Performance of pyrite-catalyzed CO reduction of NO

-

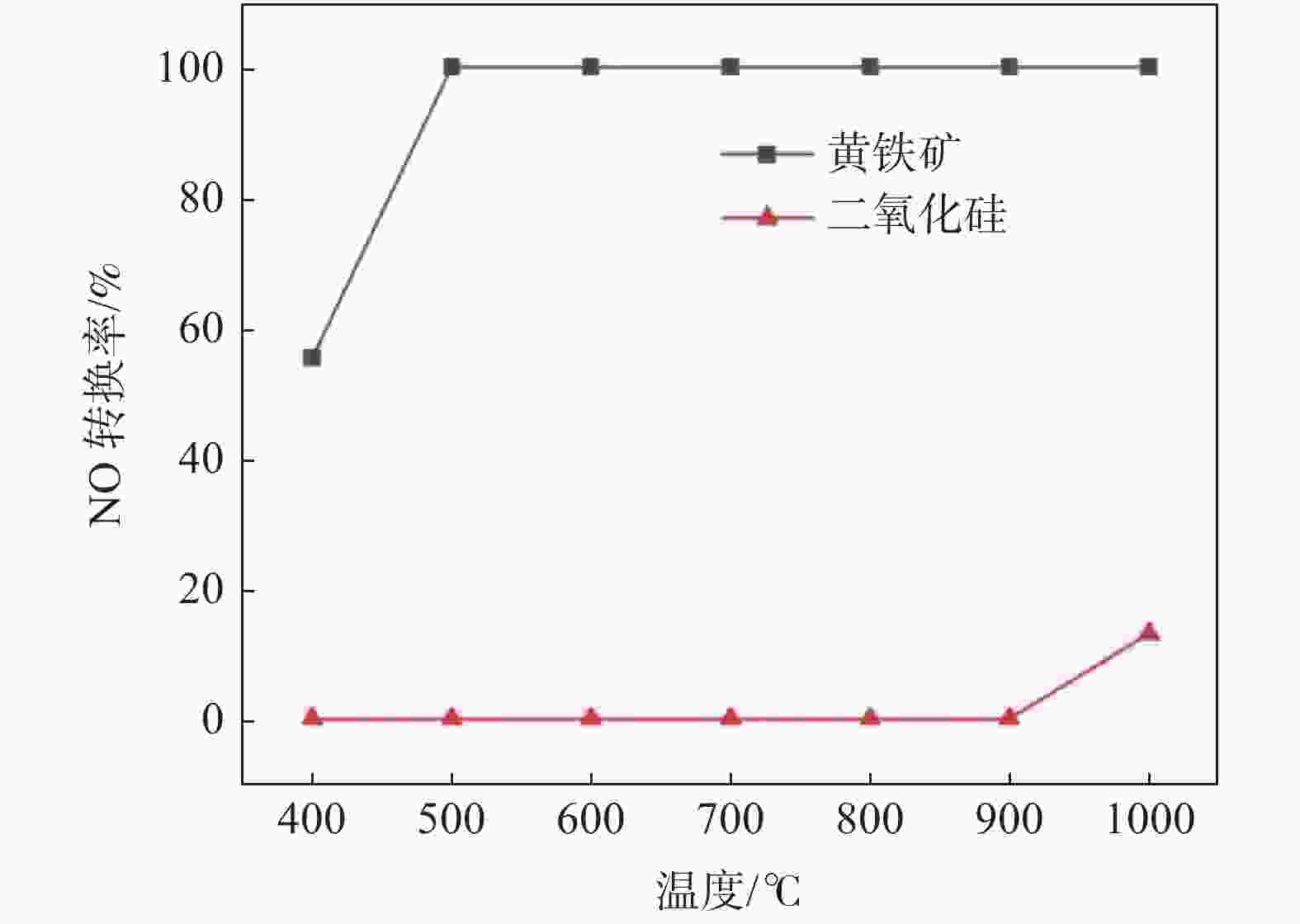

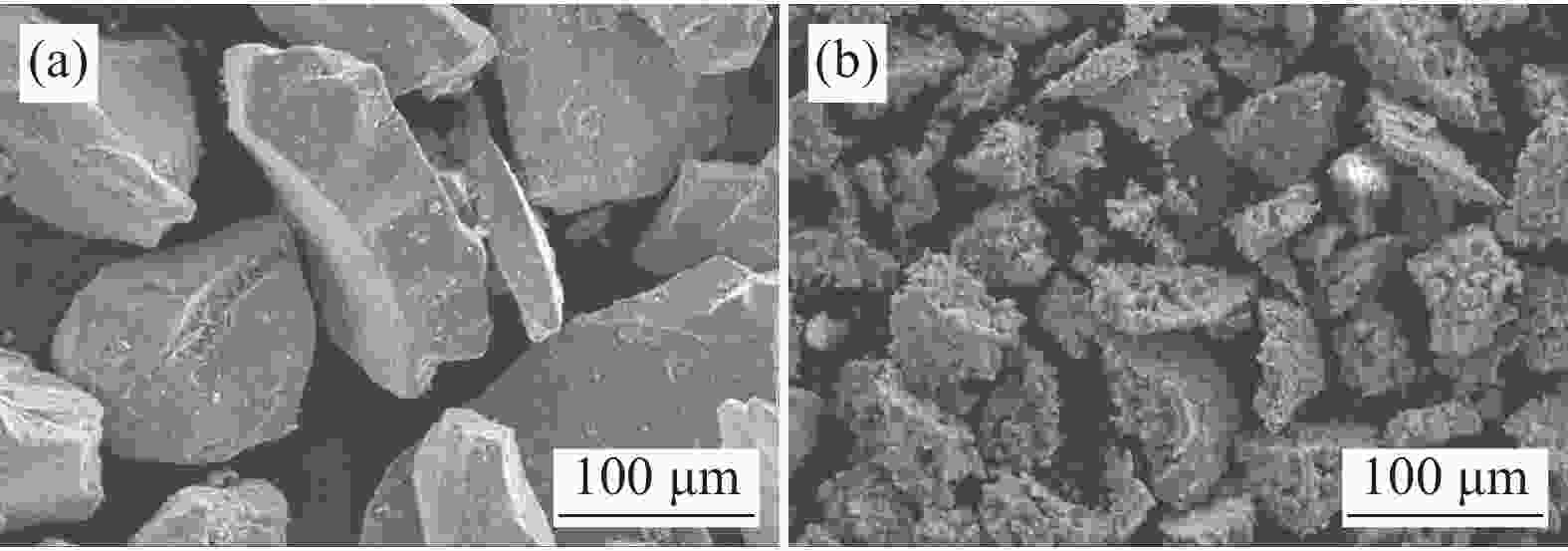

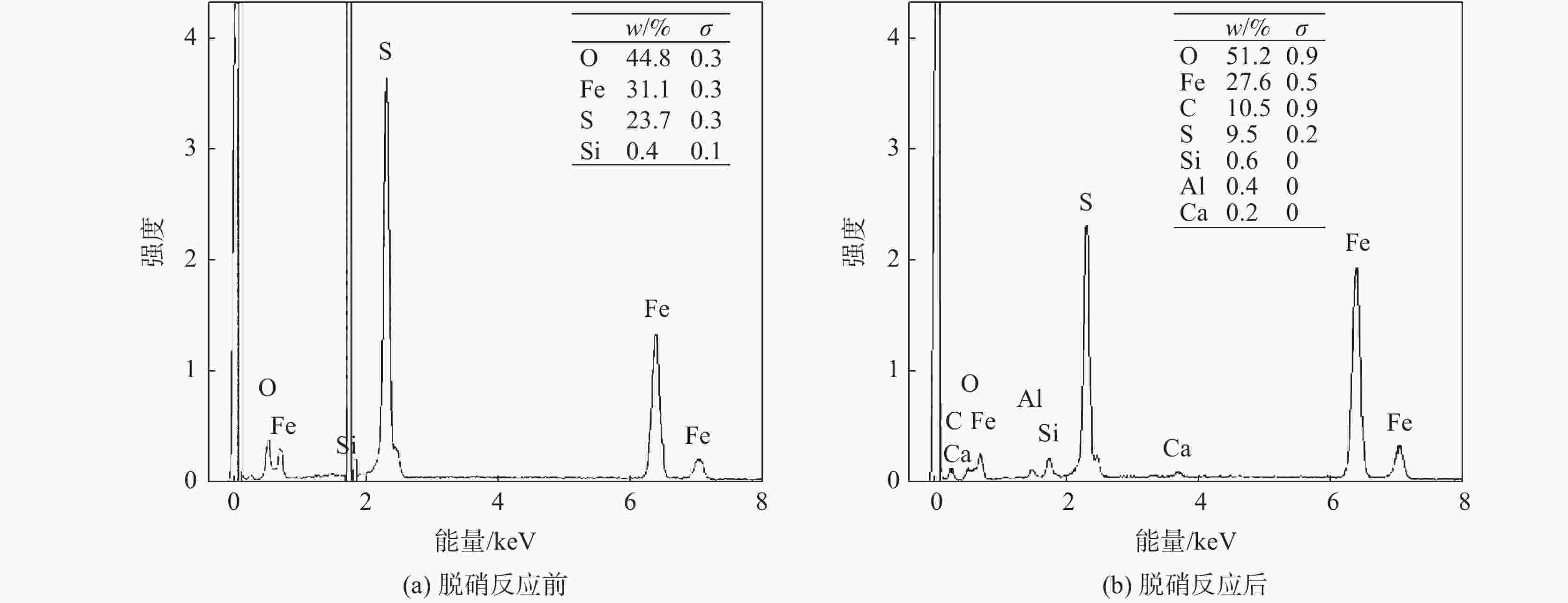

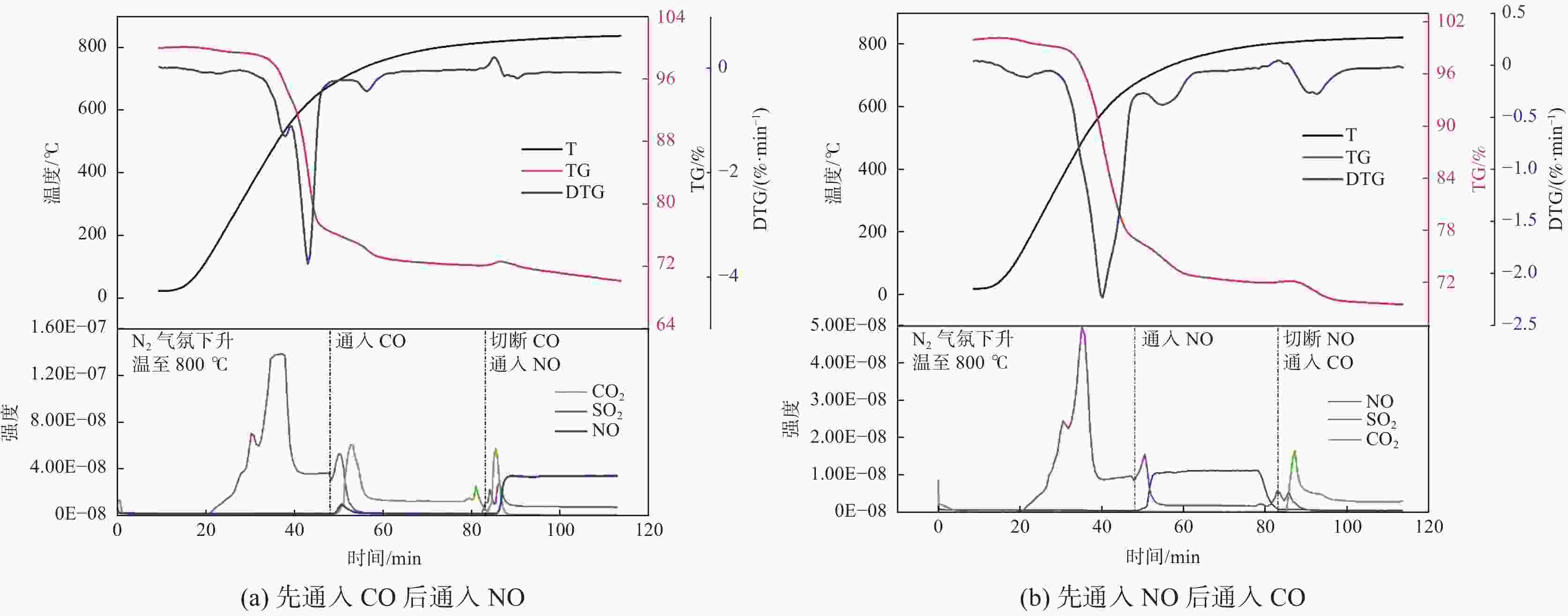

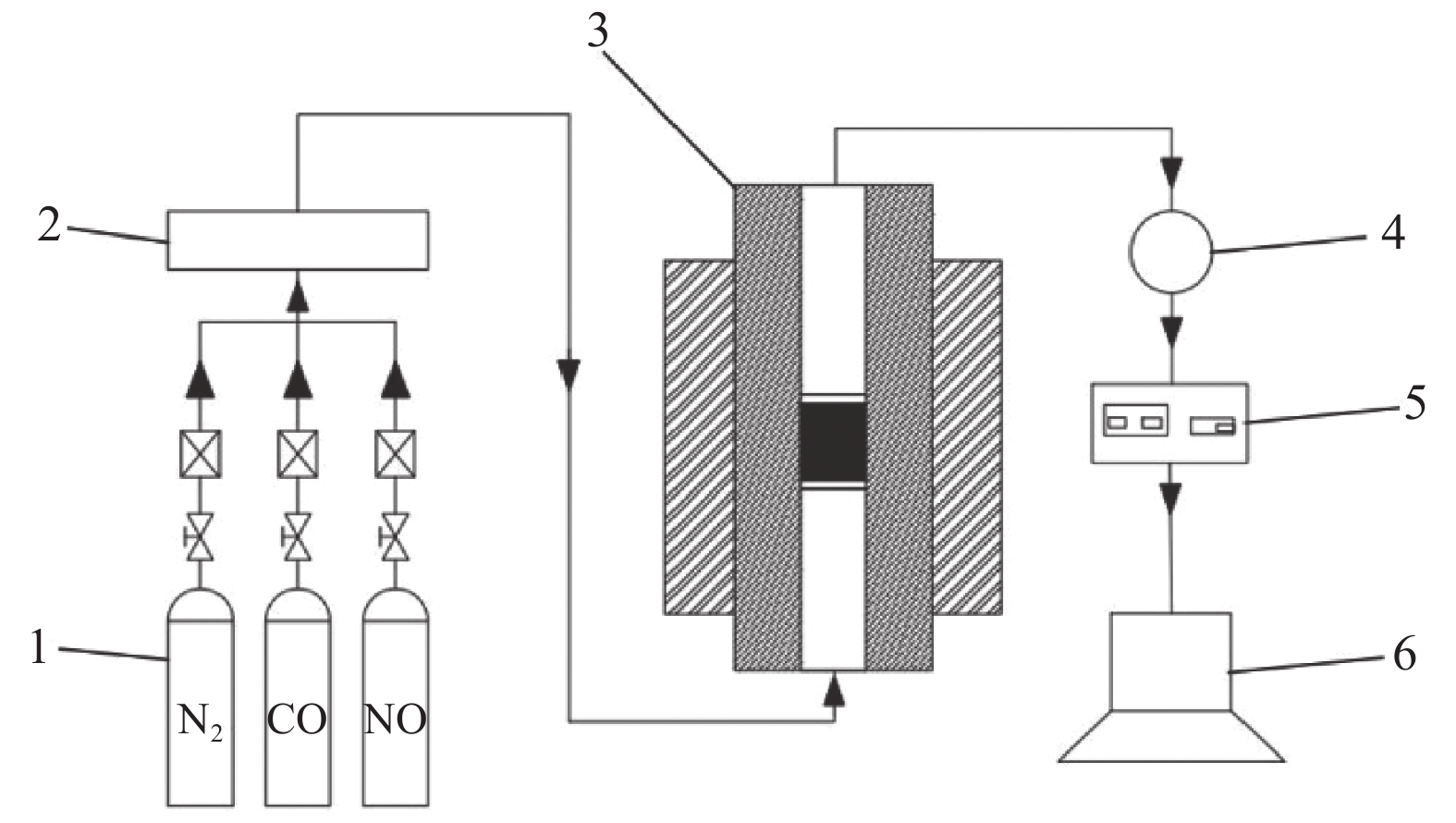

摘要: 以黄铁矿作为脱硝催化剂,探究了其催化CO还原NO的性能,并采用XRF、XRD、SEM-EDS及H2-TPR对其表征。结果表明,在400 ℃时,黄铁矿具有78.53%的NO转化率,且在500~800 ℃温度范围内,其NO转化率维持在100%保持不变,在具有优异的NO还原性能的同时还具备极高的N2选择性及良好的CO转化率;黄铁矿在参与催化反应过程中自身分解释放SO2,表面变得粗糙多孔,更有利于NO气体的吸附及还原;黄铁矿中起催化作用的物质为FeS2,其催化CO还原NO的反应遵循Redox反应机理,在反应过程中CO是通过S辅助来还原NO,S的存在更有利于吸附在催化剂表面NO解离的进行,使得黄铁矿表现出极高的催化活性。Abstract: Pyrite was used as denitrification catalyst to investigate the performance in catalytic CO reduction of NO. XRF, XRD, SEM-EDS and H2-TPR are used for characterization. The results showed that the NO conversion for pyrite was 78.53% at 400 ℃ and remained constant at 100% in the temperature range of 500~800 ℃. It shows excellent NO reduction performance and also possesses very high N2 selectivity and good CO conversion. The surface of pyrite becomes rough and porous as it decomposes and releases SO2 during the catalytic reaction. The catalytic substance in pyrite is FeS2, and its catalytic reduction of NO by CO follows the redox reaction mechanism. In the reaction process, CO is assisted by S to reduce NO, and the presence of S facilitates the adsorption and reduction of NO gas on the catalyst surface, making pyrite highly catalytic.

-

Key words:

- pyrite /

- catalytic reduction /

- CO /

- NO /

- FeS2

-

表 1 黄铁矿元素分析

Table 1. Elemental analysis of pyrite

% Fe S Si Al Ca P Co Ba Cu Cl 其他 50.32 44.48 1.77 1.09 0.72 0.54 0.38 0.3 0.17 0.14 0.09 -

[1] 苏亚欣, 毛玉如, 徐璋. 燃煤氮氧化物排放控制技术[M]. 北京: 化学工业出版社, 2005.Su Yaxin, Mao Yuru, Xu Zhang. Coal-fired nitrogen oxide emission control technology [M]. Beijing: Chemical Industry Press, 2005. [2] Zhou Haicheng, Gao Zhifang, Long Hongming, et al. NOx control technology and development trend in sintered flue gas[J]. Clean Coal Technology, 2021,27(5):77−88. (周海成, 高志芳, 龙红明, 等. 烧结烟气中NOx治理技术及发展趋势[J]. 洁净煤技术, 2021,27(5):77−88. [3] Wen Bin, Song Baohua, Sun Guogang, et al. Advances in denitrification technology for iron and steel sintering flue gas[J]. Environmental Engineering, 2017,35(1):103−107. (温斌, 宋宝华, 孙国刚, 等. 钢铁烧结烟气脱硝技术进展[J]. 环境工程, 2017,35(1):103−107. [4] Liang Lei. Preparation and experimental study of low-temperature SCR denitrification catalyst for sintered flue gas[J]. Sintered Pellets, 2021,46(3):86−92. (梁磊. 烧结烟气低温SCR脱硝催化剂的制备及试验研究[J]. 烧结球团, 2021,46(3):86−92. [5] Zhang Zhenquan, Zhao Beibei, Li Lanjie, et al. Study on selective separation of vanadium, titanium and tungsten from waste SCR denitration catalysts[J]. Iron Steel Vanadium Titanium, 2021,42(1):24−31. (张振全, 赵备备, 李兰杰, 等. 废SCR脱硝催化剂钒、钛、钨选择性分离研究[J]. 钢铁钒钛, 2021,42(1):24−31. doi: 10.7513/j.issn.1004-7638.2021.01.004 [6] Chen Yanguang, Guo Zhancheng, Wang Zhi. Simulation study of CO reduction of NO in sintering process[J]. Journal of Iron and Steel Research, 2009,21(1):6−9. (陈彦广, 郭占成, 王志. 烧结过程中CO还原NO的模拟研究[J]. 钢铁研究学报, 2009,21(1):6−9. [7] 龚志军, 武文斐, 李保卫, 等. 一种用于煤燃烧过程高温原位催化脱硝方法: 中国, CN105854589A[P]. 2016-08-17.Gong Zhijun, Wu Wenfei, Li Baowei, et al. A high-temperature in situ catalytic denitrification method for coal combustion process: China, CN105854589A[P]. 2016-08-17. [8] Qi Rui, Gong Zhijun, Hou Limin, et al. Study on the performance of catalytic semi-coke denitrification with rare earth tailings[J]. Coal Conversion, 2021,44(3):68−75. (戚瑞, 龚志军, 侯丽敏, 等. 稀土尾矿催化半焦脱硝性能研究[J]. 煤炭转化, 2021,44(3):68−75. [9] 王建. 稀土尾矿催化CO还原脱硝特性实验研究[D]. 包头: 内蒙古科技大学, 2020.Wang Jian. Experimental study on the characteristics of catalytic CO reduction denitrification with rare earth tailings[D]. Baotou: Inner Mongolia University of Science and Technology, 2020. [10] Li Na, Zhang Shuning, Mei Zheyue, et al. Preparation of rare earth tailings denitrification catalyst and its CO reduction NO performance[J]. Rare Earth, 2019,40(6):88−95. (李娜, 张舒宁, 梅哲跃, 等. 稀土尾矿脱硝催化剂的制备及其CO还原NO性能研究[J]. 稀土, 2019,40(6):88−95. [11] Wang Jian, Gong Zhijun, Meng Zhaolei, et al. Experimental study on the catalytic CO reduction of NO from Baiyun Ebo rare earth tailings[J]. Rare Metals and Cemented Carbides, 2020,48(3):38−44,72. (王建, 龚志军, 孟昭磊, 等. 白云鄂博稀土尾矿催化CO还原NO实验研究[J]. 稀有金属与硬质合金, 2020,48(3):38−44,72. [12] Wang Jian, Gong Zhijun, Xu Guodong, et al. Experimental study on the characteristics of catalytic CO reduction denitrification of rare earth tailings[J]. Rare Metals, 2020,44(12):1301−1307. (王建, 龚志军, 徐国栋, 等. 稀土尾矿催化CO还原脱硝特性试验研究[J]. 稀有金属, 2020,44(12):1301−1307. [13] Lau N T, Fang M, Chan C K. The role of SO2 in the reduction of NO by CO on La2O2S[J]. Journal of Catalysis, 2007,245(2):301−307. doi: 10.1016/j.jcat.2006.10.025 [14] Wang Xuehai, Fang Xiangcheng, Liu Zhongsheng. Study on the simultaneous reduction of NO and SO2 by CO over Fe/γ-Al2O3 catalyst[J]. Industrial Catalysis, 2012,20(10):63−67. (王学海, 方向晨, 刘忠生. Fe/γ-Al2O3催化剂上CO同时还原NO和SO2研究[J]. 工业催化, 2012,20(10):63−67. doi: 10.3969/j.issn.1008-1143.2012.10.014 [15] 赵留成. 载金硫化物中性焙烧—非氰浸金过程的研究[D]. 北京: 北京科技大学, 2016.Zhao Liucheng. Study on the neutral roasting of gold-bearing sulfide-non-cyanide gold leaching process[D]. Beijing: University of Science and Technology Beijing, 2016. [16] Cheng H, Liu Q, Man H, et al. Application of TG-FTIR to study SO2 evolved during the thermal decomposition of coal-derived pyrite[J]. Thermochimica Acta, 2013,555(555):1−6. [17] Huang F, Xin S, Mi T, et al. Study of pyrite transformation during coal samples heated in CO2 atmosphere[J]. Fuel, 2021,292(3):120269. [18] Wang Lei, Ma Jianxin, Lu Xiaofeng, et al. Catalytic reduction of SO2 and NO on rare earth oxides Ⅰ. Activation characteristics and mechanism of catalysts[J]. Journal of Catalysis, 2000,(6):542−546. (王磊, 马建新, 路小峰, 等. 稀土氧化物上SO2和NO的催化还原 Ⅰ. 催化剂的活化特性和机理[J]. 催化学报, 2000,(6):542−546. doi: 10.3321/j.issn:0253-9837.2000.06.009 -

下载:

下载: