Clean, high efficiency and green utilization of vanadium tailings extracted by calcium process

-

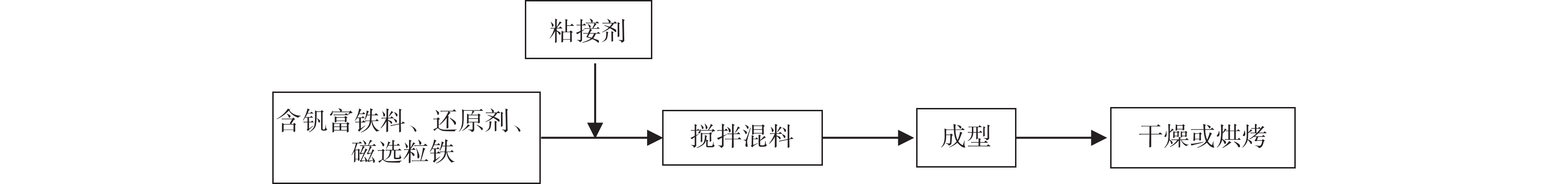

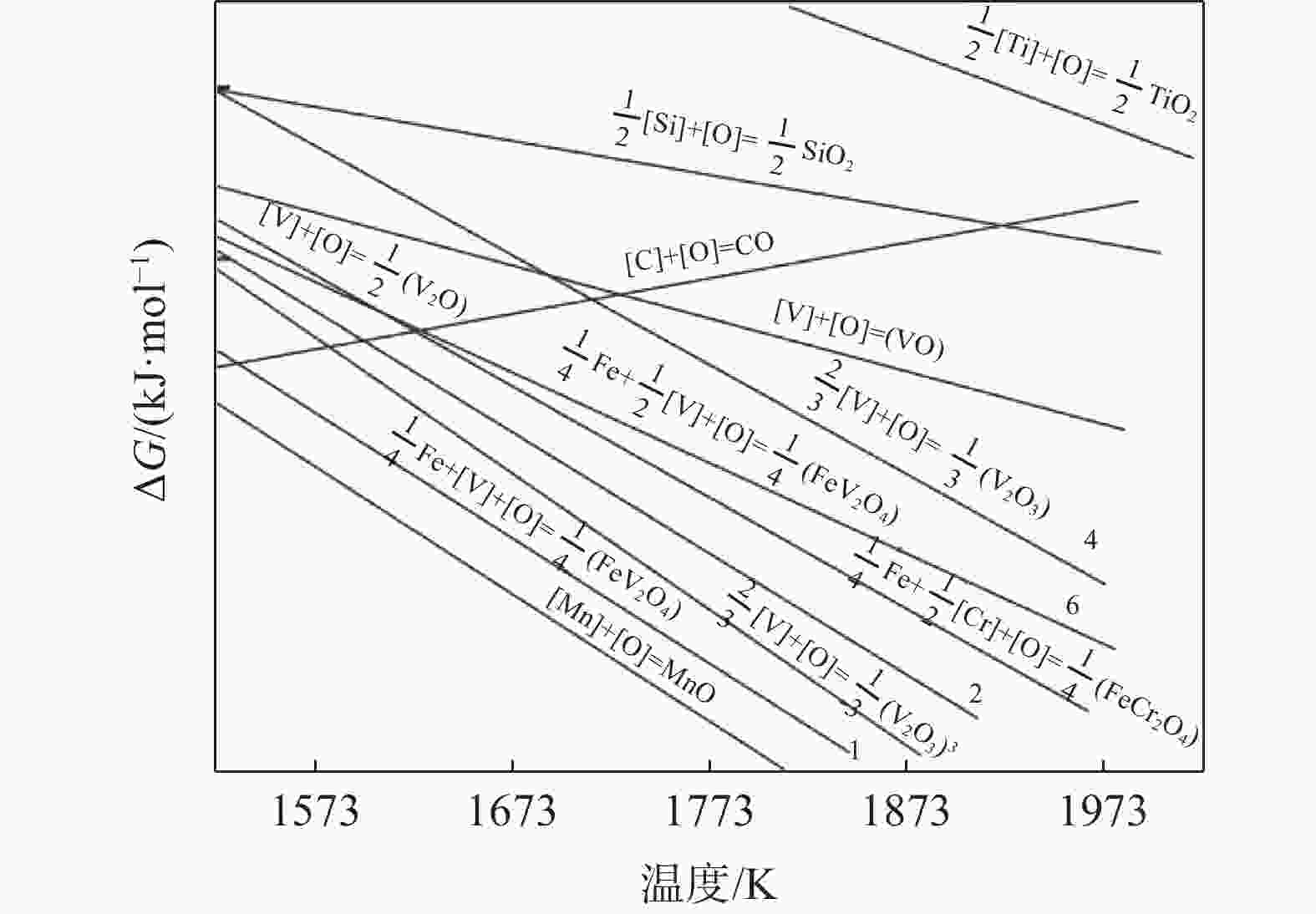

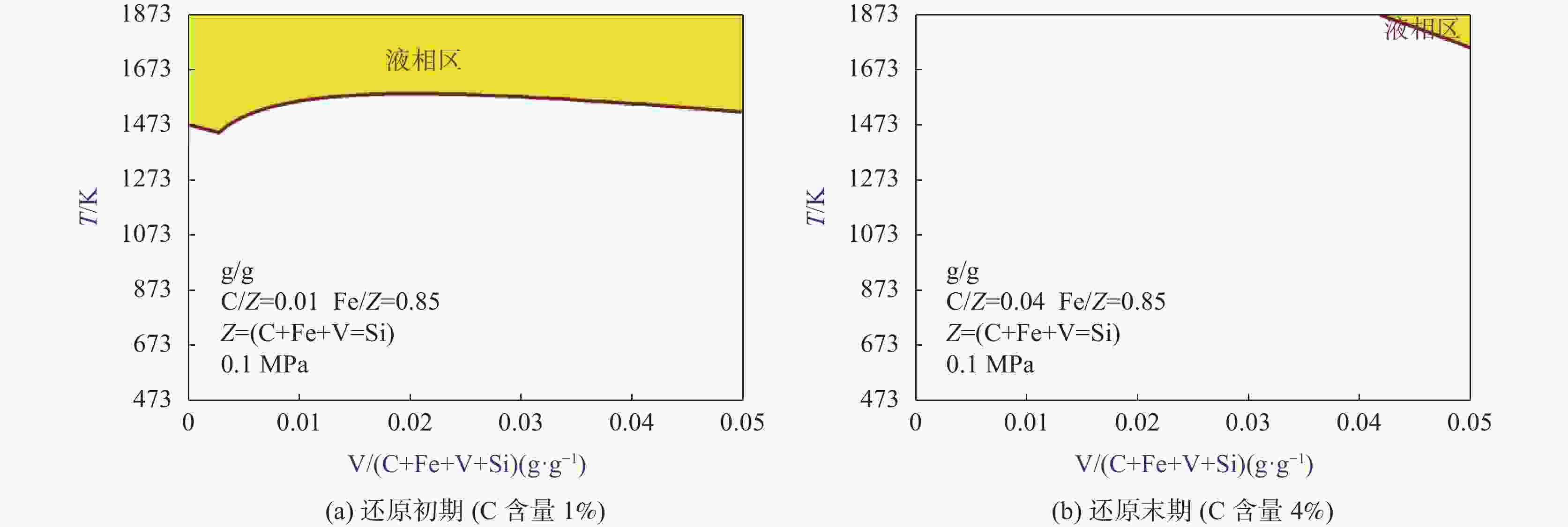

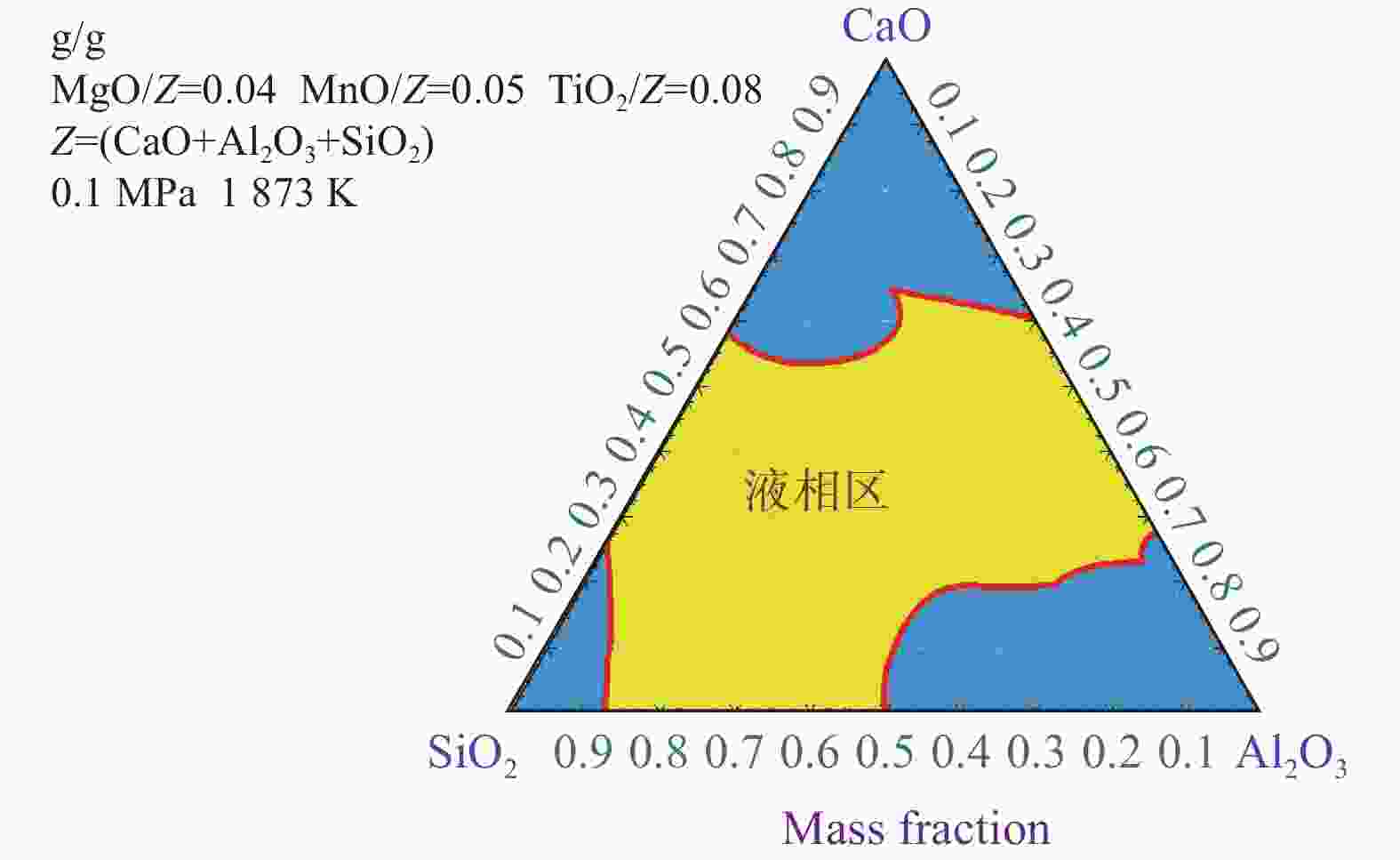

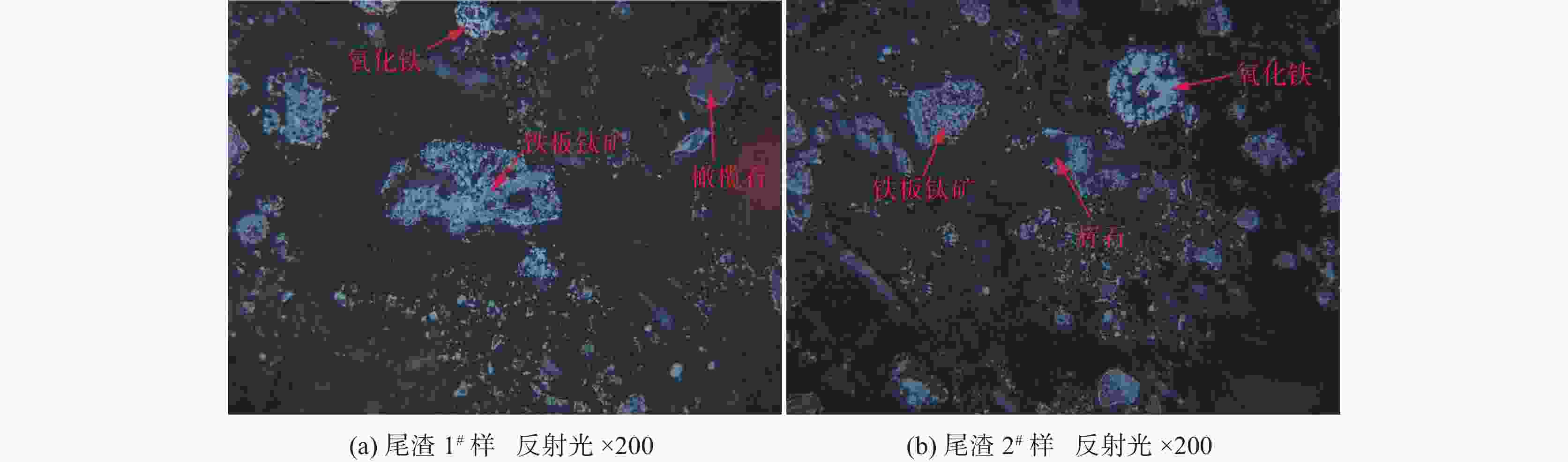

摘要: 以钙法提钒尾渣为研究对象,通过对尾渣成分、物相和主要元素赋存状态的分析,在结合前人研究的基础上,提出了钙法提钒尾渣通过物理法和火法冶金分离技术制取含钒铁合金及含钛炉渣的综合利用途径。研究表明:提钒尾渣经摇床脱硫处理后,分离出石膏渣和含钒富铁料,石膏渣供水泥厂使用,含钒富铁料配加一定比例的还原剂、粘接剂成球后,在矿热炉进行熔分还原冶炼,可获得钒含量3%左右的含钒铁合金及TiO2含量36%左右的还原渣,含钒铁合金可用于含钒钢水合金化;还原渣可用于高钛渣冶炼。能实现钙法提钒尾渣中的有价元素铁、钒、钛等有效提取与回收以及减轻环保压力。Abstract: Calcium extraction of vanadium tailings was taken as research object, the composition, phase and occurrence state of main elements of the tailings were analyzed. On the basis of combining previous studies, the comprehensive utilization of vanadium-bearing alloy and titanium-bearing furnace slag from calcium-based vanadium extraction tailings by physical method and pyrometallurgical separation technology is put forward. Studies have shown that after the removal of vanadium tailings by shaking desulfurization treatment, gypsum residue and iron-rich vanadium material were separated, gypsum residue is used in cement plants. V/Fe-rich material with a certain proportion of reducing agent and adhesive mixed press into pellets, smelting by ore-thermal furnace smelting reduction, ferroalloys with a vanadium content of about 3% and reduction slag containing about 36% TiO2 were obtained, V-containing ferroalloys can be used for alloying V-containing molten steel, and reduced slag can be used for smelting high titanium slag. It can be exploited for effective extraction and recovery of valuable elements such as Fe, V and Ti from calcium-based extraction of vanadium tailings and can reduce the environmental pollution.

-

表 1 提钒尾渣主要化学成分

Table 1. Main chemical composition of vanadium extraction tailings

% TV TFe SiO2 CaO MnO S P TiO2 H2O 0.8~1.4 20~35 10~15 4~10 3~7 1.0~2.5 0.04~0.06 7~11.0 20~35 表 2 钙法提钒尾渣中主要元素的赋存状态

Table 2. Occurrence state of main elements in vanadium tailings extracted by calcium method

% 矿物质 Al Ca Cr Fe K Mg Mn Mo Na P S Si Ti V 铁(镁)氧化物 26.07 11.41 5.01 41.53 0.00 32.74 4.83 100.00 83.46 0.00 4.92 9.05 58.47 30.57 钛(铁)氧化物 0.15 0.03 0.00 0.10 0.00 0.24 0.00 0.00 0.00 0.00 0.00 0.03 0.56 0.07 铝(铁)氧化物 1.84 0.06 0.00 0.04 0.00 0.53 0.14 0.00 0.00 0.00 0.00 0.06 0.01 0.01 铁 0.00 0.00 0.00 0.86 0.00 0.00 0.44 0.00 0.00 0.00 0.00 0.00 0.06 0.12 硅酸钙(钒-镁) 11.65 31.66 0.00 1.61 3.21 22.27 18.91 0.00 0.00 70.38 12.21 16.70 4.45 36.06 铁(钛)硅酸盐 55.18 25.46 94.97 54.84 79.73 18.19 73.05 0.00 12.18 0.00 28.46 53.17 34.42 29.19 铝硅酸盐 3.83 0.72 0.02 0.21 7.05 1.35 0.41 0.00 0.87 0.00 0.00 1.91 0.07 0.20 镁硅酸盐 0.99 2.01 0.00 0.13 0.00 24.35 0.41 0.00 0.00 0.00 0.00 8.55 1.69 2.77 硫酸钙(铁) 0.00 27.48 0.00 0.58 10.02 0.00 1.42 0.00 3.49 0.00 54.31 0.51 0.20 0.00 钒酸铁 0.24 0.09 0.00 0.10 0.00 0.24 0.10 0.00 0.00 29.62 0.00 0.06 0.00 0.94 石英 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 9.92 0.00 0.00 氧化钙 0.05 1.08 0.00 0.00 0.00 0.10 0.29 0.00 0.00 0.00 0.09 0.02 0.07 0.07 总计 100.00 100.00 100.00 100.00 100.00 100.00 100.00 100.00 100.00 100.00 100.00 100.00 100.00 100.00 表 3 提钒尾渣粒度及硫含量分布

Table 3. Particle size and sulfur content distribution of tailings

粒级/mm 重量/g 产率/% 硫含量/% 分布率/% ≥0.3 40 0.75 0.323 0.21 −0.3~+0.15 570 10.71 0.234 2.15 −0.15~+0.074 945 17.75 0.082 1.25 −0.074~+0.052 350.4 6.58 0.145 0.82 −0.052~+0.037 654.5 12.30 0.088 0.93 −0.037~+0.019 1355.3 25.46 0.087 1.90 −0.019~+0.01 762.6 14.33 0.117 1.44 <0.01 645.3 12.12 8.78 91.31 合 计 5323.1 100 1.17 100 表 4 刻槽摇床脱硫效果

Table 4. Desulfurization effect of slotting and shaking table

编 号 产 率/ % 硫品位/ % 硫回收率/ % 给 矿 100 1.17 100 刻槽-1 19.93 0.038 2.92 刻槽-2 23.53 0.045 3.43 刻槽-3 26.17 0.102 9.16 刻槽-4 20.02 1.054 47.16 刻槽-5 10.35 1.519 37.32 表 5 含钒富铁料主要化学成分

Table 5. Main chemical compositions of vanadium-rich iron material

% TV TFe SiO2 CaO MnO Al2O3 TiO2 S P 范围 1.39~1.61 37~41.8 13.34~14.6 2.2~2.9 1.52~1.62 2.1~2.38 11.98~

13.060.2~

0.30.047~

0.053平均值 1.43 40.8 13.76 2.45 1.58 2.2 12.35 0.28 0.049 表 6 含钒富铁料球团主要化学成分

Table 6. Main chemical composition of vanadium-rich iron pellet

% TFe MFe V2O5 TiO2 CaO SiO2 MnO Al2O3 S P 范围 32.36~

38.65<0.5 2.08~

2.679.87~

11.343.62~

6.1410.22~

13.281.04~

1.732.08~

3.120.22~

0.310.038~

0.052平均 35.62 <0.5 2.22 10.23 4.15 11.07 1.16 2.78 0.26 0.047 表 7 含钒铁合金主要成分

Table 7. Main components of alloy

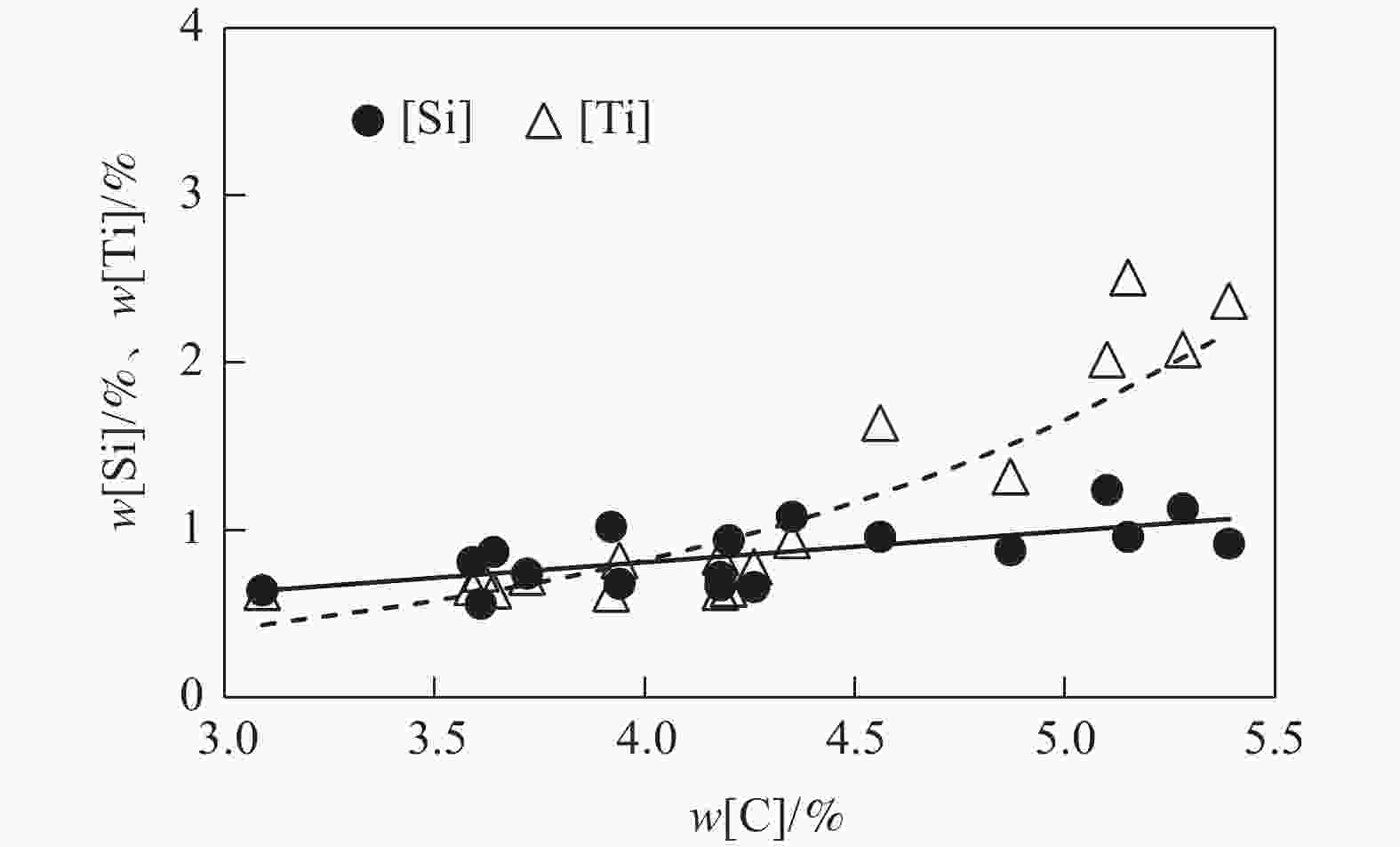

% C V Si Mn Ti S P 范围 3.09~

5.392.15~3.54 0.56~1.24 1.52~1.89 0.63~2.51 0.037~

0.0560.052~0.084 平均值 4.31 3.05 0.84 1.73 1.32 0.048 0.072 表 8 高钛还原渣主要成分

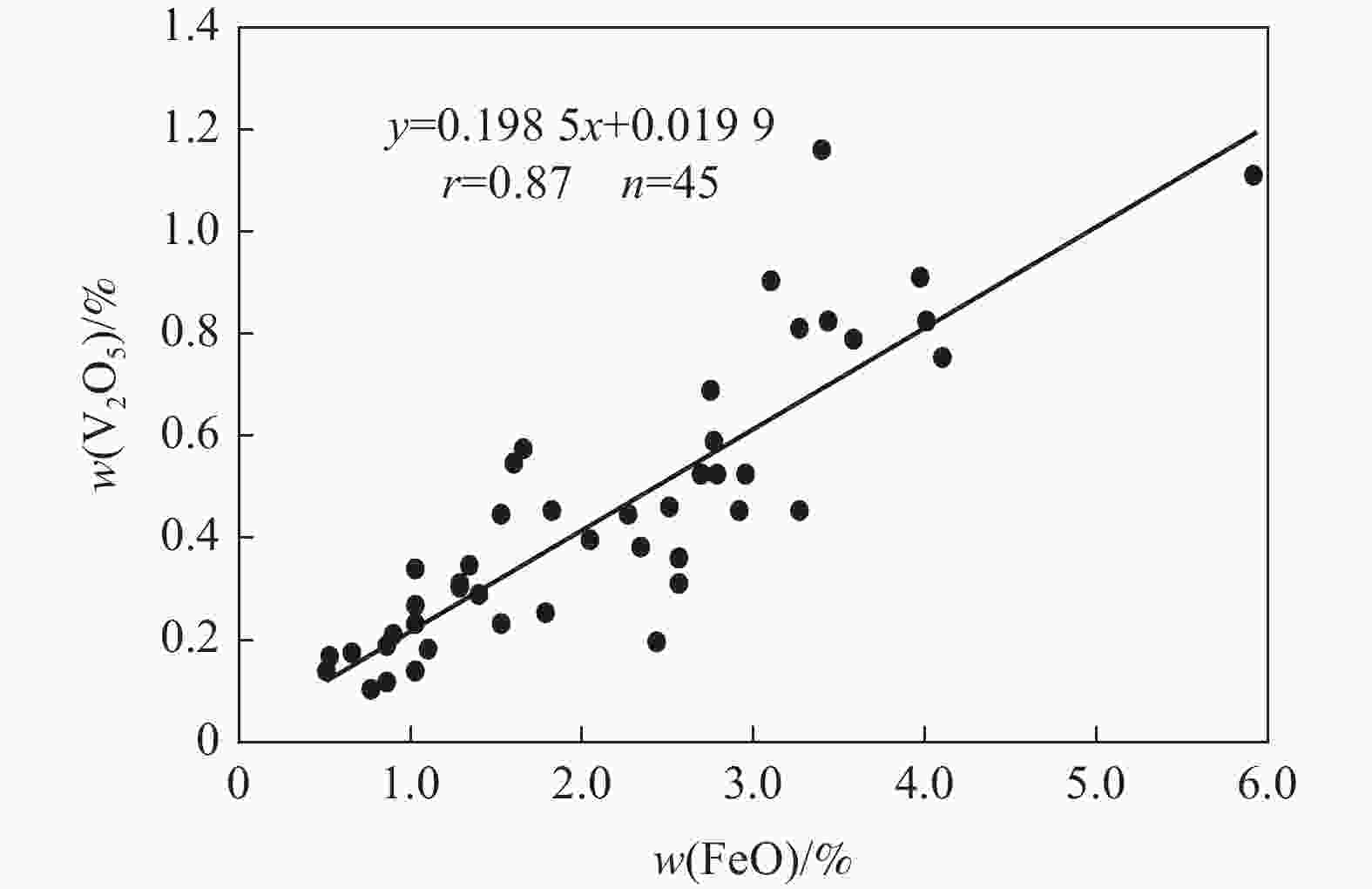

Table 8. Main components of reducing slag

% 组元 V2O5 CaO FeO MgO MnO TFe SiO2 TiO2 Al2O3 范围 0.13~0.50 19.19~35.21 0.60~5.11 2.16~3.68 0.12~0.47 1.09~2.60 9.96~15.64 32.61~38.16 4.33~10.14 平均值 0.21 28.02 2.48 2.94 0.24 2.02 14.07 36.16 6.42 表 9 HRB400E化学成分统计

Table 9. Main components of HRB400E

名称 w/% 统计

炉数C Si Mn P S V 试验 0.21~0.25 0.32~0.45 1.26~1.40 0.018~0.038 0.011~0.040 0.018~0.032 27 0.235 0.38 1.32 0.029 0.028 0.025 原生产 0.21~0.25 0.30~0.47 1.22~1.37 0.012~0.037 0.007~0.035 0.021~0.035 34 0.227 0.38 1.31 0.021 0.025 0.027 表 10 HRB400E力学性能统计

Table 10. Main mechanical properties of HRB400E

品种 规格组距/mm ReL/MPa Rm

/MPaA

/%Agt

/%强屈比 反弯 统计

炉数线材 Ø8、Ø10 (430~485)/460 (620~685)/658 (23.0~44.0)/35.0 (12.5~20.8)/16.2 (1.39~1.54)/1.47 合格 12 Ø12 (440~500)/473 (625~695)/649 (28.0~41.0)/34.0 (11.3~20.5)/15.9 (1.40~1.56)/1.49 合格 15 标准要求 ≥400 ≥540 ≥16 ≥9.0 ≥1.25 无裂纹 -

[1] Wang Lufeng, Fang Minxian. Experimental research on magnetic separation of the vanadium slag tailings reduction[J]. China Venture Capital, 2013,(20):78−79. (王录锋, 方民宪. 提钒尾渣还原渣磁选试验研究[J]. 中国科技投资, 2013,(20):78−79. doi: 10.3969/j.issn.1673-5811.2013.20.072 [2] 张海平. 钠化提钒尾渣脱钠试验研究[D]. 昆明: 昆明理工大学, 2015.Zhang Haiping. Experimental study on eliminating sodium from extracted vanadium tailings[D]. Kunming: Kunming University of Science and Technology, 2015. [3] Kahn J. A non-ruffle feedstocks for the production of titanium[J]. Journal of Metallurgy, 1984,33:36−38. [4] Rao P K, Sarma P V R B, Tripathy A K, et al. Extraction of vanadium as high-purity vanadium pentoxide from vanadium- bearing titaniferous magnetites[J]. Transtion Metal, 1979,88:87−89. [5] Sadykhow G V. Extraction of vanadium from titanium slags from the melting of titanomagnetites[J]. Izvestiya Akademi Nauk SSR, Metauy, 1991,20:2−5. [6] Zhang Haiping, Ding Yuehua, Hao Jianzhang, et al. Technology of eliminating sodium from extracted vanadium tailings[J]. Journal of Kunming University of Science and Technology(Natural Science Edition), 2015,40(6):8−12. (张海平, 丁跃华, 郝建璋, 等. 钠化提钒尾渣脱钠试验[J]. 昆明理工大学学报(自然科学版), 2015,40(6):8−12. [7] Wang Qi, Jiang Maofa, Wang Meng, et al. Leaching and extraction of vanadium and chromium from vanadium tailings[J]. Nonferrous Metals(Extractive Metallurgy), 2016,(9):13−16. (汪其, 姜茂发, 王猛, 等. 提钒尾渣中钒铬的浸出与萃取[J]. 有色金属(冶炼部分), 2016,(9):13−16. [8] Hou Jing, Wu Enhui, Li Jun. Current situation and progress of comprehensive utilization of vanadium extraction tailings[J]. Conservation and Utilization of Mineral Resources, 2017,(6):103−108. (侯静, 吴恩辉, 李军. 提钒尾渣的综合利用研究现状及进展[J]. 矿产保护与利用, 2017,(6):103−108. [9] Xu Chongguang, Wang Hailin, Yang Huan, et al. Comprehensive utilization of extracting vanadium tailings[J]. Ferro-alloys, 2018,49(1):40−43. (许崇光, 王海林, 杨欢, 等. 提钒尾渣的综合利用[J]. 铁合金, 2018,49(1):40−43. [10] Li Liang. Experimental study about preparation of sintered square brick by using vanadium tailings[J]. Bulletin of the Chinese Ceramic Society, 2018,37(6):1970−1973,1978. (李亮. 利用提钒尾渣制备烧结广场砖试验研究[J]. 硅酸盐通报, 2018,37(6):1970−1973,1978. [11] Fan Gang, Wei Chang, Ge Huaiwen, et al. Vanadium recovery from extracted vanadium residue by atmospheric pressure acid leaching[J]. Nonferrous Metals, 2010,62(4):65−68. (樊刚, 魏昶, 葛怀文, 等. 提钒尾渣常压酸浸提钒[J]. 有色金属, 2010,62(4):65−68. [12] Wu Enhui, Huang Ping, Yang Shaoli, et al. Experimental study on direct reduction of vanadium tailings carbon-containing pellets[J]. Nonferrous Metals(Extractive Metallurgy), 2011,(11):17−20. (吴恩辉, 黄平, 杨绍利, 等. 提钒尾渣内配碳球团直接还原试验[J]. 有色金属(冶炼部分), 2011,(11):17−20. [13] Yang Huifen, Wang Jingjing, Jing Lili, et al. Effect of roasting temperature on the coal-based direct reduction of high-iron vanadium tailings[J]. Journal of University of Science and Technology Beijing, 2010,32(10):1258−1263. (杨慧芬, 王静静, 景丽丽, 等. 焙烧温度对高铁提钒尾渣煤基直接还原效果的影响[J]. 北京科技大学学报, 2010,32(10):1258−1263. [14] Yang He, Mao Linqiang, Xue Xiangxin, et al. Experiment on direct reduction of iron from vanadium extraction tailings by adding carbon[J]. Iron Steel Vanadium Titanium, 2013,34(5):28−32. (杨合, 毛林强, 薛向欣, 等. 提钒尾渣配碳直接还原铁试验[J]. 钢铁钒钛, 2013,34(5):28−32. doi: 10.7513/j.issn.1004-7638.2013.05.006 -

下载:

下载: