As-cast microstructure and mechanical properties of Y12Cr18Ni9 free-cutting steel

-

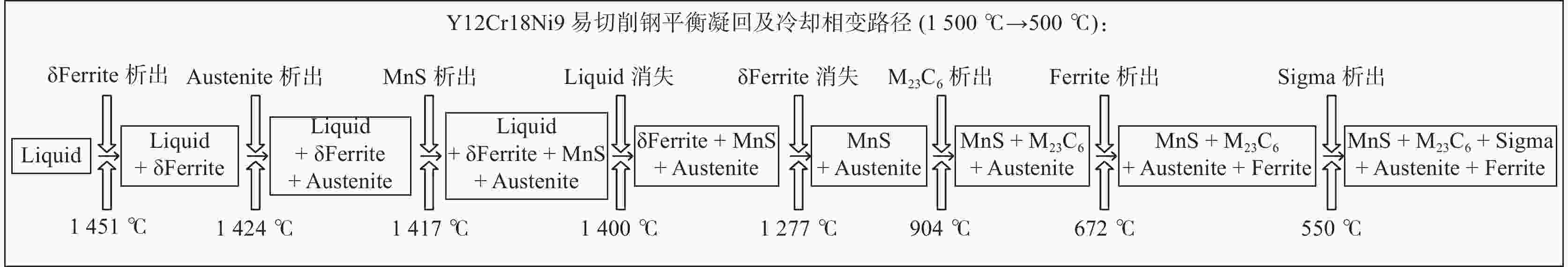

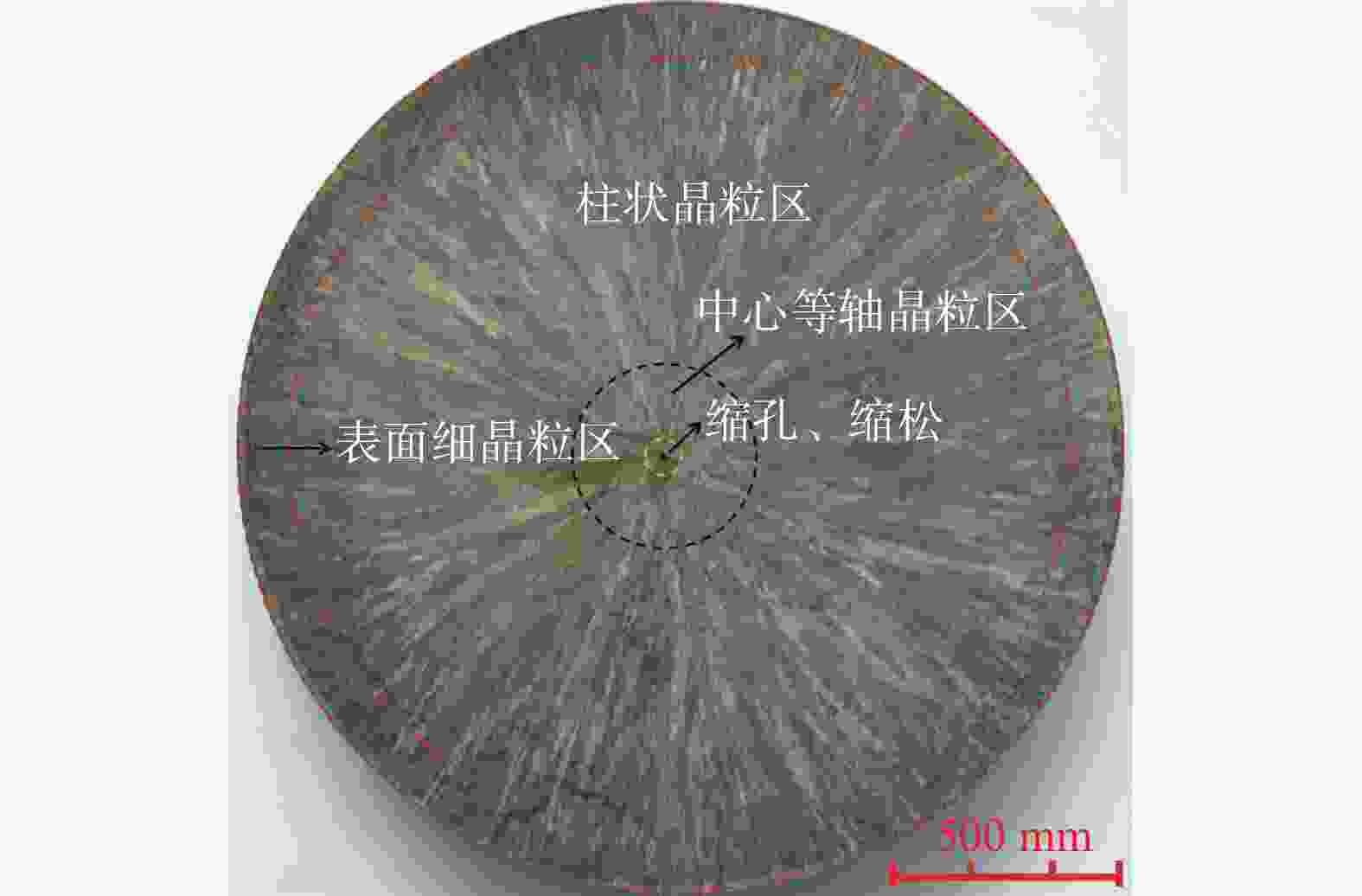

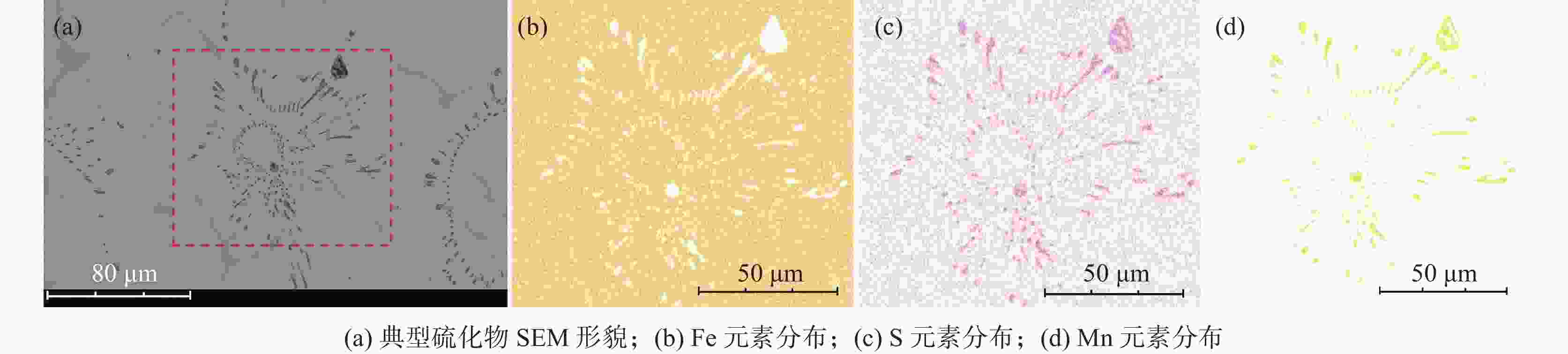

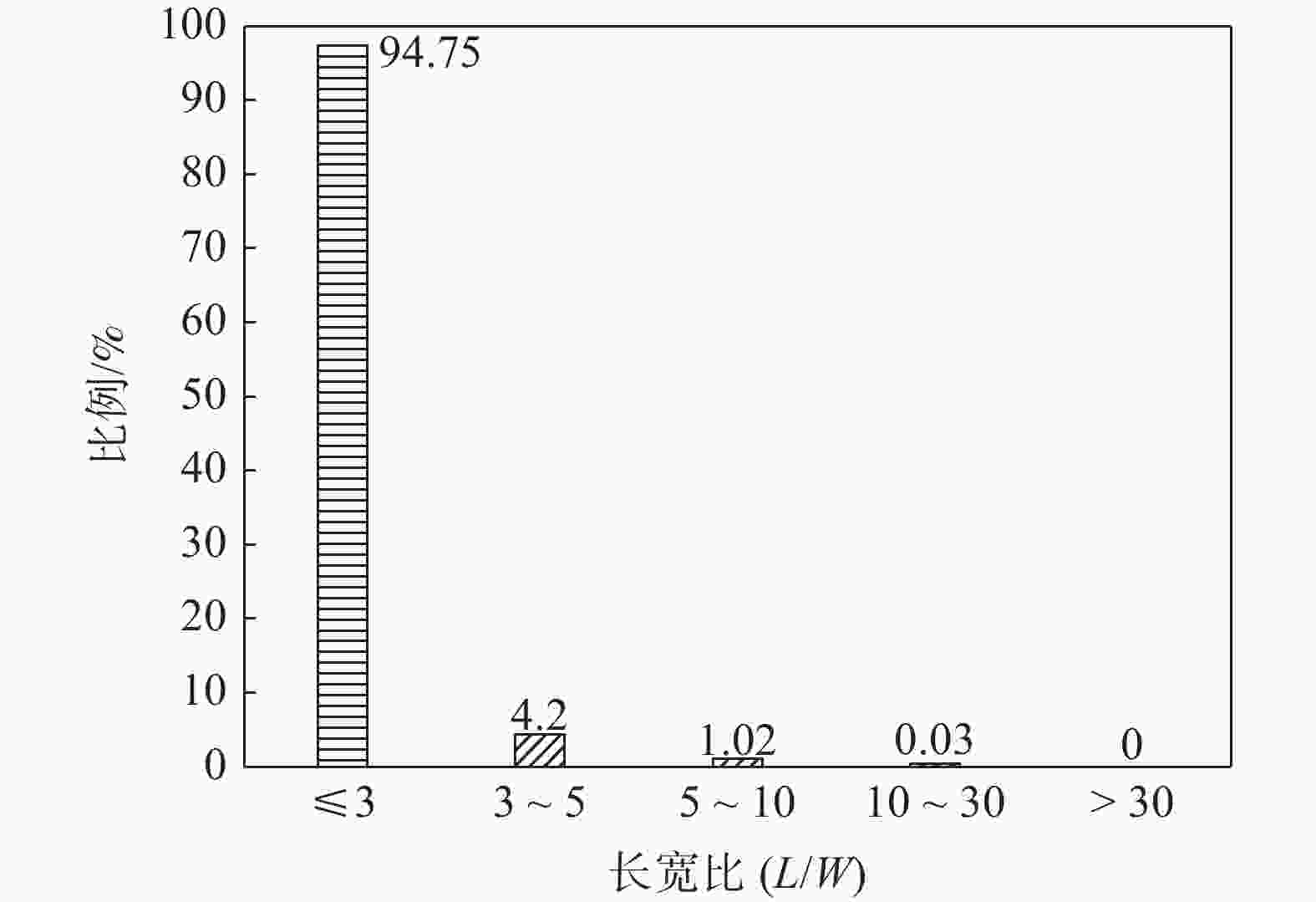

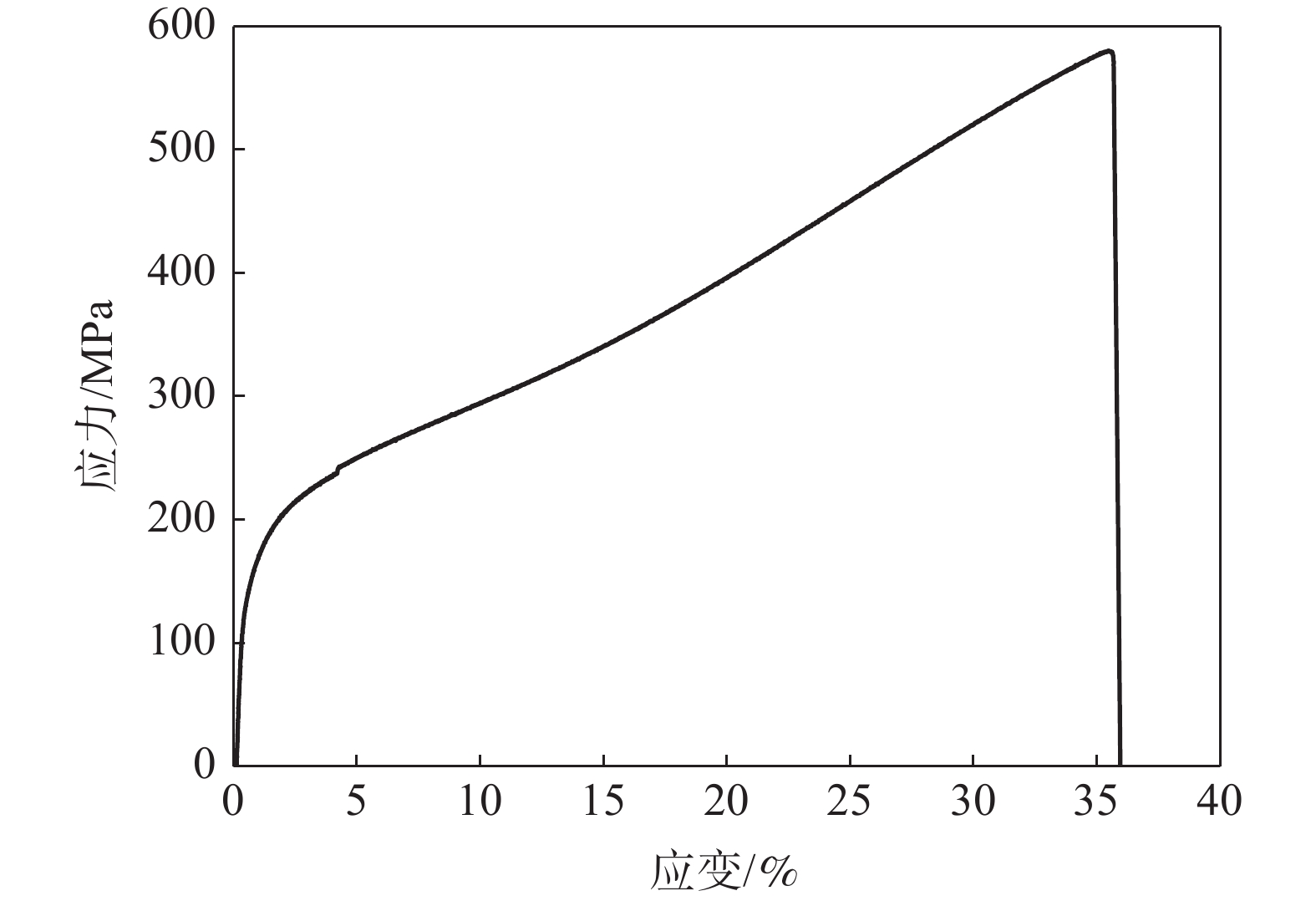

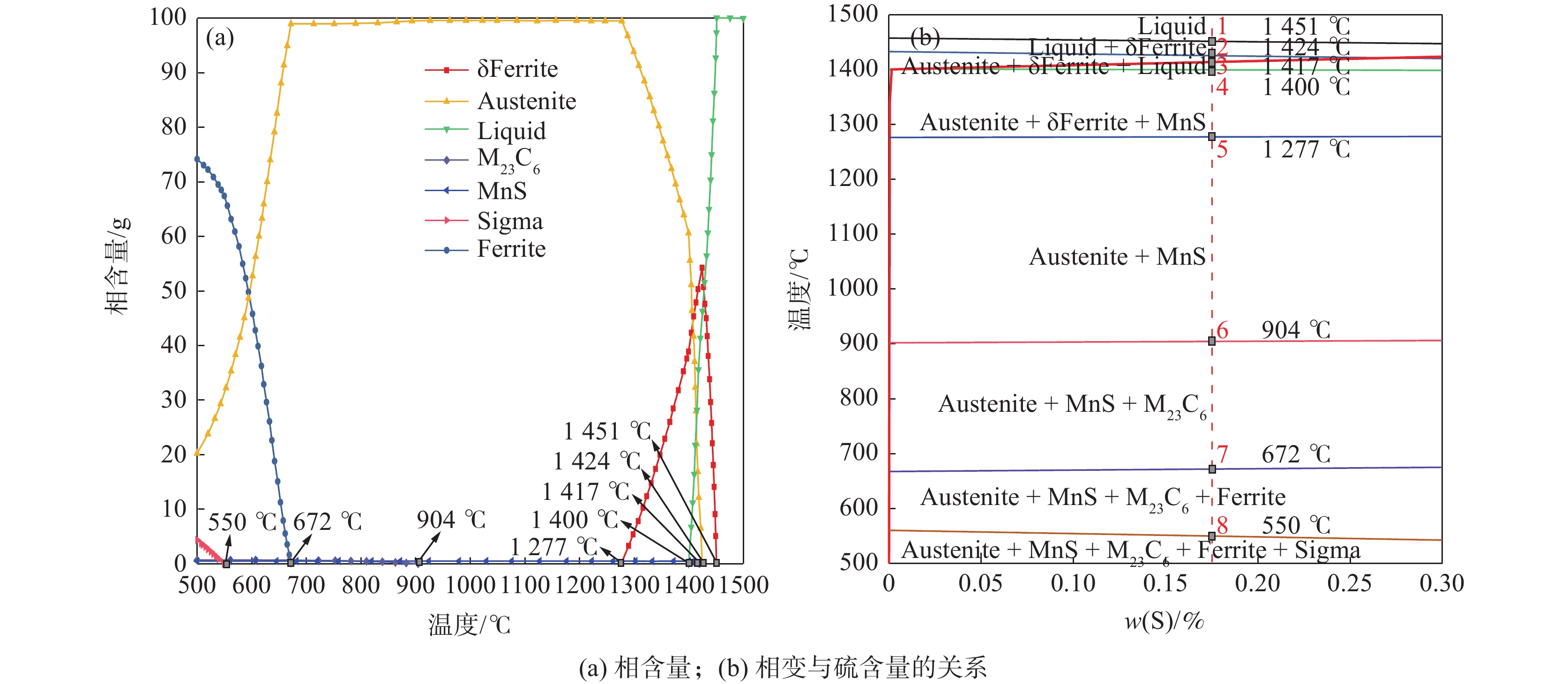

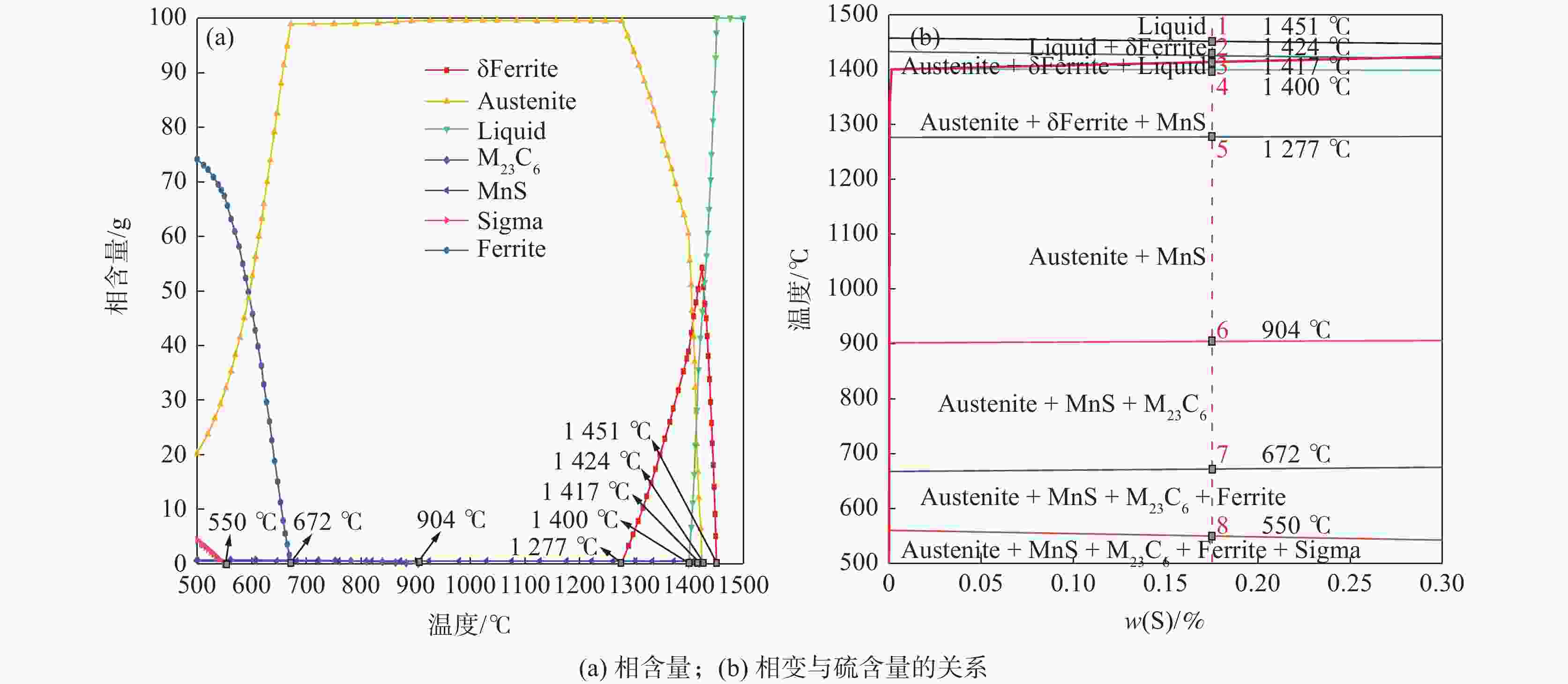

摘要: 以Y12Cr18Ni9易切削钢为研究对象,借助Factsage热力学计算软件、扫描电镜、Phenom Partical X扫描电镜-能谱仪对其铸态组织及力学性能进行研究。结果表明:Y12Cr18Ni9易切削钢中的平衡相主要有Liquid、MnS、δFerrite、Austenite、M23C6、Ferrite与Sigma。平衡凝固和冷却相变路径为:Liquid→Liquid+δFerrite→Liquid+δFerrite+Austenite→Liquid+δFerrite+MnS+Austenite→δFerrite+MnS+Austenite→MnS+Austenite→MnS+M23C6+Austenite→MnS+M23C6+Austenite+Ferrite→MnS+M23C6+Sigma+Austenite+Ferrite。试验钢中的硫化物呈球形、椭球形、纺锤形或短棒状并以簇状沿晶界分布,属于第Ⅱ类硫化物,长宽比≤3的硫化物占比达到了94.75%,尺寸≤3 μm的硫化物所占比例为80.22%,最大弦长≤3 μm的硫化物所占比例为76.02%。簇状硫化物会影响Y12Cr18Ni9易切削钢的力学性能,沿晶界分布的簇状硫化物是形成准解理面的主要原因。经室温拉伸及冲击试验测试,其抗拉强度、屈服强度、断后伸长率、断面收缩率和冲击功分别为597 MPa、233 MPa、17.7%、19.5%和21.8 J。

-

关键词:

- Y12Cr18Ni9易切削钢 /

- FactSage软件 /

- 硫化物 /

- 力学性能 /

- 显微组织

Abstract: The as-cast structure and mechanical properties of Y12Cr18Ni9 free-cutting steel were studied by means of thermodynamic calculation software FactSage, SEM and Phenom Partical X SEM-EDS. The results show that the main equilibrium phases in Y12Cr18Ni9 free-cutting steel are Liquid, MnS, δFerrite, Austenite, M23C6, Ferrite and Sigma. The equilibrium phase transition path is as follows: Liquid→Liquid+δFerrite→Liquid+δFerrite+Austenite→Liquid+δFerrite+MnS+Austenite→δFerrite+MnS+Austenite→MnS+Austenite→MnS+M23C6+Austenite→MnS+M23C6+Austenite+Ferrite→MnS+M23C6+Sigma+Austenite+Ferrite. The sulfides in the test steel are spherical, ellipsoidal, spindle shape or short-bar-like, and distributed in clusters along the grain boundary, belonging to a type II sulfide. The proportion of sulfides with length-width ratio≤3 reaches 94.75%, the proportion of sulfides with size ≤3 μm is 80.22%, and the proportion of sulfides with maximum chord length ≤3 μm is 76.02%. The cluster sulfides affect the mechanical properties of Y12Cr18Ni9 free cutting steel. The cluster sulfides distributed along the grain boundary is the main reason for the formation of quasi cleavage surface. The tensile strength, yield strength, elongation after fracture, reduction of area and impact toughness of the steel are 597 MPa, 233 MPa, 17.7%, 19.5% and 21.8 J, respectively.-

Key words:

- Y12Cr18Ni9 free-cutting steel /

- FactSage software /

- sulfide /

- mechanical property /

- microstructure

-

表 1 Y12Cr18Ni9易切削钢的化学成分

Table 1. Chemical composition of the Y12Cr18Ni9 free-cutting steel

% C Mn Si Ni Cr Mo Al P H O N S Sn Ca Mg Fe 0.035 1.83 0.273 7.79 16.24 0.198 0.0011 0.012 0.00047 0.0071 0.011 0.175 0.0036 <0.0005 <0.0005 Bal. -

[1] Zhao Maiqun, Wang Weike, Zhang Hao, et al. Analysis on sulphide inclusions in free-cutting 42CrMoS steel modified by rare earth elements[J]. Heat Treatment of Metals, 2004,29(11):20−23. (赵麦群, 王伟科, 张颢, 等. 稀土改性42CrMoS易切削钢中的硫化物夹杂分析[J]. 金属热处理, 2004,29(11):20−23. doi: 10.3969/j.issn.0254-6051.2004.11.007 [2] Wang Jinlong, Qiao Aiyun, Zhang Xinggang. Summary on mechanical of machinability and control of sulfide for sulphur free-cutting steel[J]. Science and Technology of Baotou Steel, 2015,41(1):30−32. (王金龙, 乔爱云, 张行刚. 含硫易切削钢切削性机理与硫化物控制简述[J]. 包钢科技, 2015,41(1):30−32. doi: 10.3969/j.issn.1009-5438.2015.01.010 [3] Wang Xiaohong, Xie Bing, Feng Zhongyu. Present status and development of research on free cutting steel at home and abroad[J]. Special Steel, 2005,26(4):26−28. (王小红, 谢兵, 冯仲渝. 国内外易切削钢的现状和研究进展[J]. 特殊钢, 2005,26(4):26−28. doi: 10.3969/j.issn.1003-8620.2005.04.008 [4] Lo K H, Shek C H, Lai J K L. Recent development in stainless steels[J]. Materials Science and Engineering Reports, 2009,65(4-6):39−104. doi: 10.1016/j.mser.2009.03.001 [5] Liu Zhenbao, Liang Jianxiong, Su Jie, et al. Research and application progress in ultra-high strength stainless steel[J]. Acta Metallurgica Sinica, 2020,56(4):549−557. (刘振宝, 梁剑雄, 苏杰, 等. 高强度不锈钢的研究及发展现状[J]. 金属学报, 2020,56(4):549−557. doi: 10.11900/0412.1961.2019.00453 [6] Luo Gang, Wang Huimian. Test and study on relative hot plasticity of MnS inclusion in a new free-cutting stainless steel TBPS[J]. Special Steel, 2016,37(2):5−7. (罗刚, 王辉绵. 新型易切削不锈钢TBPS中MnS夹杂相对热塑性的试验研究[J]. 特殊钢, 2016,37(2):5−7. [7] Ramalingam S, Basu K, Malkin S. Deformation index of MnS inclusions in resulphurized and leaded steels[J]. Material Science and Engineering, 1977,29(2):117−121. doi: 10.1016/0025-5416(77)90115-X [8] Zhang Yongjun, Zhu Chen, Wang Lifeng, et al. Role of tin for enhancing cutting characteristic of the free cutting steel[J]. Heat Treatment of Metals, 2006,31(1):27−29. (张永军, 朱辰, 王立峰, 等. 锡对提高材料切削性能作用的研究[J]. 金属热处理, 2006,31(1):27−29. doi: 10.3969/j.issn.0254-6051.2006.01.008 [9] Matsui N, Hasegawa T, Fujiwara J. Effect of sulfide inclusion morphology on machinability and tool wear mechanism in low carbon free cutting steel[J]. Journal of the Japan Society for Precision Engineering, 2011,77:322−326. [10] Li Hongsheng, Gao Hui. Form of manganese sulphide contained in steel and influences upon steel property[J]. CFHI Technology, 2004,(4):26−28. (李洪生, 高辉. 钢中硫化锰的形态及对钢性能的影响[J]. 一重技术, 2004,(4):26−28. doi: 10.3969/j.issn.1673-3355.2004.04.011 [11] Ding Yi, Qian Fa, Chen Gang. Failure analysis on fatigue of electric motor shaft[J]. Heat Treatment of Metals, 2001,(12):52−53. (丁毅, 钱发, 陈刚. 电机轴疲劳断裂失效分析[J]. 金属热处理, 2001,(12):52−53. [12] Zhang Shuo, Yang Shufeng, Li Jingshe, et al. Morphology of MnS inclusions in Y15 high sulfur free-cutting steel by tellurium treatment[J]. Iron and Steel, 2017,(9):28−33. (张硕, 杨树峰, 李京社, 等. 碲处理控制Y15易切削钢中MnS夹杂物形貌[J]. 钢铁, 2017,(9):28−33. [13] Katayama S. Effect of tool materials on surface machined roughness and cutting force of low-carbon resulfurized free-machining steels[J]. ISIJ International, 2007,30(4):331−337. [14] Lang Yuping, Chen Haitao, Weng Yuqing, et al. Applications of thermo-calc in research of high nitrogen austenitic stainless steels[J]. Journal of Materials Engineering, 2013,(5):16−22. (郎宇平, 陈海涛, 翁宇庆, 等. 热力学计算在高氮奥氏体不锈钢研究中的应用[J]. 材料工程, 2013,(5):16−22. doi: 10.3969/j.issn.1001-4381.2013.05.004 [15] Liu Feng, Wang Tianle. Precipitation modeling via the synergy of thermodynamics and kinetics[J]. Acta Metallurgica Sinica, 2021,57(1):55−70. (刘峰, 王天乐. 基于热力学和动力学协同的析出相模拟[J]. 金属学报, 2021,57(1):55−70. doi: 10.11900/0412.1961.2020.00413 [16] Bale C W, Belisle E, Chartrand P, et al. FactSage thermochemical software and databases[J]. Calphad, 2002,26(2):189−220. doi: 10.1016/S0364-5916(02)00035-4 [17] Deng Zhenqiang, Liu Jianhua, He Yang, et al. Phase transformations and precipitation behavior in FeCrAl stainless steel during equilibrium solidification[J]. Chinese Journal of Engineering, 2017,39(5):71−81. (邓振强, 刘建华, 何 杨, 等. FeCrAl不锈钢的平衡凝固相变与析出行为[J]. 工程科学学报, 2017,39(5):71−81. [18] 崔忠圻, 覃耀春. 金属学与热处理[M]. 北京: 机械工业出版社, 2007.Cui Zhongqi, Qin Yaochun. Metallographic and thermal treatment[M]. Beijing: China Machine Press, 2007. [19] Zhu Qiangbin, Li Jie, Deng Xiangyang, et al. Inclusion analysis in magnesium free-cutting steel[J]. Iron Steel Vanadium Titanium, 2021,42(2):179−192. (朱强斌, 李杰, 邓向阳, 等. 镁系易切削钢中夹杂物分析[J]. 钢铁钒钛, 2021,42(2):179−192. [20] Ito Y, Matsubara N, Matsubara K. Formation of manganese sulfide in steel[J]. Trans ISIJ, 1981,21(7):477−484. doi: 10.2355/isijinternational1966.21.477 [21] Ito Y, Yonezawa N, Matsubara K. Formation of manganese sulfide in low carbon steel[J]. Tetsu-to Hagane, 1982,68(10):1569−1577. doi: 10.2355/tetsutohagane1955.68.10_1569 [22] Liu H, Chen W. Effect of total oxygen content on the machinability of low carbon resulfurized free cutting steel[J]. Steel Research International, 2012,83(12):1172−1179. doi: 10.1002/srin.201200053 [23] Shao X, Wang X, Jiang M. Effect of heat treatment conditions on shape control of large-sized elongated MnS inclusions in resulfurized free-cutting steels[J]. ISIJ International, 2011,51(12):1995−2001. doi: 10.2355/isijinternational.51.1995 [24] 钟群鹏, 赵子华. 断口学[M]. 北京: 高等教育出版社, 2006: 1-10.Zhong Qunpeng, Zhao Zihua. Fractography[M]. Beijing: High Education Press, 2006: 1-10. [25] 陈南平, 顾守仁, 沈万慈. 脆断失效分析[M]. 北京: 机械工业出版社, 1993: 151-152.Chen Nanping, Gu Shouren, Shen Wanci. Brittle fracture failure analysis[M]. Beijing: China Machine Press, 1993: 151-152 -

下载:

下载: