Research on effects of multi-pass rolling and heat treatment of cast Mn18Cr18N steel

-

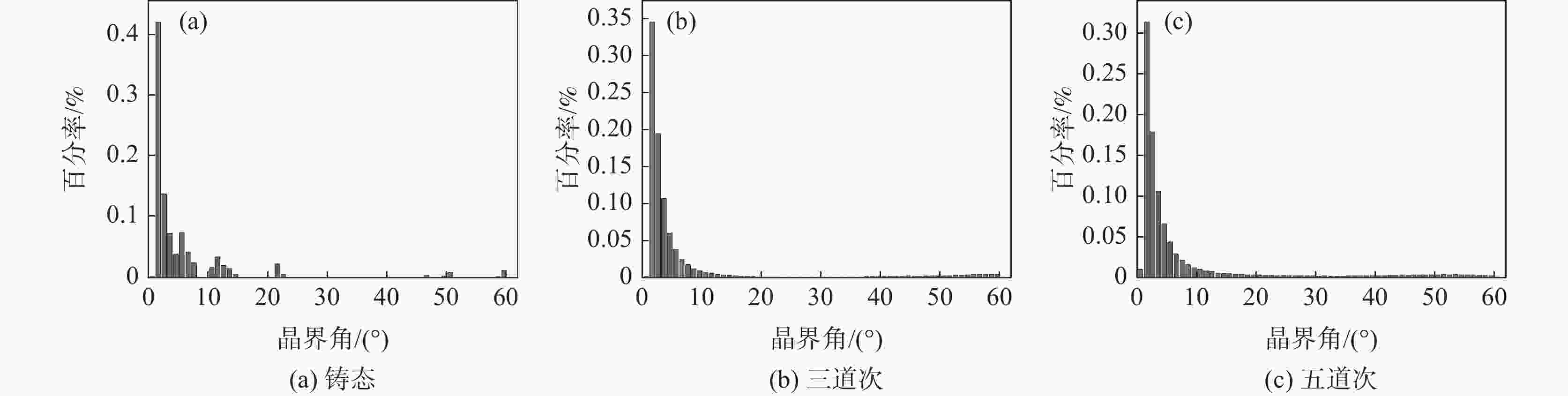

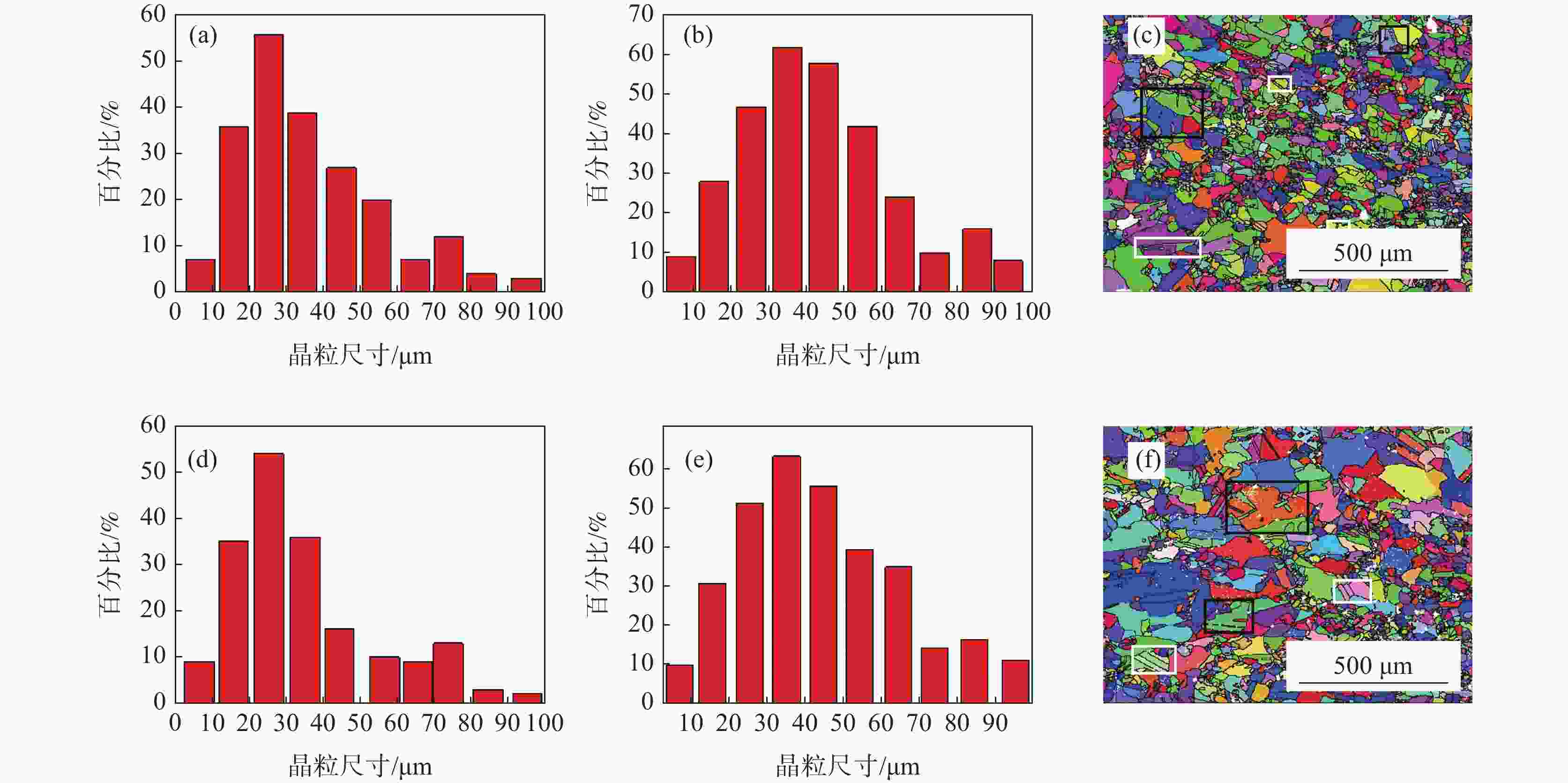

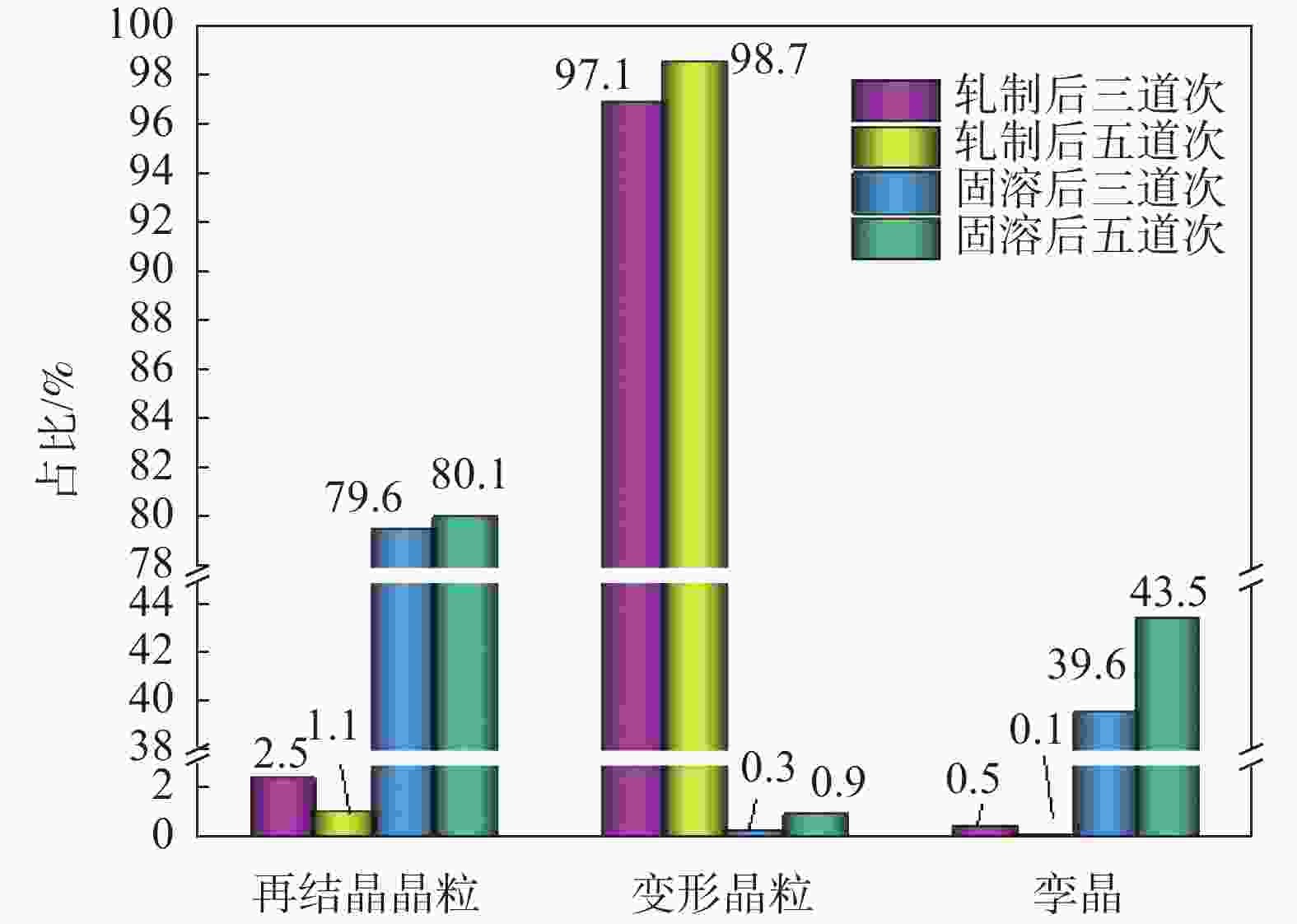

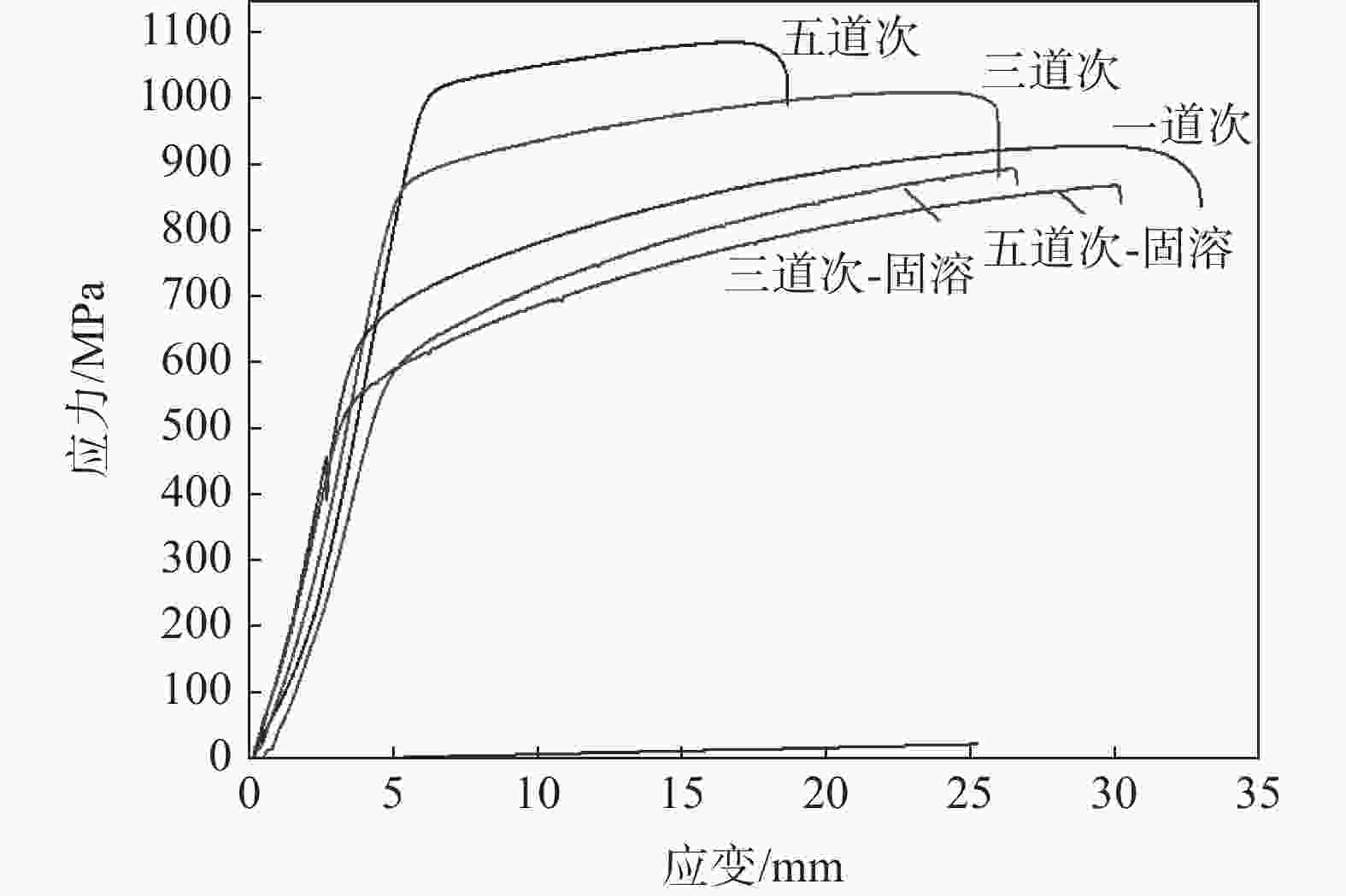

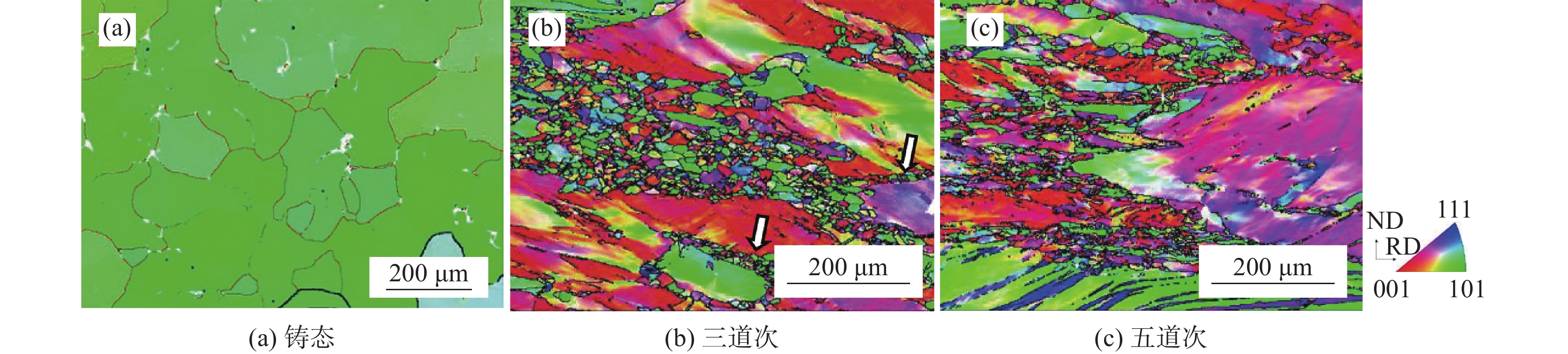

摘要: 对Mn18Cr18N电渣重熔钢进行三道次和五道次的轧制及固溶处理。借助电子背散射仪(EBSD)观察微观组织,发现随着轧制道次的增加,再结晶晶粒沿着晶界生长,呈现项链状分布,大角度晶界向小角度晶界逐渐迁移后趋于稳定,并出现大量剪切变形带,结果表明,较大的单道次压下量或较高的终轧温度有利于轧制后的Mn18Cr18N铸态奥氏体不锈钢再结晶。固溶处理后,发现晶粒细化并长大,退火孪晶增多,组织主要发生静态再结晶。对Mn18Cr18N钢进行力学性能测试,发现随着轧制道次的增加,抗拉强度由950 MPa增加至1 090 MPa,屈服强度增加,断后伸长率由43.46%降至29.55%,塑性降低;相应试样固溶处理后,抗拉强度由904 MPa降至870 MPa,屈服强度降低,断后伸长率由42%升高到48%,塑性提高,结果表明固溶处理改善了材料的组织和性能。

-

关键词:

- Mn18Cr18N钢 /

- 轧制道次 /

- 固溶处理 /

- 微观组织 /

- 力学性能

Abstract: Mn18Cr18N electro-slag remelting steel was rolled in three or five passes and subject to solid solution treatment. The microstructure observation by electron back scattering diffraction (EBSD) indicates that with the increase of rolling passes, the recrystallized grains grow along the grain boundaries and distributes into a chain structure, and the high angle grain boundaries gradually migrate to the small angle grain boundaries and then stabilize. A large number of shear deformation bands appear. A larger single pass deformation or a higher final rolling temperature is beneficial to the recrystallization of Mn18Cr18N as-cast austenitic stainless steel after rolling. After solid solution treatment,the grain becomes fine due to increasing annealing twin grain and static recrystallization. With the increase of rolling passes, the tensile strength is increased from 950 MPa to 1090 MPa, and elongation after fracture decreases from 43.46% to 29.55%. After the solid solution treatment, the tensile strength decreases from 904 MPa for 3-passes to 870 MPa for 5-passes, with the strength decreasing; and the elongation after fracture increases from 42% to 48% accordingly. The results showes that the solid solution treatment can improve the microstructure and properties of the material.-

Key words:

- Mn18Cr18N steel /

- rolling passes /

- solution treatment /

- microstructure /

- mechanical properties

-

表 1 Mn18Cr18N 钢的化学成分

Table 1. Chemical composition of Mn18Cr18N steel

% Mn Si Ni Cr Mo Al N Ti Fe 19.3 0.6 0.2 20.1 0.02 0.03 0.6 0.016 其他 表 2 Mn18Cr18N 钢在不同状态下的抗拉强度、屈服强度和断后伸长率

Table 2. Tensile strength, yield strength and total elongation of Mn18Cr18N steel obtained under different states

轧制后 固溶后 抗拉强度/

MPa屈服强度/

MPa断后伸长率/% 抗拉强度

/MPa屈服强度

/MPa断后伸长率

/%三道次 950 864 43.46 904 579 42 五道次 1090 1015 29.55 870 533 48 -

[1] Sun Hongying, Sun Yongduo, Zhang Ruiqian, et al. Hot deformation behavior and microstructural evolution of a modified 310 austenitic steel[J]. Materials and Design, 2014,64:374−380. doi: 10.1016/j.matdes.2014.08.001 [2] Jiang Yi, Cheng Manlang, Jiang Haihong, et al. Microstructure and properties of 08Cr19Mn6Ni3Cu2N (QN1803) high strength nitrogen alloyed low nickel austenitic stainless steel[J]. Acta Metallurgica Sinica, 2020,56(4):264−274. (蒋一, 程满浪, 姜海洪, 等. 高强度含Ni奥氏体不锈钢08Cr19Mn6Ni3Cu2N (QN1803)的显微组织及性能[J]. 金属学报, 2020,56(4):264−274. [3] Zhang Yunfei, Zhao Yingli, Chang Jinbao, et al. Research on hot deformation behavior of low-nickel high nitrogen austenitic stainless steel[J]. Shanghai Metals, 2018,40(6):19−23. (张雲飞, 赵英利, 常金宝, 等. 节镍型高氮奥氏体不锈钢热变形行为的研究[J]. 上海金属, 2018,40(6):19−23. doi: 10.3969/j.issn.1001-7208.2018.06.004 [4] Pei Haixiang, Zeng Li, Wang Lixin, et al. Hot deformation behavior and structure evolution of high nitrogen ultra-low-carbon austenite stainless steel 316LN[J]. Special Steel, 2014,35(6):54−56. (裴海祥, 曾莉, 王立新, 等. 316LN高氮超低碳奥氏体不锈钢的热变形行为和组织演变[J]. 特殊钢, 2014,35(6):54−56. doi: 10.3969/j.issn.1003-8620.2014.06.016 [5] Li Jianxin, Zhao Yingli, Wang Guoying, et al. Effect of cold rolling deformation on structure and property of high nitrogen austenitic stainless steel Mn17Cr19N0.6[J]. Special Steel, 2020,41(1):61−63. (李建新, 赵英利, 王国营, 等. 冷轧变形量对高氮奥氏体不锈钢Mn17Cr19N0.6组织和性能的影响[J]. 特殊钢, 2020,41(1):61−63. doi: 10.3969/j.issn.1003-8620.2020.01.016 [6] 王岩. δ相对GH4169合金高温变形及再结晶行为的影响[D]. 哈尔滨: 哈尔滨工业大学, 2008.Wang Yan. Effect of delta phase on hot deformation and recrystallization behavior of alloy GH4169[D]. Harbin: Harbin Institute of Technology, 2008. [7] Hayes J S ,Kyte R, Prangnell P B. Effect of grain size on the tensile behavior of a submicron grained Al-3%Mg alloy produced by severe deformation[J]. Materials Science and Technology, 2000,16(11):1259−1263. [8] Yang Gang, Sun Lijun, Zhang Lina, et al. Annihilation of defor mation twins and for mation of annealing twins[J]. Journal of Iron and Steel Research, 2009,21(2):39−43. (杨钢, 孙利军, 张丽娜, 等. 形变孪晶的消失与退火孪晶的形成机制[J]. 钢铁研究学报, 2009,21(2):39−43. doi: 10.13228/j.boyuan.issn1001-0963.2009.02.002 [9] Gao Yubi, Ding Yutian, Chen Jianjun, et al. Behavior of cold work hardening and annealing softening and microstructure characteristics of GH3625 superalloy[J]. The Chinese Journal of Nonferrous Metals, 2019,29(1):44−53. (高钰璧, 丁雨田, 陈建军, 等. GH3625合金冷变形硬化、退火软化行为及其组织特征[J]. 中国有色金属学报, 2019,29(1):44−53. doi: 10.19476/j.ysxb.1004.0609.2019.01.06 [10] Li Juan, Zhao Guanghui, Ma Lifeng, et al. Hot deformation behavior and microstructural evolution of as-cast 304L antibacterial austenitic stainless steel[J]. Materials Research Express, 2018,5(2):1847−1853. [11] Chen Xiaoqiu, Pang Wuji, Shang Feng, et al. Effects of solution treatment on microstructure and properties of SAF 2507 duplex stainless steel prepared by powder injection molding[J]. Hot Working Technology, 2019,48(6):203−206. (陈晓秋, 庞午骥, 尚峰, 等. 固溶处理对粉末注射成形SAF 2507双相不锈钢组织和性能的影响[J]. 热加工工艺, 2019,48(6):203−206. -

下载:

下载: