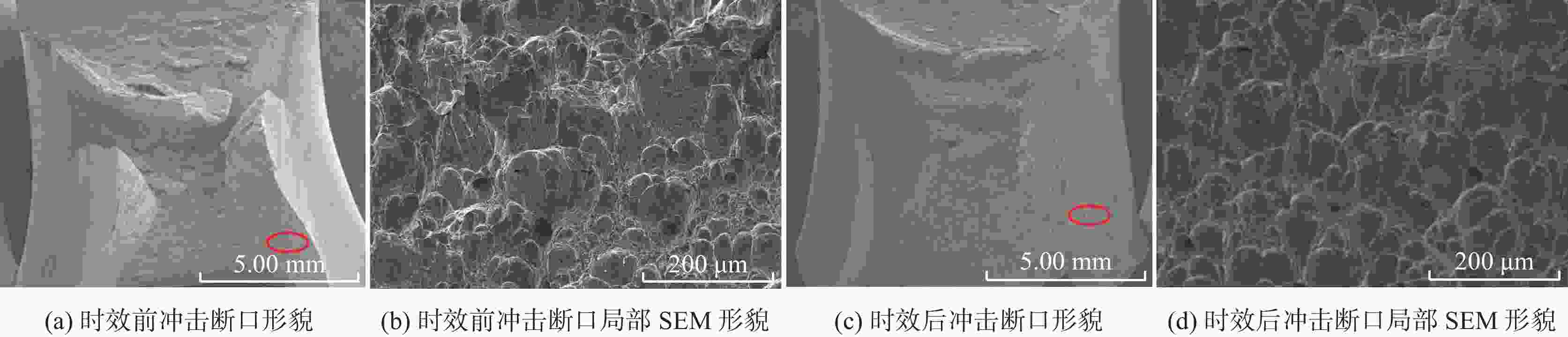

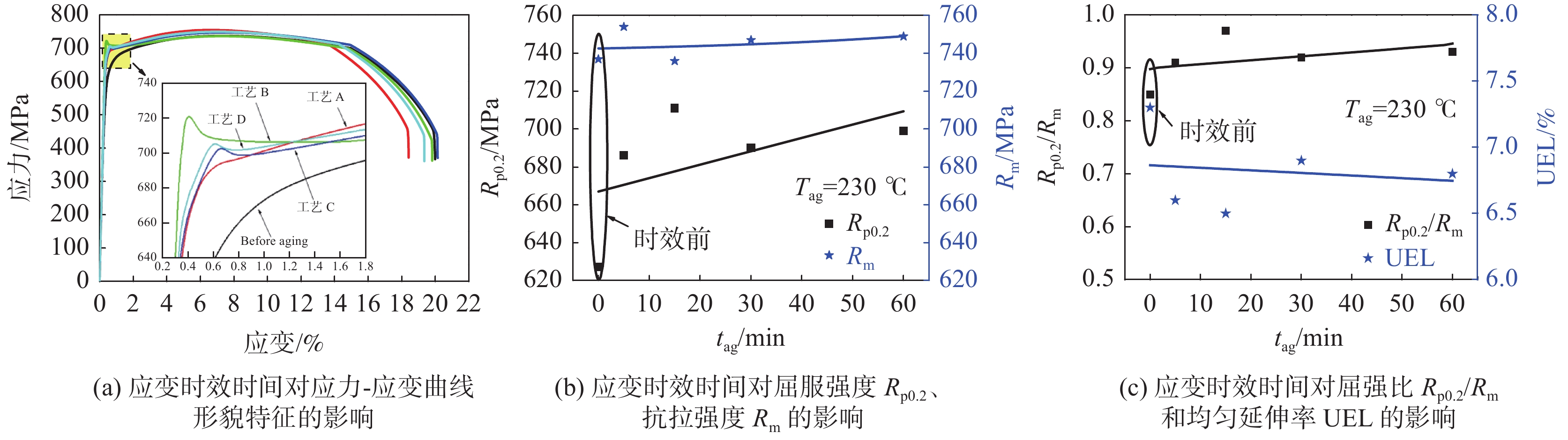

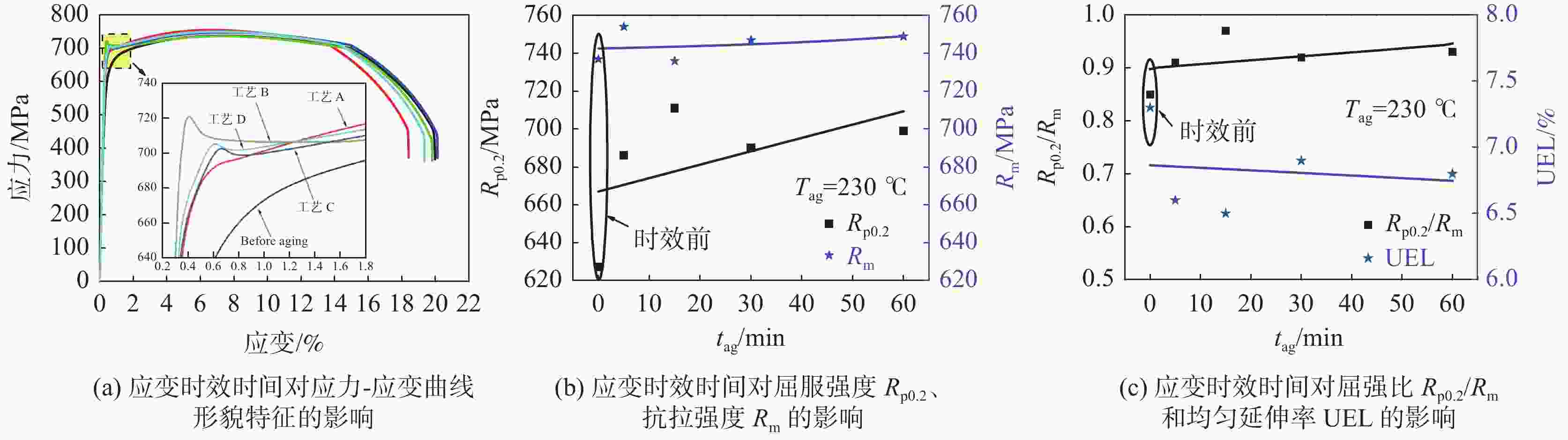

摘要: X90管线钢管是一种新型高强、高韧性管材,随着强度的提高,应变时效行为的揭示与控制成为学术界研究的焦点。利用OM、SEM、TEM、应变时效敏感性试验、拉伸试验和夏比冲击试验对X90高强管线钢组织特征、冲击断口形貌、应变时效敏感性、拉伸性能、低温冲击性能和应变时效行为进行了研究。结果表明,应变时效对X90高强管线钢组织无显著影响,时效前后均为针状/块状铁素体+板条状/粒状贝氏体+M/A组元的复相组织,但对拉伸性能和拉伸曲线形态以及低温冲击韧性有显著影响。当时效温度为230 ℃时(聚乙烯层熔结温度),随时效时间延长,X90钢屈服强度、抗拉强度、屈强比和应变时效敏感性系数逐渐增大,均匀延伸率和低温冲击吸收功逐渐减小。应力-应变曲线逐渐失去连续屈服强化特征,由时效前的“Round House”拱顶型连续屈服、强化型转变成为带有明显尖峰和屈服平台的“Lüders”型曲线,15 min是X90钢应力-应变曲线形态发生转变的时效时间拐点。为了控制应变时效对X90高强管线钢的不利影响,应从减小应变量、降低防腐预热温度和缩短防腐预热高温停留时间三方面进行综合调控。建议对管材生产制备工艺进行革新,成型方面如采用柔性校平法取代刚性辊压校平法,多步渐进成型取代一步螺旋成型法;防腐方面如缩短预热高温停留时间或降低预热温度(当预热温度≥230 ℃时,高温停留时间应≤5 min;若预热温度选定<230 ℃时,高温停留时间应<15 min)。Abstract: X90 pipeline steel pipe is a new type of high-strength and high-toughness pipe. With the increase in strength, the revealing and controlling of strain aging behavior of X90 pipeline steel has become the focus of research. The microstructure characteristics, fracture morphology, strain-aging sensitivity, tensile properties, impact toughness in low temperature, and strain aging sensitivity of X90 high-strength pipeline steel before and after strain aging treatment were investigated by OM, SEM, TEM, strain-aging sensitivity test, tensile test and Charpy impact experiments. The results indicate that the strain aging has no significant effect on the microstructure of X90 high-strength pipeline steel. The microstructure of X90 high-strength pipeline steel before and after aging is a complex structure of acicular/bulk ferrite, lath/granular bainite and M/A component. However, strain aging has a significant effect on the tensile properties, tensile curve morphology and low temperature impact toughness of X90 high-strength pipeline steel. When the aging temperature is 230 ℃ (the fusion temperature of polyethylene layer), the yield strength, tensile strength, yield ratio and strain-aging sensitivity coefficient of X90 steel gradually increase with the prolongation of aging time. At the same time, the uniform elongation and low temperature impact absorption energy of X90 steel gradually decrease with the prolongation of aging time. In addition, the X90 pipeline steel gradually loses continuous yielding and strengthening characteristics, and the tensile curve changes from the round-house-type before aging to the Lüders-type yield curve after aging with obvious peaks and yield platform. 15min is the inflection point of aging time for the transformation of the stress-strain curve of X90 steel. In order to reduce the adverse effect of strain aging on X90 high-strength pipeline steel, comprehensive regulation should be carried out from three aspects: reducing strain, reducing anti-corrosion preheating temperature and shortening high temperature residence time of anti-corrosion preheating. It is recommended to innovate and revise the pipe production and preparation process, such as shortening the high temperature preheating residence time or reducing the preheating temperature, and adopting the flexible leveling method to replace the rigid roll leveling method, and the multi-step incremental forming to replace the one-step spiral forming method. It is recommended to innovate the production and preparation process of pipes. For example, in the pipe forming process, the flexible leveling method could be used to replace the rigid roll leveling method, and the multi-step progressive molding method could be used to replace the one-step spiral molding method to effectively control the prestrain. Another example, in the pipe anticorrosion process, the residence time of high temperature preheating should be shortened or the preheating temperature should be reduced (when the preheating temperature ≥ 230 ℃, the high temperature residence time should be ≤ 5 min; if the preheating temperature < 230 ℃, the high temperature residence time should be < 15 min).

-

Key words:

- X90 high-strength pipeline steel /

- strain aging /

- aging time /

- impact toughness /

- acicular ferrite

-

表 1 X90级管线钢的化学成分

Table 1. Chemical composition of X90 pipeline steel

% C Si Mn P S Ni Cr Cu Nb V Ti Mo Al B CEPcm Fe 0.05 0.26 1.94 0.006 0.0012 0.21 0.34 0.22 0.08 0.03 0.016 0.34 0.03 0.0004 0.21 Bal. 注:CEPcm为冷裂纹敏感系数,对于碳含量≤0.12%的高强管线钢材料更能准确反映其焊接性能。 表 2 应变时效前后X90级管线钢拉伸性能测试结果

Table 2. Test results of tensile properties of X90 pipeline steel before and after strain aging

工艺 Rp0.2/MPa Rm/MPa Rp0.2/Rm UEL/% 时效前 627 737 0.85 7.3 A 686 754 0.91 6.6 B 711 736 0.97 6.5 C 690 747 0.92 6.9 D 699 749 0.93 6.8 表 3 应变时效处理前后X90高强管线钢的低温冲击韧性指标和应变时效敏感性系数

Table 3. Low-temperature impact test results and strain-aging sensitivity coefficient of X90 high-strength pipeline steel before and after strain aging treatment

工艺 T/℃ Ai/J Ap/J Ak/J 平均值/J CV/% 时效前 −20 92 306 398 401 95 310 405 93 306 399 A −20 90 300 390 390 2.7 91 295 386 92 302 394 C −20 90 283.5 373.5 376.5 6.1 89 287 376 92 288 380 D −20 91 269 360 357 10.97 89 269 358 85 269 354 -

[1] Bi Zongyue. Key technologies research for new generation large transportation capacity oil and gas pipeline manufacturing[J]. Welded Pipe and Tube, 2019,41(7):10−25. (毕宗岳. 新一代大输量油气管材制造关键技术研究进展[J]. 焊管, 2019,41(7):10−25. [2] GB/T 23257-2009. 埋地钢质管道聚乙烯防腐层[S].GB/T 23257-2009. Polyethyene coating for buried steel pipeline[S]. [3] SY/T 0315—2013. 钢质管道熔结环氧粉末外涂层技术规范[S].SY/T 0315—2013. Technological specification of external fusion bonded epoxy coating for steel pipeline[S]. [4] Zhou Shiyan, Wang Xu, Chu Yuanlin, et al. Cause analysis and control measures of cracks in 3 PE external anti-corrosion coating of oil and gas pipeline[J]. Welded Pipe and Tube, 2021,44(8):55−68. (周石燕, 王旭, 褚元林, 等. 油气管道3PE外防腐层产生裂纹原因分析及控制措施[J]. 焊管, 2021,44(8):55−68. [5] Zhang Liang, Cai Ke, Mo Zixiong, et al. Study of temperature influence on external anticorrosion coating performance of oil and gas pipeline[J]. Petroleum Tubular Goods & Instruments, 2019,(2):46−48. (张良, 蔡克, 莫子雄, 等. 温度对油气管道外防腐层性能的影响规律研究[J]. 石油管材与仪器, 2019,(2):46−48. [6] Yang Jun, Bi Zongyue, Nan Huanghe, et al. Investigation of strain aging behavior and sensitive temperature of X90 high strength pipeline steel[J]. Chinese Journal of Materials Research, 2021,35(10):769−777. (杨军, 毕宗岳, 南黄河, 等. X90高强管线钢的应变时效行为和敏感温度[J]. 材料研究学报, 2021,35(10):769−777. [7] Yang Jun, Bi Zongyue, Wang Xueyi, et al. Strain aging behavior and sensitive time of X90 high-strength pipeline steel[J]. Journal of Plasticity Engineering, 2022,29(1):167−176. (杨军, 毕宗岳, 王雪怡, 等. X90高强管线钢应变时效行为及敏感时间研究[J]. 塑性工程学报, 2022,29(1):167−176. doi: 10.3969/j.issn.1007-2012.2022.01.024 [8] De A K, De Blauwe K, Vandeputte S, et al. Effect of dislocation density on the low temperature aging behavior of an ultra low carbon bake hardening steel[J]. J Alloys Compd, 2000,310(1):405. [9] Jiang Yongwen, Niu Tao, An Chenggang, et al. Strain aging behavior of X70 pipeline steel[J]. Chinese Journal of Materials Research, 2016,30(10):767−772. (姜永文, 牛涛, 安成钢, 等. X70管线钢的应变时效行为[J]. 材料研究学报, 2016,30(10):767−772. [10] Zuo Xiurong, Li Rutao. Research of strain aging in pipeline steel with a ferrite / martensite dual‐phase microstructure[J]. Steel Research International, 2015,86(2):163−168. doi: 10.1002/srin.201300465 [11] Ji Lingkang, Chen Hongyuan, Zhang Jiming. Study on aging effect of X80 line steel pipe mechanical properties[J]. Petroleum Tubular Goods & Instruments, 2018,4(6):27−35. (吉玲康, 陈宏远, 张继明. 时效对X80管线钢管力学性能的影响规律研究[J]. 石油管材与仪器, 2018,4(6):27−35. [12] Wu Shengjie, Nie Wenjin, Shang Chengjia, et al. Strain aging sensitivity of multi-phase pipeline steel[J]. Journal of University of Science and Technology Beijing, 2014,36(1):63−68. (吴圣杰, 聂文金, 尚成嘉, 等. 多相组织管线钢的应变时效敏感性[J]. 北京科技大学学报, 2014,36(1):63−68. [13] Guo Aimin, Zou Dehui, Yi Lunxiong, et al. Effects of aging on microstructure and mechanical property of ultralow carbon acicular ferrite steel[J]. Acta Metallurgica Sinica, 2009,45(4):390−395. (郭爱民, 邹德辉, 易伦雄, 等. 时效处理对极低碳针状铁素体钢组织和力学性能的影响[J]. 金属学报, 2009,45(4):390−395. doi: 10.3321/j.issn:0412-1961.2009.04.002 [14] Zhao Mingchun, Shan Yiyin, Yang Ke. Effect of aging treatment on mechanical property and H2S resistant behavior of acicular ferrite pipeline steels[J]. Acta Metallurgica Sinica, 2004,40(9):948−954. (赵明纯, 单以银, 杨柯. 时效处理对针状铁素体管线钢力学性能和抗硫化氢行为的影响[J]. 金属学报, 2004,40(9):948−954. doi: 10.3321/j.issn:0412-1961.2004.09.010 [15] Kan Liye, Ye Qibin, Wang Yimin, et al. Effect of aging temperatures on microstructure and mechanical properties of 890 MPa grade copper-bearing steel[J]. Journal of Northeastern University(Natural Science), 2020,41(4):499−504. (阚立烨, 叶其斌, 王益民, 等. 时效温度对890 MPa级含铜钢组织与性能的影响[J]. 东北大学学报(自然科学版), 2020,41(4):499−504. doi: 10.12068/j.issn.1005-3026.2020.04.008 [16] GB/T 4160-2004. 钢的应变时效敏感性试验方法[S].GB/T 4160-2004. Steel-strain ageing sensibility test (Charpy impact method)[S]. [17] Bi Zongyue, Yang Jun, Niu Hui, et al. Ipmact toughness of base metal and welding seams of X90 high-strength pipeline steel[J]. Transactions of Materials and Heat Treatment, 2017,38(10):72−79. (毕宗岳, 杨军, 牛辉, 等. X90 高强管线钢母材及焊缝的冲击韧性[J]. 材料热处理学报, 2017,38(10):72−79. [18] Bi Zongyue, Yang Jun, Niu Hui, et al. Impact toughness of base metal and welded joints of X90 high-strength pipeline steel[J]. Transactions of the China Welding Institution, 2018,39(10):35−40. (毕宗岳, 杨军, 牛辉, 等. X90 管线钢管埋弧焊缝组织与性能分析[J]. 焊接学报, 2018,39(10):35−40. [19] Kumar A, Singh S B, Ray R K. Influence of bainite / martensite content on the tensile properties of low carbon dual-phase steels[J]. Mater Sci Eng A, 2008,474(1/2):270. [20] Nie Wenjin, Shang Chengjia, Guan Hailong, et al. Control of microstructures of ferrite/bainite (F/B) dual-phase steel and analysis of their resistance to deformation behavior[J]. Acta Metall Sin., 2012,48(3):298. (聂文金, 尚成嘉, 关海龙, 等. 铁素体/贝氏体(F/B)双相钢组织调控及其抗变形行为分析[J]. 金属学报, 2012,48(3):298. doi: 10.3724/SP.J.1037.2011.00634 [21] 马鸣图, 吴宝榕. 双相钢-物理和力学冶金[M]. 2版. 北京: 冶金工业出版社, 2009: 286.Ma Mingtu, Wu Baorong. Dual phase steel physical and mechanical metallurgy[M]. 2nd Ed. Beijing: Metallurgical Industry Press, 2009: 286. -

下载:

下载: