Research on radio frequency plasma spheroidized Ti-25Ta powder and its fabrication by selective laser melting

-

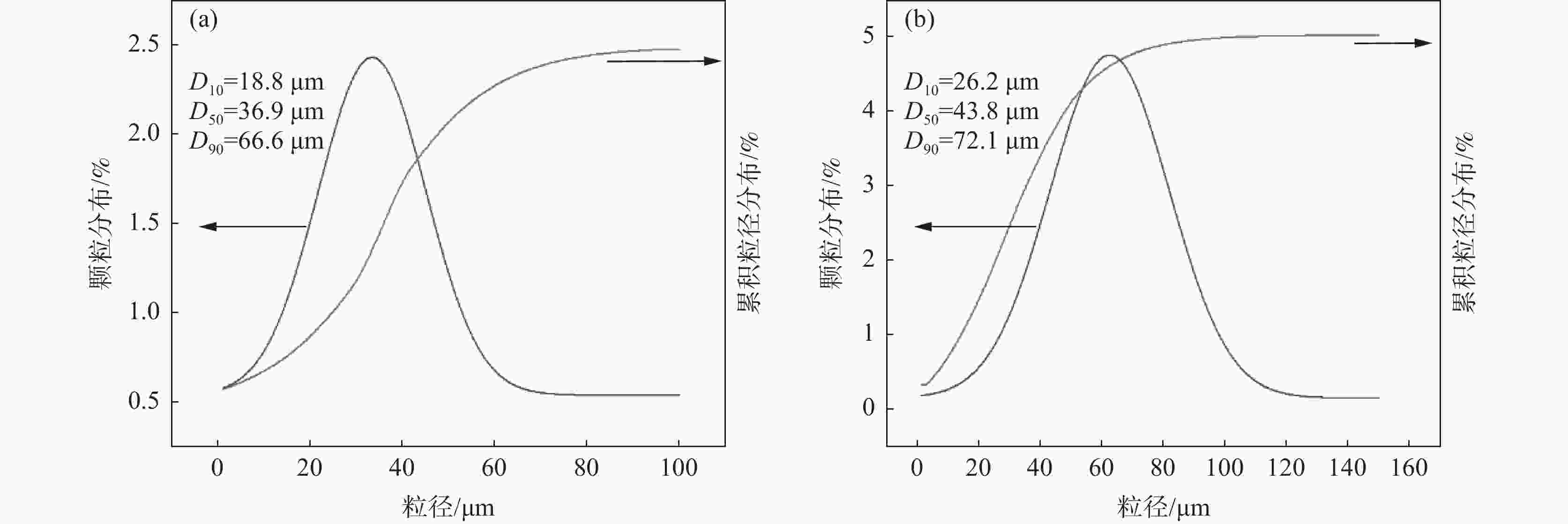

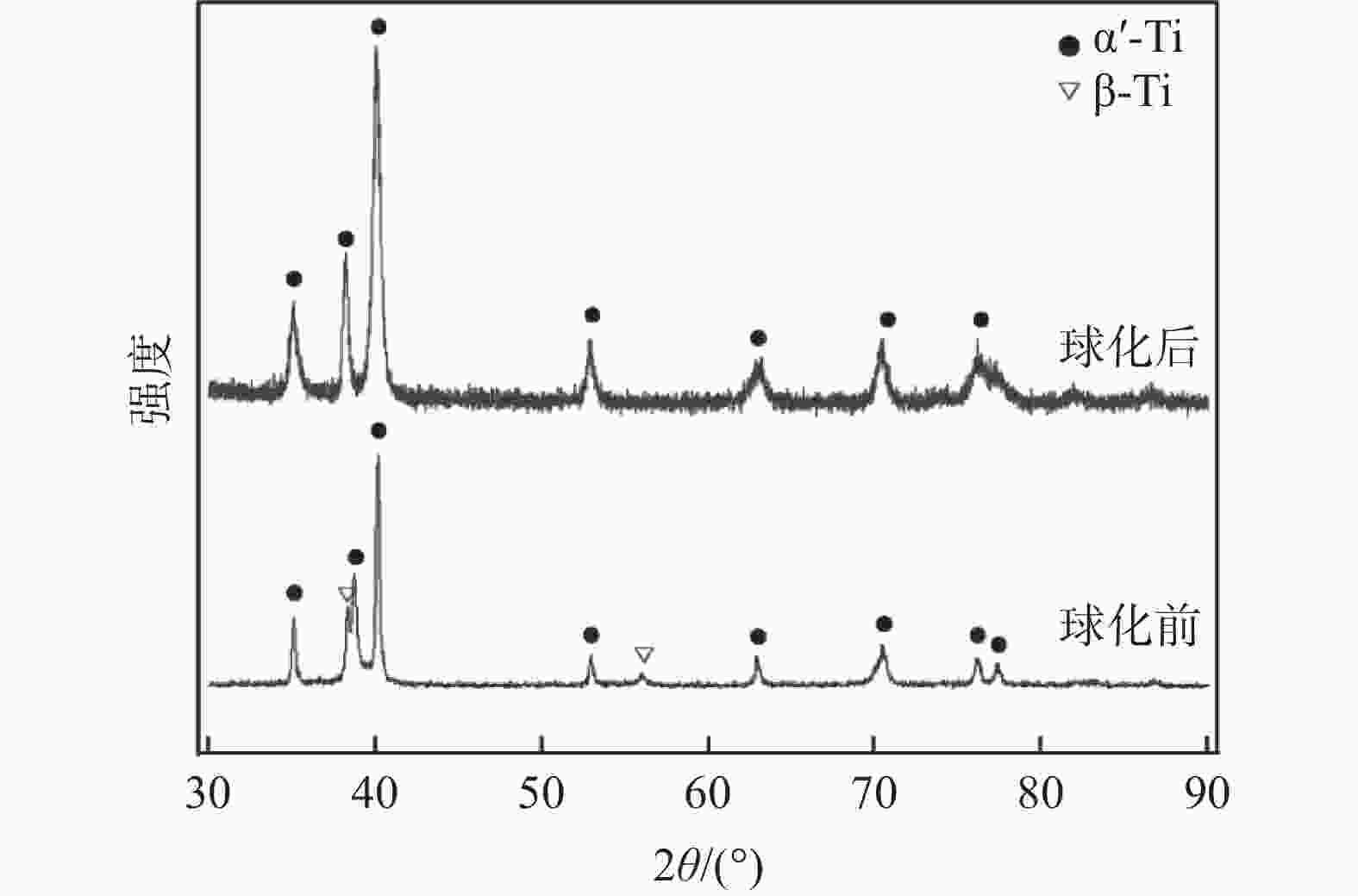

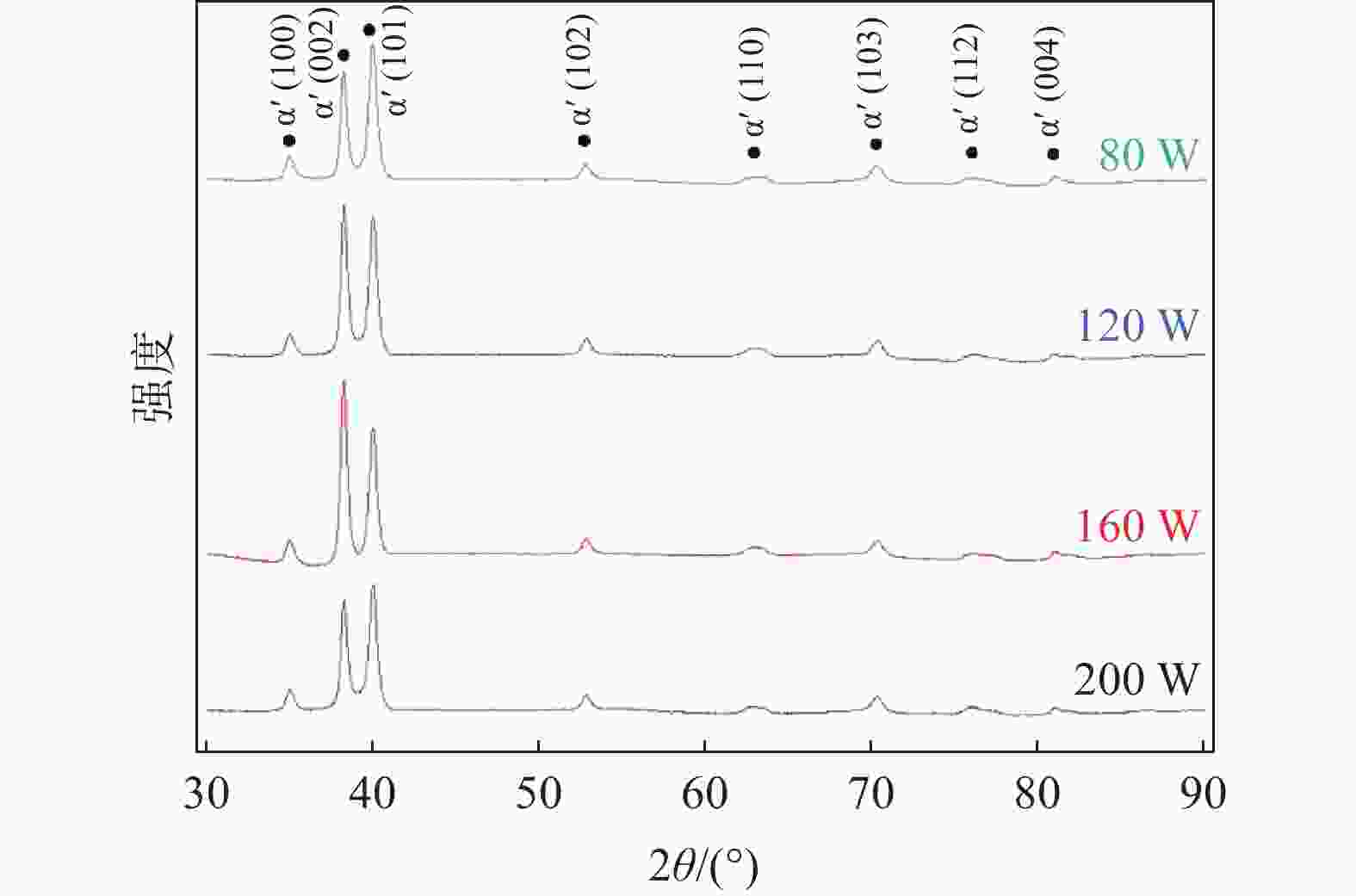

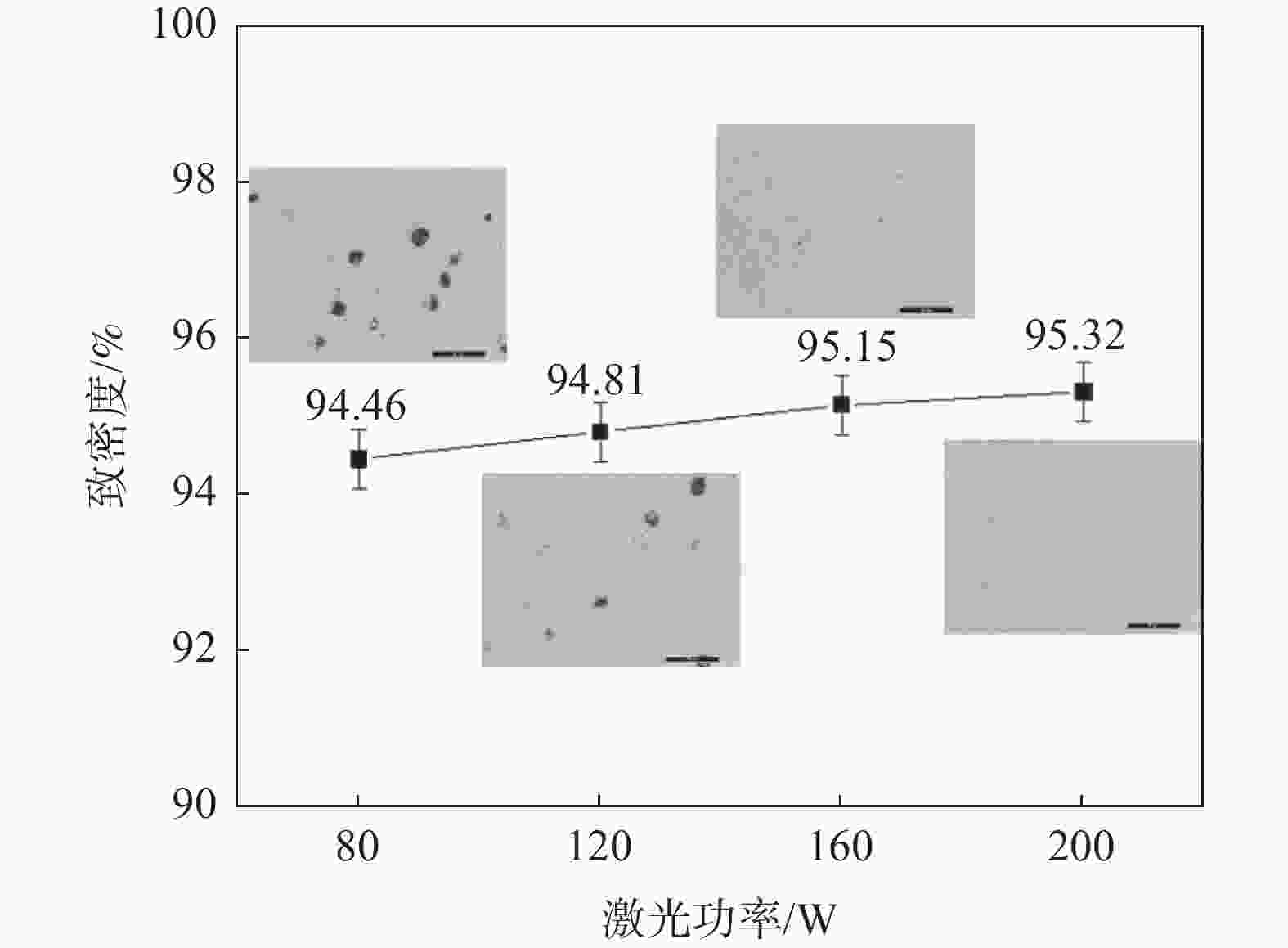

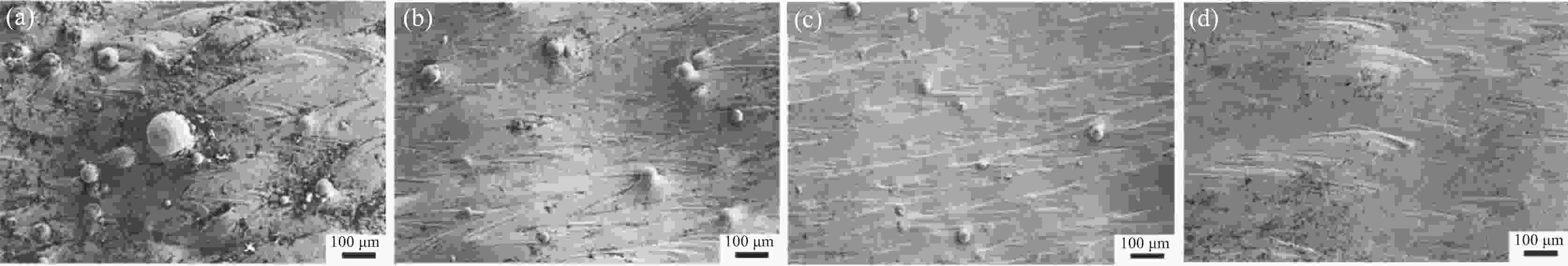

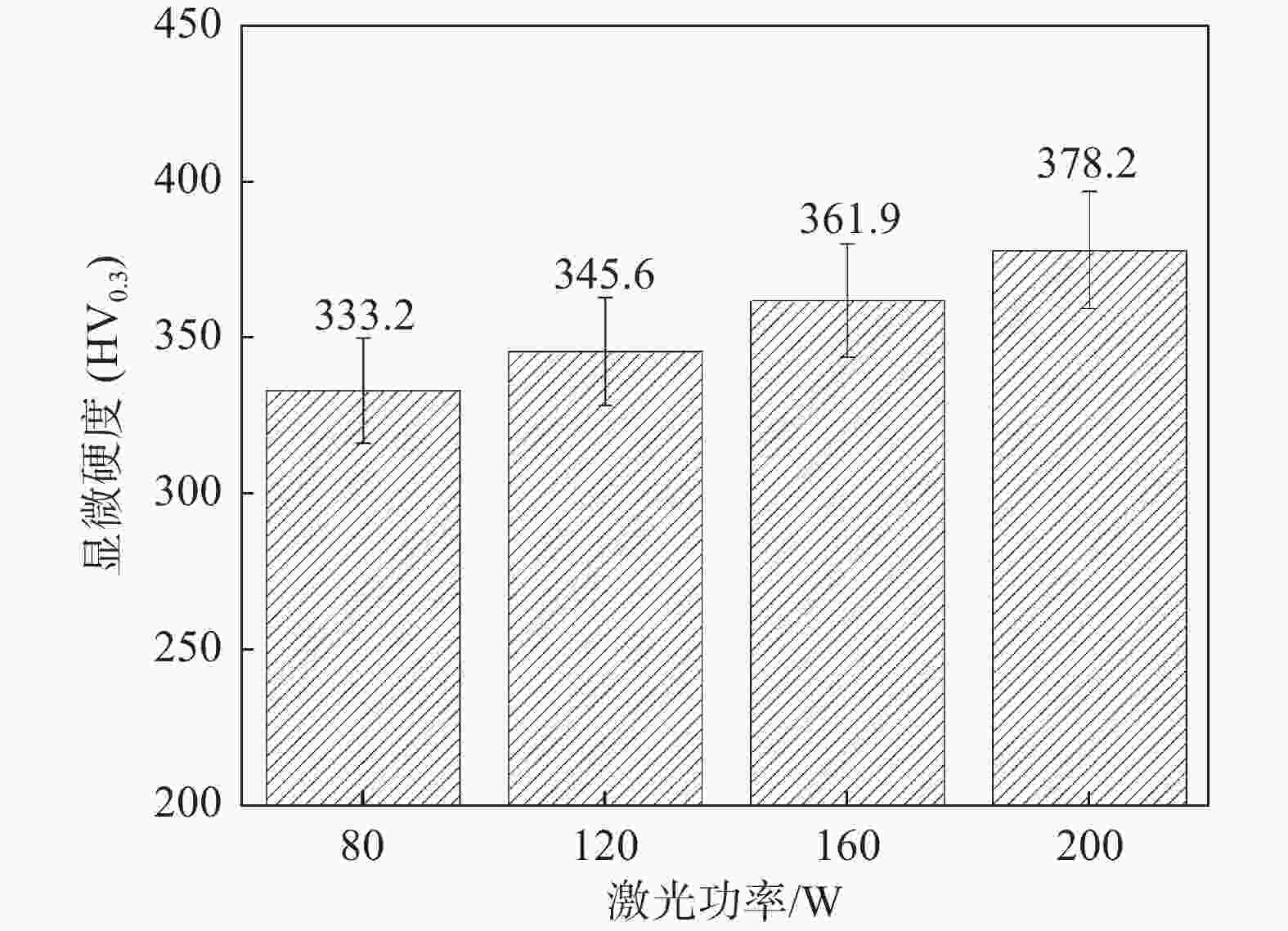

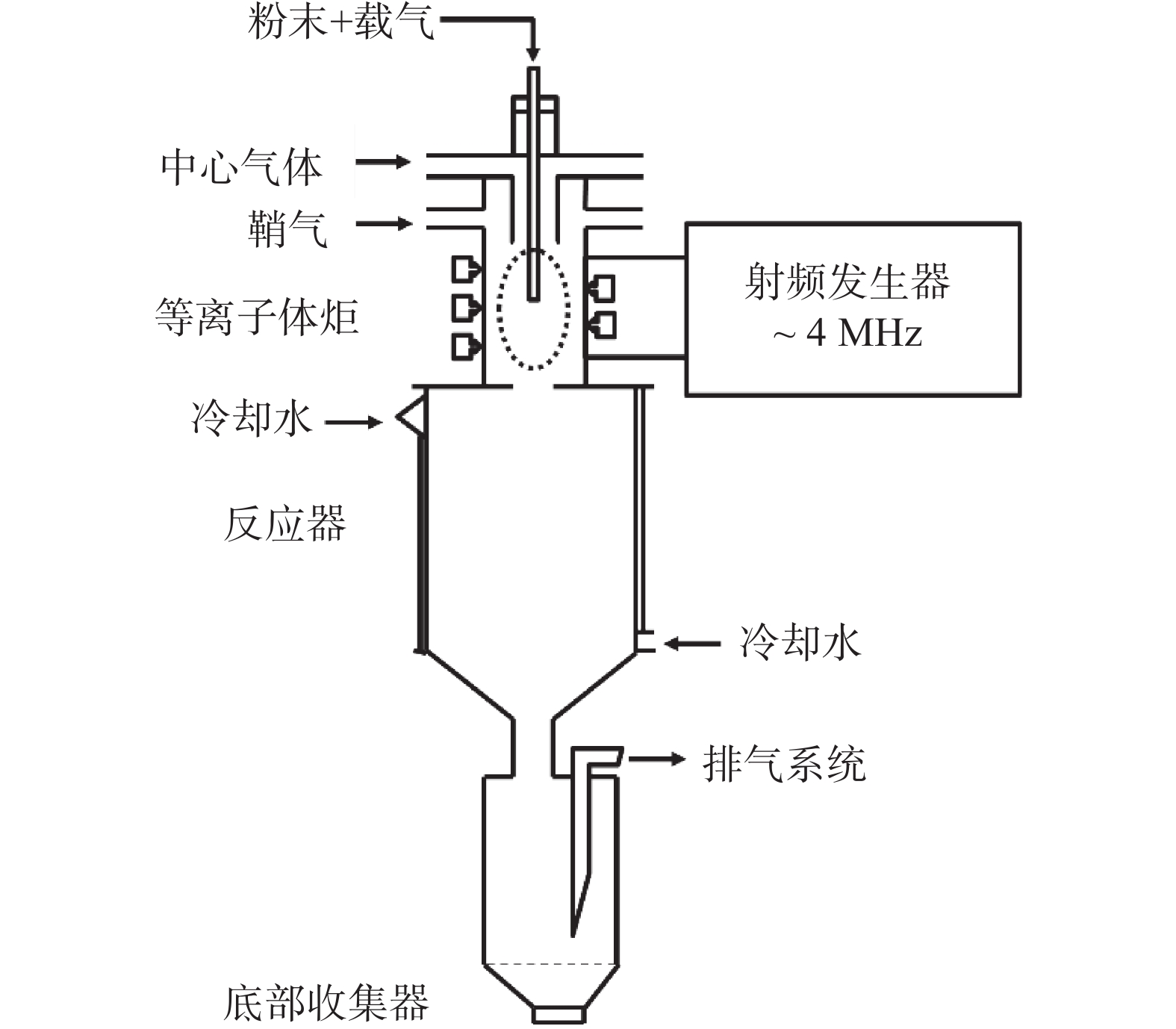

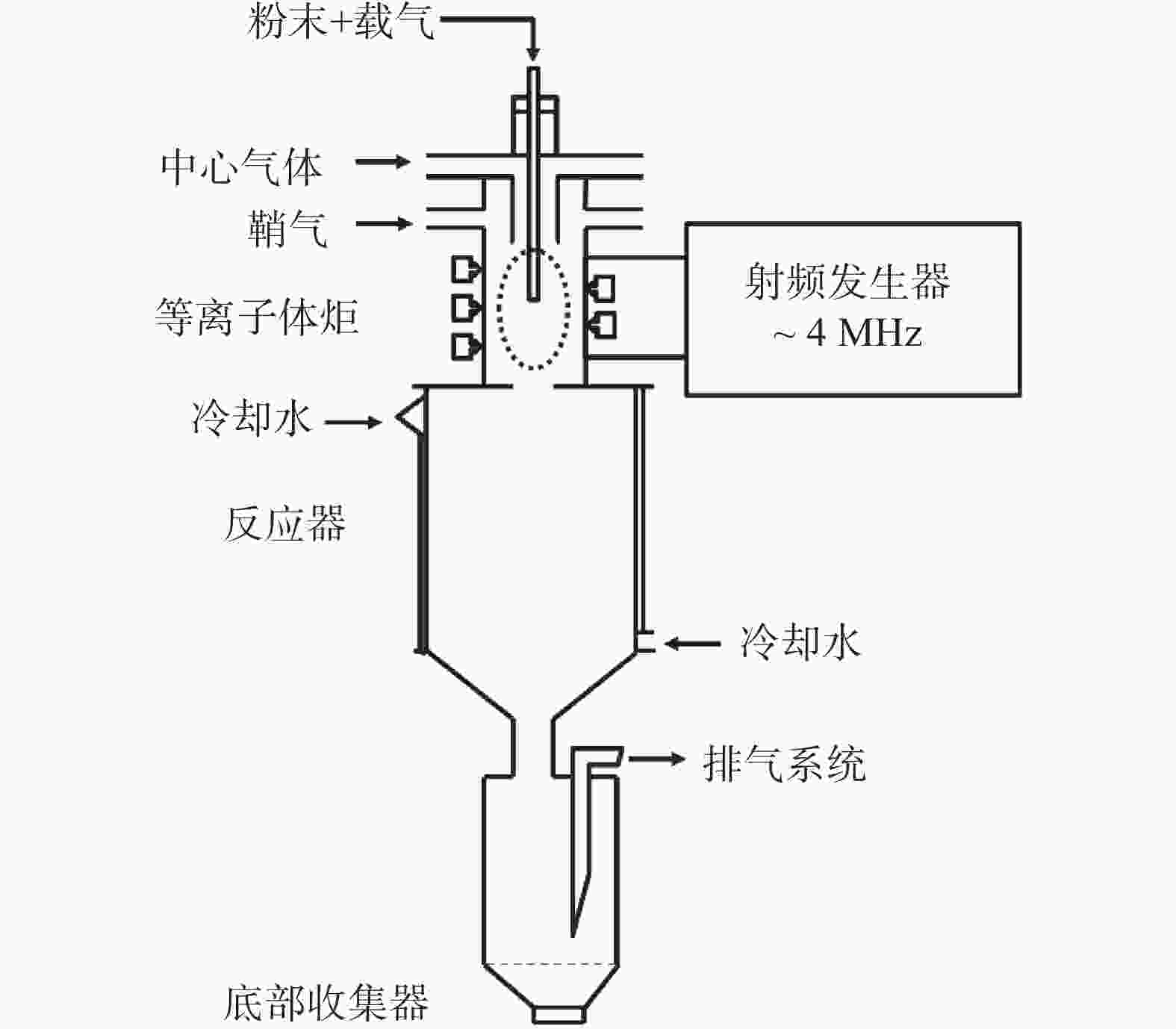

摘要: 利用射频等离子体球化工艺成功制备了Ti-25Ta合金粉末,采用选区激光熔化成形Ti-25Ta合金球形粉末,研究了激光功率对打印件表面形貌、致密度、微观组织和力学性能的影响。结果显示,球化后Ti-25Ta合金粉末D50为43.8 μm,较原料粒径略有增大。原料粉末内部为枝晶组织,球化后粉末内部呈胞状组织。粉末的流动性、松装密度和振实密度均有大幅提高。随着激光功率增加,α'马氏体细化明显。在较高激光功率200 W时,致密度达到最大95.32%,显微硬度(HV0.3)为378.2。拉伸试验表明,随着激光功率的增大,材料断裂机制由脆性断裂转变为脆性和韧性断裂。Abstract: The Ti-25Ta alloy powder was successfully prepared by radio frequency plasma spheroidization, and the Ti-25Ta alloy spherical powder was subsequently formed by selective laser melting. The effect of laser power on the surface morphology, density, microstructure and mechanical properties was studied. The results show that the D50 of the Ti-25Ta alloy powder after spheroidization is 43.8 μm, which is slightly larger than that of the raw material. The interior of the raw material powder exhibits dendrite structure, while the interior of the powder after spheroidization shows a cellular structure. The flowability, bulk density and tap density of the powder are greatly improved. As the laser power increases, the α′ martensite refinement is obvious. At a higher laser power of 200 W, the density reaches a maximum of 95.32% vs. solid, and the microhardness (HV0.3) is 378.2. The tensile testing shows that with the increase in laser power, the fracture mechanism of the material changes from brittle fracture to brittle-ductile fracture.

-

表 1 射频等离子体球化Ti-25Ta合金粉末试验参数

Table 1. Experimental parameters of radio frequency plasma spheroidization of Ti-25Ta powder

载气(Ar)输送量/

(L·min−1)鞘气(He)输送量/

(L·min−1)输送粉末速率/

(g·min−1)等离子体输

出功率/kW5 10 30 26 表 2 选区激光熔化成形参数

Table 2. SLM process parameters

编号 激光功

率/W扫描速度/

(mm·s−1)层厚/

μm扫描间距/

μm激光能量密度/

(J·mm−3)S1 80 500 30 60 88.88 S2 120 500 30 60 133.33 S3 160 500 30 60 177.77 S4 200 500 30 60 222.22 表 3 Ti-25Ta合金粉末球化前后的粉末特征

Table 3. Particle characteristics of Ti-25Ta powder before and after spheroidization

钛钽合金粉末 流动性

(以50 g计)/s松装密度/

(g·cm−3)振实密度/

(g·cm−3)原料粉末 1.38 2.54 球化粉末 6.27 3.11 7.73 表 4 球化前后Ti-25Ta合金粉末化学成分

Table 4. Chemical compositions of Ti-25Ta powder before and after spheroidization

% Ti Ta H O C 球化前 Bal. 26.57 0.028 0.15 0.032 球化后 Bal. 28.24 0.02 0.16 0.026 表 5 不同功率下Ti-25Ta合金试样的拉伸性能

Table 5. Tensile properties of Ti-25Ta specimens fabricated using various laser powers

编号 激光功率/W 抗拉强度/MPa 屈服强度/MPa 延伸率/% S1 80 408 219 1 S2 120 906 468 2 S3 160 831 397 4 S4 200 1035 523 5 -

[1] Oliveira Campos F, Araujo A C, Munhoz A L J, et al. The influence of additive manufacturing on the micromilling machinability of Ti6Al4V: A comparison of SLM and commercial workpieces[J]. Journal of Manufacturing Processes, 2020,60:299−307. doi: 10.1016/j.jmapro.2020.10.006 [2] Harun W S W, Manam N S, Kamariah M, et al. A review of powdered additive manufacturing techniques for Ti-6Al-4V biomedical applications[J]. Powder Technology, 2018,331:74−97. doi: 10.1016/j.powtec.2018.03.010 [3] Sopata M, Sadej M, Jakubowicz J. High temperature resistance of novel tantalum-based nanocrystalline refractory compounds[J]. Journal of Alloys and Compounds, 2019,788:476−484. doi: 10.1016/j.jallcom.2019.02.230 [4] Sun P, Fang Z Z, Zhang Y, et al. Microstructure and mechanical properties of Ti-6Al-4V fabricated by selective laser melting of powder produced by granulation-sintering-deoxygenation method[J]. JOM, 2017,69(12):2731−2737. doi: 10.1007/s11837-017-2584-3 [5] Vrancken B, Thijs L, Kruth J P, et al. Microstructure and mechanical properties of a novel β titanium metallic composite by selective laser melting[J]. Acta Materialia, 2014,68:150−158. doi: 10.1016/j.actamat.2014.01.018 [6] Morita A, Fukui H, Tadano H, et al. Alloying titanium and tantalum by cold crucible levitation melting (CCLM) furnace[J]. Materials Science and Engineering:A, 2000,280(1):208−213. doi: 10.1016/S0921-5093(99)00668-1 [7] Laheurte P, Prima F, Eberhardt A, et al. Mechanical properties of low modulus β titanium alloys designed from the electronic approach[J]. Journal of the Mechanical Behavior of Biomedical Materials, 2010,3(8):565−573. doi: 10.1016/j.jmbbm.2010.07.001 [8] Málek J, Hnilica F, Veselý J, et al. Microstructure and mechanical properties of Ti-35Nb-6Ta alloy after thermomechanical treatment[J]. Materials Characterization, 2012,66:75−82. doi: 10.1016/j.matchar.2012.02.012 [9] Brodie E G, Robinson K J, Sigston E, et al. Osteogenic potential of additively manufactured Ti-Ta alloys[J]. ACS Applied Bio Materials, 2021,4(1):1003−1014. doi: 10.1021/acsabm.0c01450 [10] Sehhat M H, Behdani B, Hung C H, et al. Development of an empirical model on melt pool variation in laser foil printing additive manufacturing process using statistical analysis[J]. Metallography, Microstructure and Analysis, 2021,10(5):684−691. doi: 10.1007/s13632-021-00795-x [11] Hung C H, Turk T, Sehhat M H, et al. Development and experimental study of an automated laser-foil-printing additive manufacturing system[J]. Rapid Prototyping Journal, 2022,28(1):20−21. [12] Behdani B, Senter M, Mason L, et al. Numerical study on the temperature-dependent viscosity effect on the strand shape in extrusion-based additive manufacturing[J]. Journal of Manufacturing and Materials Processing, 2020,4(2):46. doi: 10.3390/jmmp4020046 [13] Han C, Fang Q, Shi Y, et al. Recent advances on high‐entropy alloys for 3D printing[J]. Advanced Materials, 2020,32(26):1903855. doi: 10.1002/adma.201903855 [14] Sun P, Fang Z Z, Zhang Y, et al. Review of the methods for production of spherical Ti and Ti alloy powder[J]. JOM, 2017,69(10):1853−1860. doi: 10.1007/s11837-017-2513-5 [15] Ogren J R. Powder metallurgy of iron and steel[J]. Journal of Materials Engineering and Performance, 1998,7(4):455. [16] Samal P, Newkirk J. Powder metallurgy methods and applications[J]. JOM, 2020,31(10):1356−1357. [17] Gu Z T, Ye G Y, Jin Y P. Composition analysis of spherical titanium powder prepared by radio frequency induced plasma[J]. Intense Laser and Particle Beam, 2012,24(6):1409−1413. doi: 10.3788/HPLPB20122406.1409 [18] Jiang X L, Boulos M. Induction plasma spheroidization of tungsten and molybdenum powders[J]. Transactions of Nonferrous Metals Society of China, 2006,16(1):13−17. doi: 10.1016/S1003-6326(06)60003-4 [19] Soro N, Attar H, Brodie E, et al. Evaluation of the mechanical compatibility of additively manufactured porous Ti–25Ta alloy for load-bearing implant applications[J]. Journal of the Mechanical Behavior of Biomedical Materials, 2019,97:149−158. doi: 10.1016/j.jmbbm.2019.05.019 -

下载:

下载: