Y2O3 dispersion strengthened TC4 powder and its laser cladding microstructure

-

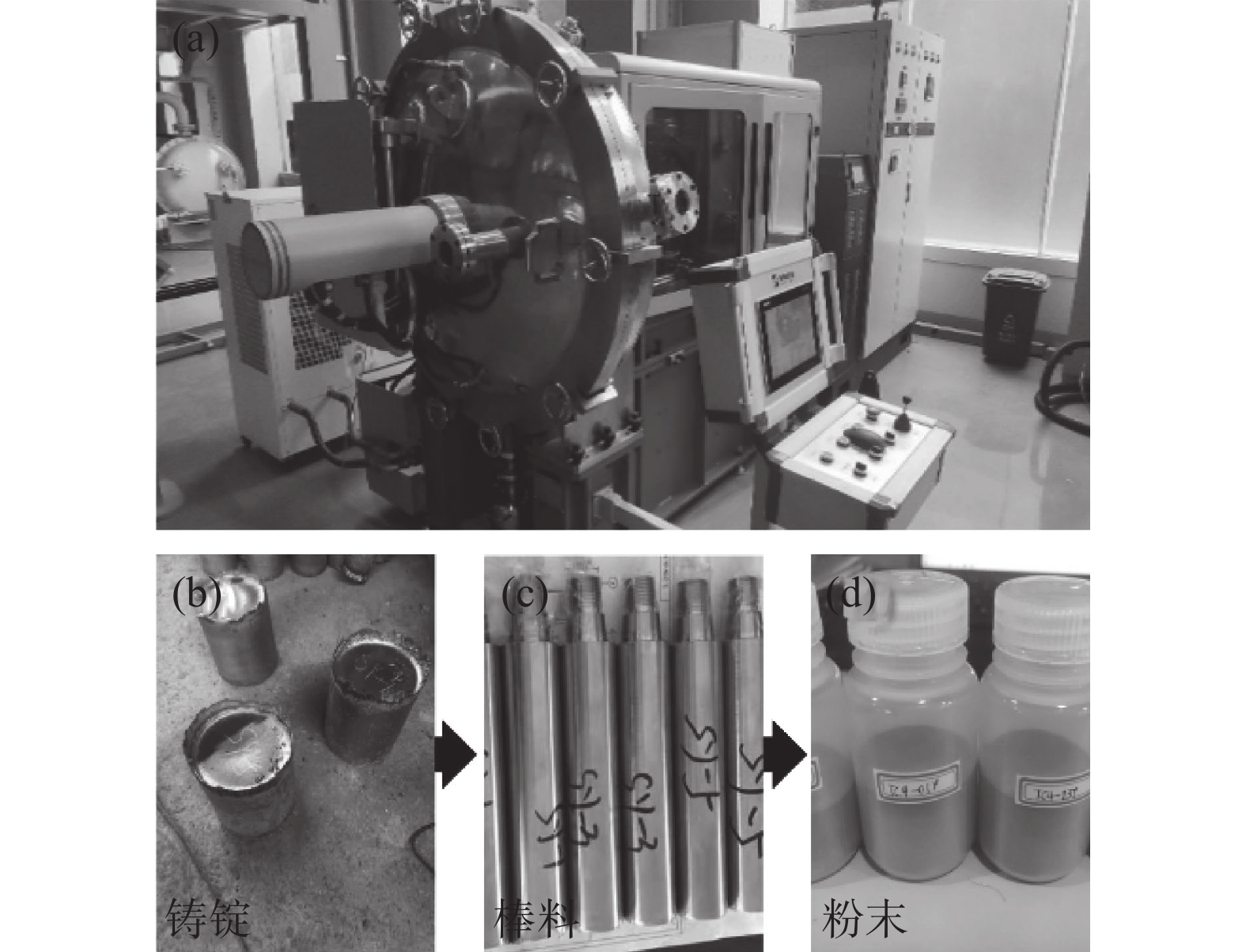

摘要: 激光熔覆修复技术可用于修复损伤的钛合金工件。与锻造件相比,熔覆件在激光熔覆过程中容易引入氧,导致氧含量偏高和强度偏低的问题。采用等离子旋转电极法(PREP)制备了TC4-xY(x = 0,0.1,0.3,0.5)的预合金粉末,并使用该合金粉末通过激光熔覆工艺技术方法修复TC4合金工件。结果表明,在钇(Y)引入后产生的弥散体Y2O3均匀分布在粉末上,随着Y含量的增加,粉末的显微维氏硬度增加。在TC4-xY熔覆层中,其显微维氏硬度随着Y含量的增加而增加。然而,由于脆性相析出的影响,熔覆层的拉伸性能呈现先上升后下降的趋势,其伸长率呈现相反的趋势,TC4-0.3Y熔覆层的1058 MPa拉伸性能最优异,同时伸长率也达到7.2%。通过对Y含量的调控,能够促进熔覆层组织改善与力学性能提升。Abstract: Laser cladding repairing technology can be used to repair damaged TC4 alloy components. Compared with forged components, oxygen is more easily introduced during laser cladding, which results that cladding components have the problems of high oxygen content and low strength. In this study, TC4-xY (x = 0, 0.1, 0.3, 0.5) prealloyed powder was prepared by plasma rotating electrode process (PREP), then TC4 alloy components were laser cladding repaired with the powder. The results indicate that the introduction of yttrium (Y) induces Y2O3 dispersion evenly distributed on the powder, as the Y content increases, Micro Vickers hardness of the powder rises. In the TC4-xY cladding layers, the Micro Vickers hardness rises with the increase of Y content. However, because of the excessive precipitation of brittle phase, the tensile property of the cladding layers shows a trend from rise to decline, then the elongation just shows the reverse trend. The 1058 MPa tensile property of the TC4-0.3Y cladding layer is the most excellent, then its 7.2% elongation is the worst. The regulation of Y content is conducive to improving the tensile strength of the cladding layer.

-

表 1 TC4-0.5Y粉末表面分散相和基体EDS点分析元素含量

Table 1. Elements content of dispersion and matrix EDS point analysis on TC4-0.5Y powder

元素 y/% 弥散相 基体 Al 8.32 9.70 Ti 69.43 82.23 V 2.60 3.60 O 18.18 4.25 Y 1.47 0.22 总量 100.00 100.00 -

[1] Li Yong, Wang Qiulin, Zhou Qing, et al. Research status and prospect of laser cladding technology on titanium alloy surfaces[J]. Journal of Chengdu Aviation Vocational and Technical College, 2021,37(2):63−65,88. (李勇, 王秋林, 周青, 等. 钛合金表面激光熔覆技术研究现状与展望[J]. 成都航空职业技术学院学报, 2021,37(2):63−65,88. doi: 10.3969/j.issn.1671-4024.2021.02.020 [2] Xie Faqin, He Peng, Wu Xiangqing, et al. Research and prospect of laser cladding technology for titanium alloy surfaces[J]. Rare Metal Materials and Engineering, 2022,51(4):1514−1524. (谢发勤, 何鹏, 吴向清, 等. 钛合金表面激光熔覆技术的研究及展望[J]. 稀有金属材料与工程, 2022,51(4):1514−1524. [3] Zhang Leitao, Liu Dexin, Zhang Weiqiang, et al. Research progress of laser cladding coatings on titanium alloy surfaces[J]. Surface Technology, 2020,49(8):97−104. (张蕾涛, 刘德鑫, 张伟樯, 等. 钛合金表面激光熔覆涂层的研究进展[J]. 表面技术, 2020,49(8):97−104. doi: 10.16490/j.cnki.issn.1001-3660.2020.08.011 [4] 张德强, 刘贤德, 张文博, 等. TC4钛合金激光熔覆实验研究[J/OL]. 热加工工艺, 1-4[2022-12-06].Zhang Deqiang, Liu Xiande, Zhang Wenbo, et al. Experimental study on TC4 titanium alloy laser cladding[J/OL]. Hot Working Technology, 1-4[2022-12-06]. [5] Ju J, Zhao C L, Kang M D, et al. Effect of heat treatment on microstructure and tribological behavior of Ti-6Al-4V alloys fabricated by selective laser melting[J]. Tribol Int, 2021,159:106996. doi: 10.1016/j.triboint.2021.106996 [6] Zhao Z, Chen J, Tan H, et al. Microstructure and mechanical properties of laser repaired TC4 titanium alloy[J]. Rare Metal Mat Eng, 2017,46(7):1792−1797. doi: 10.1016/S1875-5372(17)30168-6 [7] Quazi M M, Fazal M A, Haseeb A S M A, et al. Effect of rare earth elements and their oxides on tribo-mechanical performance of laser claddings: A review[J]. J Rare Earth, 2016,34(6):549−564. doi: 10.1016/S1002-0721(16)60061-3 [8] Pilchak A L, Williams J C. Effect of yttrium on the fatigue behavior of investment-cast and wrought Ti-6Al-4V[J]. Metall Mater Trans A, 2009,40a(11):2603−2615. [9] Kim D K, Kim Y I, Kim Y D, et al. Comparative study for microstructural characterisations and properties of Ti-Y powders produced by vacuum induction gas atomization cold crucible process[J]. Powder Metall, 2021,64(5):396−403. doi: 10.1080/00325899.2021.1921962 [10] Weng W J, Biesiekierski A, Lin J X, et al. Impact of the rare earth elements scandium and yttrium on beta-type Ti-24Nb-38Zr-2Mo-base alloys for orthopedic applications[J]. Materialia, 2020,9:100586−100597. doi: 10.1016/j.mtla.2020.100586 [11] Yang Y F, Luo S D, Schaffer G B, et al. Impurity scavenging, microstructural refinement and mechanical properties of powder metallurgy titanium and titanium alloys by a small addition of cerium silicide[J]. Mat Sci Eng a-Struct, 2013,573:166−174. doi: 10.1016/j.msea.2013.02.042 [12] Li A, Ma S, Yang Y J, et al. Microstructure and mechanical properties of Y2O3 reinforced Ti6Al4V composites fabricated by spark plasma sintering[J]. J Alloy Compd, 2018,768:49−56. doi: 10.1016/j.jallcom.2018.07.229 [13] Zhang D Y, Qiu D, Gibson M A, et al. Refining prior-I3 grains of Ti-6Al-4V alloy through yttrium addition[J]. J Alloy Compd, 2020,841:155733−155740. doi: 10.1016/j.jallcom.2020.155733 [14] He W W, Liu Y, Tang H P, et al. Microstructural characteristics and densification behavior of high-Nb TiAl powder produced by plasma rotating electrode process[J]. Mater Design, 2017,132:275−282. doi: 10.1016/j.matdes.2017.06.072 [15] Yamanoglu R, German R M, Karagoz S, et al. Microstructural investigation of as cast and PREP atomised Ti-6Al-4V alloy[J]. Powder Metall, 2011,54(5):604−607. doi: 10.1179/1743290110Y.0000000006 [16] Yin J O, Chen G, Zhao S Y, et al. Microstructural characterization and properties of Ti-28Ta at. % powders produced by plasma rotating electrode process[J]. J Alloy Compd, 2017,713:222−228. doi: 10.1016/j.jallcom.2017.04.195 [17] Gao Z N, Bu H C, Feng Y, et al. Strengthening mechanism of Y2O3 nanoparticles on microstructure and mechanical properties of the laser additive manufacturing joint for large thickness TC4 titanium alloy[J]. J Manuf Process, 2021,71:37−55. doi: 10.1016/j.jmapro.2021.09.011 [18] Song X, Niinomi M, Nakai M, et al. Improvement in fatigue strength while keeping low Young's modulus of a beta-type titanium alloy through yttrium oxide dispersion[J]. Mat Sci Eng C-Mater, 2012,32(3):542−549. doi: 10.1016/j.msec.2011.12.007 [19] Wang L X, Yang L J, Huang Y M, et al. Effects of Y2O3 addition on the microstructure and wear-resistant performance of TiN/TiB-reinforced Ti-based laser-clad coatings on Ti-6Al-4V alloys[J]. Mater Today Commun, 2021,29:102752−102764. doi: 10.1016/j.mtcomm.2021.102752 [20] Weng F, Yu H J, Chen C Z, et al. Microstructures and properties of TiN reinforced Co-based composite coatings modified with Y2O3 by laser cladding on Ti-6Al-4V alloy[J]. J Alloy Compd, 2015,650:178−184. doi: 10.1016/j.jallcom.2015.07.295 [21] Wang X, Zhang L J, Ning J, et al. Effect of addition of micron-sized lanthanum oxide particles on morphologies, microstructures and properties of the wire laser additively manufactured Ti-6Al-4V alloy[J]. Mat Sci Eng a-Struct, 2021,803:632−639. [22] Wang J, Lin X, Li J Q, et al. Effects of deposition strategies on macro/microstructure and mechanical properties of wire and arc additive manufactured Ti-6Al-4V[J]. Mat Sci Eng a-Struct, 2019,754:735−749. doi: 10.1016/j.msea.2019.03.001 -

下载:

下载: