Effects of carbon microalloying on microstructure and mechanical properties of low-cost Ti-4.5Al-3.5Zr-2Fe titanium alloy

-

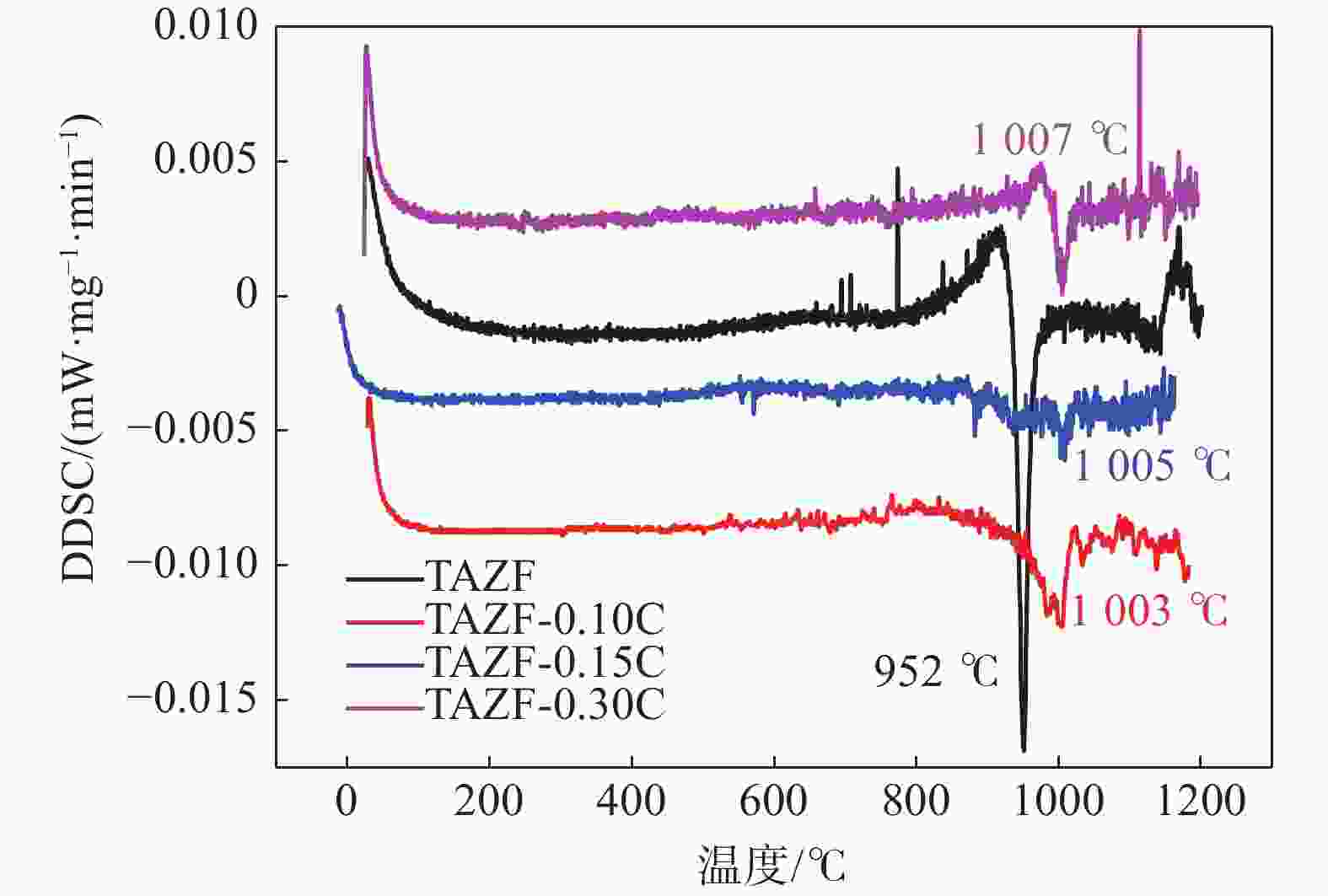

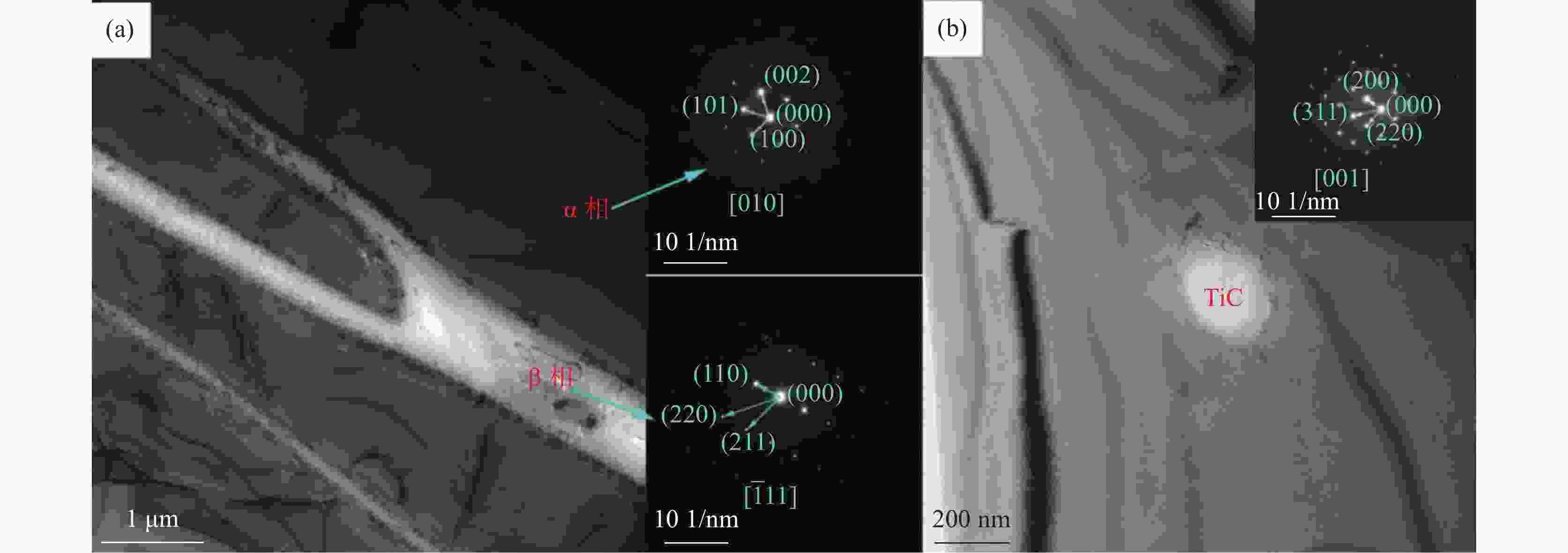

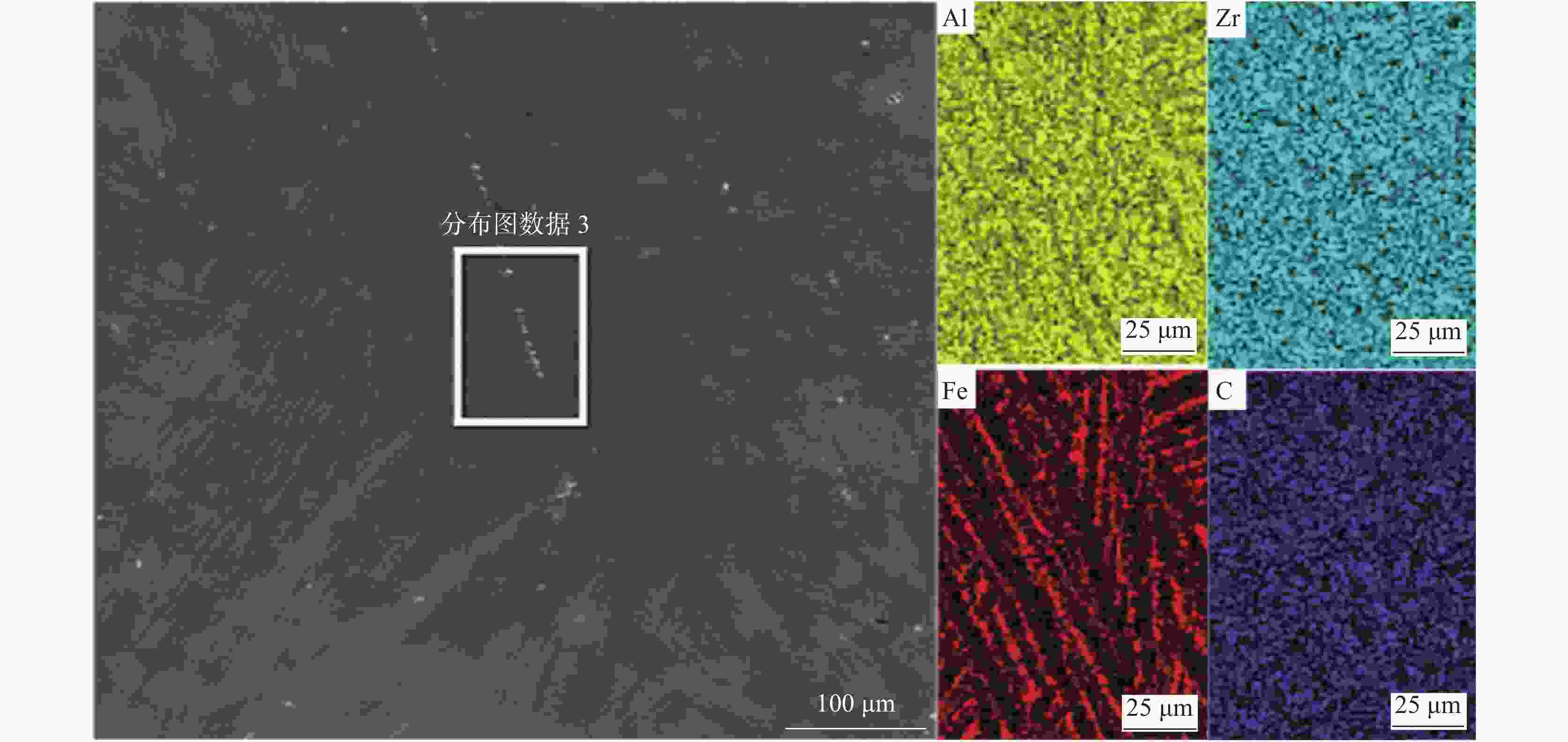

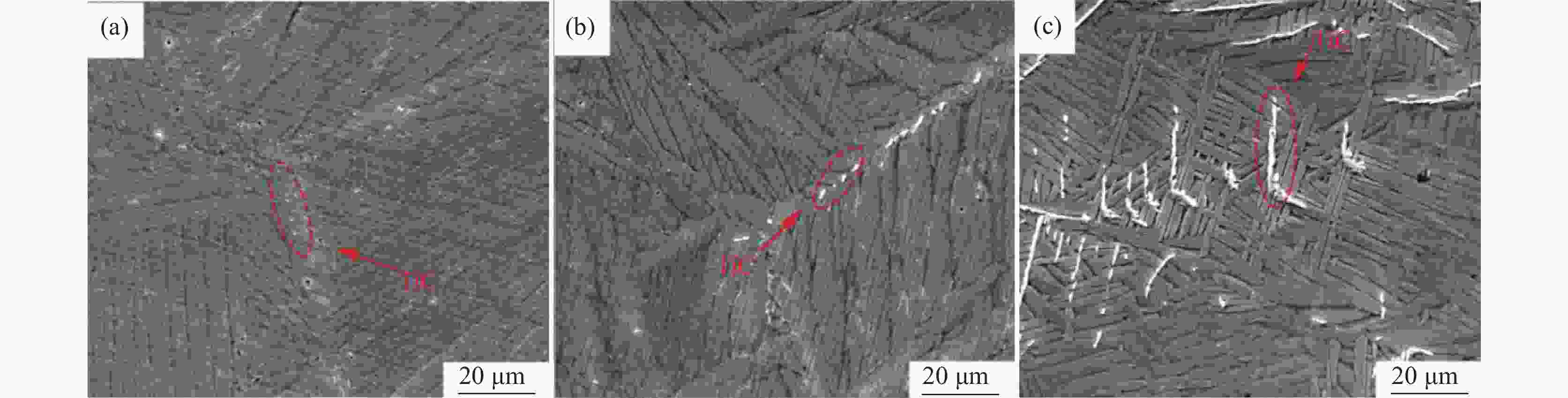

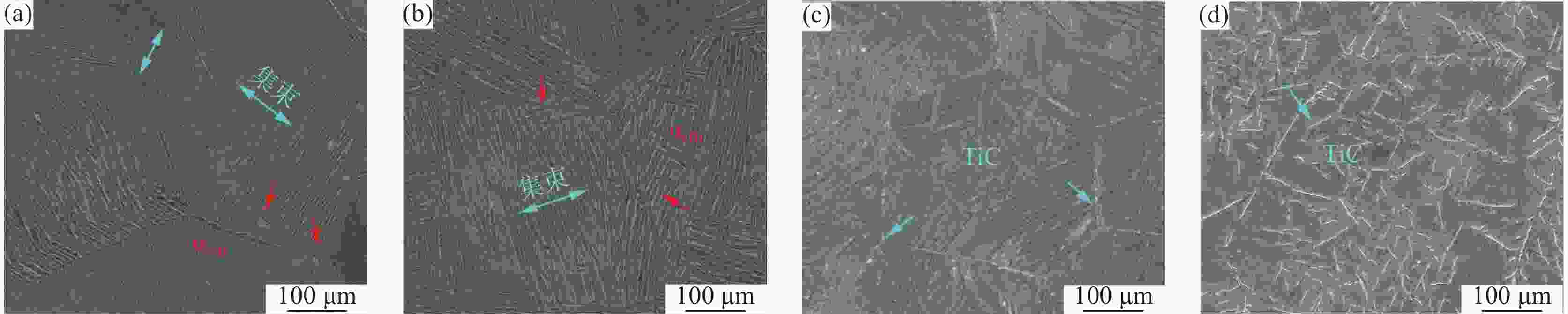

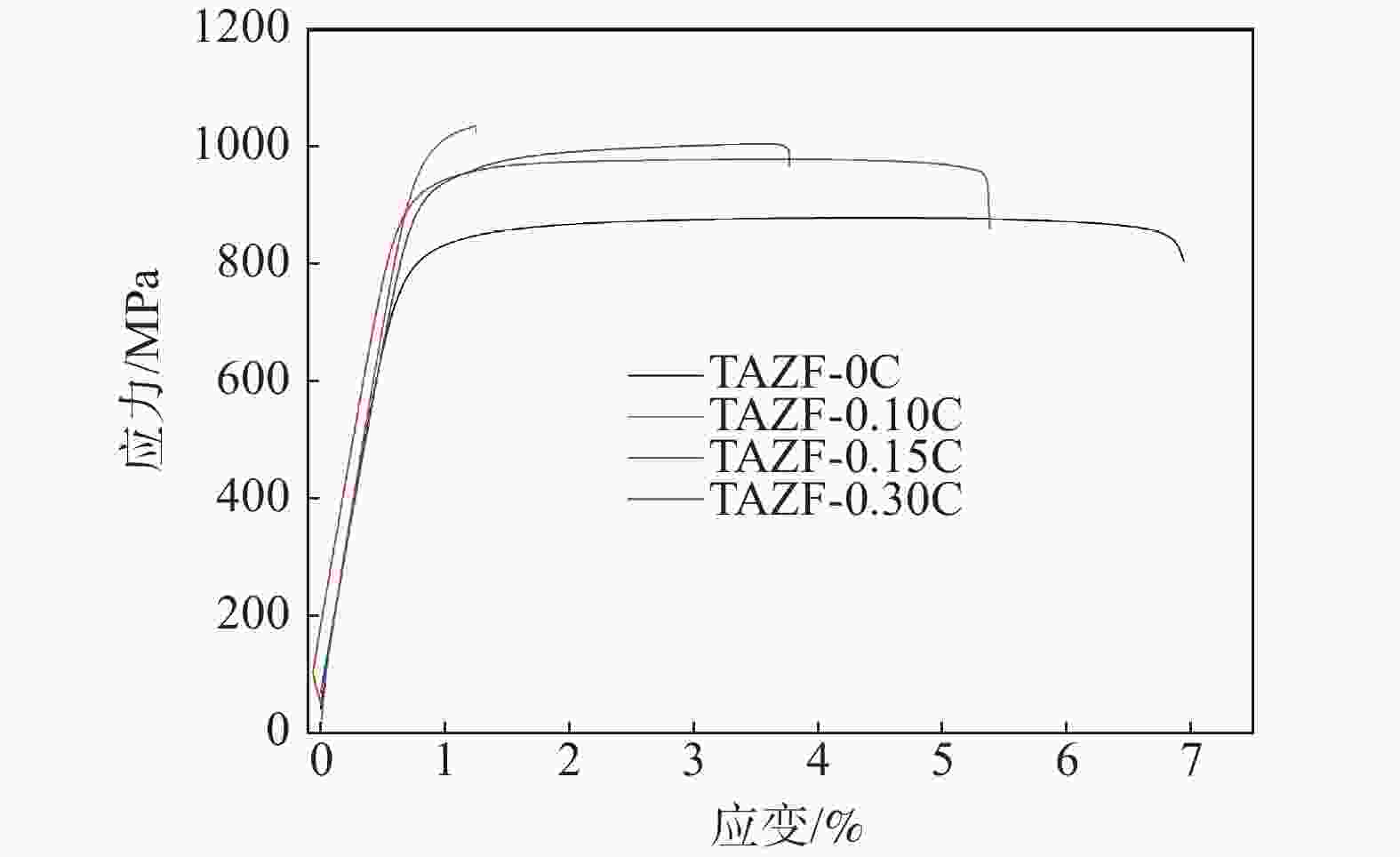

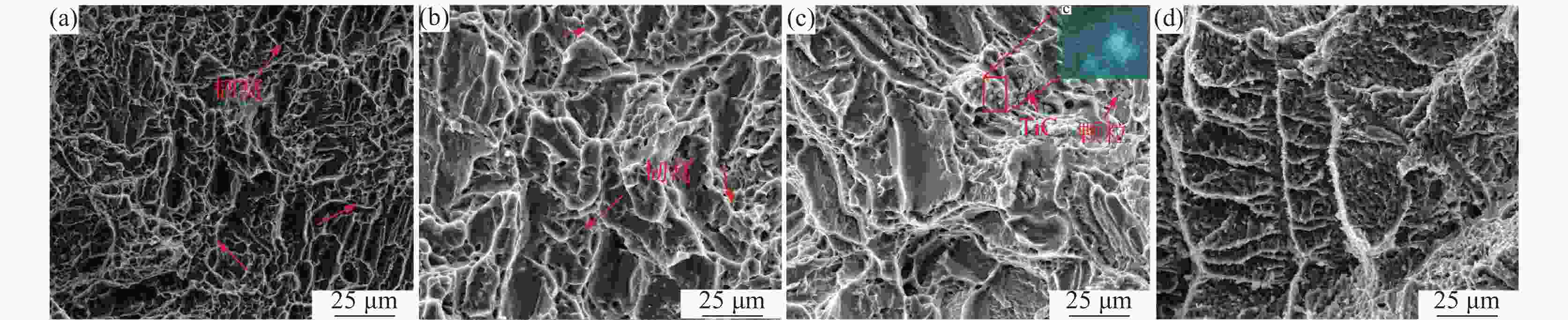

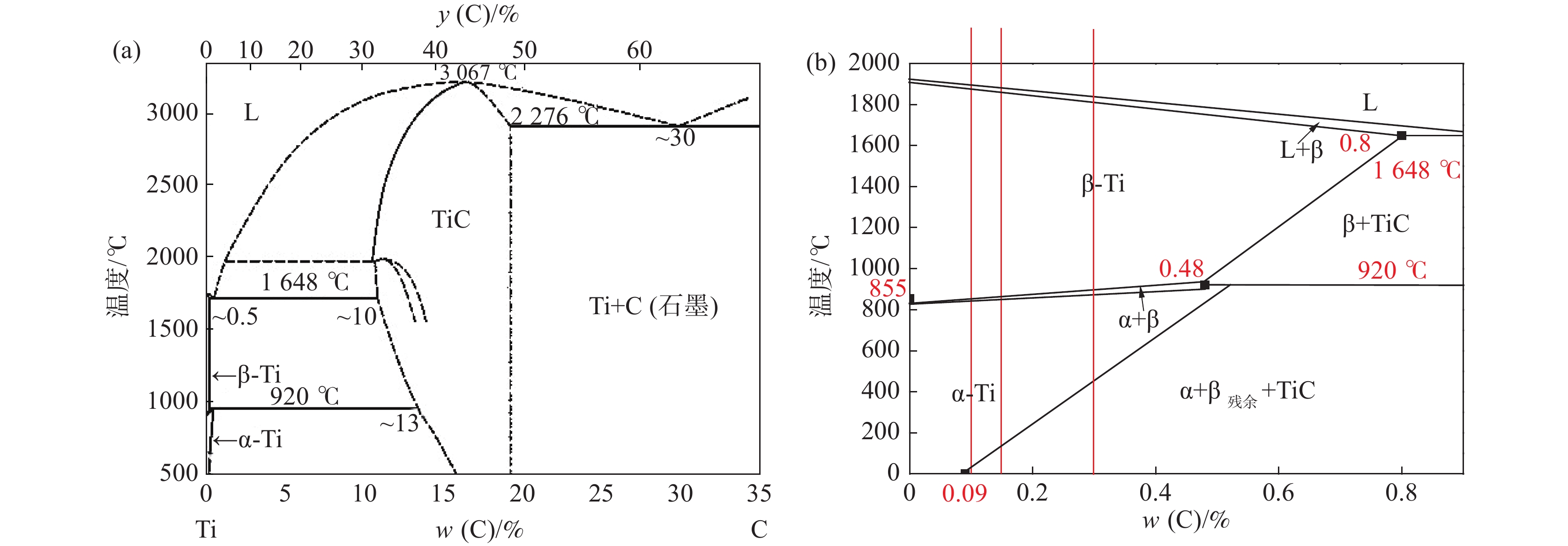

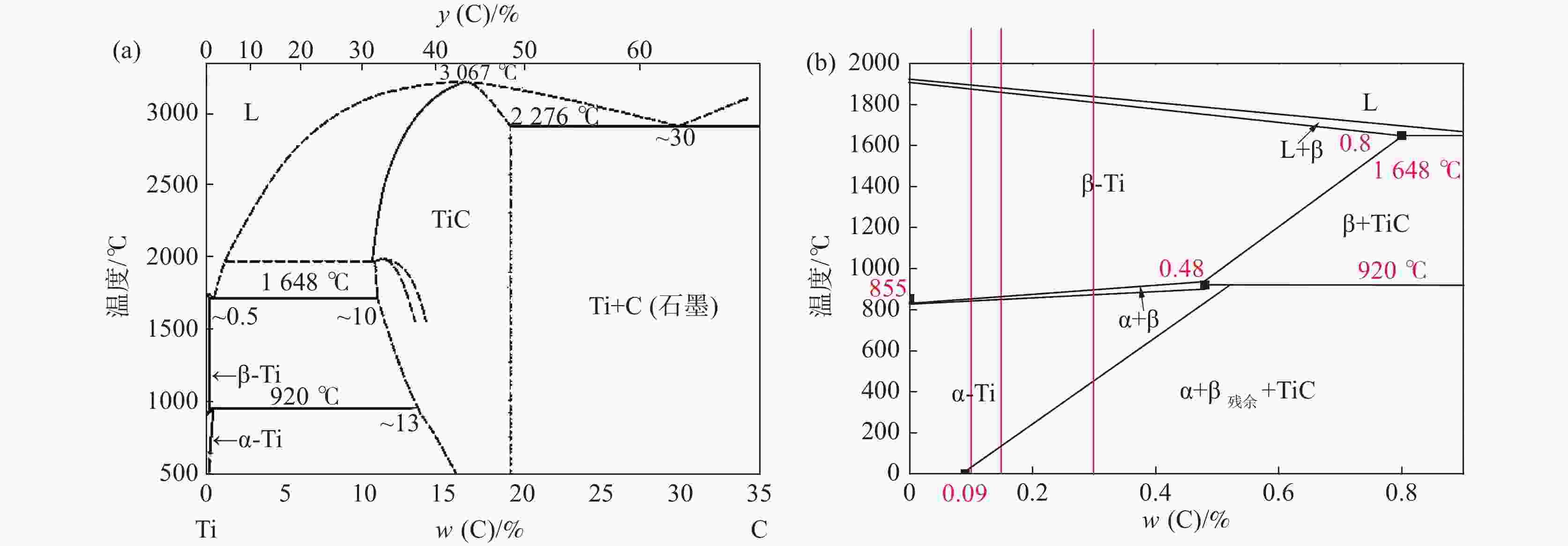

摘要: 采用水冷铜坩埚真空感应悬浮熔炼炉制备了不同碳含量为0、0.1%、0.15%和0.3%的Ti-4.5Al-3.5Zr-2Fe低成本钛合金,研究了碳微合金化对钛合金铸态组织和力学性能的影响。结果表明:随着碳元素的引入,原始β晶粒以及α片层宽度尺寸有一定的细化,合金铸态凝固组织由魏氏组织逐渐转变为网篮组织,TiC在晶界析出。碳含量增加,合金强度增强,塑性降低,其中Ti-4.5Al-3.5Zr-2Fe-0.1C合金综合力学性能最佳,抗拉强度和屈服强度分别为 979 MPa 和 920 MPa,延伸率为 5.4%。Abstract: Low-cost Ti-4.5Al-3.5Zr-2Fe titanium alloys with different carbon content of 0, 0.1%, 0.15% and 0.3% were prepared in a water-cooled copper crucible vacuum induction levitation melting furnace. The effects of carbon microalloying on the as-cast microstructure and mechanical properties of the titanium alloys were investigated. The results show that with the introduction of carbon element, the original β grain and α lamellar width are refined to a certain extent, and the as-cast solidification microstructure of the alloy is gradually transformed from Widmanstätten microstructure to basket-weave microstructure, and TiC precipitates at grain boundary. Ti-4.5Al-3.5Zr-2Fe-0.1C alloy has the best comprehensive mechanical properties, with a tensile strength and yield strength of 979 MPa and 920 MPa, respectively, and an elongation of 5.4%.

-

表 1 合金实际成分

Table 1. Chemical compositions of the alloys

% Ti Al Zr Fe C H O N TAZF Bal. 4.58 3.62 2.01 0 0.0045 0.036 0.005 TAZF-0.1C Bal. 4.66 3.5 1.98 0.11 0.0033 0.087 0.056 TAZF-0.15C Bal. 4.58 3.54 1.72 0.15 0.003 0.072 0.0045 TAZF-0.3C Bal. 4.78 3.49 2.14 0.31 0.0052 0.088 0.0054 表 2 铸态合金室温力学性能

Table 2. Mechanical properties of the as-cast alloys at RT

合金 σs/MPa σ0.2/MPa El/% TAZF 881.6 811.5 6.9 TAZF-0.1C 979 920 5.4 TAZF-0.15C 1005.7 930 3.8 TAZF-0.3C 1036 1003 1.3 -

[1] Williams J C, Boyer R R. Opportunities and issues in the application of titanium alloys for aerospace components[J]. Metals - Open Access Metallurgy Journal, 2020,10(6):705. [2] Boyer R R. An overview on the use of titanium in the aerospace industry[J]. Materials Science and Engineering A, 1996,213(1-2):103−114. doi: 10.1016/0921-5093(96)10233-1 [3] Huang Haiguang, Xiao Han, Xiong Hancheng, et al. Development and application on low cost production technology of titanium materials[J]. Yunnan Metallurgy, 2020,49(6):59−67. (黄海广, 肖寒, 熊汉城, 等. 钛材低成本生产技术的开发和应用[J]. 云南冶金, 2020,49(6):59−67. doi: 10.3969/j.issn.1006-0308.2020.06.013 [4] 杜赵新. 新型高强β钛合金的热处理和微合金化以及高温变形行为研究[D]. 哈尔滨: 哈尔滨工业大学, 2014.Du Zhaoxin. Heat treatment and microalloying and high temperature deformati, on behavior of new beta high strength titanium alloy[D]. Harbin: Harbin Institute of Technology, 2014. [5] Tan Qiming, Sui Nan. Research and development of particle reinforced titanium matrix composites[J]. New Materials Industry, 2019,(1):59−64. (谭启明, 隋楠. 颗粒增强钛基复合材料的研究与进展[J]. 新材料产业, 2019,(1):59−64. doi: 10.19599/j.issn.1008-892x.2019.01.014 [6] 刘诚. TC4-DT钛合金热变形行为及显微组织演变的模拟研究[D]. 南昌: 南昌航空大学, 2015.Liu Cheng. Simulation study on hot deformation behavior and microstructure evolution of TC4-DT titanium alloy[D]. Nanchang: Nanchang Hangkong University, 2015. [7] Zhang Hongju, Zhang Donghui, Li Pu, et al. Testing methods for titanium alloy phase transition point[J]. Hot Working Technology, 2013,42(10):89−92. (张红菊, 张东晖, 李璞, 等. 钛合金相转变点检测方法[J]. 热加工工艺, 2013,42(10):89−92. doi: 10.14158/j.cnki.1001-3814.2013.10.028 [8] Tian Fei, Zeng Weidong, Ma Xiong, et al. Measurement of beta transus temperature of BT25 titanium alloy by physical analysis and metallographic observation methods[J]. Journal of Materials and Heat Treatment, 2011,32(5):5. (田飞, 曾卫东, 马雄, 等. 物理分析法与金相法测定BT25钛合金相变点[J]. 材料热处理学报, 2011,32(5):5. doi: 10.13289/j.issn.1009-6264.2011.05.002 [9] Liu Shibing, Lou Yanchun, Zhao Jun, et al. Effect of casting process on microstructure and properties of titanium alloy Ti5Al2.5Sn ELI[J]. Rare Metal Materials and Engineering, 2021,50(2):575−580. (刘时兵, 娄延春, 赵军, 等. 铸造工艺对钛合金Ti5Al2.5Sn ELI铸态组织及性能的影响[J]. 稀有金属材料与工程, 2021,50(2):575−580. [10] Hu D, Johnson T P, Loretto M H. Titanium precipitation in substoichiometric TiC particles[J]. Scripta Metallurgica et Materialia, 1994,30:8(8):1015−1020. [11] Lu W J, Zhang D, Zhang X N, et al. Microstructure and tensile properties of in situ (TiB+TiC)/Ti6242 (TiB∶TiC=1∶1) composites prepared by common casting technique[J]. Materials Science & Engineering A, 2001,311(1-2):142−150. [12] Min W A, Hy B, Zs C, et al. Microstructural evolution, mechanical properties and wear behavior of in-situ TiC-reinforced Ti matrix composite coating by induction cladding[J]. Surface and Coatings Technology, 2021,412:127048. doi: 10.1016/j.surfcoat.2021.127048 -

下载:

下载: