Analysis of inclusions in the whole process of 20MnCr5 gear steel

-

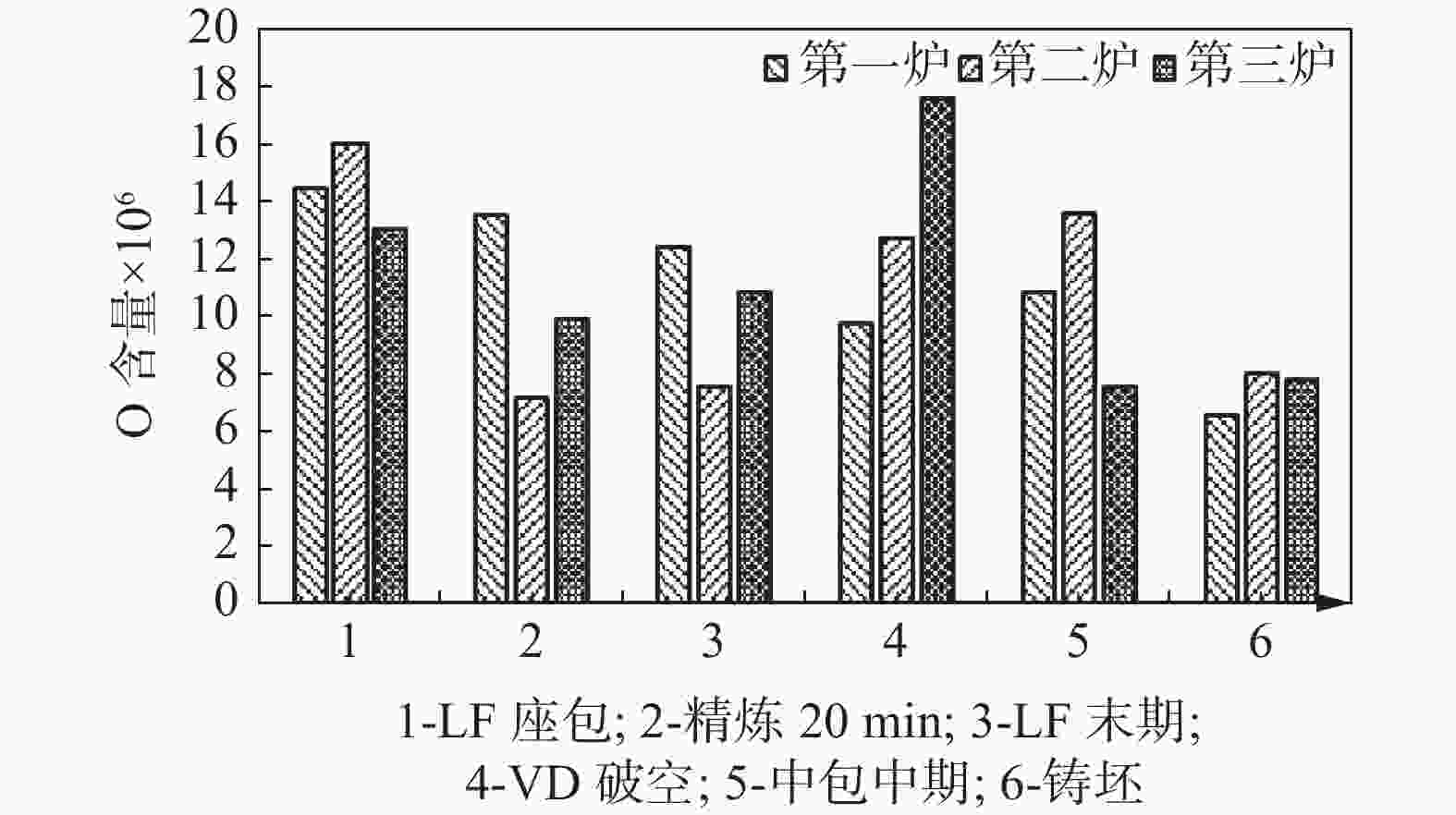

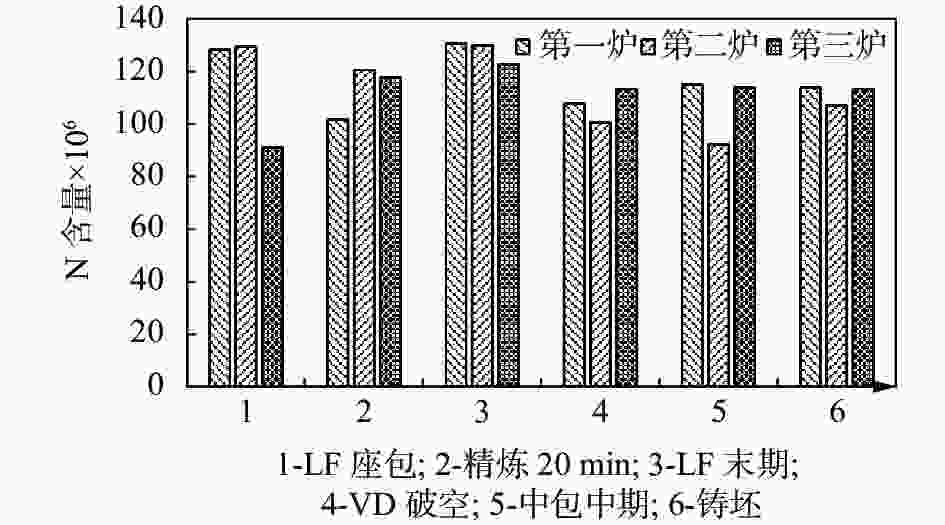

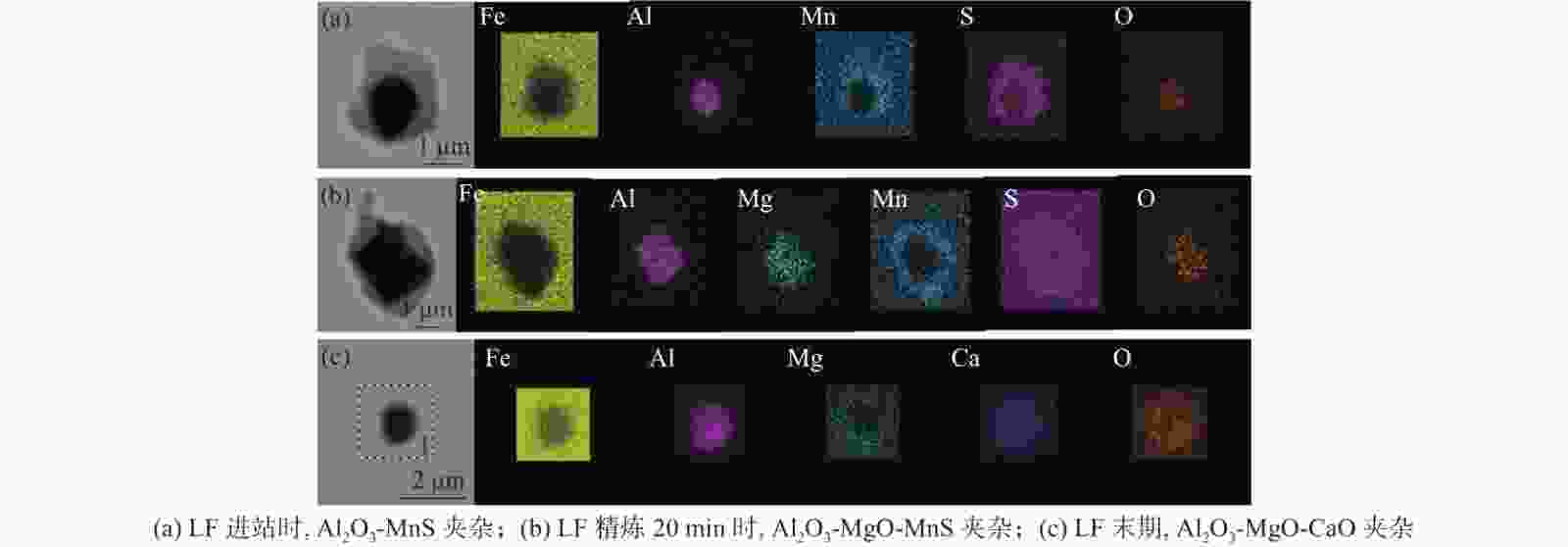

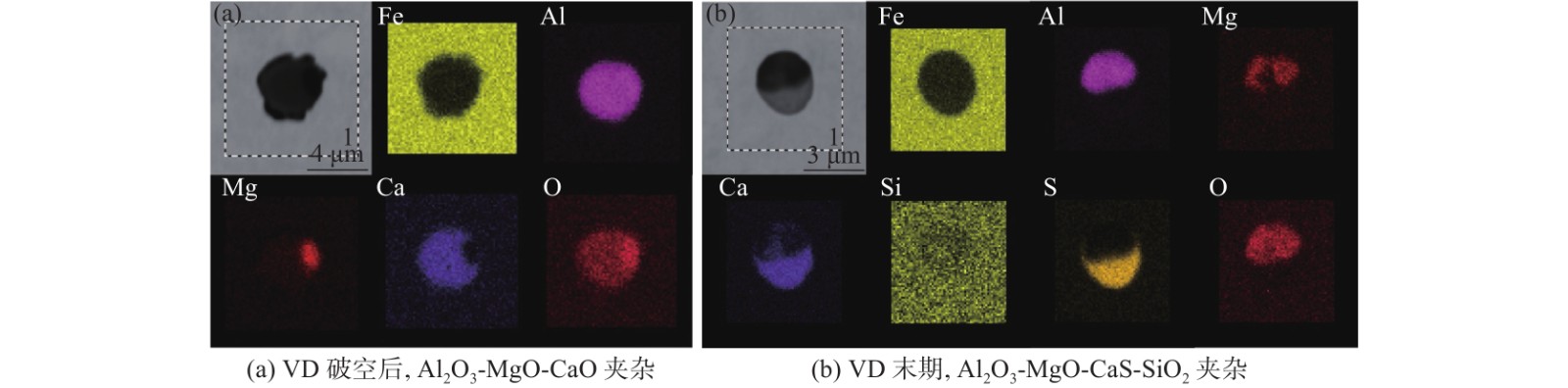

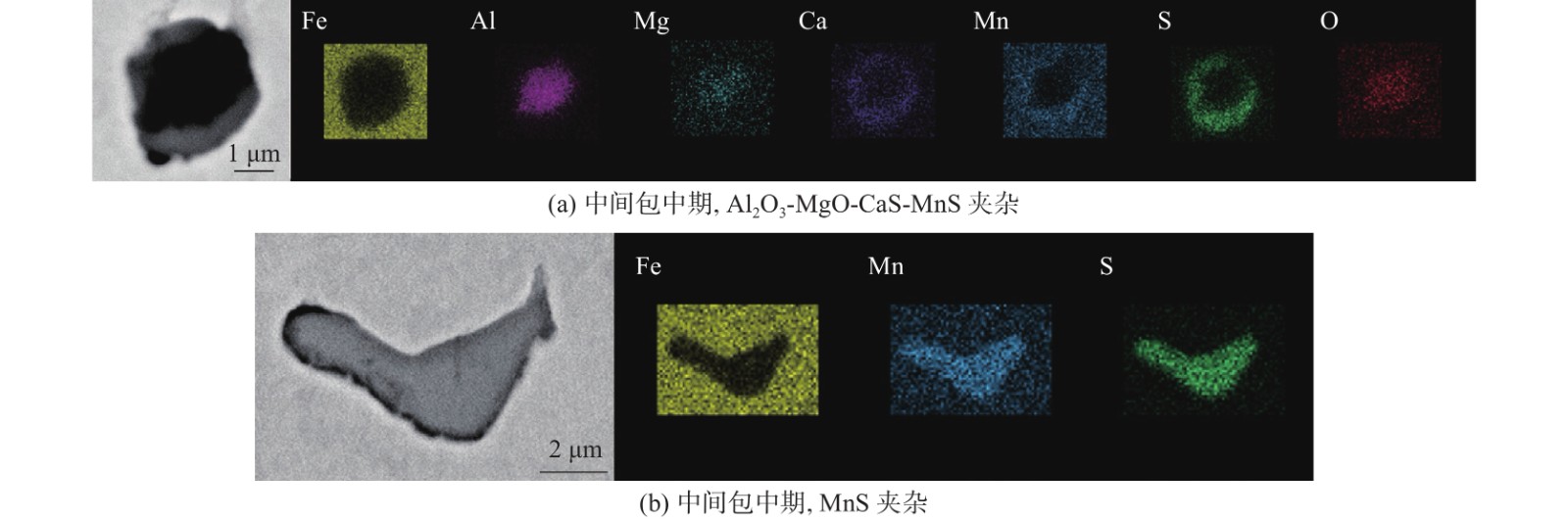

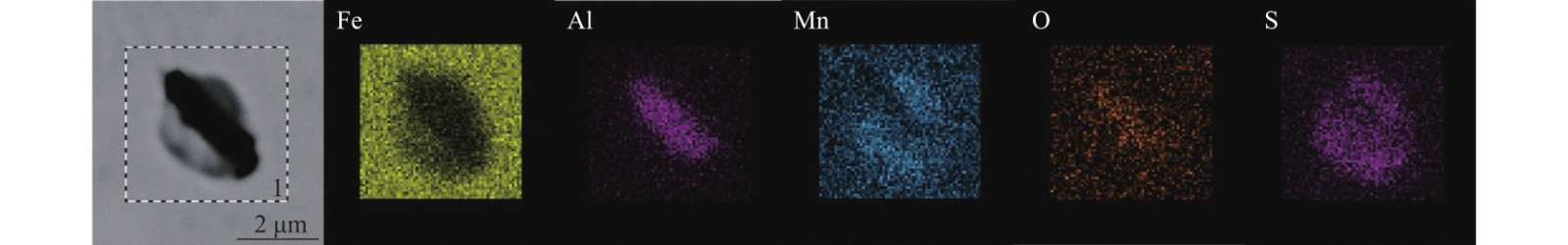

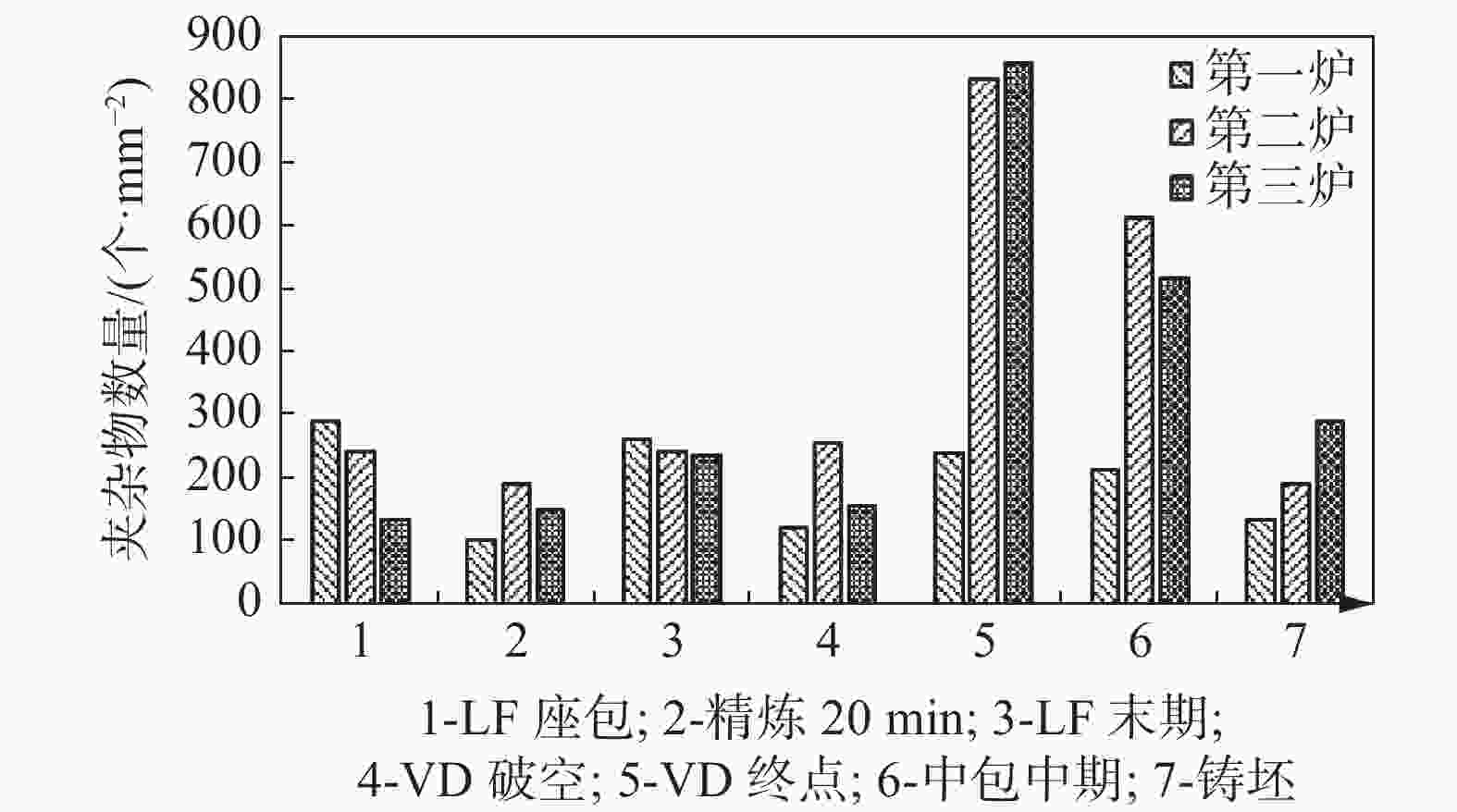

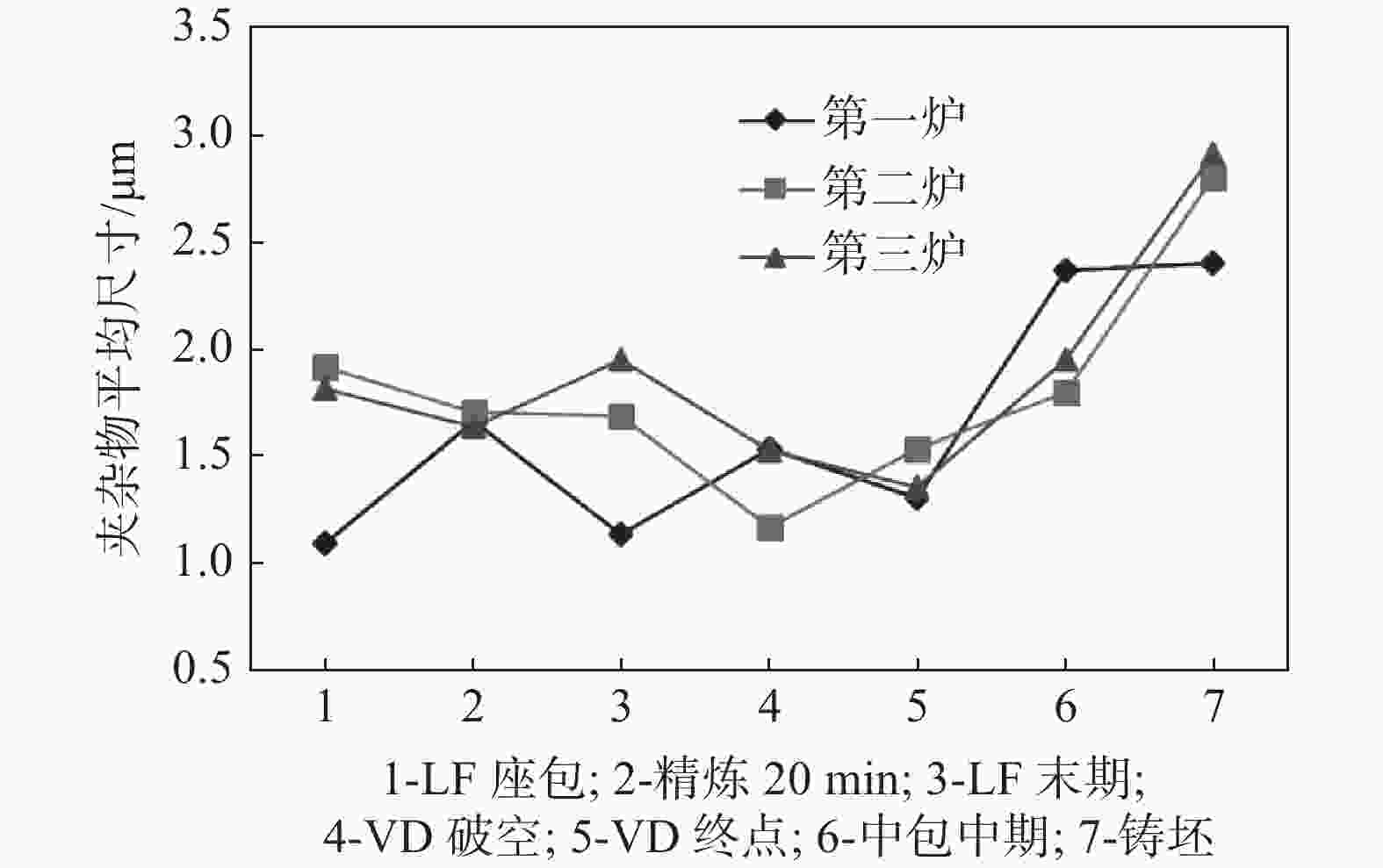

摘要: 为有效改善齿轮钢的洁净度,提高产品质量,必须明确齿轮钢冶炼过程中非金属夹杂物的演变行为。以某厂20MnCr5齿轮钢为研究对象,通过对LF-VD-CC工艺齿轮钢生产过程的全流程取样分析,利用扫描电子显微镜对冶炼过程不同阶段的夹杂物成分、形貌、尺寸和数量等特性进行系统分析研究。结果表明,LF进站时,主要夹杂物为Al2O3-MnS复合夹杂物,其中还分布了大量的MnS夹杂物;精炼20 min后取样,观察到Al2O3-MgO-MnS复合夹杂物和Al2O3夹杂物;LF末期,产物基本不变;VD破空后,观察到的主要夹杂物为MnS夹杂物和呈近球形的以Al2O3为核心的MnS包裹的复合夹杂物,还有许多镁铝尖晶石,其有的含有少量CaO,有的有少量MnS,但主要成分为镁铝尖晶石。针对该钢厂镁铝尖晶石较多的情况,可通过调控精炼渣或者减少耐火材料的侵蚀进行改善。Abstract: In order to effectively improve the cleanliness of gear steel and product quality, it is necessary to clarify the evolution behavior of non-metallic inclusions in the smelting process of gear steel. This paper takes 20MnCr5 gear steel as the research object. Through sampling and analysis of the whole LF-VD-CC gear steel production process, a scanning electron microscope is used to systematically analyze the characteristics of inclusion composition, morphology, size, and quantity at different stages of the smelting process. When LF enters the station, the primary inclusions are Al2O3-MnS composite inclusions, among which many MnS inclusions are distributed. After 20 minutes of refining, Al2O3-MgO-MnS composite and Al2O3 inclusions were observed. At the end of LF, the product is unchanged. After VD breaking, the primary inclusions observed are MnS inclusions, which are nearly spherical and consist of MnS inclusions with Al2O3 as the core. There are many magnesia-aluminum spinels, some of which have a small amount of CaO, and some have a small amount of MnS. However, the main component is the magnesia-aluminum spinel.

-

Key words:

- gear steel /

- non-metallic inclusion /

- composition /

- morphology /

- whole process analysis

-

表 1 20MnCr5钢主要化学成分

Table 1. Main chemical composition of 20MnCr5

% C Si Mn Cr S P Ni 0.14~0.22 ≤0.12 1.00~1.50 0.80~1.30 0.020~0.035 ≤0.035 0.80~1.30 表 2 取样方案

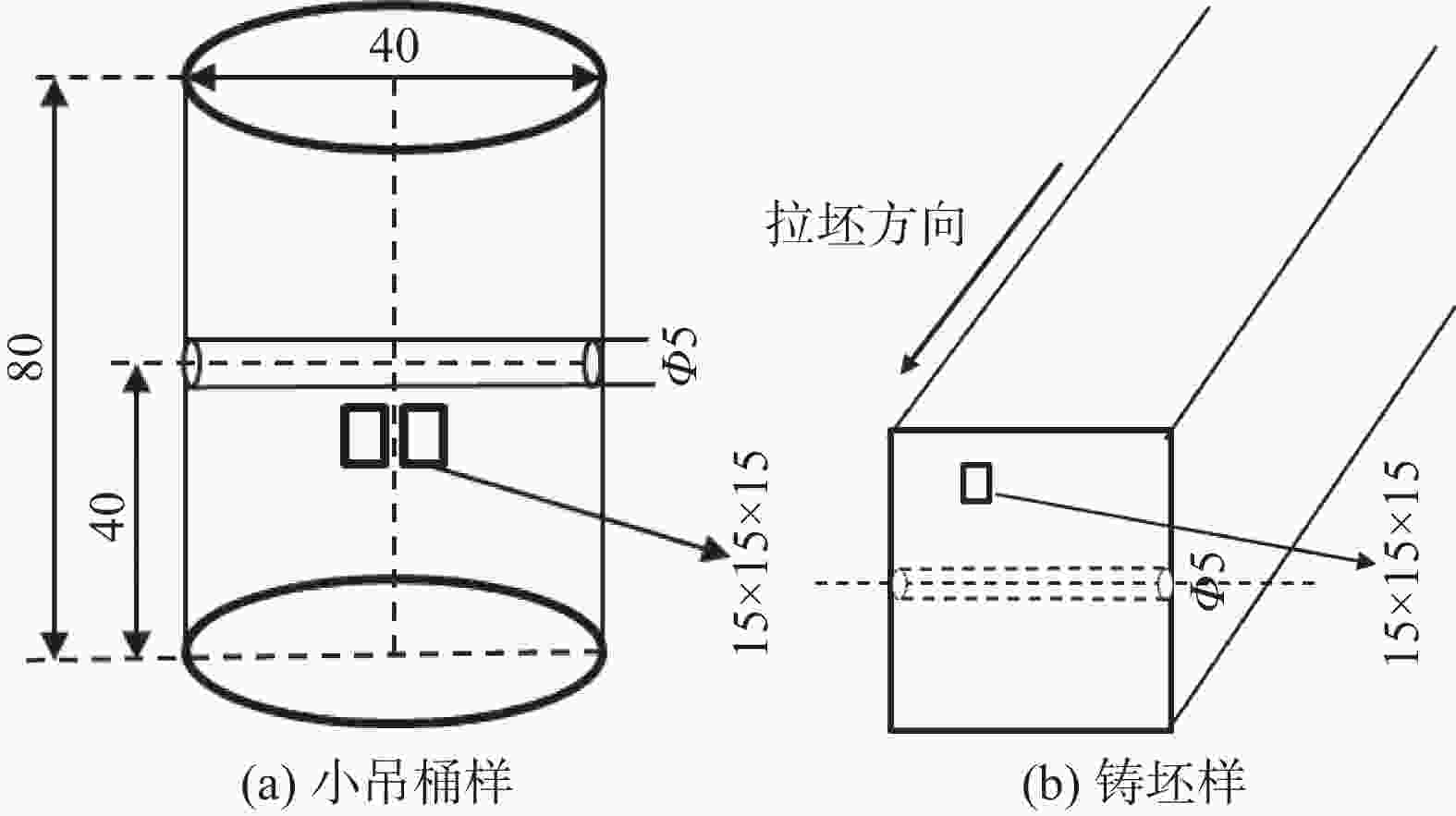

Table 2. Sampling plan

编号 取样工位点 试样编号 饼样 渣样 吊桶样 测温 1 LF座包 LF1 √ √ √ √ 2 精炼20 min LF2 √ √ √ √ 3 LF末期 LF3 √ √ √ √ 4 VD破空 VD1 √ × √ √ 5 VD终点 VD2 √ × √ √ 6 中间包 中包中期 × × √ √ 7 铸坯 铸坯 全断面截取,200 mm 表 3 不同炉次各阶段夹杂物的尺寸分布

Table 3. The size distribution of inclusions in different furnaces at each stage

工序 夹杂物比例/% <1.0 μm 1.0~2.0 μm 2.0~3.0 μm 3.0~5.0 μm >5.0 μm 第一炉 第二炉 第三炉 第一炉 第二炉 第三炉 第一炉 第二炉 第三炉 第一炉 第二炉 第三炉 第一炉 第二炉 第三炉 LF座包 48.80 20.29 26.24 49.20 41.55 44.55 1.60 23.67 16.83 0.40 13.53 9.9 0 0.97 2.48 LF精炼20 min 21.59 29.52 30.23 48.86 41.57 44.96 25.00 20.48 17.05 4.55 6.63 7.75 0 1.81 0 LF末期 50.88 30.77 22.28 44.69 40.38 43.07 4.42 19.23 18.32 0 8.17 12.38 0 1.44 3.96 VD破空 27.88 50.91 41.35 54.81 42.73 39.10 9.62 3.18 9.02 7.67 3.18 9.77 0 0 0.75 VD终点 43.63 37.17 43.46 40.20 41.80 40.87 14.71 13.32 11.58 1.47 6.73 3.68 0 0.98 0.41 中包中期 11.40 22.81 22.40 38.04 50.19 46.38 27.71 15.02 16.52 17.93 9.13 10.41 5.43 2.85 4.30 铸坯 9.48 12.05 33.62 33.13 23.69 32.76 23.50 17.67 17.24 21.69 27.71 6.90 9.64 12.45 -

[1] Jia Yi, Liu Chunyang, Han Shaowei, et al. Analysis of nitrogen content control in Al-killed steel[J]. China Metallurgy, 2021,31(3):116−121. (贾毅, 刘春阳, 韩少伟, 等. 铝镇静钢氮含量控制分析[J]. 中国冶金, 2021,31(3):116−121. doi: 10.13228/j.boyuan.issn1006-9356.20200435 [2] Zeng Yaoxian. Cleanness control of sulfur bearing gear steel 20CrMnTiH[J]. Iron & Steel, 2021,56(2):76−81. (曾耀先. 含硫齿轮钢20CrMnTiH洁净度控制[J]. 钢铁, 2021,56(2):76−81. [3] Chen Wu, He Xiaofei, Yu Wenchao, et al. Characterization of the microstructure and hardness of case-carburized gear steel[J]. Micron, 2021,144:103028. doi: 10.1016/j.micron.2021.103028 [4] He Xiaofei, Hu Chengfei, Xu Le, et al. Effect of total oxygen on the nonmetallic inclusion of gear steel[J]. Chinese Journal of Engineering, 2021,43(4):537−544. (何肖飞, 胡成飞, 徐乐, 等. 总氧含量对齿轮钢中非金属夹杂物的影响[J]. 工程科学学报, 2021,43(4):537−544. [5] Fang Yurong, Chen Zhengquan. Oxygen content and inclusion characteristics of 20CrMnTi gear steel produced by 120 t BOF-LF-VD-CC process[J]. Special Steel, 2020,41(6):64−67. (方宇荣, 陈正权. 120 t BOF-LF-VD-CC流程冶炼的20CrMnTi齿轮钢氧含量和夹杂物特性[J]. 特殊钢, 2020,41(6):64−67. doi: 10.3969/j.issn.1003-8620.2020.06.015 [6] Ma Wenjun, Bao Yanping, Zhao Lihua, et al. Control of the precipitation of TiN inclusions in gear steels[J]. International Journal of Minerals, Metallurgy and Materials, 2014,21(3):234−239. doi: 10.1007/s12613-014-0900-2 [7] Yin Chuanlei, Lin Peng, Zhang Hongcai, et al. Experiment on effect of nitrogen content in steel on sulfide of sulfur-containing gear steel[J]. China Metallurgy, 2020,30(7):61−67. (印传磊, 林鹏, 张洪才, 等. 钢中氮含量对含硫齿轮钢硫化物影响的试验[J]. 中国冶金, 2020,30(7):61−67. doi: 10.13228/j.boyuan.issn1006-9356.20200013 [8] Liu Jian, Ma Yumin, Zhou Weiji, et al. Theoretical analysis and application of 100 t RH vacuum dehydrogenation[J]. Henan Metallurgy, 2020,28(3):8−12,38. (刘建, 马玉民, 周伟基, 等. 100 t RH真空脱氢理论分析及应用实践[J]. 河南冶金, 2020,28(3):8−12,38. doi: 10.3969/j.issn.1006-3129.2020.03.003 [9] Li Tao, Sun Dali, An Jie. Study on inclusion of automobile gear steel 8620RH in continuous cast billet[J]. Continuous Casting, 2017,42(3):39−42. (李涛, 孙大利, 安杰. 汽车齿轮钢8620RH连铸坯中夹杂物研究[J]. 连铸, 2017,42(3):39−42. [10] Jiang Fangjie, Wu Huajie, Zhang Yongchao. Study on inclusion behavioe of 20CrMnTi gear steel produced by BOF-LF-VD-CC[J]. Henan Metallurgy, 2017,25(4):1−4,45. (蒋芳杰, 吴华杰, 张永超. BOF-LF-VD-CC生产20CrMnTi齿轮钢的夹杂物行为研究[J]. 河南冶金, 2017,25(4):1−4,45. doi: 10.3969/j.issn.1006-3129.2017.04.001 [11] Wang Yong, Tang Haiyan, Wu Tuo, et al. Research on the cleanliness of 50CrVA spring steel produced by the BOF-LF-CC process[J]. Chinese Journal of Engineering, 2016,38(S1):187−194. (王勇, 唐海燕, 吴拓, 等. BOF-LF-CC工艺生产50CrVA弹簧钢洁净度研究[J]. 工程科学学报, 2016,38(S1):187−194. [12] Wang Jianzhong, Cheng Limei, Ren Ying, et al. Thermodynamic study on deoxidization and inclusion control of sulfur-containing gear steel[J]. Steelmaking, 2020,36(1):8−14,26. (王建忠, 程礼梅, 任英, 等. 含硫齿轮钢脱氧过程中非金属夹杂物生成热力学及工业实践[J]. 炼钢, 2020,36(1):8−14,26. [13] Hu Yujun. Technical oractice for reduction of 20CrMnTiH gear steel inclusions[J]. Fujian Metallurgy, 2020,49(1):30−33. (胡玉军. 降低20CrMnTiH齿轮钢夹杂物工艺实践[J]. 福建冶金, 2020,49(1):30−33. doi: 10.3969/j.issn.1672-7665.2020.01.009 [14] Sun Houjin, Zhang Yong, an, Zhang Sanping. Influencing factors of austenite grain size and analysis on mixed crystal of 22CrMoH gear steel[J]. Shandong Metallurgy, 2019,41(6):29−31. (孙后金, 张永安, 张三平. 22CrMoH齿轮钢奥氏体晶粒度影响因素及混晶原因分析[J]. 山东冶金, 2019,41(6):29−31. [15] Cao Xiaojun, Fang Guangjin, Yang Guo, et al. High quality 20MnCr5(SH) steel production technology practice[J]. Foundry Technology, 2019,40(12):1303−1306. (曹小军, 方光锦, 杨国, 等. 汽车齿轮用高品质20MnCr5(SH)钢生产工艺实践[J]. 铸造技术, 2019,40(12):1303−1306. [16] Yang Guangwei, Chen Zhaoping, Liu Xiangchun, et al. Effect of holding time after VD on large-sized inclusions of gear steel[J]. Steelmaking, 2019,35(6):31−34,45. (杨光维, 陈兆平, 柳向椿, 等. VD镇静时间对齿轮钢大颗粒夹杂物的影响[J]. 炼钢, 2019,35(6):31−34,45. -

下载:

下载: