Industrial study on modification of sulfide in Y1Cr13free-cutting stainless steel by tellurium

-

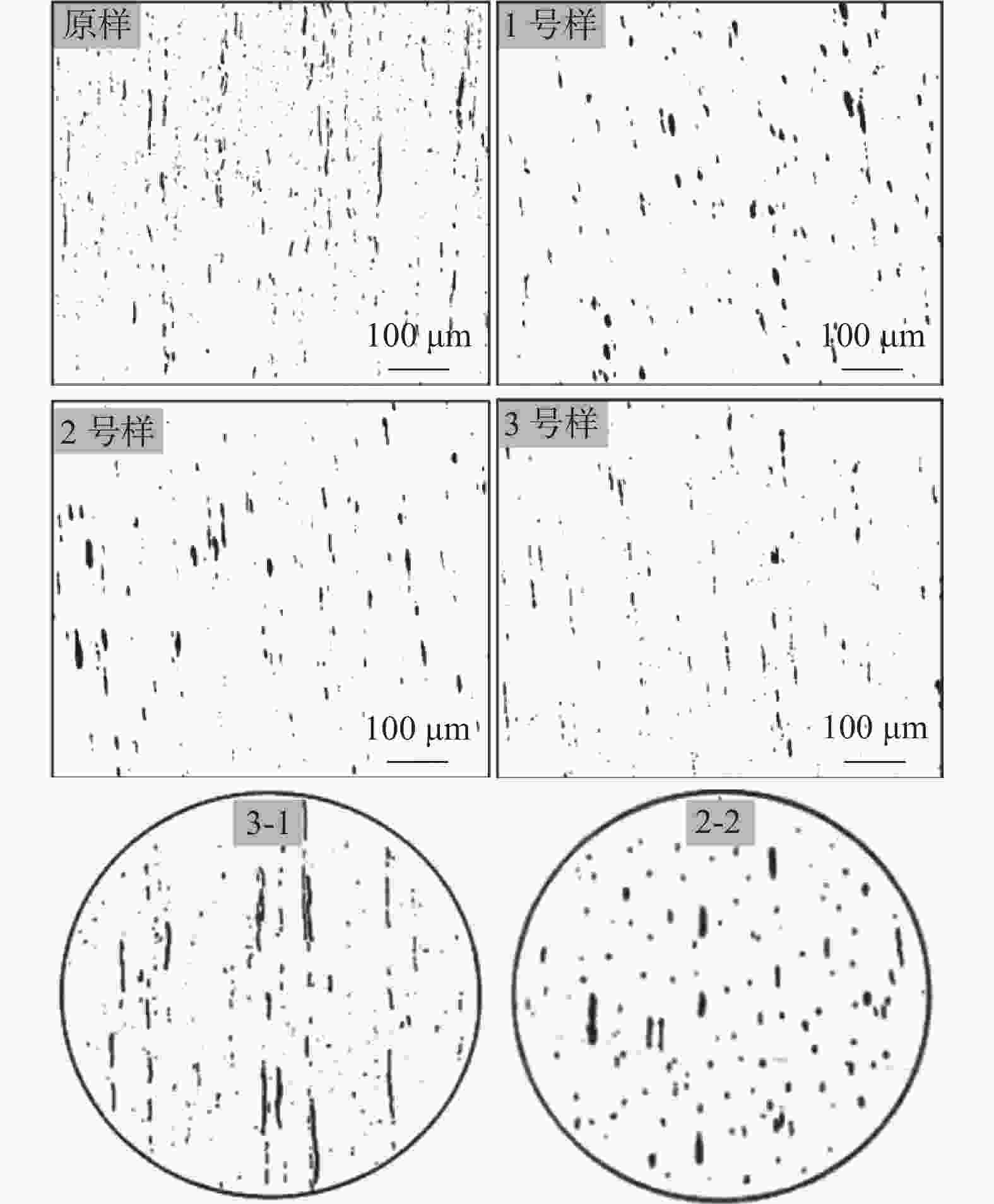

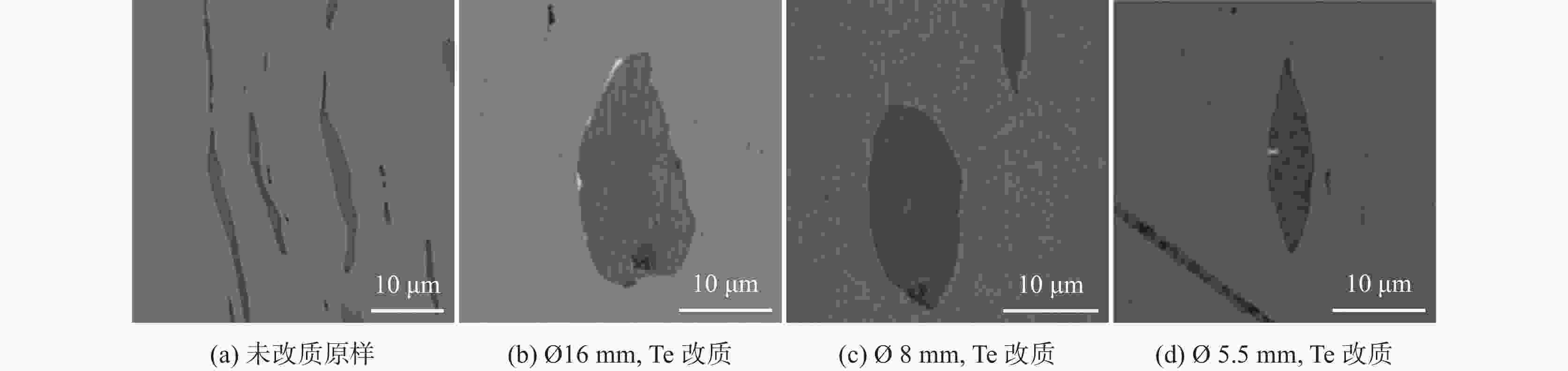

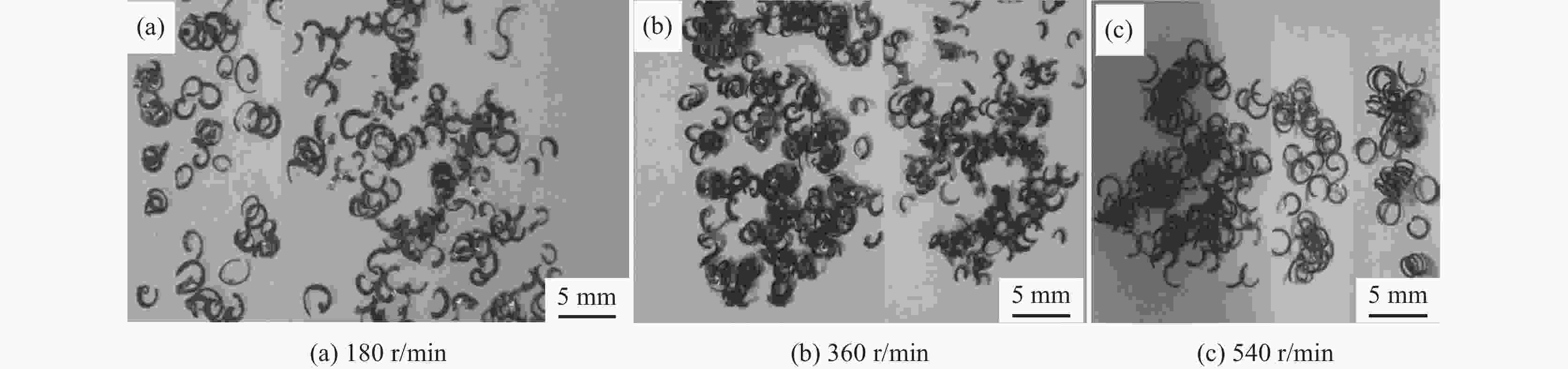

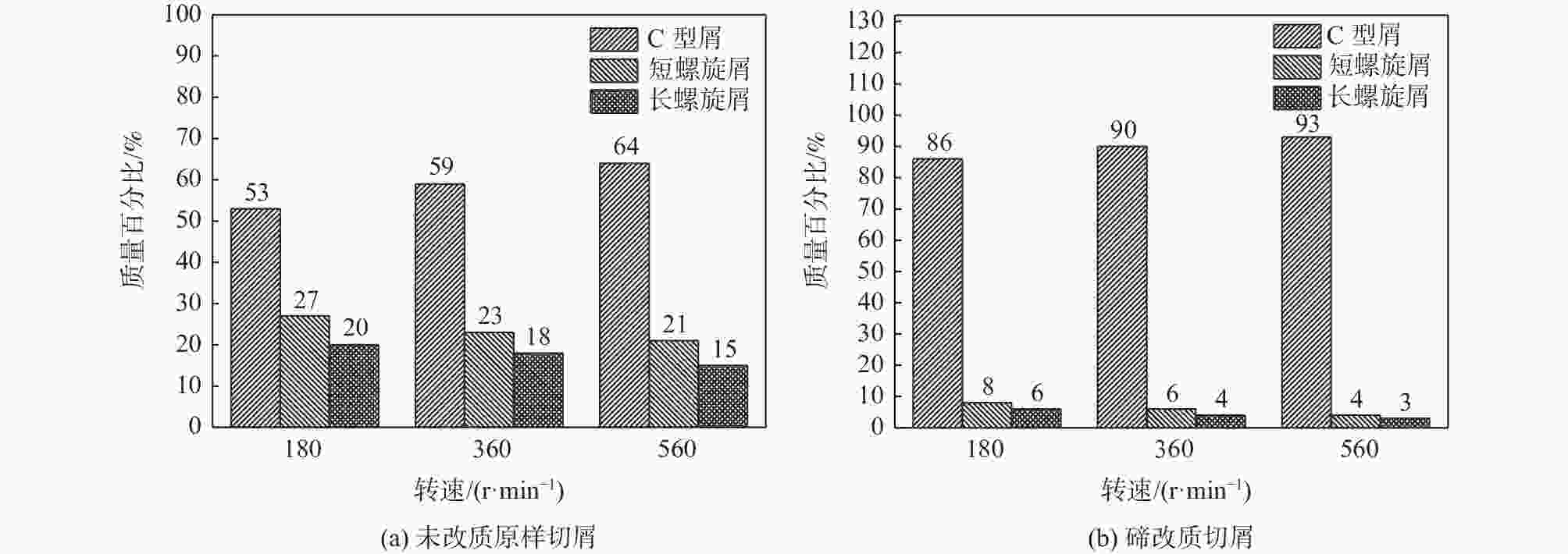

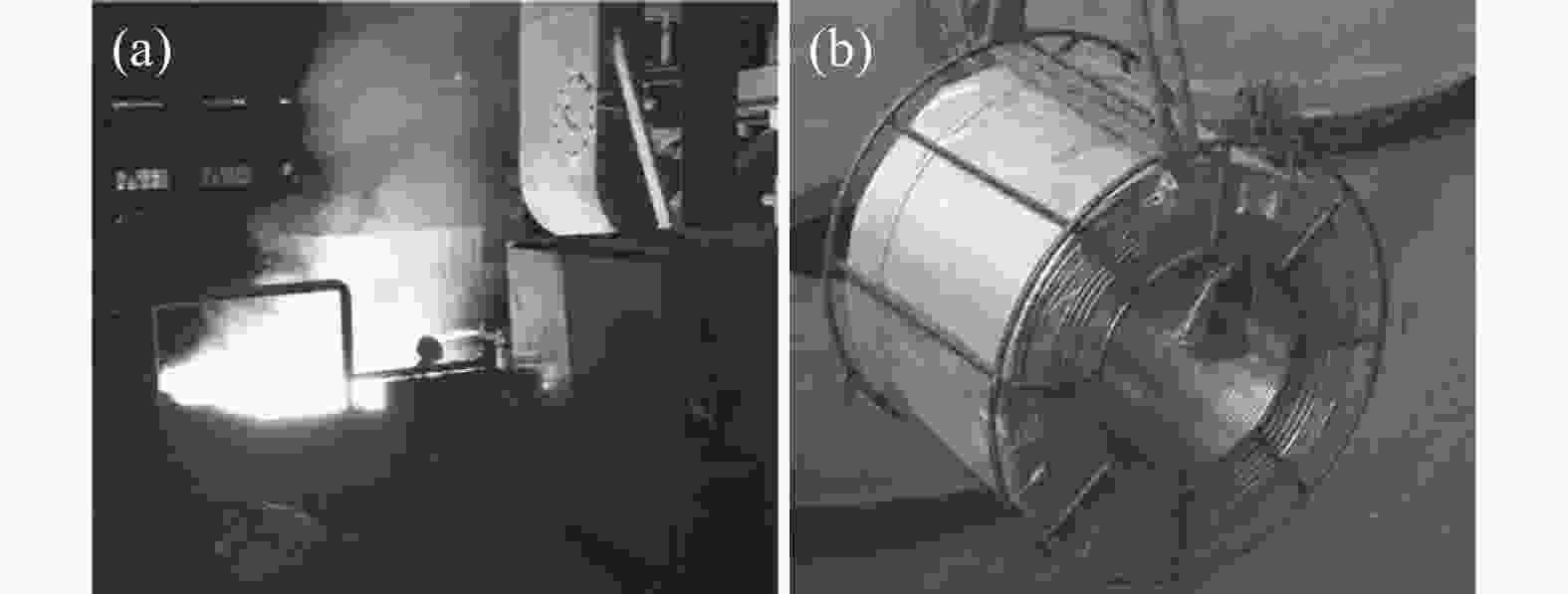

摘要: 借助金相显微镜、扫描电子显微镜,Image-Pro Plus图像分析软件等手段分析了碲改质Y1Cr13不锈钢中硫化物的效果并进行了对比。结果表明,当钢中加入0.011%的碲时MnS夹杂周围析出了MnTe夹杂,促使了硫化物夹杂粗化,大多数硫化物的形貌呈椭球状、纺锤状且分布弥散,同时碲增强了硫化物夹杂的抗变形能力。钢中加碲后,硫化物纺锤率由未改质前的55.4%提高到了86.5%,硫化物评级由未改质前的3-1级下降到了2-2级,硫化物形态及评级得到了显著提升。切削试验表明,钢中未加碲时,在切削速率分别为180、360、560 r/min时,切削后所得C型屑百分比分别为53%、59%、64%,且工件切削表面粗糙度Ra分别为3.407、2.112、4.186 μm,然而当钢中添加碲后,切削后所得C型屑百分比分别为86%、90%、93%,且工件切削表面粗糙度Ra分别为2.302、1.978、3.220 μm。因此,钢中添加碲后,显著提升了钢的切削性能。Abstract: The effect of sulfide modification by Te was analyzed and compared by means of metallographic microscopy, scanning electron microscope and Image-Pro Plus image analysis software. The results show that MnTe inclusions precipitated around the MnS inclusions when 0.011% Te added to the steel, resulting in the coarsening of sulfide inclusions. The morphology of most sulfides is ellipsoidal and spindle with dispersive distribution. Te enhanced the deformation resistance ability of sulfide inclusions. After adding Te to steel, the spindle percentage of sulfide inclusions increased from 55.4% to 86.5% compared to non-addition of Te. The sulfide rating decreased from 3-1 to 2-2. Thus, the sulfide morphology and rating are significantly improved. The machining test shows that when the cutting speed was 180 , 360 and 560 r/min, the percentage of C-chip obtained after cutting was 53%, 59% and 64%, respectively, and the surface roughness (Ra) value of workpiece was 3.407, 2.112 and 4.186 μm, respectively. However, when the Te powder was added to the steel, the percentage of C-chip obtained after cutting was 86%, 90% and 93%, and the surface roughness (Ra) of workpiece after cutting was 2.302, 1.978 and 3.220 μm, respectively. Therefore, the cutting property of steel was improved with Te addition.

-

Key words:

- Y1Cr13 stainless steel /

- sulfides /

- tellurium modification /

- cutting performance

-

表 1 试验钢的主要化学成分

Table 1. Main chemical compositions of the experimental steels

% 试样 C Si Mn P S Cr Ni Te 原样 0.13 0.45 1.15 0.03 0.34 17.25 0.04 碲改质 0.12 0.44 1.17 0.03 0.35 17.14 0.04 0.011 表 2 Y1Cr13不锈钢原样及碲改质轧材A类硫化物评级对比

Table 2. Grade of type A inclusions in Y1Cr13 stainless steel and Te modified rolled bars

样品 国标评级(GBT 10516-2005 ) 德标评级 原样 粗系4.5级,细系5.5级 3-1级 1#样 粗系4.0级,细系2.5级 2-2级 2#样 粗系4.0级,细系4.0级 2-2级 3#样 粗系2.5级,细系3.0级 2-2级 表 3 轧材硫化物统计

Table 3. Statistics of the inclusions in the rolled bars

样品 规格/mm 硫化物平均面积/μm2 硫化物平均等效直径/μm 硫化物密度/(个·mm−2) 总长宽比 原样 Ø16 5.4 2.2 4232 6.79 1#样 Ø16 24.07 5.70 1624 3.65 2#样 Ø8 13.71 4.78 1853 3.89 3#样 Ø5.5 9.95 3.32 2245 3.31 表 4 切削钢表面粗糙度统计

Table 4. Statistics of surface roughness of the machining steels

转速/

(r·min−1)Ra/µm 原样 碲改质 测定值 平均值 测定值 平均值 180 3.155,3.276,3.790 3.407 2.184,2.449,2.274 2.302 360 2.165,2.074,2.098 2.112 1.977,1.903,2.055 1.978 560 4.000,4.392,4.167 4.186 3.199,3.187,3.274 3.220 -

[1] Lin Qizeng, Li Cheng. Rapidly developing stainless steel industry in China[J]. Iron and Steel, 2006,41(12):1−2. (林企曾, 李成. 迅速发展的中国不锈钢工业[J]. 钢铁, 2006,41(12):1−2. doi: 10.3321/j.issn:0449-749X.2006.12.001 [2] Wu Hailong, Huang Yun, Huang Zhi, et al. Experimental research on the abrasive belt grinding turbine blades material 1Cr13 stainless steel[J]. Key Engineering Materials, 2011,487(1):452−453. [3] Cardoso P H S, Kwietniewski C, Porto J P, et al. The influence of delta ferrite in the AISI 416 stainless steel hot workability[J]. Materials Science and Engineering A, 2003,351(1):1−2. [4] Domizzi G, Anteri G, Ovejero-Garcia J. Influence of sulphur content and inclusion distribution on the hydrogen induced blister cracking in pressure vessel and pipeline steels[J]. Corrosion Science, 2001,43(2):325−326. doi: 10.1016/S0010-938X(00)00084-6 [5] Li Yanmei, Zhu Fuxian, Cui Fengping, et al. Analysis on formation mechanism of delamination defect in medium and heavy steel plate[J]. Journal of Northeast University:Natural Science Edition, 2007,28(7):1002−1003. (李艳梅, 朱伏先, 崔凤平, 等. 中厚钢板分层缺陷的形成机制分析[J]. 东北大学学报:自然科学版, 2007,28(7):1002−1003. [6] Li Tai. Hot forging crack analysis and improvement measures of non-uenched and tempered steel F45MnVS[J]. Special Steel, 2015,36(5):28−30. (李泰. 非调质钢F45MnVS热顶锻裂纹分析和改进工艺措施[J]. 特殊钢, 2015,36(5):28−30. [7] Chen Xiaokang, Yang Shufeng, Li Jingshe. Inclusion modification of E36 ship plate steel containing yttrium[J]. China Metallurgy, 2019,29(12):25−26. (陈晓康, 杨树峰, 李京社. 含钇E36船板钢硫化物改性[J]. 中国冶金, 2019,29(12):25−26. [8] A. Mahmutoviü, M. Rimac. Modification of non-metallic inclusions by tellurium in austenitic stainless steel[J]. Journal of Trends in the Development of Machinery and Associated Technology, 2015, 19(1): 53-56. [9] Zhang Shuo, Yang Shufeng, Li Jingshe, et al. Control of MnS inclusion morphology in Y15 free-cutting steel by tellurium treatment[J]. Iron and Steel, 2017,52(9):27−29. (张硕, 杨树峰, 李京社, 等. 碲处理控制Y15易切削钢中MnS硫化物形貌[J]. 钢铁, 2017,52(9):27−29. [10] Li Jie, Zhu Qiangbin, Fu Jianxun, et al. Morphology of MnS inclusions in tellurium modified 303Cu stainless steel[J]. Iron Steel Vanadium Titanium , 2020,41(6):135−136. (李杰, 朱强斌, 付建勋, 等. 碲改质303Cu不锈钢中MnS夹杂物形态[J]. 钢铁钒钛, 2020,41(6):135−136. doi: 10.7513/j.issn.1004-7638.2020.06.024 [11] Zheng L, Malfliet A, Wollants P, et al. Effect of surfactant Te on the formation of MnS inclusions in steel[J]. Metallurgical and Materials Transactions B, 2017,48(5):2447−2448. doi: 10.1007/s11663-017-1050-5 [12] Shen Ping, Yang Qiankun, Zhang Dong, et al. Application of tellurium in free-cutting steels[J]. Journal of Iron and Steel Research International, 2018,25(8):787−789. doi: 10.1007/s42243-018-0123-2 [13] Wu Xiangyu, Wu Liangping, Fu Jianxun, et al. Modification of sulfide by Te in Y1Cr13 free-cutting stainless steel[J]. Metallurgical Research & Technology, 2020,117(1):107−108. [14] Xie Jianbo, Wu Liangping, Fu Jianxun, et al. Morphology and composition characteristics of solid solution in Te-treated Y1Cr17 steel[J]. Emerging Materials Research, 2020,9(4):1145−1146. doi: 10.1680/jemmr.19.00138 [15] Hao Yuan, Zhu Pingshun. Effect of tellurium on cast steel[J]. Journal of Lanzhou University of Technology, 1991,(3):53−54. (郝远, 朱平顺. 碲在铸钢中的作用[J]. 兰州理工大学学报, 1991,(3):53−54. -

下载:

下载: