Effect of heat treatment on microstructure and properties of Ti84Al11FeMo4 titanium alloy

-

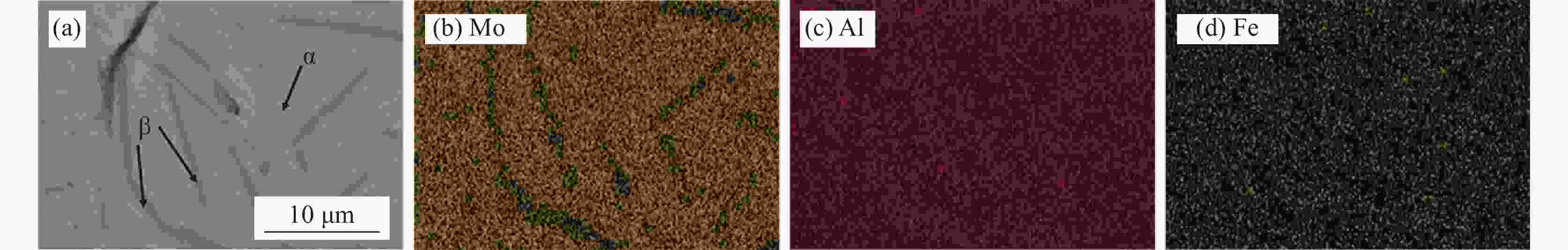

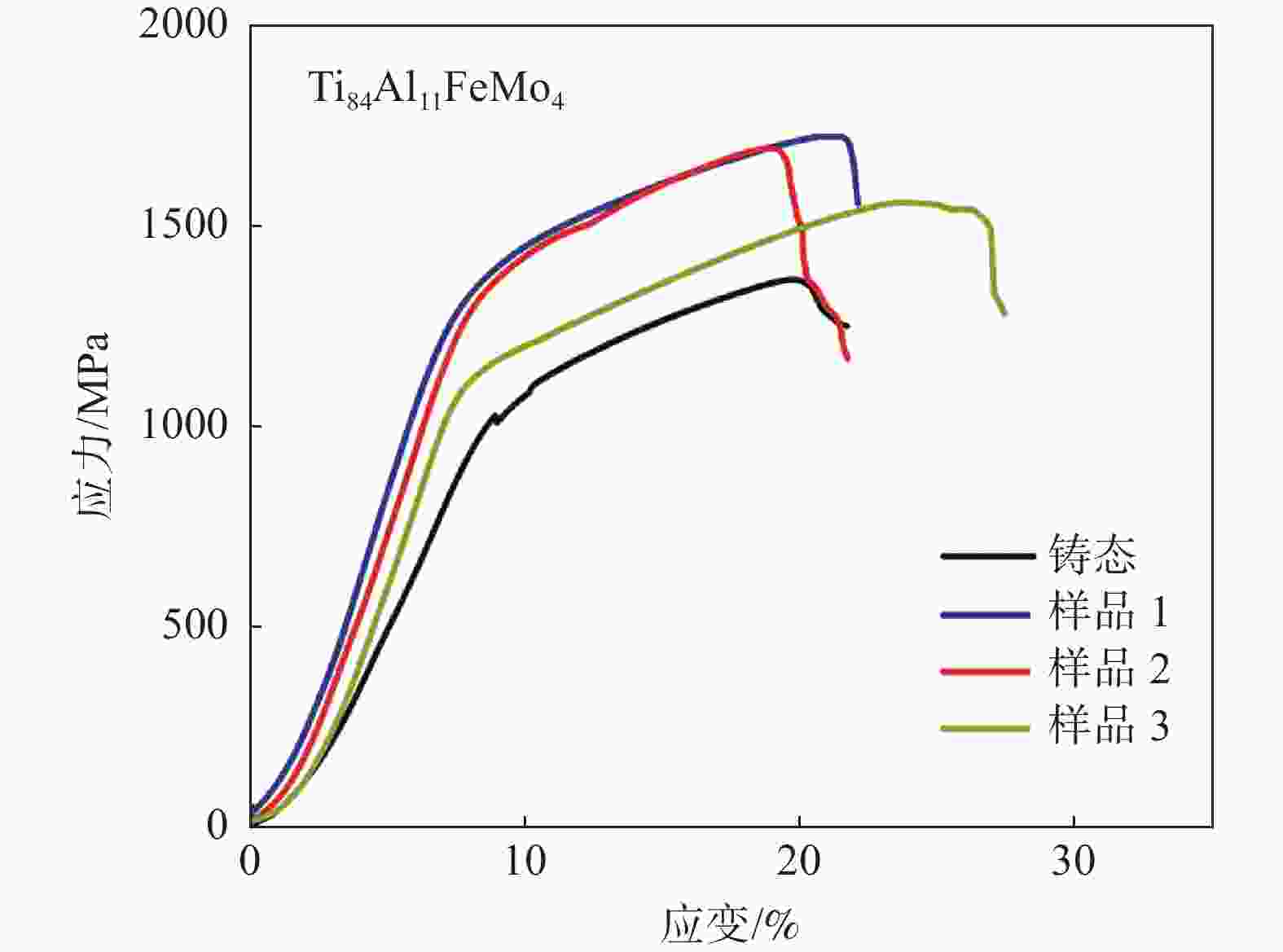

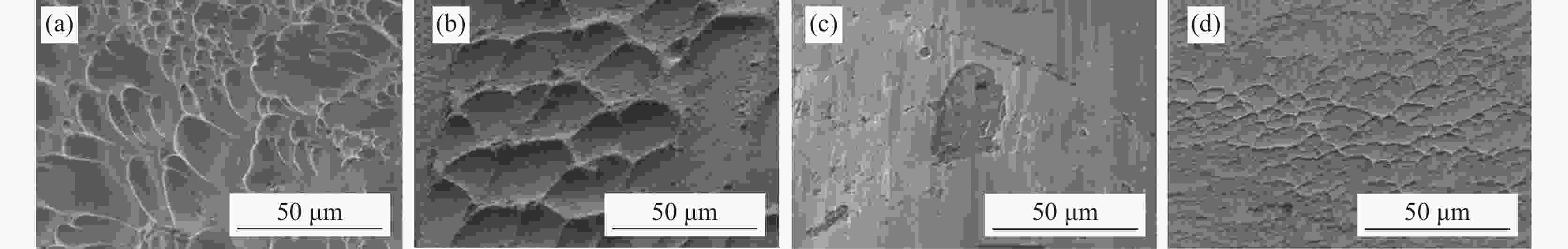

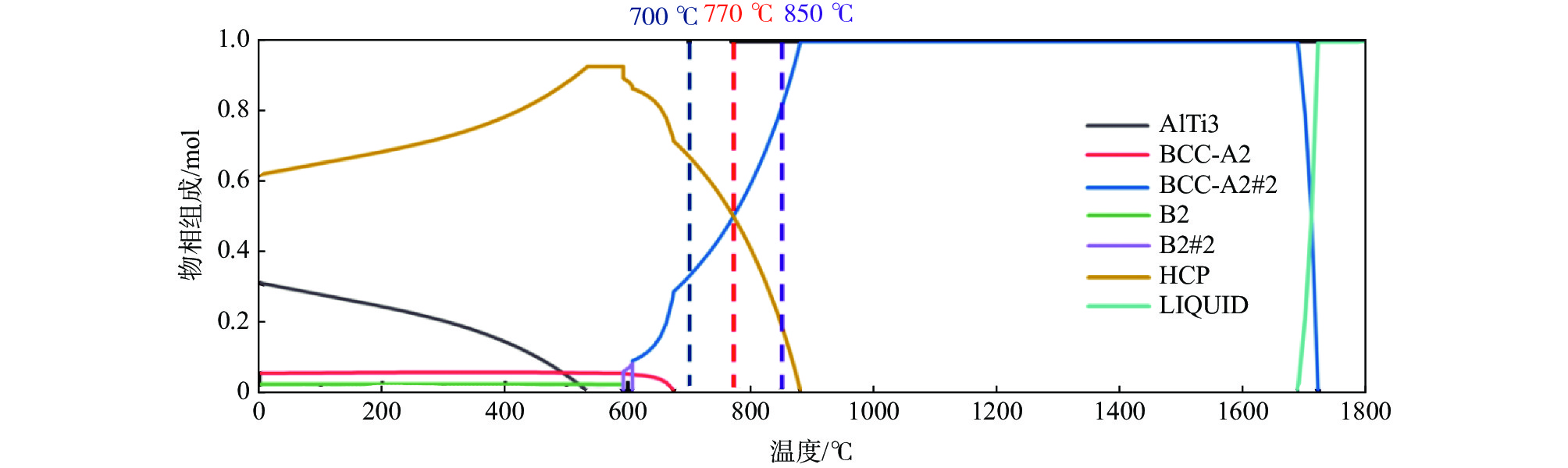

摘要: 通过d电子理论设计出新型两相钛合金Ti84Al11FeMo4,分析了物相组成随温度的变化关系。结合热力学计算结果,分别研究了700、770 ℃以及850 ℃不同时效温度下钛合金的微观组织与力学性能的演化关系。结果表明,随着时效处理温度的提高,Ti84Al11FeMo4钛合金微观组织中β相的含量逐渐增多。当时效温度增加到850 ℃时,β析出相的含量最多,且在粗β相间分布着大量细小尺寸的β相。Ti84Al11FeMo4钛合金经不同时效温度处理后表现出不同的力学性能,在700 ℃和770 ℃下时效处理后可显著提高钛合金的压缩强度,而在850 ℃下时效后可以实现钛合金的强度和塑性的同步提升。

-

关键词:

- 钛合金 /

- Ti84Al11FeMo4 /

- 热处理 /

- 强度 /

- 塑性

Abstract: A novel two-phase titanium alloy of Ti84Al11FeMo4 was designed based on d-electron theory and the phase composition as a function of temperature was analyzed. Combined with the thermodynamic calculation results, the evolution relationship between the microstructure and mechanical properties of titanium alloys at different aging temperatures of 700 ℃, 770 ℃ and 850 ℃ was studied, respectively. The results show that the amount of β phase in the microstructure of Ti84Al11FeMo4 titanium alloy gradually increases with the increase of aging temperature. When the aging temperature is increased to 850 ℃, the amount of β precipitates reaches the maximum, and a large number of small-sized β phases are distributed among the coarse β phases. Ti84Al11FeMo4 titanium alloy exhibits different mechanical properties after aging treatment at different temperatures. The compressive strength of titanium alloy could be significantly improved after aging at 700 ℃ and 770 ℃, while the high strength and ductility could be simultaneously obtained after aging at 850 ℃.-

Key words:

- titanium alloy /

- Ti84Al11FeMo4 /

- heat treatment /

- strength /

- ductility

-

表 1 Ti中不同元素Bo、Md参数值

Table 1. Bo and Md parameter values of different elements in Ti alloy

元素 Bo Md Ti 3.513 2.447 Fe 3.428 0.969 Al 3.297 2.2 Mo 3.759 1.961 表 2 热处理制度及热力学理论物相组成

Table 2. Heat treatment system and thermodynamic theory phase composition

序号 固溶温度/℃ 时效温度/℃ 物相组成/% α-Ti β-Ti 样品1 950+WQ 700+WQ 65 35 样品2 950+WQ 770+WQ 50 50 样品3 950+WQ 850+WQ 20 80 注:WQ表示水冷。 表 3 不同时效温度下Ti84Al11FeMo4合金压缩强度和断裂塑性

Table 3. Compressive strength and fracture ductility of Ti84Al11FeMo4 alloy obtained at different aging temperatures

样品 压缩强度/MPa 断裂塑性/% 铸态 1366 20 样品1 1712 22 样品2 1695 18.9 样品3 1558 24 -

[1] Oh J M, Park C H, Yeom J T, et al. High strength and ductility in low-cost Ti-Al-Fe-Mn alloy exhibiting transformation-induced plasticity[J]. Materials Science and Engineering:A, 2020,772:138813. doi: 10.1016/j.msea.2019.138813 [2] Zhu W, Lei J, Tan C, et al. A novel high-strength β-Ti alloy with hierarchical distribution of α-phase: The superior combination of strength and ductility[J]. Materials & Design, 2019,168:107640. [3] Das J, Gogia A K, Satyanarayana D V V. Effect of iron and nickel impurities on creep and tensile behaviour of Ti-24Al-20Nb-0.5Mo alloy[J]. Materials Science and Engineering:A, 2008,496(1-2):1−8. doi: 10.1016/j.msea.2008.07.014 [4] Fan J, Li J, Zhang Y, et al. Formation and crystallography of nano/ultrafine-trimorphic structure in metastable β titanium alloy Ti-5Al-5Mo-5V-3Cr-0.5Fe processed by dynamic deformation at low temperature[J]. Materials Characterization, 2017,130:149−155. doi: 10.1016/j.matchar.2017.06.005 [5] Fan J, Kou H, Zhang Y, et al. Formation of slip bands and microstructure evolution of Ti-5Al-5Mo-5V-3Cr-0.5Fe alloy during warm deformation process[J]. Journal of Alloys and Compounds, 2019,770:183−193. doi: 10.1016/j.jallcom.2018.08.097 [6] Wang W L, Wang X L, Mei W, et al. Role of grain size in tensile behavior in twinning-induced plasticity β Ti-20V-2Nb-2Zr alloy[J]. Materials Characterization, 2016,120:263−267. doi: 10.1016/j.matchar.2016.09.016 [7] Sun F, Zhang J Y, Marteleur M, et al. Investigation of early stage deformation mechanisms in a metastable β titanium alloy showing combined twinning-induced plasticity and transformation-induced plasticity effects[J]. Acta Materialia, 2013,61(17):6406−6417. doi: 10.1016/j.actamat.2013.07.019 [8] Zafari A, Xia K. Stress induced martensitic transformation in metastable β Ti-5Al-5Mo-5V-3Cr alloy: Triggering stress and interaction with deformation bands[J]. Materials Science and Engineering:A, 2018,724:75−79. doi: 10.1016/j.msea.2018.03.070 [9] Dong R, Li J, Kou H, et al. Precipitation behavior of α phase during aging treatment in a β-quenched Ti-7333[J]. Materials Characterization, 2018,140:275−280. doi: 10.1016/j.matchar.2018.04.008 [10] Xue Q, Ma Y J, Lei J F, et al. Mechanical properties and deformation mechanisms of Ti-3Al-5Mo-4.5V alloy with varied β phase stability[J]. Journal of Materials Science & Technology, 2018,34(12):2507−2514. [11] Ren L, Xiao W, Chang H, et al. Microstructural tailoring and mechanical properties of a multi-alloyed near β titanium alloy Ti-5321 with various heat treatment[J]. Materials Science and Engineering:A, 2018,711:553−561. doi: 10.1016/j.msea.2017.11.029 [12] Šmilauerová J, Janeček M, Harcuba P, et al. Ageing response of sub-transus heat treated Ti-6.8Mo-4.5Fe-1.5Al alloy[J]. Journal of Alloys and Compounds, 2017,724:373−380. doi: 10.1016/j.jallcom.2017.07.036 [13] Kim Y K, Park S H, Yu J H, et al. Improvement in the high-temperature creep properties via heat treatment of Ti-6Al-4V alloy manufactured by selective laser melting[J]. Materials ence & Engineering A, 2018,715:33−40. [14] Lee K H, Yang S Y, Yang J G. Optimization of heat-treatment parameters in hardening of titanium alloy Ti-6Al-4V by using the Taguchi method[J]. International Journal of Advanced Manufacturing Technology, 2017,90:753−761. doi: 10.1007/s00170-016-9433-3 [15] Najafizadeh M, Bahadoran A, Bozorg M, et al. Microstructures and mechanical properties of high strength Ti-XAl-2Fe-3Cu alloys fabricated by powder compact extrusion[J]. Journal of Alloys and Compounds, 2021,(1):161136. [16] Sui S, Chew Y, Hao Z, et al. Effect of cyclic heat treatment on the microstructure and mechanical properties of laser aided additive manufacturing Ti-6Al-2Sn-4Zr-2Mo alloy[J]. Advanced Powder Materials, 2022,1:100002. doi: 10.1016/j.apmate.2021.09.002 [17] Li D, Hui S X, Ye W J, et al. Microstructure and mechanical properties of a new high-strength and high-toughness titanium alloy[J]. Rare Metals, 2016:1−7. doi: 10.1007/s12598-016-0722-7 [18] Li C L, Hong J K, Narayana P L, et al. Realizing superior ductility of selective laser melted Ti-6Al-4V through a multi-step heat treatment[J]. Materials Science and Engineering A, 2020,799:140367. [19] Yumak N, Aslanta K. Effect of heat treatment procedure on mechanical properties of Ti-15V-3Al-3Sn-3Cr metastable β titanium alloy[J]. Journal of Materials Engineering and Performance, 2021,30(2):1066−1074. doi: 10.1007/s11665-020-05445-x [20] Kurdi A, Basak A K. Micro-mechanical behaviour of selective laser melted Ti6Al4V under compression[J]. Materials Science & Engineering A, 2021,826:141975. [21] Elkhateeb M G, Shin Y C. Analysis of the effects of microstructure heterogeneity on themechanical behavior of additively manufactured Ti6Al4V using mechanics of structure genome[J]. Materials and Design, 2021,204:109643. doi: 10.1016/j.matdes.2021.109643 [22] Yuan B G, Du J F, Zhang X X, et al. Microstructures and room-temperature compressive properties of Ti6Al4V alloy processed by continuous multistep hydrogenation treatment[J]. International Journal of Hydrogen Energy, 2020,45(46):25567−25579. doi: 10.1016/j.ijhydene.2020.06.265 [23] Zhao Y Q, Zhou L. Current research situation of titanium alloys in China[J]. Materials Research and Application, 2005,15(S01):82−91. [24] Zhang X, Liu H Y, Che C, et al. Development status of low cost titanium alloy processing technology[J]. China Foundry, 2021,70(10):1141−1148. [25] Kong J T, Hu R, Kou H C, et al. Alloy design of low-density Nb-Ti superalloy based on d-electrons theory[J]. Rare Metal Materials and Engineering, 2015,44(5):1119−1123. -

下载:

下载: