Study on the evolution law of surface decarburization of Cr-Mo-V cold heading steel

-

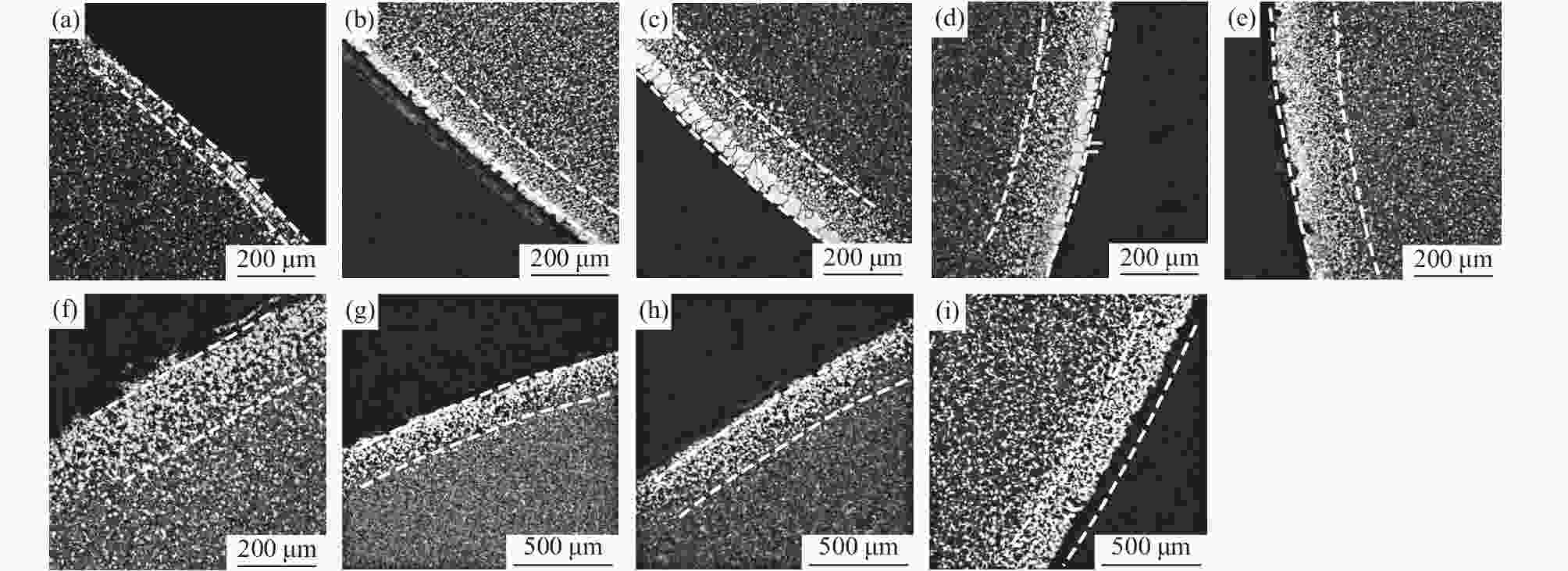

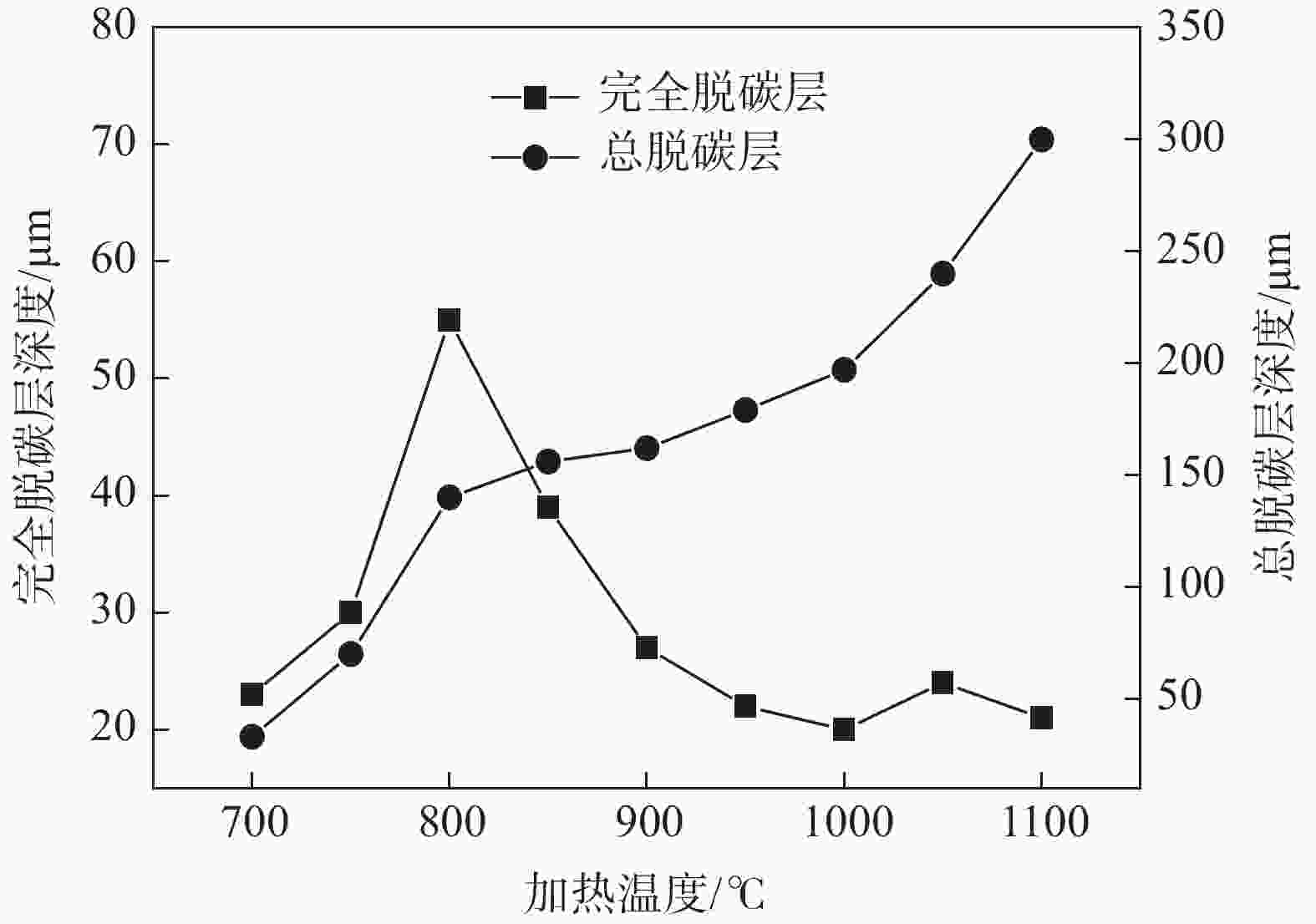

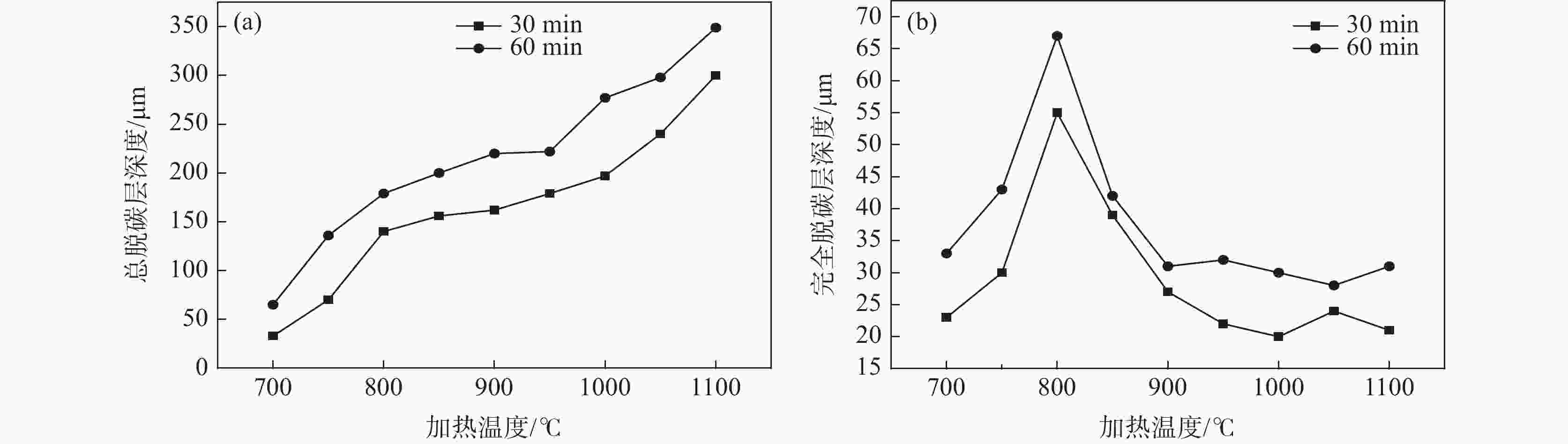

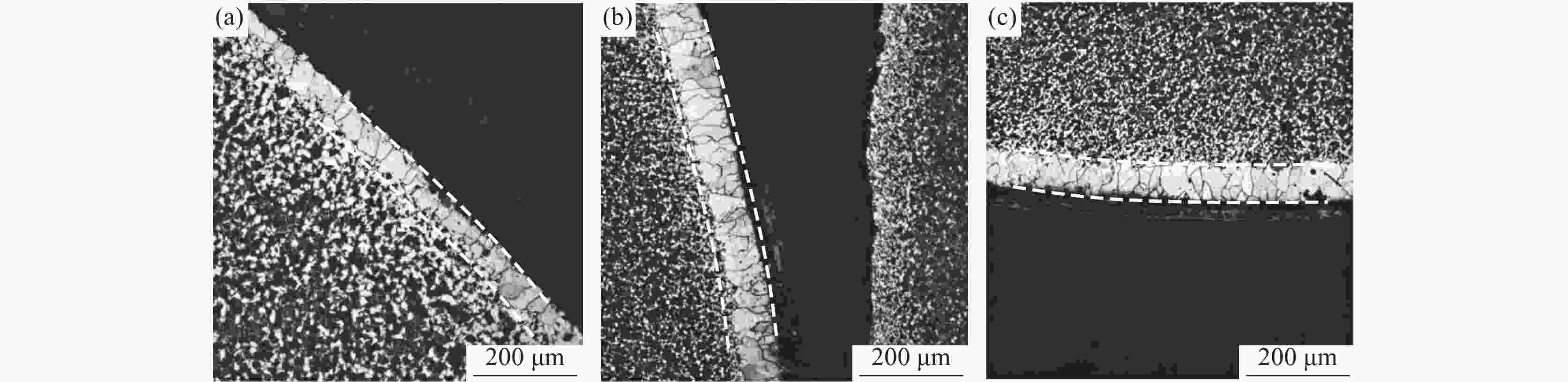

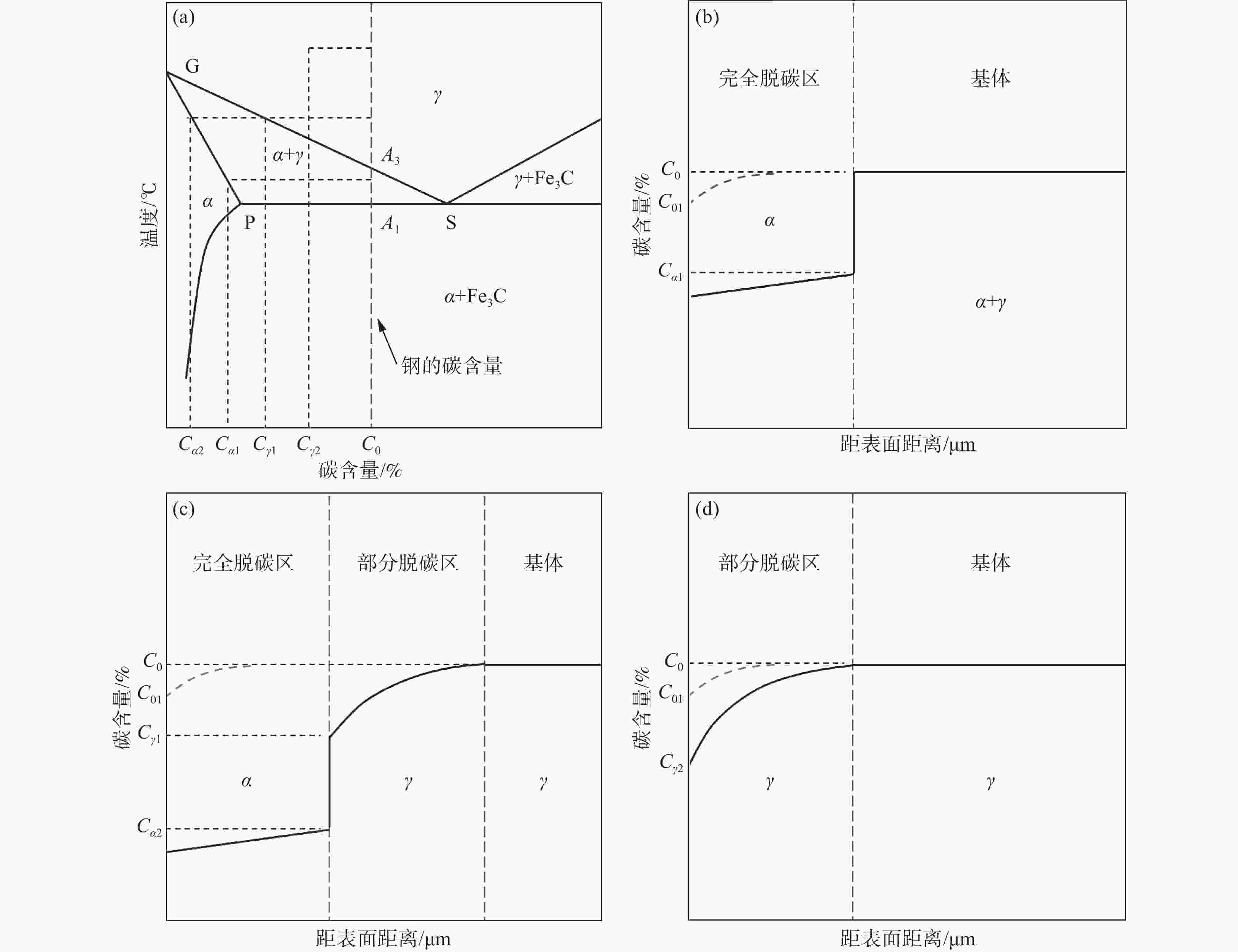

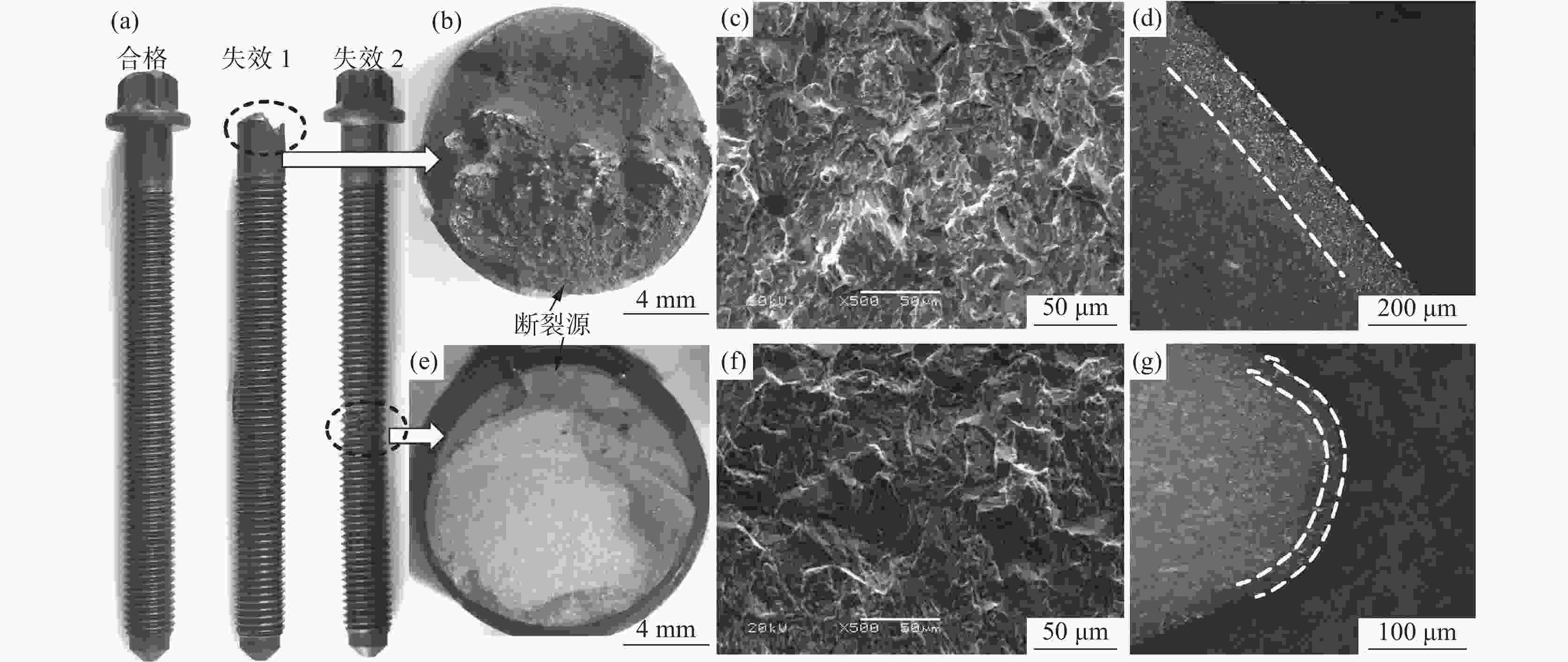

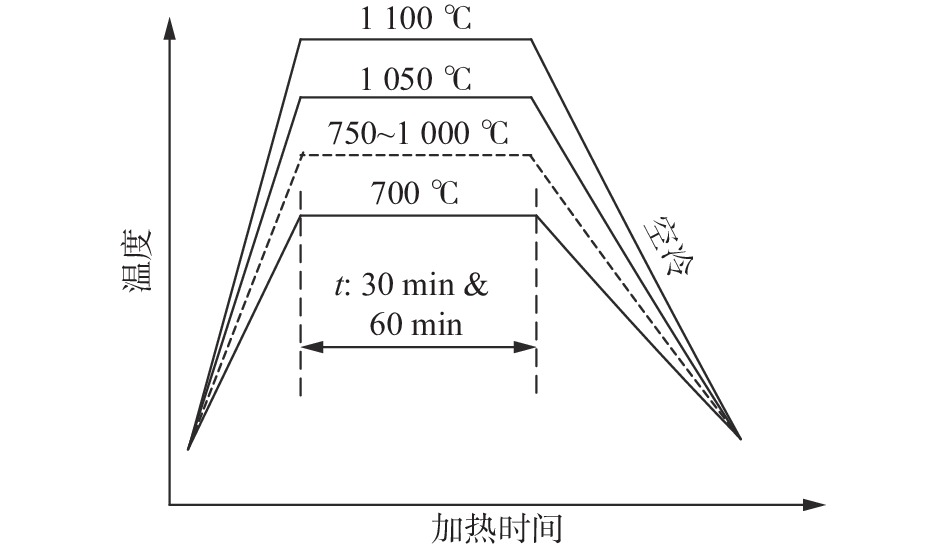

摘要: 研究了冷镦钢40CrMoV加热温度、加热时间及表面处理对脱碳层深度和组织形貌的影响,并分析了表面脱碳随温度变化的演变机理。结果表明,冷镦钢40CrMoV在700~1100 ℃加热时,其总脱碳层深度随温度的升高逐渐增大, 750~850 ℃为完全脱碳层生成的敏感温度区间,其在800 ℃时达到峰值;保温时间的延长使得脱碳层深度进一步加深;表面车削处理后使总脱碳层降低50%,完全脱碳层得到恶化。对冷镦钢40CrMoV在工业生产中表面脱碳的控制提出了建议。Abstract: The effects of heating temperature, heating time, and surface treatment on the depth of decarburized layer and microstructure of cold heading 40CrMoV steel were studied, and the evolution mechanism of surface decarburization with temperature was analyzed. The results show that when the cold heading 40CrMoV steel is heated at 700-1100 ℃, the total decarburized layer depth increases gradually with the increase in temperature. 750-850 ℃ is the sensitive temperature range for forming a complete decarburized layer, and it reaches its peak value at 800 ℃. With the extension of holding time, the depth of the decarburized layer is further deepened. Additionally, after surface turning treatment, the total decarburized layer is reduced by 50%, and the complete decarburized layer deteriorates. As a summary, the control of surface decarburization of cold heading 40CrMoV steel in industrial production is proposed.

-

Key words:

- cold heading steel /

- 40CrMoV /

- decarburization /

- microstructure /

- fatigue fracture

-

表 1 高强度冷镦钢的主要化学成分

Table 1. Main chemical composition of high strength cold heading steel

% C Si Mn P S Cr Mo V 0.40 0.18 0.82 0.001 0.0008 0.98 0.22 0.02 -

[1] Dong Han, Lian Xintong, Hu Chundong, et al. High performance steels: The scenario of theory and technology[J]. Acta. Metall. Sin., 2020,56(4):558−582. (董瀚, 廉心桐, 胡春东, 等. 钢的高性能化理论与技术进展[J]. 金属学报, 2020,56(4):558−582. doi: 10.11900/0412.1961.2020.00058 [2] Hu Chundong, Meng Li, Dong Han. Research and development of ultrahigh strength steels[J]. Trans. Mater. Heat Treat., 2016,37(11):178−183. (胡春东, 孟利, 董瀚. 超高强度钢的研究进展[J]. 材料热处理学报, 2016,37(11):178−183. doi: 10.13289/j.issn.1009-6264.2016.11.030 [3] Hui Weijun, Dong Han, Weng Yuqing. Research and development trends of high strength steel for bolts[J]. Mater. Mech. Eng., 2002,26(11):1−5. (惠卫军, 董瀚, 翁宇庆. 高强度螺栓钢的发展动向[J]. 机械工程材料, 2002,26(11):1−5. doi: 10.3969/j.issn.1000-3738.2002.11.001 [4] Qiu C, Zurob H S, Hutchinson C R. The coupled solute drag effect during ferrite growth in Fe–C–Mn–Si alloys using controlled decarburization[J]. Acta Mater., 2015,100:333−343. doi: 10.1016/j.actamat.2015.08.065 [5] Zhang Kai, Chen Yinli, Sun Yanhui, et al. Effect of H2O(g) on decarburization of 55SiCr spring steel during the heating process[J]. Acta. Metall. Sin., 2018,54(10):1350−1358. (张凯, 陈银莉, 孙彦辉, 等. 加热过程中H2O(g)对55SiC弹簧钢脱碳的影响[J]. 金属学报, 2018,54(10):1350−1358. doi: 10.11900/0412.1961.2017.00558 [6] Yuan J H, Zhan Q, Huang J, et al. Decarburization mechanisms of WC-Co during thermal spraying: Insights from controlled carbon loss and microstructure characterization[J]. Mater. Chem. Phys., 2013,142:165−171. doi: 10.1016/j.matchemphys.2013.06.052 [7] Wang X J, Wei L Q, Zhou X, et al. A superficial coating to improve oxidation and decarburization resistance of bearing steel at high temperature[J]. Appl. Surf. Sci., 2012,258:4977−4982. doi: 10.1016/j.apsusc.2012.01.135 [8] Song Z Q. Oxidation and decarburization study and prediction of M2 steel in heating process [D]. Anshan: Liaoning Science and Technology, 2017: 12. [9] Wang Ningtao, Li Shilin, Ruan Shipeng, et al. Effect of finish rolling and spinning temperature on phase structure of iron oxide skin of SCM435 wire rod[J]. Special Steel, 2019,40(4):4. (王宁涛, 李世琳, 阮士朋, 等. 精轧和吐丝温度对SCM435线材氧化铁皮物相结构的影响[J]. 特殊钢, 2019,40(4):4. doi: 10.3969/j.issn.1003-8620.2019.04.002 [10] Ma H Y, He Y S, Liu Y, et al. Effects of precipitation on the scale and grain growth in 9% Cr tempered martensite steel upon steam oxidation[J]. Mater. Charact., 2020, 167: 1. [11] Liu Y B, Zhang W, Tong Q, et al. Effects of Si and Cr on complete decarburization behavior of high carbon steels in atmosphere of 2vol. % O2[J]. J Iron Steel Res Int, 2016,23(12):1316. doi: 10.1016/S1006-706X(16)30194-7 [12] Liang Z Y, Wang Y G, Gui Y, et al. Micro-structural evolution of oxide scales formed on a Nb-stabilizing heat-resistant steel at the initial stage in high-temperature water vapor[J]. Mater. Chem. Phys., 2020,242:1. [13] Hu Lei, Wang Lei, Ma Han. Behaviors of oxidation and decarburization on surfaces of high carbon steel wire rods[J]. J Iron Steel Res Int, 2016,28(3):67. (胡磊, 王雷, 麻晗. 高碳钢盘条的表面氧化与脱碳行为[J]. 钢铁研究学报, 2016,28(3):67. doi: 10.13228/j.boyuan.issn1001-0963.20150280 [14] Wang Ping, Shen Qiancheng, Wu Xuming, et al. Effect of heating atmosphere on oxidation and decarburization properties of GCr15 bearing steel[J]. Hot Wor. Technol., 2018,47(22):78. (王萍, 沈千成, 吴旭明, 等. 加热气氛对 GCr15 轴承钢氧化和脱碳特性的影响[J]. 热加工工艺, 2018,47(22):78. [15] Xu Le, Chen Liang, Chen Gaojin, et al. Oxidation decarburization characteristics and fatigue properties of 65Si2MnW spring steel[J]. Heat Treatment of Metals, 2018,43(8):83−89. (徐乐, 陈良, 陈高进, 等. 65Si2MnW弹簧钢的氧化脱碳特性及疲劳性能[J]. 金属热处理, 2018,43(8):83−89. [16] Nomura M, Morimoto H, Toyama M. Calculation of ferrite decarburizing depth, considering chemical composition of steel and heating condition[J]. ISIJ Int. 2000, 40: 619-623. [17] Zhao F, Wu M, Jiang Bo, et al. The effect of carbon contents on intragranular ferrite formed in the V-Ti-N microalloyed steel with a carbon content gradient prepared by controlling the surface decarburization[J]. Mater. Charact., 2018,140:217−224. doi: 10.1016/j.matchar.2018.04.014 -

下载:

下载: