Experimental study on multistage continuous countercurrent decantation for vanadium containing leaching ore pulp

-

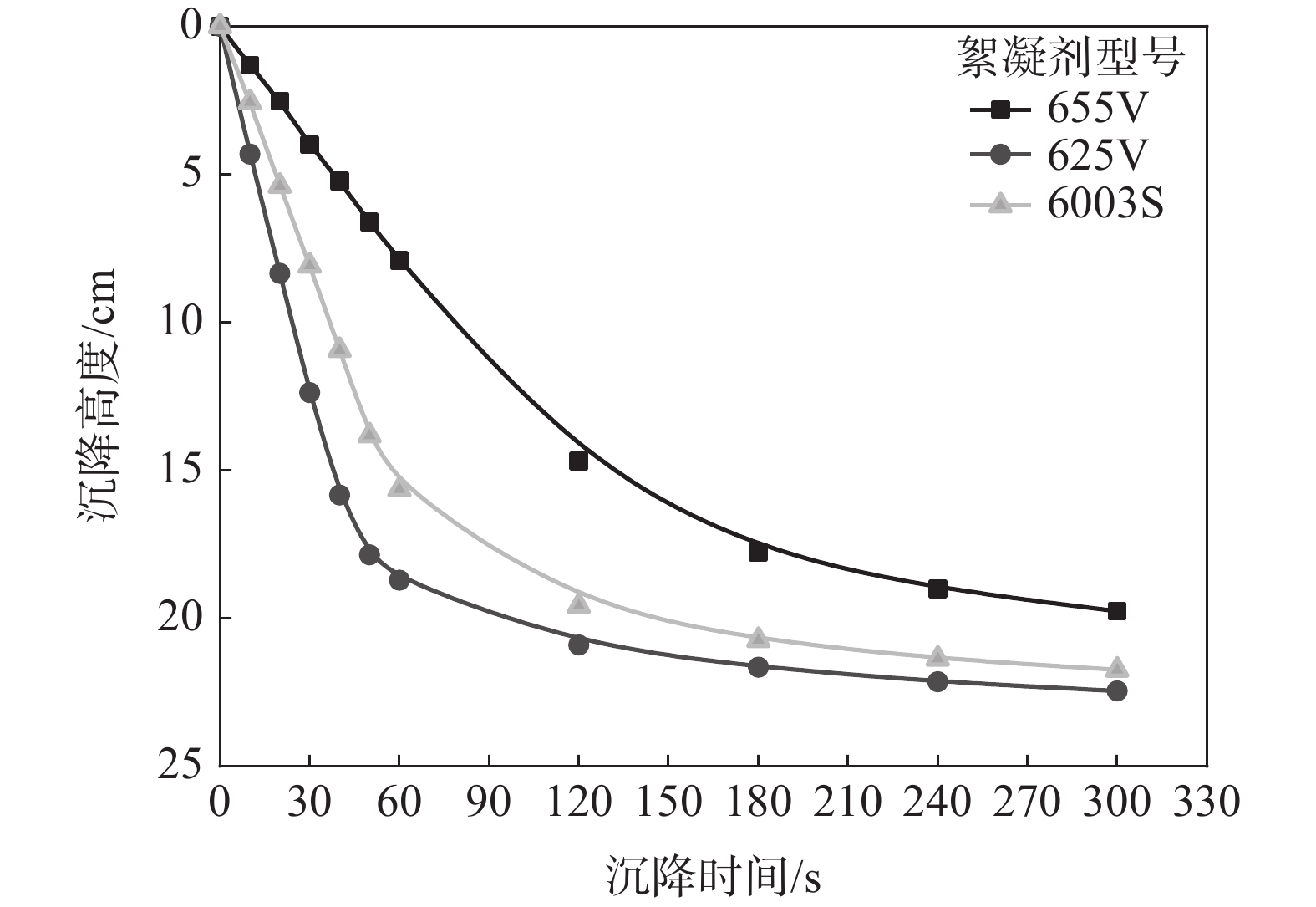

摘要: 含钒钢渣浸出矿浆絮凝浓缩提高浓度,然后采用多级连续逆流洗涤工艺将高浓度矿浆液相内的钒离子洗脱至洗液用于后续回收。通过絮凝沉降试验对洗涤工艺中的沉降参数进行研究,确定了钒渣浸出矿浆适用的絮凝剂为APAM-625V,用量40 g/t,最佳初始矿浆浓度10%,各级洗涤矿浆底流浓度62%。利用洗涤各级的物料平衡原理,列出钒离子在各级溶液组分的“一次多元联立方程组”,计算出在洗涤液固比为1,洗涤级数5的条件下,钒离子的理论洗涤效率为97%。以计算出的洗涤工艺参数进行多级连续逆流洗涤试验验证,钒离子的洗涤效率为96.4%,与理论计算结果基本一致。Abstract: After acid leaching of vanadium-bearing steel slag, the slurry is flocculated and concentrated to produce high-concentration leached slag. For subsequent recovery of vanadium ions, the multistage continuous countercurrent decantation is used to wash the leached residue. Through the flocculation sedimentation experiment, it is determined that the suitable flocculant for this pulp is APAM-625V, the dosage is 40 g/t, the optimal initial feed concentration is 10%, and the pulp underflow concentration after washing at each levels is 62%. Based on the principle of material balance of each washing stage in the washing process, the “first-order multivariate simultaneous equations” of the solution components of the vanadium slag leaching pulp in the washing process were calculated. The results of theoretical calculation show that the washing efficiency of vanadium ion is 97% under the condition of washing liquid-solid ratio of 1 and washing order of 5. The vanadium ion washing efficiency is 96.4% in the continuous countercurrent decantation experimentation research, which is basically consistent with the theoretical calculation results.

-

表 1 浓密底流压缩浓度试验结果

Table 1. Test results of dense underflow compression concentration

压缩时间/min 底流浓度/ % 40 58.70 60 60.25 195 64.40 300 65.00 315 65.26 表 2 CCD逆流洗涤理论计算结果

Table 2. Theoretical calculation results of CCD countercurrent washing

固体量/t 液体量/t 矿浆总量/t 固体浓度/% 钒金属浓度/(g·L−1) 浸出矿浆浓密 进料 25 75 100 25 2.06 溢流 0 60 60 0 2.06 底流 25 15 40 62 2.06 CCD1 进料 25 40 65 38 2.06 溢流 0 25 25 0 1.059 底流 25 15 40 62 1.059 CCD2 进料 25 40 65 0 1.059 溢流 0 25 25 0 0.606 底流 25 15 40 62 0.606 CCD3 进料 25 40 65 38 0.606 溢流 0 25 25 0 0.332 底流 25 15 40 62 0.332 CCD4 进料 25 40 65 38 0.332 溢流 0 25 25 0 0.163 底流 25 15 40 62 0.163 CCD5 进料 25 40 65 38 0.163 溢流 0 25 25 0 0.062 底流 25 15 40 62 0.062 洗涤清水 0 25 25 0 0 表 3 CCD逆流洗涤各级底流浓度

Table 3. CCD countercurrent washing underflow concentration at all levels

洗涤级别 底流浓度/% CCD1 61.3 CCD2 61.2 CCD3 60.5 CCD4 61.4 CCD5 61.2 -

[1] Monakhov I N, Khromov S V, Chernousov P I, et al. The flow of vanadium-bearing materials in industry[J]. Metallurgist, 2004,48(7-8):381−385. [2] Zhou Xinglong. Methods for settlement experiment of slurry in the measuring cylinder[J]. Nonferrous Metals(Mineral Processing Section), 2005,(5):30−32. (周兴龙. 量筒内进行矿浆沉降试验的方法[J]. 有色金属(选矿部分), 2005,(5):30−32. [3] Jiang Zuzhao. Application and comparison of several computational countercurrent decantation washing methods[J]. Nonferrous Metals(Extractive Metallurgy), 1978,(3):53−56. (蒋祖昭. 几种计算逆流倾析洗涤方法的应用和比较[J]. 有色金属(冶炼部分), 1978,(3):53−56. [4] Yin Shuyan, Lu Yeda. Equipment selection and calculation of CCD circuit[J]. Equipment and Automation, 2010,(5):37−40. (殷书岩, 陆业大. CCD逆流洗涤设备选型及计算方法[J]. 设备及自动化, 2010,(5):37−40. [5] Xiang Yun. Calculation of multi-effect countercurrent washing for thickener[J]. Nonferrous Metals(Extractive Metallurgy), 1973,(1):62−66. (翔云. 浓密机多效逆流洗涤的计算[J]. 有色金属(冶炼部分), 1973,(1):62−66. [6] Huang Liwei. Calculation method for multi-stage continuous countercurrent washing of leached pulp[J]. Mining&Metallurgy, 2009,(18):50−53. (黄利伟. 浸出矿浆多级连续逆流洗涤的计算方法[J]. 矿冶, 2009,(18):50−53. -

下载:

下载: