Molecular dynamics simulation of tensile mechanical properties of AlxCoCrFeNi

-

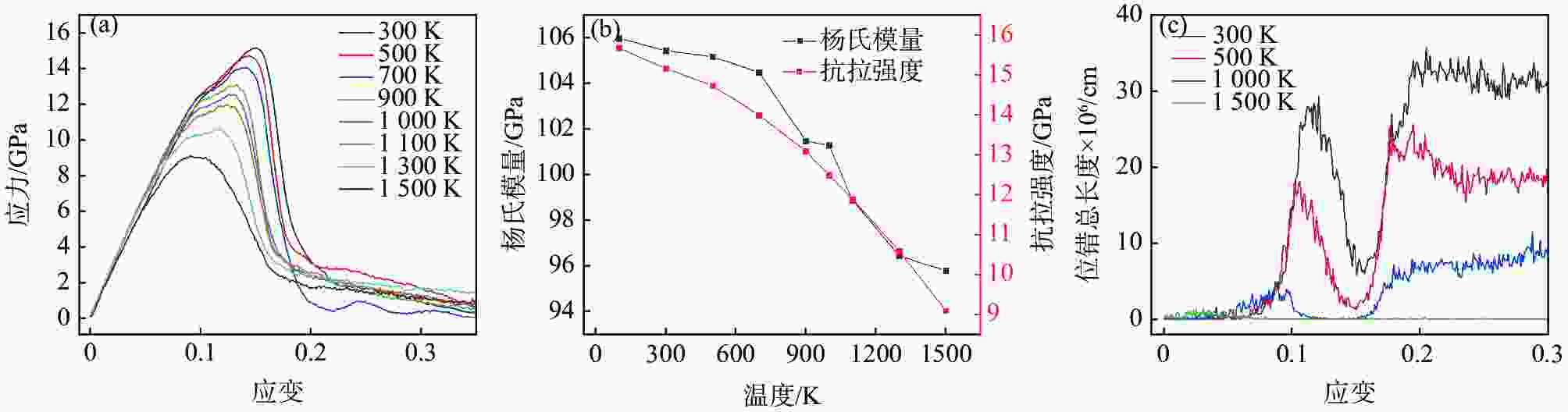

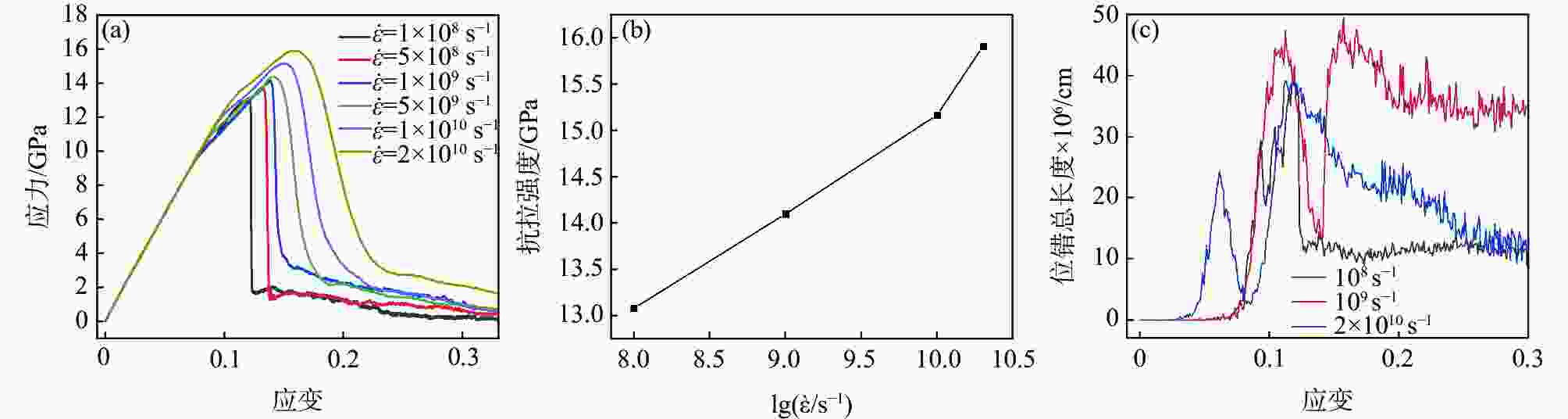

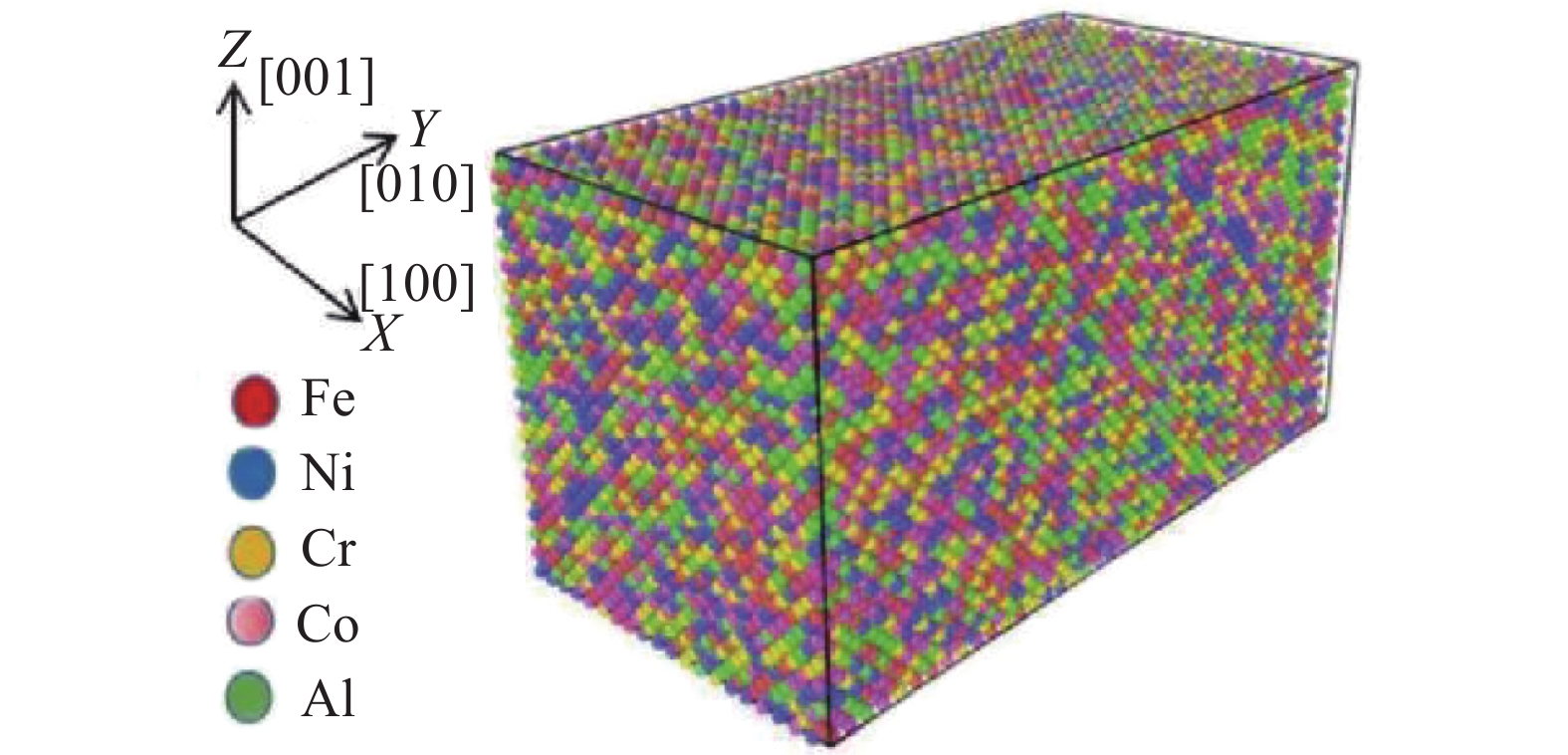

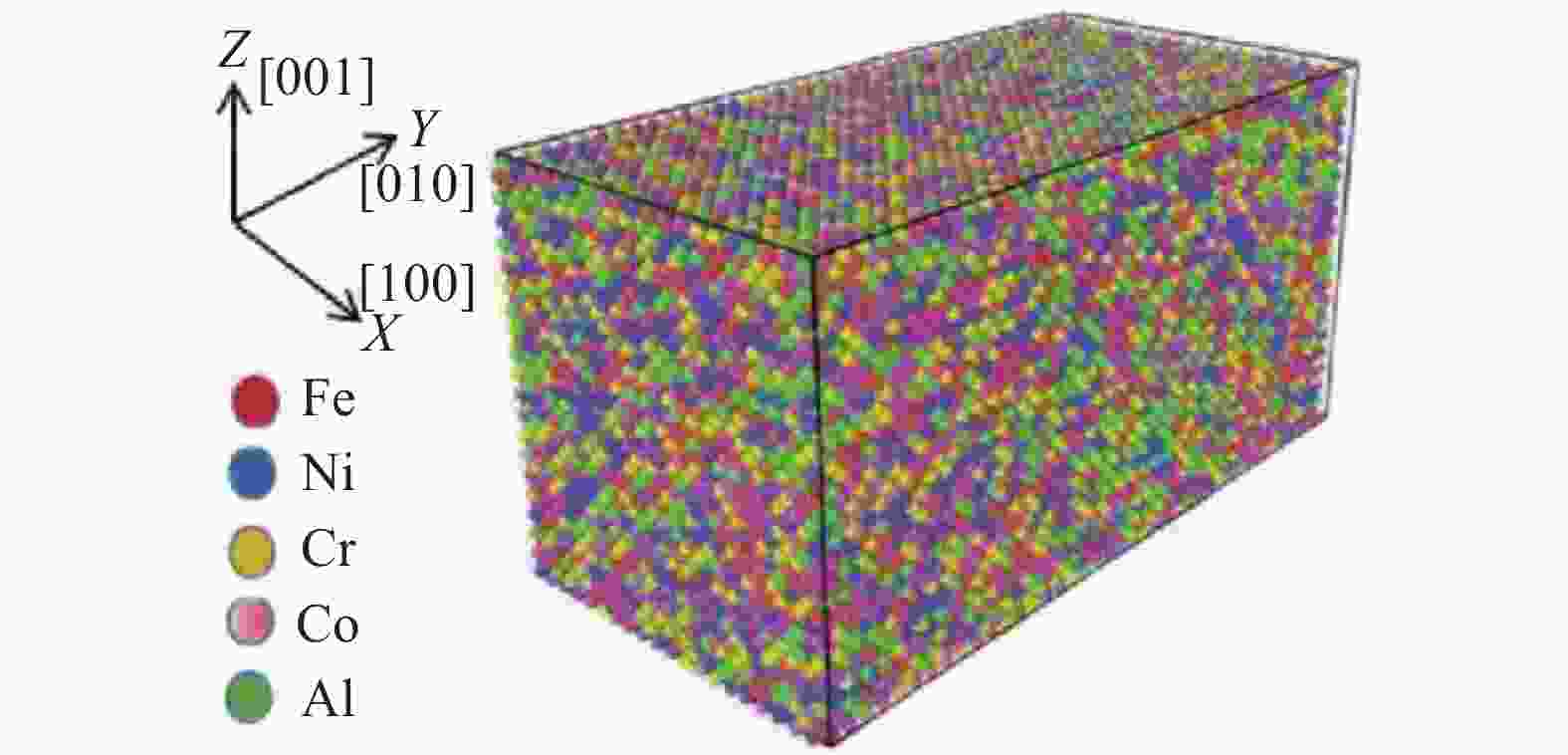

摘要: 采用分子动力学方法研究了AlxCoCrFeNi高熵合金(HEAs)在单轴拉伸下的微观组织演变、变形机制和力学性能,重点研究了Al摩尔比0.1至1.0时Al含量、高温和高应变速率对AlxCoCrFeNi力学性能的影响。研究表明:Al摩尔比0.1至1.0时,常温环境下(300 K)屈服应力及应变随Al含量及温度的上升呈下降趋势。Al含量的增加导致HEAs会在更小的应变处开始屈服,更早进入屈服阶段,从而使HEAs更容易变形,力学性能降低。在300~1500 K环境下随着温度的上升,位错逐渐减少,不同位错之间的相互作用减弱,无法形成固定位错阻碍材料运动,导致材料强度下降。AlxCoCrFeNi屈服应变、应力与应变速率变化呈正相关,且屈服应力对高应变速率敏感。Abstract: In this paper, the molecular dynamics method studied the microstructural evolution, deformation mechanism, and mechanical properties of AlxCoCrFeNi high entropy alloy (HEAs) under uniaxial tension. The effects of Al content, high temperature, and high strain rate on the mechanical properties of AlxCoCrFeNi at 0.1 to 1.0 molar ratio were investigated. The results show that when the molar ratio of Al is 0.1 to 1.0, the yield strain and stress at room temperature (300 K) decrease with the Al content and temperature increase. With the increase of Al content, HEAS will begin to yield at a minor strain and enter the yield stage earlier, which makes HEAS easier to deform and reduce the mechanical properties. At 300 − 1500 K, with the increase in temperature, the dislocations gradually decrease, the interaction between different dislocations is weakened, and the fixed dislocations cannot be formed, which hinders the movement of materials and leads to the decline of material strength. AlxCoCrFeNi yield strain and yield stress are positively correlated with the change of strain rate, and the yield stress is sensitive to high strain rate.

-

Key words:

- high entropy alloy /

- mechanical properties /

- molecular dynamics /

- uniaxial tension /

- temperature

-

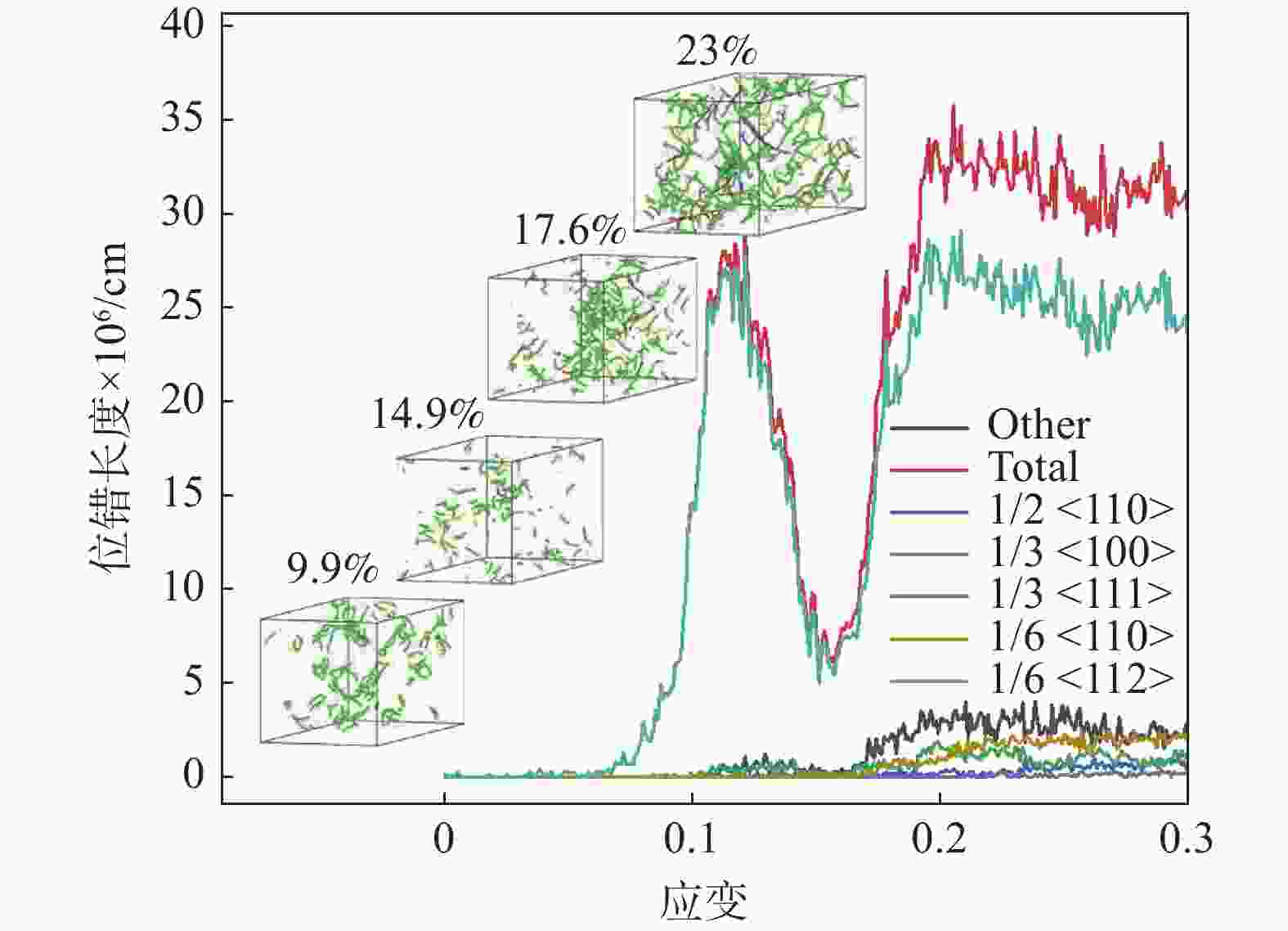

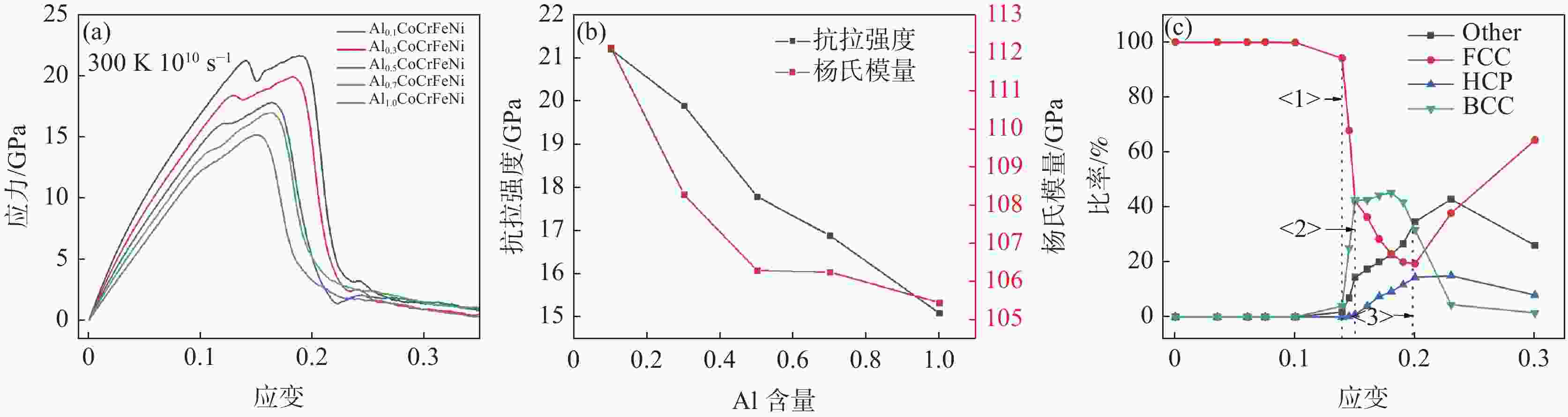

图 5 (a)AlxCoCrFeNi应力-应变曲线,(b)AlxCoCrFeNi屈服应力和杨氏模量曲线,(c)Al0.1CoCrFeNi中FCC,HCP,BCC以及Other原子数目随应变的变化

Figure 5. (a) The stress-strain curve of AlxCoCrFeNi HEAs, (b) The Young’s Modulus and yield stress of AlxCoCrFeNi HEAs as a function of Al concentration, (c) variation of the numbers of FCC, HCP, BCC and Other atom clusters with strain of Al0.1CoCrFeNi

表 1 HEAs应变速率及弛豫时间

Table 1. tensile strain rate and relaxation time of HEAs

拉伸应变速率/s−1 弛豫时间/ps 108 5000 5×108 2500 109 500 5×109 250 1010 50 2×1010 25 -

[1] Yeh J W, Chen S K, Lin S J, et al. Nanostructured high‐entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes[J]. Advanced Engineering Materials, 2004,6(5):299−303. doi: 10.1002/adem.200300567 [2] Zou Y, Maiti S, Steurer W, et al. Size-dependent plasticity in an Nb25Mo25Ta25W25 refractory high-entropy alloy[J]. Acta Materialia, 2014,65:85−97. doi: 10.1016/j.actamat.2013.11.049 [3] Yang C C, Chau J, Weng C J, et al. Preparation of high-entropy AlCoCrCuFeNiSi alloy powders by gas atomization process[J]. Materials Chemistry and Physics, 2017,202:151−158. doi: 10.1016/j.matchemphys.2017.09.014 [4] Yao M J, Pradeep K G, Tasan C C, et al. A novel, single phase, non-equiatomic FeMnNiCoCr high-entropy alloy with exceptional phase stability and tensile ductility[J]. Scripta Materialia, 2014,72-73:5−8. doi: 10.1016/j.scriptamat.2013.09.030 [5] Zhang L, Yu P, Cheng H, et al. Nanoindentation creep behavior of an Al0.3CoCrFeNi high-entropy alloy[J]. Metallurgical and Materials Transactions A, 2016,47(12):5871−5875. doi: 10.1007/s11661-016-3469-8 [6] Zhao Chendong, Li Jinshan, Liu Y, et al. Optimizing mechanical and magnetic properties of AlCoCrFeNi high-entropy alloy via FCC to BCC phase transformation[J]. Journal of Materials Science & Technology, 2021,73:83−90. [7] Jia Li, Fang Qihong, Liu Bin, et al. Mechanical behaviors of AlCrFeCuNi high-entropy alloys under uniaxial tension via molecular dynamics simulation[J]. RSC Advances, 2016,6(80):76409−76419. doi: 10.1039/C6RA16503F [8] Zhang Luming, Ma Shengguo, Li Zhiqiang, et al. Molecular dynamics simulation of mechanical properties of AlxCoCrFeNi high entropy alloy[J]. Journal of High Pressure Physics, 2021,35(5):22−30. (张路明, 马胜国, 李志强, 等. AlxCoCrFeNi高熵合金力学性能的分子动力学模拟[J]. 高压物理学报, 2021,35(5):22−30. [9] Afkham Y, Bahramyan M R. Tensile properties of AlCrCoFeCuNi glassy alloys: A molecular dynamics simulation study[J]. Materials Science & Engineering A, 2017,698:143−151. [10] Li Jia, Chen Haotian, Li Sixu, et al. Tuning the mechanical behavior of high-entropy alloys via controlling cooling rates[J]. Materials Science & Engineering A, 2019,760:359−365. [11] Kawamura M, Asakura M, Okamoto N L, et al. Plastic deformation of single crystals of the equiatomic CrMnFeCoNi high-entropy alloy in tension and compression from 10 K to 1273 K[J]. Acta Materialia, 2021,203(supplement):116454. [12] Zhu J M, Zhang H F, Fu H M, et al. Microstructures and compressive properties of multicomponent AlCoCrCuFeNiMox alloys[J]. Journal of Alloys and Compounds, 2010,497:1−2. doi: 10.1016/j.jallcom.2010.02.156 [13] Sharma A, Balasubramanian G. Dislocation dynamics in Al0.1CoCrFeNi high-entropy alloy under tensile loading[J]. Intermetallics, 2017,91:31−34. doi: 10.1016/j.intermet.2017.08.004 [14] Liu Y X, Cheng C Q, Shang J L, et al. Qxidation behavior of high-entropy alloys AlxCoCrFeNi (x=0.15, 0.4) in supercritical water and comparison with HR3C steel[J]. Transactions of Nonferrous Metals Society of China, 2015,25(4):1341−1351. doi: 10.1016/S1003-6326(15)63733-5 [15] Gawel Richard, Rogal Łukasz, Dąbek Jarosław, et al. High temperature oxidation behaviour of non-equimolar AlCoCrFeNi high entropy alloys[J]. Vacuum, 2021,184:109969. doi: 10.1016/j.vacuum.2020.109969 [16] Kemény Dávid Miklós, Miskolcziné Pálfi Nikolett, Fazakas Éva. Examination of microstructure and corrosion properties of novel AlCoCrFeNi multicomponent alloy[J]. Materials Today:Proceedingsy, 2021,45(6):4250−4253. [17] Wang C T, He Y, Guo Z, et al. Strain rate effects on the mechanical properties of an AlCoCrFeNi high-entropy alloy[J]. Metals and Materials International, 2021,27:2310−2318. doi: 10.1007/s12540-020-00920-5 [18] ZhangY, Yang X, Liaw P K. Alloy design and properties optimization of high-entropy alloys[J]. JOM:The Journal of the Minerals, Metals & Materials Society, 2012,64(7):830−838. [19] Steve Plimpton. Fast parallel algorithms for short-range molecular dynamics[J]. Journal of Computational Physics, 1995,117(1):1−19. doi: 10.1006/jcph.1995.1039 [20] Antonaglia J, Xie X, Tang Z, et al. Temperature effects on deformation and serration behavior of high-entropy alloys (HEAs)[J]. JOM, 2014,66(10):2002−2008. doi: 10.1007/s11837-014-1130-9 [21] Zhang Ping, Li Yuantian, Zhang Jinyong, et al. Effect of Si addition on hot corrosion behavior of AlCoCrFeNi high entropy alloys[J]. Rare Metal Materials and Engineering, 2021,50(10):3640−3647. (张平, 李远田, 张金勇, 等. Si对AlCoCrFeNi高熵合金热腐蚀行为的影响[J]. 稀有金属材料与工程, 2021,50(10):3640−3647. [22] Jiang J, Chen P, Qiu J, et al. Microstructural evolution and mechanical properties of AlxCoCrFeNi high-entropy alloys under uniaxial tension: A molecular dynamics simulations study[J]. Materials Today Communications, 2021,28:102525. doi: 10.1016/j.mtcomm.2021.102525 [23] Farkas D, Caro A. Model interatomic potentials and lattice strain in a high-entropy alloy[J]. Journal of Materials Research, 2018,33(19):3218−3225. doi: 10.1557/jmr.2018.245 [24] Koh S J A, Lee H P, Lu C, et al. Molecular dynamics simulation of a solid platinum nanowire under uniaxial tensile strain: Temperature and strain-rate effects[J]. Physical Review B, 2005,72(8):85414. doi: 10.1103/PhysRevB.72.085414 -

下载:

下载: